Engines MMVZ-3 115 often used on maps and — with appropriate upgrades-cooling system — tillers and microfracture. Among the works on their service, there is also such as installation of ignition. At first glance it runs just the ignition timing that is specified in the instructions to the engine corresponds to the rotor position sensor, when its longitudinal groove coincides with the projection on the winding frame sensor. But not always: the spark occurs either too early or too late than it should be. Apparently, due to the scatter of the electrical parameters of the switch.

Engines MMVZ-3 115 often used on maps and — with appropriate upgrades-cooling system — tillers and microfracture. Among the works on their service, there is also such as installation of ignition. At first glance it runs just the ignition timing that is specified in the instructions to the engine corresponds to the rotor position sensor, when its longitudinal groove coincides with the projection on the winding frame sensor. But not always: the spark occurs either too early or too late than it should be. Apparently, due to the scatter of the electrical parameters of the switch.

To set the correct ignition timing you can use a more reliable system — with strobe lights, but the easiest way to do the following.

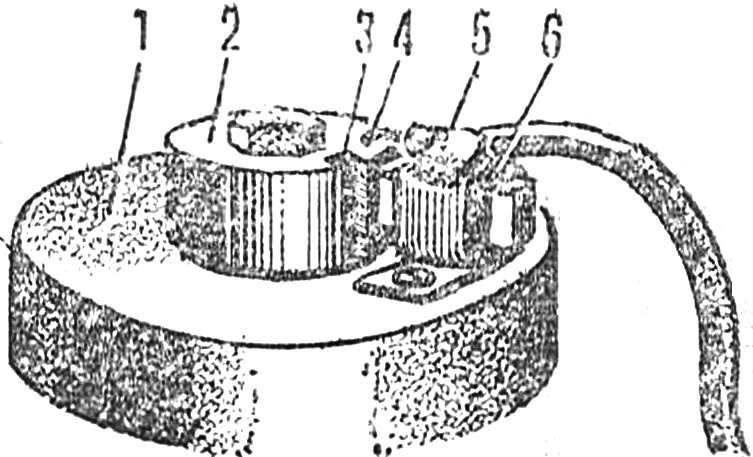

In the ignition coil high-voltage plug-in candle wire of such a length that it had before the rotor and set the ignition, as recommended in the instructions: the value of the advance 3-3. 5 mm before top dead centre (TDC) and the position of the projection on the winding frame of the sensor opposite the groove in the shank of the rotor.

The time of occurrence of spark:

1 — stator, 2 — rotor, 3 longitudinal groove, 4 — bare end wires, 5 — clay, 6 — coil sensor.

Now, the coil fastened (even clay) high voltage wire with bare end so that it is defended from the rotor by 3-4 mm. Rotating the rear wheels in direct transmission included (maps, tillers on a stand), you can see the moment of the sparks (the test should be carried out in a darkened room). The spark should slip in the direction of the rotor just at the combination of the groove with the bare end of the wire. If it occurs sooner or later, that is hits the groove, and next, it is necessary to amend to make the rotor mark with a chisel, which later put on the ignition, turning the generator stator in one direction or another.

D. SUKACHEV, Novgorod