The reasons of breakage of the nozzle on the Microdrive, a great many. And to do so more quickly, a new chiseled mikrodetal is not always possible.

The reasons of breakage of the nozzle on the Microdrive, a great many. And to do so more quickly, a new chiseled mikrodetal is not always possible.

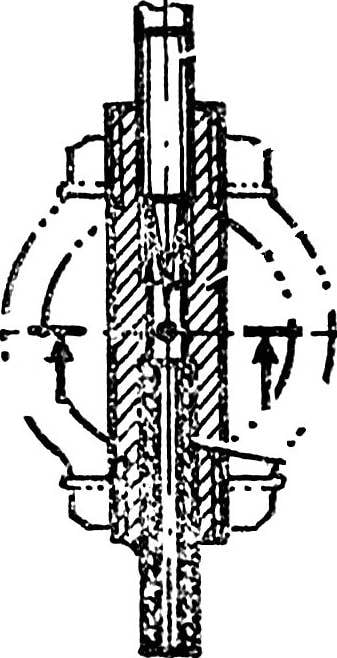

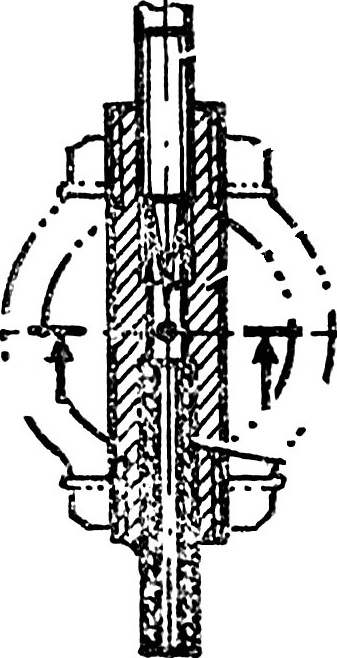

But, it turns out, engaged in the jewelry processing work is not required! Enough to pick up the two small metal tubes cut (they should be suitable for soldering, so the aluminum will not work), one with outer Ø 4 mm other Ø 2,5—3 mm. To a greater nearly half the length of the cut internal thread M2,5 and the ends — of the outer M4, better small. In the middle of spraying transverse drilled hole Ø 1 mm; on the side opposite the internal thread, reams the hole for a thin tube, whereupon the latter is inserted and sealed. Her butt will serve as the seat of the needle jet. And the needle made of a suitable cut spokes Ø 2.5 mm, but more often it is possible to still use the regular, remaining generally intact. When making a new needle, you should pay attention to the correct cone shape. Fixing the needle from loosening when the engine is arbitrary. For example: the needle napivaetsya corrugated wheel nut from unnecessary spring, and a nut of fastening of a casing of the nozzle is enclosed by a check box, similar to that installed on the Microdrive MK-12V.