Well, if you’re not to another fisherman or hunter, then this machine just need.

And in recent years he made three more all-terrain vehicle (materials on the previous two published in №1’2000, and No. 12’, 2003).

All machines have in common is that they have the same propulsion—Pneumatics (the author believes that this is the most versatile gear for any time of year). Otherwise, each machine has its own characteristics, but the latter is perhaps the strongest and most perfect of them.

Talking about my next vehicle on the tires, was begun in the No. 12 for 2003. At the very end of that publication I gave a brief technical description of the new intended to create a design. Now, when the machine is assembled, debugged and tested, it is time to tell the story to the readers of the journal.

As according to preliminary estimates, the car was done with all four wheels — in General, a full-fledged SUV.

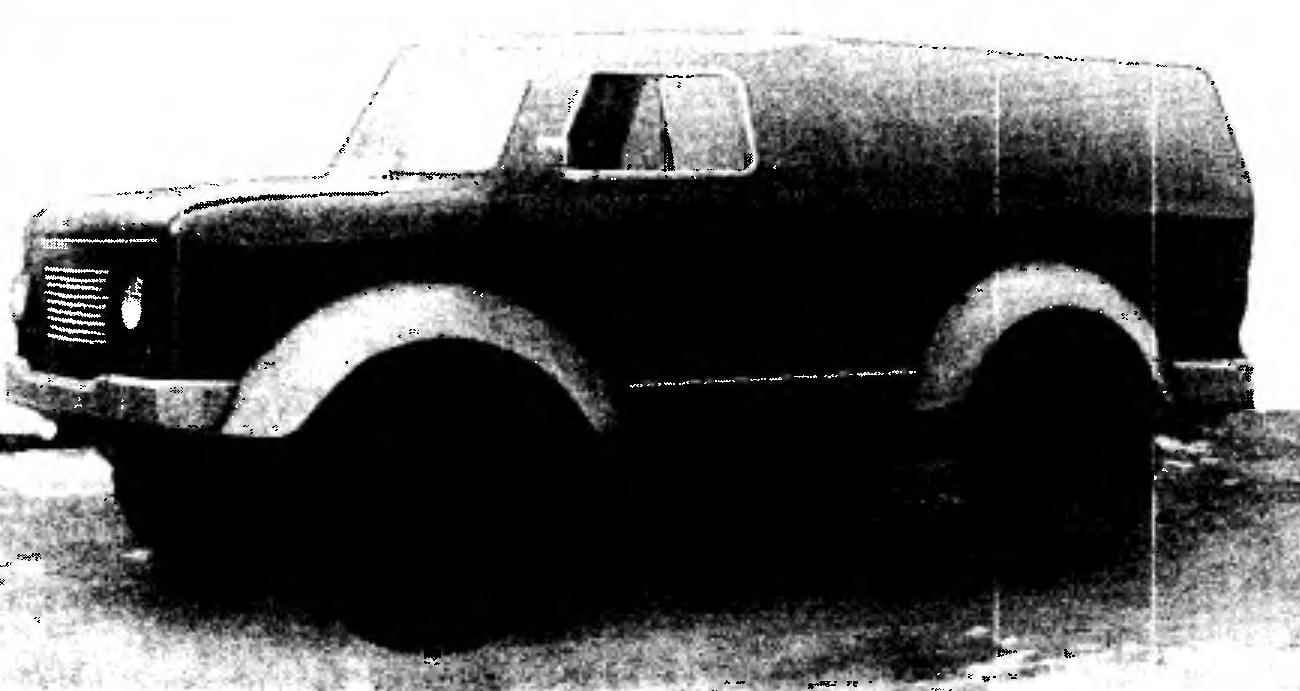

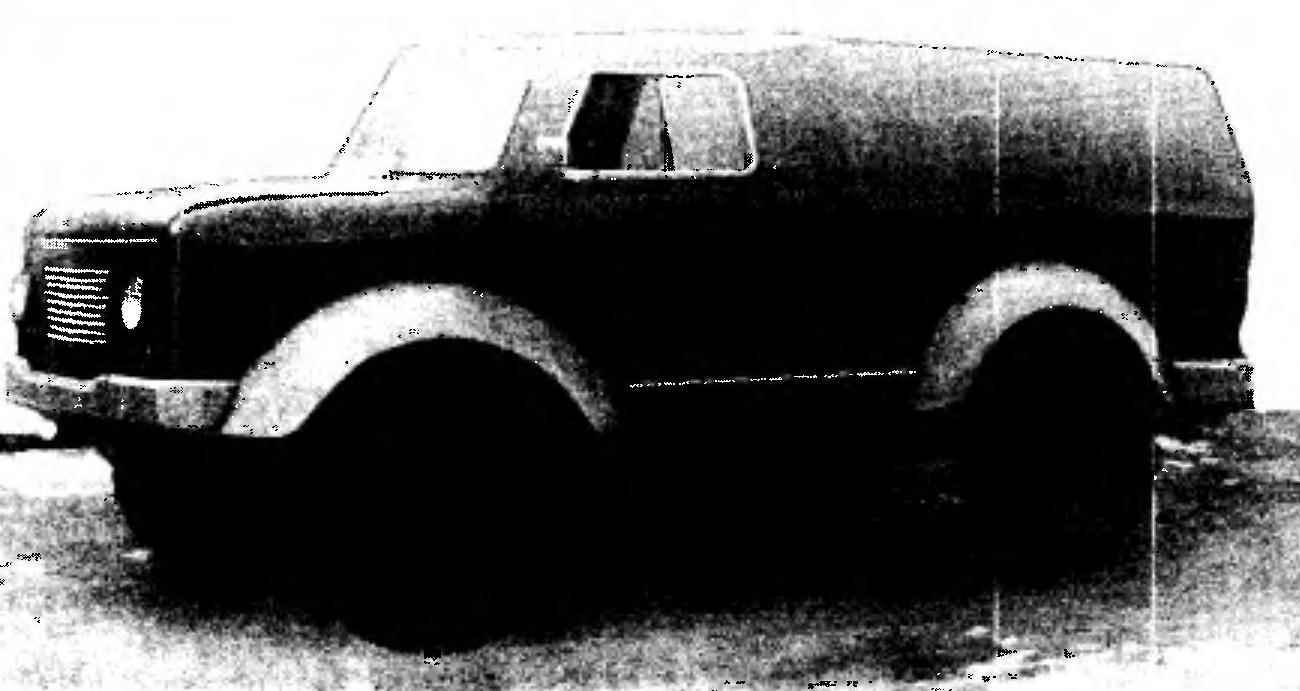

General view of the Rover:

a) on homemade tires (all-season version); b) on the wheels of the car UAZ-469 (old version)

Diagram of a powertrain of the vehicle:

1 — the engine (from the car “Zaporozhets”, 40 HP); 2— adapter housing with the clutch from the car “Lada”, 3— gear shift (from the car “Lada”); 4. short propeller shaft; 5 — gear box; 6 — propeller shaft, rear axle; 7 — gear rear wheel drive; 8 — drive mechanism is the rear wheels (2 PCs); 9— hub reduction rear wheels (2 PCs); 10 — drive mechanism of the front wheel (2 PCs.); 11 — hub reduction front wheel (2); 12—reducer of front wheel drive

All season operation of the vehicle provide Pneumatics— they have proved themselves reliable digitalin length any terrain. Grip with slippery ice is due to the bolts installed in bandage straps

For this it was necessary to perform transmission at the same time with similar powertrains “Fields” and Loiza. The similarity between the first manifested by locking two-speed transfer case, two main gears (front and rear wheels), transfer of torque from the main gearbox to the wheels by shafts with constant velocity joints. The similarity with the LUAZ is manifested in the presence in the same transmission cardan shafts and wheel gearbox with a gear ratio of i = 2—for all-terrain vehicle tires on the large diameter last mechanisms is also necessary. Cylindrical gears with module of 3.75 (z1 = 15, z2 = 30) ordered professionals, other parts of gearboxes, including the carters, a self — made.

The body is made two-volume (engine compartment and cab, combined with a Luggage compartment) — this layout is, in my opinion, is the most rational. For the engine compartment and the cab has adapted the front half of the body of the car “Zaporozhets” (ZAZ-968). The Luggage compartment is made combined: the lower part of the sides of the metal (welded of the door the car); the upper part of the sides and the ceiling (or rather the roof, but this is the beginning of reform and I stopped liking) — plywood, sheathed outside and inside with leatherette. Cavity at the bottom of the cab and sides of body building scored foam to provide buoyancy and insulation. The latter circumstance is of great importance: the Autonomous will topete-La in the cabin yet and the influx of warm air is only coming from the engine compartment through a hatch in the front wall. The back wall is completely made of metal. It is arranged in the metal door with a height of 990 and a width of 655 mm — only one for the whole Rover. Maybe someone such body structure may seem unusual and even bizarre (after all, some cars — even small cars — their doors, gaining up to five), but I believe that for this vehicle it is justified. Increased body rigidity with the constant movement over rough terrain not superfluous, however, as the tightness on the ice-covered rivers and ponds during the winter fishing have to travel quite often.

Frame:

1 —front rim (tube d16); 2 — spacer (tube d16, 2 PCs.), 3 — jumper (tube 50×25); 4 — steering-column spar (tube 50×25, 2); 5 — front cross member (tube 50×25); 6—anterior longitudinal beam (tube 25×25,2); 7 — arc the front wheel arch (area 25×25, 2); 8 — bearing Cup spring (2 pieces); 9 — bolt (pipe d16); 10 — brace front wheelhouse (area 25×25, 4 items); 11 — transverse front beam (tube 25×25, 2); 12 median longitudinal beam (tube 25×25, 2); 13 — spar box (area 35×35,4 pieces); 14 — threshold (area 25×25, 2); 15— transverse rear beam (tube 50×25, 2); 16 — rear longitudinal beam (tube 25×25, 2); 17 — arch rear wheel arch (area 25×25, 2); 18 — detail of rear frame overhang (tube 25×25, 2); 19 — rear (tube d35); 20 — brace frame rear overhang (tube 25×25, 2); 21 — crossbeam box (area 35×35,4 PCs.); 22 console bearing Cup spring (tube 25×25,4 pieces); 23 — resistant front Cup springs (tube 25×25, 2); 24—jumper stands (tube 25×25); 25 — bar for mounting engine mounting brackets (STZ, sheet z, 2); 26 — front box (area 35×35,4 pieces); 27 — metal trim boxes (STZ, sheet s); 28 — fiberglass sheathing ducts (fiberglass, epoxy, 3 layers)

The door like on most cars with a station wagon or hatchback, rises up and is held by two springs (from the front fork of the motorcycle “Minsk”). In the door there is a small window and doorway banded a hermetic seal. In the cabin only two seats in front: the driver and passenger. For a seat — free space size 1700×1350 mm. it can comfortably accommodate even two people.

The windshield — of the car “Zaporozhets”. The side Windows have sliding vents. Over time, I think to make a roof hatch for better ventilation in the summer and in case of using it as emergency exit.

The frame of the vehicle rather peculiar: it is based on a box of simple rectangular shape with ribs of steel angles 35×35 mm. of the Top edge of the box welded to the underbody. The box protects the components of the transmission from dirt and accidental damage while riding on the road and creates additional displacement, with the aim of flooding the machine is to move around sometimes and weak ice. In the box in almost all units and components of the powertrain: transmission, transfer case, propeller shafts, crankcases main gears of both bridges. In the area of the front and rear walls of the box and the bottom is made of 3 mm steel sheet, and between them — made of fiberglass (a few layers of fiberglass, impregnated with epoxy resin). Access to them through hatches in the bottom. To the vertical side walls of the box at the mounting locations to the frame of the levers of suspension brackets privernuty steel area with shelves 45×45 mm. By the end walls of the box (front and back) are attached to the crankcases via the main gear welded to the corner brackets.

Ahead on the frame in the engine compartment fixed the engine from “Zaporozhets” with 40 HP Engine compared to how it is installed in the base vehicle, now deployed to 180°. Box with the clutch docked to it the Zhiguli. This had the clutch housing replaced by a makeshift shroud adapter, one side suitable for mounting holes of the engine and the other to the transmission. Transfer box is hand made. Its body is welded from steel sheets with thickness from 4 to 6 mm. Pouring oil is made through one of the top holes to bolt the cover to the housing, and drain oil through the same hole in the bottom of the box.

The front wheel drive:

1 — underbody (of a car ZAZ-968); 2 — Carter, the main transmission (the details of a reducer of the rear bridge are not shown, from the VAZ-2101); 3 — axis (from the VAZ-2101); 4 cuff; 5 — splined bushing; 6 — brake disk; 7 — locking pin with washer and cotter pin; 8 — a box-frame (steel, sheet s3); 9 — bolt M10 bracket levers (2 sets); 10— M8 screws with square washer for fastening the bearing housing (4 PCs); 11 —bearing; 12 — cuff; 13 — the bearing 205; 14 — bolt M10 plain and spring washers; 15 — spring (3 leaves, from the “Moskvich-412”); 16— an arm of fastening of levers (steel area 45×45); 17 — bolt M16 with nut silent-block and two washers (2 sets); 18 — bolt M8 connection flange with spring washer (4 sets); 19 — the case of the cuff with boot; 20— spline flange (agricultural equipment); 21 — a flange with cardan fork (agricultural machinery); 22— cross (farm); 23 — cardan fork slotted sleeve (from agricultural equipment); 24— upper arm (steel pipe 032); 25 — podrugina Cup; 26 spline shaft CV joint; 27 — rubber case; 28 — restrictive nut; 29 — absorber (rubber washer); 30 — rubber boot of the CV joint (from the car “Niva”); 31 — upper ball joint (from the VAZ-2101); 32 — wheel reducer; 33—lower ball joint (from the VAZ-2101); 34 — lower control arm (steel pipe d32)

The design feature of the transfer box is the fact that it is used to collect the differential of the rear axle from the car “Lada”. He only machined the outer surface of the housing. On the body planted special glass gear (picked up from the farm), on a circular ledge which cut teeth with a module 3.5. Under this module was ordered and all the other gears and the gears transfer box. The end face of the glass (it collar) attached to the crown gear wheel mounted on the differential case. All mentioned parts are connected in one node by M10 screws (longer than stock).

Engine placement and all of the transmission units is symmetrical relative to the longitudinal axis of the machine. Even the gear of the front axle is located in the middle between the wheels, under the engine.

Behind the boxes under the underbody mounted fuel tank capacity of 35 liters.

Drives all wheels are the same. Suspension is also the same type — spring loaded with dampers, only the front — wishbone and rear — trailing. The front suspension is still reinforced by transverse leaf spring of three leaves from the car “Moskvich”, and the wheels are made turnable.

Wheel all-terrain vehicle replacement. In the summer I put wazowski, and in the rest of the year — a homemade airguns — they are the same as the front on the previous model of the Rover. Description and drawings of the tires was published in the № 1 ‘2000 of the journal “modelist-Konstruktor”. In wazowski wheels so they approached moskvichesky flanges, cut the middle part of the disk with holes, and in its place welded a different improvised with suitable openings.

Dvuhstoronka transfer box with differential lock (modules of all the gears and gear wheels m = 3,5):

1—М16х1 nut 5 spring washer (4 PCs); 2 — flange connection short cardan shaft; 3 — first shaft; 4 — the duster (3 PCs); 5 cuff (4 PCs); 6 — M6 screws(24 PCs); 7 — the bearing housing (2); 8 — the bearing 205 (4x); 9 — small gear input shaft (z = 26); 10 — clutch; 11 — gear; 12 — a gear wheel of a primary shaft (z = 36); 13 — drive of a manual brake; 14 — the Parking brake; 15 — differential lock; 16 — end differential lock clutch; 17—transfer case front shaft; 18 — the bearing; 19 — bearing 208; 20 — Cup-gear (z = 33); 21 — Carter transfer case (steel sheet, s4…6); 22 — the M8 screw fixing the cover to the housing (6 PCs.); 23 — crown gear (z = 43); 24 — differential (from the VAZ-2101, Assembly); 25 — the case of the bearing; 26 — 207 bearing; 27 — housing cover bearing (2 PCs.); 28 — crankcase cover (steel sheet s6); 29 — rear transfer case shaft

Wheel reducers (a — front right b — front left, rear right):

1 — bracket lower arm front suspension (STZ, sheet s); 2 — bearing; 3 — housing cover of the bearing; 4 — a nut М16х1,5 with washer; 5 — the bearing 205; 6 — remote thrust washer; 7 — bracket upper front control arm (STZ, sheet s); 8— the boot (STZ); 9 — the bearing housing with labyrinth grooves; 10 — the bearing 207 (3). 11 spline shaft (CV joint VAZ-2108, modified); 12 — pinion (m = 3,75, z = 15); 13 — M6 screws (15 pieces); 14— the bearing; 15 — cover; 16 — special nut; 17 — a flange of fastening of wheels; 18 — screw of the finger; 19 — a cover of a bearing housing; 20 — cuff; 21— duster; 22 — the case of the wheel gear (STZ); 23 — the driven gear (wheel, m = 3,75; z = 30); 24 — cover of the gearbox housing (STZ, sheet s); 25 — M4 screw (8 PCs); 26 — the breather (from the farm); 27 — trailing arm suspension the rear wheel (tube d60x3); 28 — solitaire of fastening of the lever (STZ, sheet z, 2 PCs.)

Mount the crankcase main gear box to the frame:

1 — Carter; 2 — base plate; 3 — angled bracket; 4 — cross box (area 35×35); 5 — M10 bolt with nut and spring washer (4 PCs); 6 — lining boxes (STZ, sheet s3)

Steering control scheme:

1 front idler (2); 2 — steering (steering wheel, shaft, worm gearbox, fry); 3 — the first intermediate thrust; 4 — duplici pendulum arm; 5 — the second intermediate thrust; 6 — wheel gear lever (2 PCs); 7 — right-thrust; 8 — right hinge; 9 — average thrust; 10 — left hinge; 11 — the left tie-rod

Wings over the wheel arches made removable: when replacing the wheels on the Pneumatics removed and wings.

When changing propellers be changed a bit and some dimensions: the height of the Rover wheels is 1770 mm, on the same tires — 1900 mm, and the width, respectively, 1920 and 2100 mm. Similarly changed and the ride height from 370 mm to 500.

All the mechanisms, units and parts, steering parts from car “Lada” and only the steering wheel — from “zaporozhtsa”.

The speed of the vehicle, along with speedometer readings with different propellers with the same engine at the same the different. The speedometer is configured to wazowski speed of the wheels, and driving on tires these readings have to be adjusted — multiplied by a factor of 1.5.

Maximum speed on wheels from UAZ when you low gear nozzle-Ki — 40 km/h, at higher than 60 km/h On the tires in a higher gear I don’t include — even at low gear speed reaches 60 km/h.

B. RYZHOV, the city of Sharypovo, Krasnoyarsk Krai

Recommend to read POLYETHYLENE COVER From the lids for mayonnaise-tion jars and milk bottles can be cut uplotnitelya strip — polyethylene sufficiently elastic material. And cut the rim of the lid — ready clamp for rubber... VELOVIC WITH POCKETS Two-wheeled transport — an indispensable tool: the products whether to go to a distant shop or a neighbouring market, potatoes from the garden to bring — but few if any economic goods in...

Scroll back to top

The author and Creator of the Rover, about which speech will go, — Boris Ryzhov — a longtime friend of the readers of our magazine. Photographs of the manufactured machines (crawler and six-wheeled all-terrain vehicles) were published in the journal in 1990 (No. 7). But the desire to create and to make a more perfect vehicle all-terrain since it gets cold. Professional aircraft mechanic and restless Amateur designer, after retirement, continued to build all-terrain vehicles. Why? Yes, until (and, apparently, for a long time) to get to most places in the depths of Siberia, where he lives, Boris Nikolaevich, it is possible only on such machines.

The author and Creator of the Rover, about which speech will go, — Boris Ryzhov — a longtime friend of the readers of our magazine. Photographs of the manufactured machines (crawler and six-wheeled all-terrain vehicles) were published in the journal in 1990 (No. 7). But the desire to create and to make a more perfect vehicle all-terrain since it gets cold. Professional aircraft mechanic and restless Amateur designer, after retirement, continued to build all-terrain vehicles. Why? Yes, until (and, apparently, for a long time) to get to most places in the depths of Siberia, where he lives, Boris Nikolaevich, it is possible only on such machines.