Cars with front-wheel drive today is not a novelty: they are building nearly three dozen firms. Prosperity “front-drive” started in the sixties. But in the thirties several of the companies produced cars of such design schemes.

Cars with front-wheel drive today is not a novelty: they are building nearly three dozen firms. Prosperity “front-drive” started in the sixties. But in the thirties several of the companies produced cars of such design schemes.

The first was the French plant “Still”, which is more than 70 years ago created the two-seater with front-wheel drive. His initiative tried to pick up others. At first it seemed that everything should work out as well as possible: the engine, transmission and the main transmission, are combined in one compact unit, fits nicely in the area of the front wheels, the rotation on them is transmitted by means of two axle shafts, each of which was equipped with a pair of universal joints. In this case the front wheels, the remaining guide, “part-time” was and leading. But… and then began the difficulties.

If the wheel “walks” up and down, rolling through the bumps, turns left and right on the winding road, then the outer gimbal hinge axle has to work in very difficult conditions — with angles of 30-35°. Conventional devices for this were not good. At angles more than 10-12° in the gimbal transmission dramatically increased the power loss, the rotation is transferred unevenly, and as a result, quickly wore out tires and the gears and transmission shafts worked with large loads.

Needed a so-called cardan joint of equal angular speeds, which would not suffer a congenital uneven torque transfer. Today we would say that the ideal ball constant velocity joint, invented by the Hungarian plant “Weiss” (now “Csepel”), It is widely used on cars of the increased passability in the drive to the front driving wheels. But it is today. In the early thirties the mass production of hinges for technologists difficult task. And then came on the scene the so-called sharikovy hinge of equal angular speeds of “Path” created by the French engineers. Compact, simple, cheap to produce, it helped the car designers in those years to develop a lot of interesting models.

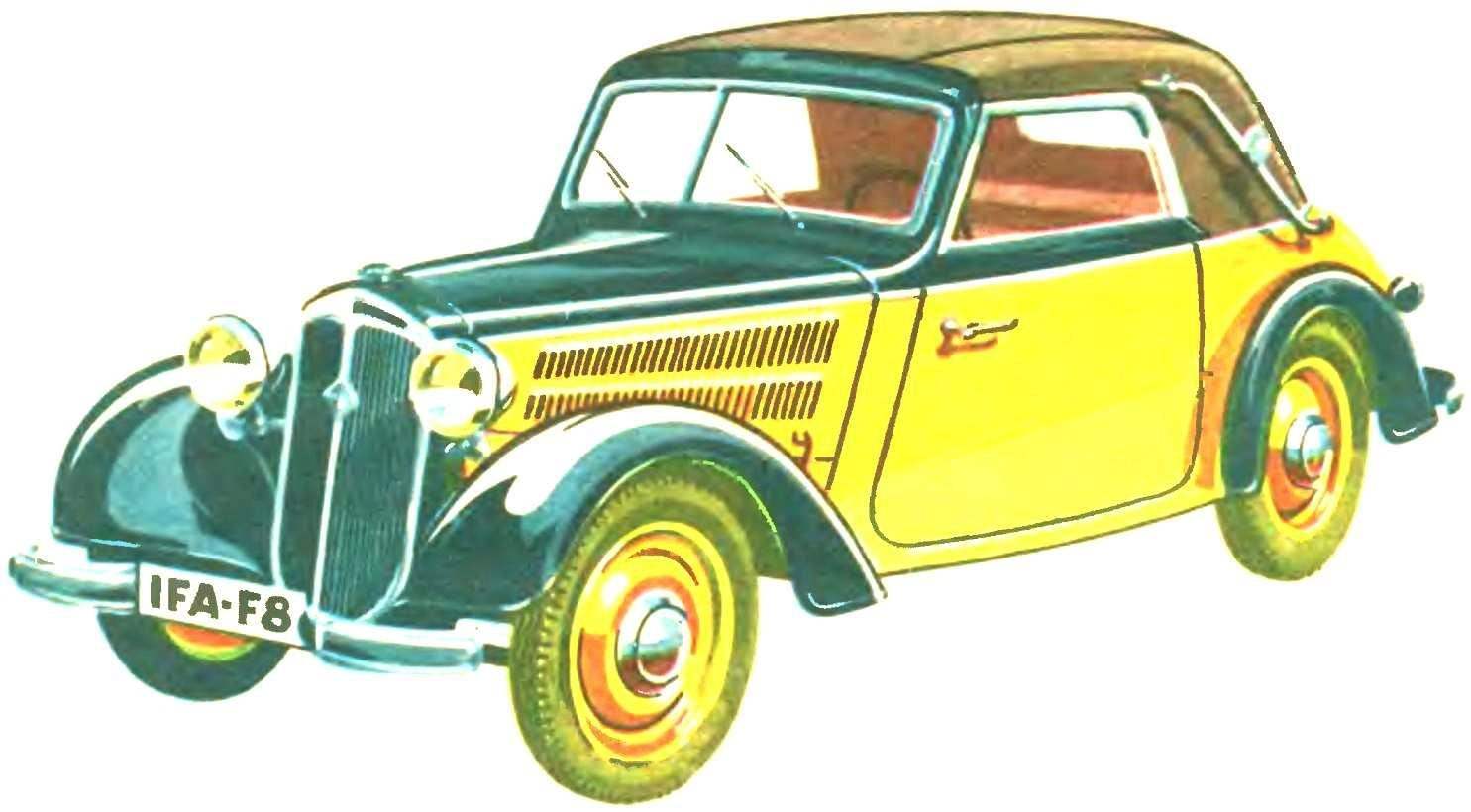

IFA-F8 with a body “sedan”

Sedan f-8 with a body “convertible”

A sports version of the f-8

Car JAVA sport option

Among firms—supporters of the front-drive stood two of the plant: French “Citroen” and the German DKV. The latter in the thirties, developed the design of a subcompact with front-wheel drive and a transverse engine layout. Plant DIV — “Das Kleine Wunder” (German for “little miracle”) has started issuing double open runabout F1 with front-wheel drive, hinges “Tract”, two-cylinder two-stroke engine working volume of 584 cm3 and a power of 18 HP and independent suspension on all wheels. The axis of the engine crankshaft was parallel to the axis of the front wheels. He was the motor behind the gearbox, the shafts of which lay parallel to the crankshaft, and the main transmission was carried out cylindrical (cheaper to manufacture than a conical) gears. The radiator was above the main gear and on the right end of the crankshaft (like a scooter “Tula”) was Dean-starter — node, which when starting the engine served as a starter, and then worked in the regime of the Dynamo.

Machine from year to year improved. To replace F1 came in 1932, F2, F4 for it, and finally, F8 is the most famous mass runabout was produced until 1955.

After the defeat of fascism the German people in the Eastern part of the country started the construction of socialism. Former private enterprises were nationalized, and they resumed production of passenger cars and trucks, desperately needed the young German Democratic Republic. Plants “Doody” and “Horch” in Zwickau, stared at the company IFA — the “society for automotive engineering”. It was in 1948 resumed production of the prewar cars F8, which under the name IFA has won wide popularity not only in East Germany, but also abroad.

A lot of these small cars was after the war in our country. Incidentally, cars DKW F7 and F8 were at that time equipped with the 1st taxi Park of Leningrad. One hundred of these cars first came on the go 20 October 1946 and served until admission of large batches of “Victories”.

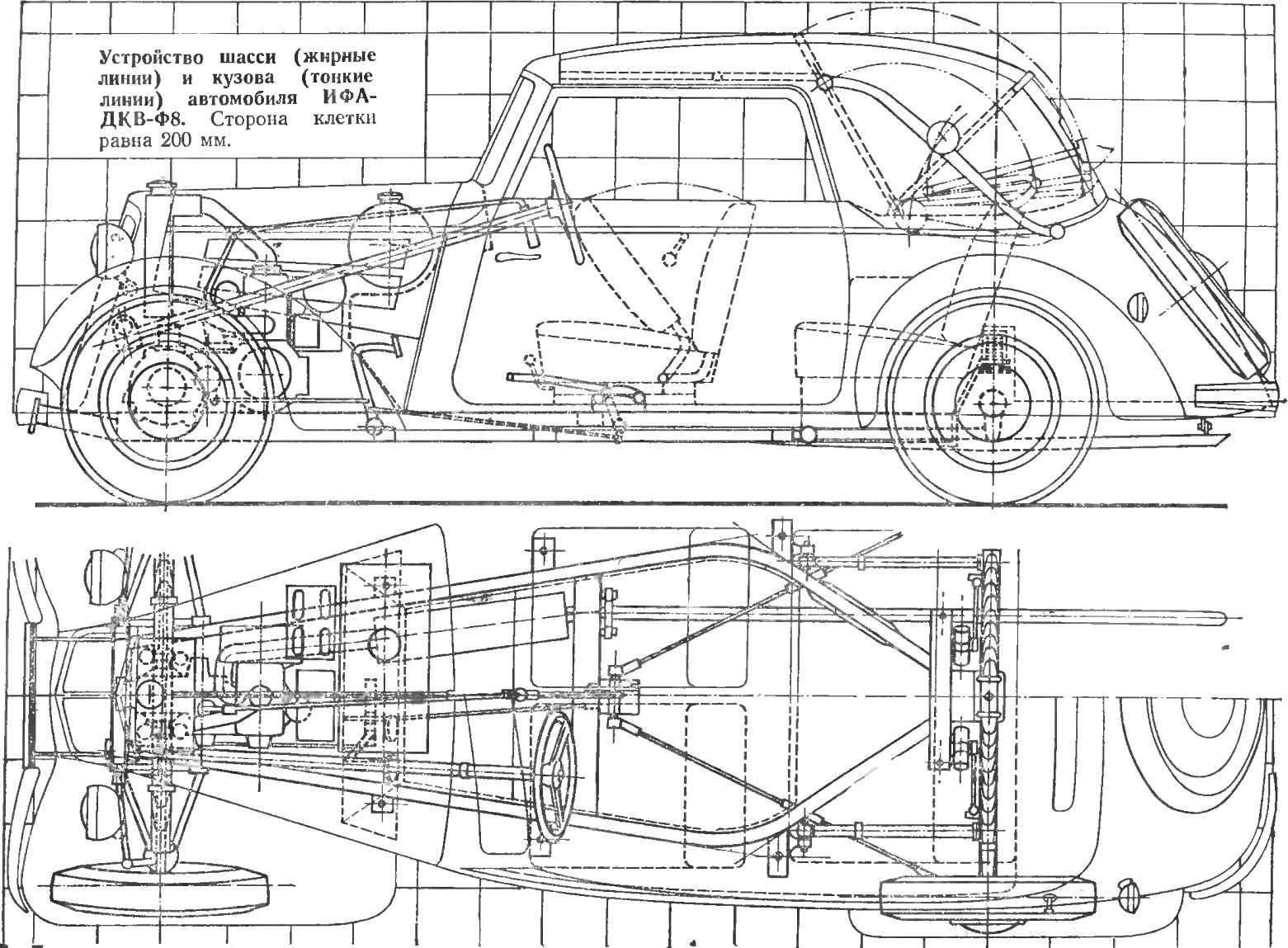

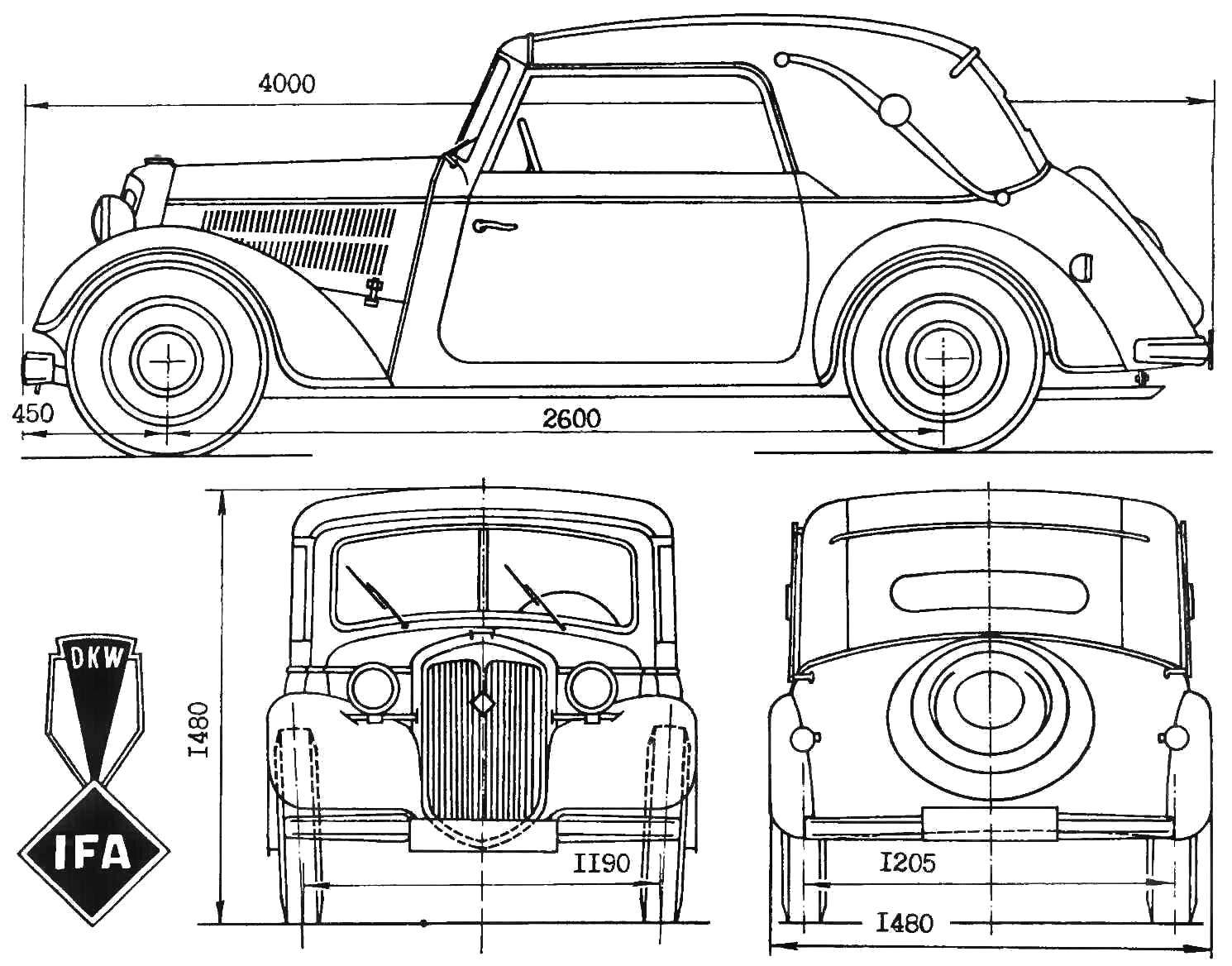

What is IFA-F8? In size it is close to the “Moskvich-407”. When the “eff-eight” and its predecessor came out on the road, they were struck by a squat. Front-engine and front-wheel drive makes it unnecessary driveshaft and tunnel over them, allowed to minimize the floor of the truck. The center of gravity at IFA-F8 was quite low, and a unique suspension design stake”: minimize roll when cornering. Wheel suspension on transverse leaf springs (front independent and rear dependent).

The first DKV differed spinal frame, and the option of F8 so-called peripheral frame, which, if you look at the car from above, had a pear-shaped configuration. Such a construction and shape of the frame from IFA-F8 inherited and other compact car, produced by the factories of the GDR: IFA-F9 and “Wartburg-311”, up-to-date “Wartburg-353”.

IFA-F8, as well as all the pre-war DKW, had a wooden body. Steel stamped hood, fenders, instrument panel. The wooden body frame was sheathed with plywood. The design turned out quite heavy: the body weighed 240 kg, while curb weight was 750 kg. But in the production of vehicles and DKW IFA was cheap wood raw material. By the way, until 1933 Godet factory made only one kind of body — the so-called “two-seat Roadster”. Later started production of two-door cars with a body “sedan”, “convertible”, “Shay”, “van”. Very simple, almost primitive equipment and equipment compartment, the minimum number of brilliant decorative parts, brake with mechanical operation greatly reduced the cost of production and allowed for low cost raw materials and labour to produce annually about 60 thousand cars.

Of course, the demand for the car is too Spartan outfit and appearance could not be very large, and the plant therefore produced models, starting with the F4, on two versions: standard and enhanced. The latter had a richer finish and hardware of the body, a more powerful battery, tyres increased section (size of 5.00—16 instead of 4.00—19), centralized regulators, chassis and clutch. Finally, an improved version was fitted with a more powerful engine — with increased from 585 to 677 cm3 working volume he developed a power not 18, and 20 HP at 3500 Rev/min., Respectively, were changed gear ratio main gear, m, as a consequence, the maximum speed increased from 85 to 90 km/h.

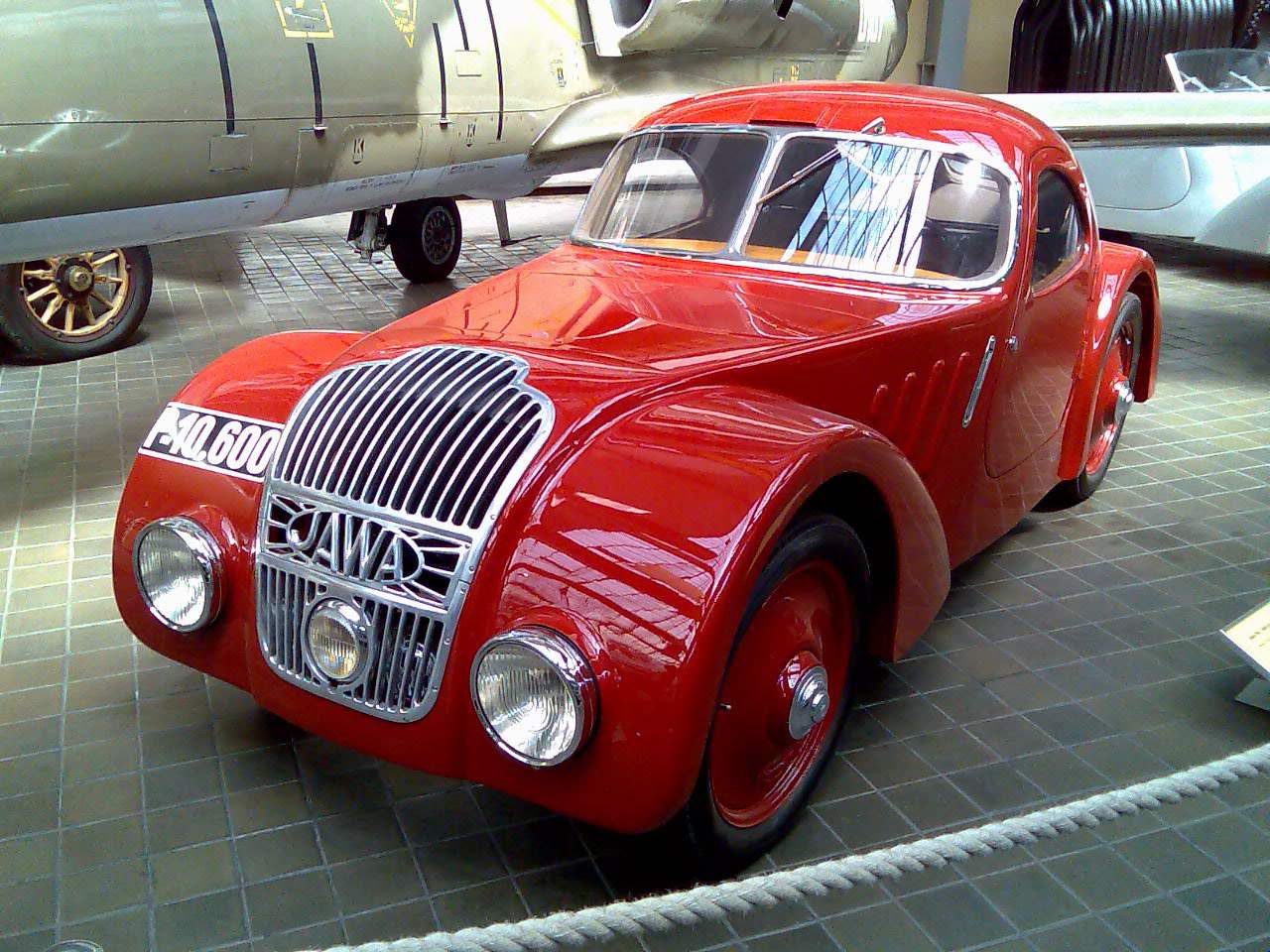

JAVA with a streamlined body type coupe

IFA-F9 (1949-1955).

Car P-70 with a plastic body

By the way, when in 1948, after six years of democratic workers of Germany has resumed production of the F8 option, they expressed a preference for just a more perfect version of the 20-sepium engine.

That represented centralized lubrication and clutch! First, the first. All nodes of the chassis: steering joints, suspension joints was connected by tubes to a Central lubricating unit. Once every 100 miles the driver presses on the pedal of this unit, and liquid oil (same as what is poured into the crankcase) under pressure is supplied to all the lubricated points.

The clutch is the same freedom of movement, as conceived by the designers, was to reduce fuel consumption. The fact that vehicles with two-stroke engines (and it was all such models DKW and IFA) spend about 15-20% more fuel than a four stroke. The clutch that works on the same principle as the Bicycle rear hub of the wheel, on the model of the F8 and its predecessors was to let the car go coasting, as soon as the driver “throttle”. The transmission through the clutch connected to the drive wheels, the vehicle is driven by inertia, and the engine has been running with minimal fuel consumption. However, the clutch gave and the other undesirable effect: it eliminates the possibility of engine braking and therefore did ride on wet and icy roads unsafe. The output of the blocking mechanism of the clutch which subsequently began to put.

The emblem of automobile plant in Zwickau were changed three times: from DKW IFA, then BS and now”, Sachsenring”

Distinctive features of the car IFA-F8 were reliability and ease of operation. Absent such sources is a frequent problem, as the fuel pump (fuel was fed by gravity], the distributor (it was replaced two spools of serving each cylinder), water pump (water in the cooling system circulates due to the temperature difference) cooling fan belt driven. Because the engine was two stroke, it did not require periodic adjustment kpap”.new and add oil, the inevitable four-stroke engines.

Licensed DKV from 1934 to 1938 the Czechoslovak JAVA factory produced cars. For participation in the race was created a few interesting modifications with streamlined bodies that reached speeds of 115 km/h. Serial IFA-F8 with a 20-horsepower engine came out in 85— 90 km/h. However, due to the installation of a prototype streamlined body speed has been raised to 120 km/h. This experiment, conducted in 1939, gave the designers a wealth of material that was used to create a new machine F9. Her prototypes were ready in 1940, but the serial production began only after the war, in 1949-m. it is Curious that in the GDR, the factory started to build IFA F9 immediately with a new, three-cylinder two-stroke engine. A branch of the former DKV, located in the Western part of Germany started production of the model a year later F9 and with the old two-cylinder “heart”. And only in 1953, he was finally able to learn a new, three-cylinder motor.

IFA plant in Zwickau (GDR) did “EF-ninth” until 1953, when its productions were transferred to the company gave in Eisenach, where two years later she gave way to a more perfect car “Wartburg” (in Germany F9 until 1963.). Passing in Eisenach production “EF-ninth”, plant ELISA reconstructed plants to produce new car. It marked a new stage not only in the history of the plant, but also in the global automotive industry.

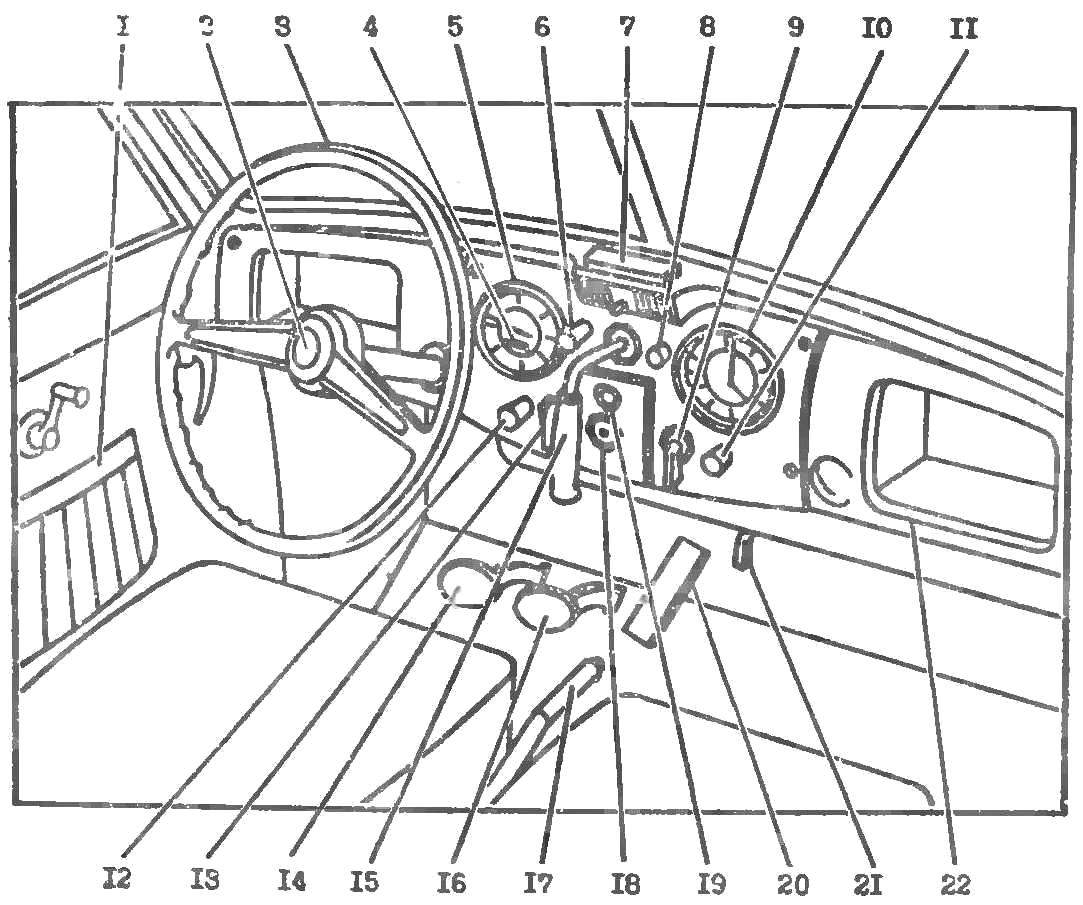

The driver of the car IFA-DKW-F8:

1 — pocket, 2 — button signal, 3 — wheel, 4 — speedometer, 5 — a speedometer, 6 — button gas constant, 7 — ashtray, 8 — the switch of a wiper, 9 — switch light, 10 — watch, 11 — winding, 12 — button air valve (“choke”), 13 — the switch of turn indicators, 14 — clutch 15 — handle shifter, 16 — brake pedal 17, the brake lever, 18 — ignition 19 — warning lamp battery charging, 20 — accelerator pedal, a 21 — tap of the fuel tank, 22 — glove box.

New car — she was given the index П70 — became the world’s first production car with plastic body. The material, called “Duroplast”, as the technology of manufacturing bodies, was developed by the specialists of the GDR. On П70 used many components and assemblies of the model F8. However, when larger body novelty was noticeably shorter than its predecessor. Its length was equal to a 3.74 m (almost the same as the modern “plows”), and the distance between axles (base) has decreased from 2,600 to 2380 mm. Reduction of the database have achieved, brought the whole power unit forward on front wheels. The car had a heater, 12-volt electrical system, a better carb. The displacement of the engine remained former (688 cm3), but the compression ratio increased to 6.8 (first at 5.9), and the capacity increased to 22 HP Model П70 equipped with a more comfortable body, a few “added weight” (870 kg), but became fast (110 km/h).

П70 produced from 1955 to 1959, with four kinds of bodies: “sedan”, “sedan” with sliding pucom in the roof, “universal” and double “coupe”. If the model П70 literally was the daughter of the tested car IFA-F8, the “Trabant P50”, which in 1958 began to roll off the production line in Zwickau, you can call him grandson. “Trabant” inherited from П70 technology Duroplast body, but from F8 — configuration, with a transverse two-stroke engine and front-wheel drive.

Car IFA-DKW-F8

With the transition to the production of mini-cars (displacement car P50 was first 500 and later 600 cm3) plant in Zwickau again changed his name. It was called “Sachsenring” (“Saxon ring” — in honor of the nearby famous racing tracks).

If you compare “Trabant”, which is a modernized version (П601) is available today, with IFA-F8, you can see that with the same capacity and much higher comfort it was almost a foot shorter (length 3,56 m) and 135 pounds lighter (weight 615 kg). His two-stroke two-cylinder air-cooled engine with working volume 594 cm3 develops a power of 26 HP and the maximum speed is 100 km/h.

Today, the “Trabant” are well known in many countries of the world. These compact machines built by the workers of the German Democratic Republic, and to this day attract attention by the originality of design and advanced solutions, which they have received in inheritance from their ancestors DKW and IFA.

The Modeler note

Tab, and the drawing shows the car IFA-F8 production of the GDR with a body of type “double Roadster”. He has a folding fabric tent with compasses. On the “live” IFA-F8 tent was made of dark grey waterproof material such as canvas.

Because the folded top you can clearly see the interior of the body, try to carefully work out its details: lined pockets with the “Assembly” on the inner door panels, hand brake lever on the floor, “poker” gear shift sticking out of the instrument panel, handle door locks and power Windows. Arm “poker”, the steering wheel and separate buttons on the dash can be black (and it was on most machines), and ivory. Electric windshield wiper with two “janitors” were on the top of the windshield frame.

Glass doors — solid, no turning vents. On the chrome wheel covers are sculpted widawka, echoing the emblem of the plant — the letters IFA on the square. The doors are made the speakers, and the bottom is given more than the top. The semaphore turn indicators out of the body sideways, perpendicular to its surface. Their swing axis located in the upper part, and the semaphore (excluding end normally lying flush with the body) — red or orange.

Often IFA-F8 painted in dark brown and dark green. But a limited number of cars painted in two colors, as shown in tab. From external parts with a shiny coating on the ELISA-F8 were the wheel caps, front and rear bumpers, radiator grille, outer door handles, headlight rims, hood latch, frame of the windshield molding along the belt line, on models with a body “sedan” and “convertible” and even edging the gutter.

Those who want to make a model with a body “sedan”, can be guided as given in the text pattern, and the molding along the belt line, to run more narrow than “Roadster”. Be aware that cars with a body “sedan” and “convertible” that worked in a taxi in Leningrad, had no special distinguishing features, and the band “the checkered” along the side in 1946, have not yet entered us in everyday life.

This feature: IFA-F8 rear wheel had an independent suspension, so do not try to give them a “clubfoot” as the “Zaporozhets” or “Skoda”.

A few words about the logo. At IFA, except for the wheel caps, she was on the b-pillar facing the radiator. At the same time on top of the veneer until 1952, remained the emblem of the DKV. As for production machines DKV, in addition to the emblem they bore the sign of four rings mounted on the b-pillar facing the radiator, and the wheel was stamped three letters — DKV.

L. SHUGUROV