Modification Go 242A-2 was intended for dropping paratroopers. It was assumed that they will be transported to the landing area, there’s paratroopers will jump out and empty the glider is towed back to base for the next unit. To the whole group left the glider for a short time, in the lower part of the folding section of the fuselage cut additional doors opened in flight. Experience has shown the viability of this idea – parachutists from gliders in a combat situation never jumped. The main task was delivery of various cargoes. However, and then produced the gliders that are adapted for dropping paratroopers (model V-3 and V-4). Himself Go 242A-2 could be used for boarding and disembarkation of troops, and on small sites. For this he was fitted with a brake parachute.

For multiple towing gliders train the lock in the nose of the fuselage was replaced by a reinforced, designed for 9 – 10 t, and in the rear we installed a second – 5.9 – 6 m of Discharged truck got larger wheel sizes 950×350 mm, while in parallel was used and old trucks. Devices And modifications (especially type A-1) accounted for most of the released Go 242, their production ceased in late 1942

Then I went to the glider modification; built variants of b-1, b-2, b-3 and b-4. The main difference between them was fixed to the wheeled chassis. Go 242V-1 had a main stand with brake wheel size 950×350 mm, mounted on a single axle with leaf spring or torsion axle. Bow front is also equipped with spring shock absorbers and carrying the driven wheel. The glider was equipped with only the tow lock in the nose.

Go 242V-3 was intended for dropping paratroopers and differed from In-1 availability in the tail section of additional doors. Since the doors are used on mods A-1 was inconvenient and had to be cut on the lateral vertical surface of the folding part.

Modification Go 242V-2 had a main landing gear of pyramidal design with oil-air shock absorber. The size of the main wheels – 935×345 mm. bow front also received a similar shock. The glider could be towed by a train, which in the nose was installed the lock on 9 – 10 t, and aft – 6 T. there was also a light version of this glider, which has a rear tow lock was removed, and the front was replaced by the usual (6 t). The very design of the fuselage is facilitated, particularly regarding the cargo floor. As a result, the empty weight of the car has been reduced by 250 kg But this option is not widely used because of the reduction in overall strength, which led to the reduction of the useful load.

Go 242V-4 was created on the basis of type-2 and differed from an additional hinged door on the fuselage for dropping parachutists. Option Go 242V-5 had a full dual controls and used for training pilots, and the rest conformed at 242V-2.

Modification Go 242С-1 was designed for attacks on ships of the British fleet in its main base of Scapa Flow in the fall of 1944, Each glider was to deliver a group of saboteurs, a speed boat-a catamaran and a ton of explosives. The landing was supposed to be right in the area, for which the airframe hull made watertight, and the bottom and gave the boat lines. The inside of the case put rubber inflatable bags to provide buoyancy. Under the wing of established support floats. To take off used reset two-wheeled cart. Data on number of new gliders Go 242С-1 vary widely. Some authors speak about a few pieces, while others put the number at 43. Whatever it was, surgery was canceled in the fighting Go 242С-1 did not participate. Later they remade the planes Go 244С-2.

In the summer of 1942 conducted experiments with takeoff boosters. Two liquid rocket boosters Walter R1 202Ь were installed under the wing beams (one each side). They developed a thrust of 500 kg for 30 s. the Application of accelerators substantially shortened the run and have very little impact on the controllability of a glider – how they work and when you reset.

But the liquid boosters were difficult to operate: the hydrogen peroxide -liquid is dangerous, prone to unexpected explosions, samovosproizvoditsja upon contact with any organic matter, and simply poisonous. Therefore, preference is given to solid fuel boosters Rheinmetall RI 502 a thrust of 500 kgf within 6 s. a Package of four boosters attached to the discharged farm in the rear of the fuselage. They were run in series, which provided a nominal thrust within 24 C. During operation of the accelerators, the pilot should pay special attention because when you switch there was a jerking thrust. Despite the lower total thrust and complexity of piloting, it is this system recommended for use – it created much less of a hassle terrestrial composition. It should be noted that the accelerators used infrequently, only to take off heavily overloaded gliders, but mostly the flights were performed in the usual way.

Especially for conditions the Soviet-German front, a group of designers from Rechlin developed snow skis to install on the Go 242. The flights were carried out near the town of Dorpat (Tartu) in Estonia in the winter of 1941/42 G. Just has completed 45 take-offs and landings. As the tug used the bomber Not 111Н-6, also fitted with skis. With a load of 2500 kg the length of the run of the glider was 1000 m and the landing run is 250 m. the Ski is allowed to increase the maximum takeoff weight of about 150 kg. as Flight data capture, and free of the airframe was reduced slightly. The skis were used sparingly when the supply of German troops were surrounded near the town of Hill in the late winter of 1941/1942 G.

The PLANE Go 244

During the operation of gliders arose a natural question: how to return to the landing quite expensive equipment for re-use? One of the options involves the use of a temporary power plant. After unloading the glider on its nose, it was proposed to install an 8-cylinder engine Argus Аѕ10С on a removable frame. As a result, the glider was able to fly and return to base. But it came back empty. However, life showed that it would be nice to save a few things back (e.g., wounded). For this thrust Argus was not enough. Therefore, removable from the engine was abandoned in favor of the installation of two permanent engines with a capacity of 500 – 750 HP This alteration turned the glider almost a full transport aircraft.

The search began for a suitable motor. This had problems as they were required for military vehicles. Therefore, designers are invited to look for what was not in the course. On the instructions of reichsminister aviation in the summer of 1942 built three prototype aircraft, named the Go 244, with different motors air cooling. So, Go 244V1 had German 9-cylinder BMW 132Z engines with a capacity of 660 HP, Go 244V2 got a pair of 14-cylinder French Gnome-Rhone 14М06/07 (opposite, right and left rotation) 700 HP, Go 244/3 -Sovetskaya 9-cylinder M-25A 750 HP Latest installed on fighters I-16 And I-15, and in 1941 in significant quantities in the hands of the enemy. Of all available to the Germans, they were the most powerful and provided the best power to weight ratio. But the stock M-25A was limited, and supply of spare-parts, was not expected at all. Therefore, the choice was made in favor of the French Gnome-rhône 14M, representing a 14-cylinder double star. He spun French three-blade variable-pitch propeller rat’e. The plant was imported from France complete with all units and hoods from the factory in Merignac.

The aircraft was converted only gliders modification, having a wheeled chassis. Go 242V-1 was altered to Go 244В-1,-2 – Go 244В-2 and-3, respectively, in Go 244В-3, then went 244В Go-4 and Go 244В-5. Modification Go 244С-got 2 engines Gnome Rhone 14M 04/05 equipped four-bladed propellers, the pitch of which could be changed only on the ground.

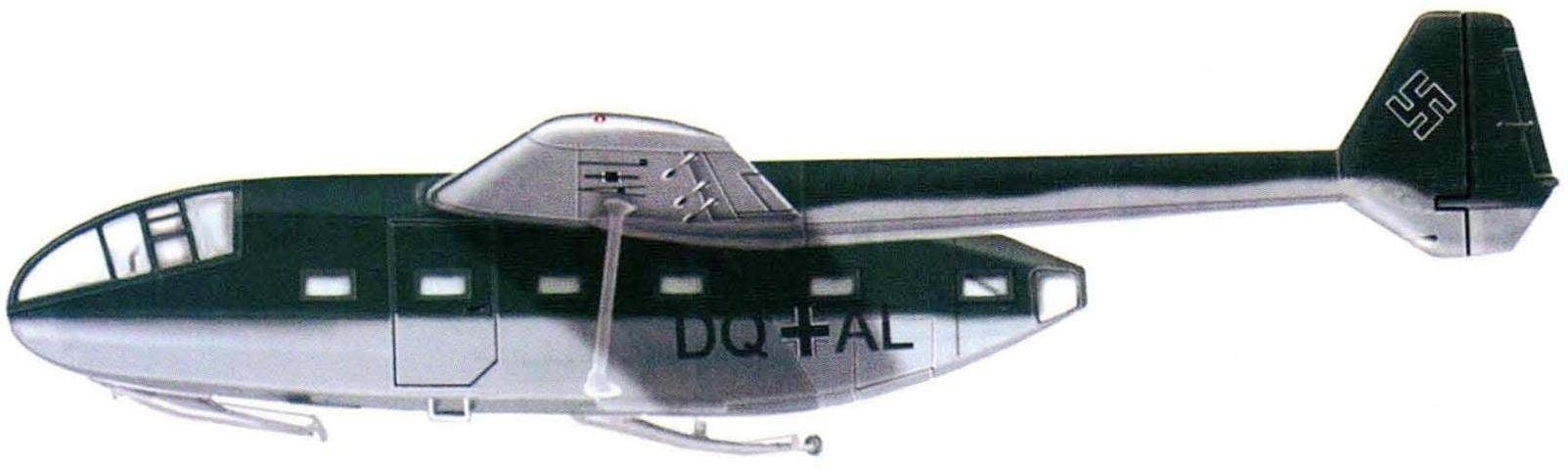

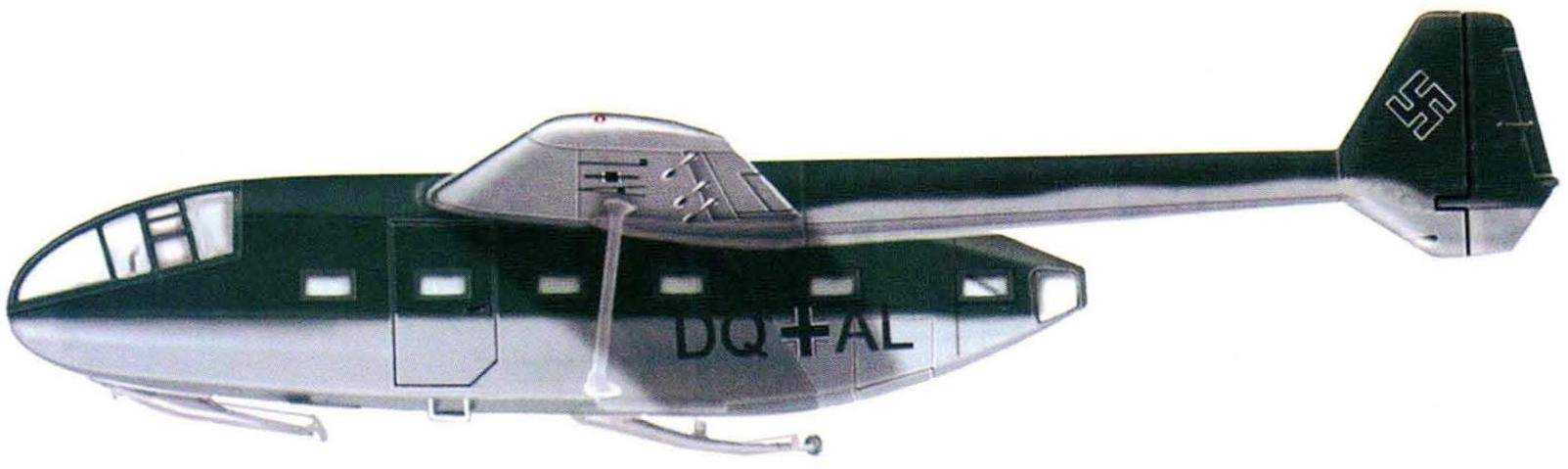

The Plane Go 244 B-1. Clearly the chassis design

The alterations were minimal. Tail boom extended forward, setting the engine mounts, welded steel pipes. The hood for the motor made of aluminum, it had a skirt to adjust the cooling. The oil cooler was mounted behind the engine, the air came to him from above, and the exhaust is carried down under the wing. In each beam was located at the two fuel tanks: front and rear, total capacity 345 l (total fuel capacity was 690 BHP) and oil tank 28 l (56 l). Laid pipes for motor control and in the cockpit, installed the necessary instrumentation. The aircraft received the radio antenna which stretched from the mast over the cabin to the right of the keel.

All of these improvements increased the empty weight of machine 1300 kg. Respectively dropped payloads up to 1800 kg. the Operation showed that the flight data of the new aircraft are low. The ceiling at full load was only 2500 m, and in case of failure of one engine it could fly only with a reduction. Turned bad and maneuverability.

Production of the Go 242 was continued in 1942, during the two years of the plant has produced 682 of the airframe, of which 133 were converted to Go 244. In addition, we have collected 41 new aircraft. It should be noted that the chassis design on the Go 244 were often varied, sometimes even within the same series. This was especially true of the nose.

Due to bad flying qualities, the production of 244 Go pretty quickly turned, and the plant returned to making gliders. In the same 1942 to the production of connected enterprise in the Czech town of Ceske Budejovice, where he built 47 Go 242 and a number of Go 244.

COMBAT use of the Go 242 and Go 244

In 1941, the glider Go 242 was adopted. As their income from industry was formed six squadrons had designations from 1/to 6 Go 242/Go 242. It was attached to the aircraft towing. All of the squadron were located on the territory of the Reich and obey the command of those air districts where they were based. It quickly became clear that Go 242 do not have to participate in airborne operations, and the main challenge for them will be the transportation of goods. This they did in the first period of his service. The second main task is training of pilots and training (including parachute) soldiers of the airborne divisions.

Soon the squadron re-formed into special groups, members of the airborne squadron. Each group included the Go 242 squadron and two squadrons of gliders 230. Their functions were limited to the transfer of cargo in Germany, and in the front line.

Baptism of fire double “Goths” were the Soviet-German front. On 21 January 1942 a group of German troops numbering about 5,500 people were surrounded in the area of the Holm of the Novgorod region. The supply of “pot” was carried out by air. Food, ammunition and medical supplies were dropped by parachute from transport aircraft and delivered landing glider Go 242. In addition to cargo gliders were brought reinforcements, and the return journey took out the wounded. Thanks to the air support, German troops survived and 5 may 1942, he escaped to his own, losing 1552 people. Soviet losses were much greater. The experience gained under the Hill, the Germans later used in Stalingrad, but the result was quite different.

That summer of 1942 two groups (КGrzbV.5 and КGrzbV.30), flying in Not 111, completed the glider Go 242. After the reformation they became part of the 4th air fleet, located in the southern sector of the Soviet-German front. In addition, it was formed several separate glider squadrons with towing is Not 111, including a squadron of “Donau” (“don”), from the title which makes it clear where she worked. But soon all of these individual squadrons brought part of the 4th transport group.

Transport group ||lzbV 1, where along with the aircraft Ju 52, was a member of the glider Go 242, supplied surrounded in Stalingrad the German group until its surrender. The group flew from Sal’sk, and later, when the front approached from Zverevo (Rostov oblast). The goods were delivered to the airfield of PITOMNIK near Stalingrad.

At the end of 1942 to supply surrounded at Stalingrad 6th army, consisting of airborne squadron LLG 1 formed a towed squadron (Luftlandegeschwader-Schleppverband). The fleet had been mixed: on the one hand, there was the Me 321 gliders and towing Not 111Z, on the other – Go 242 and Not the usual 111. But while this division has reached the advanced platform in Makeyevka, Soviet troops had seized the last airfields inside the encirclement and come to the aid of soldiers of Paulus squadron did not.

Some glider groups based in Greece and Sicily. Their task was to deliver cargo to the African corps of Rommel and transport in the Balkans. A number of Go 242 gliders got Romania who used them within the country and in the Balkans.

In winter 1943/44, the group of I/LLG 1 rearmed with a Go 242 gliders and towing Not 111. Operated there earlier DFS 230 gliders took off, and the aircraft Do 17 was sent to the rear for use in the support units.

This group, together with others, ensured the provision of the 1st German Panzer army at Kamenets-Podolsk. Group numbering some 200, OOO people were surrounded in March 1944, Despite recessie airfields and bad weather, the Germans managed to organize its supply by air. The gliders were often transporting fuel for tanks. The red Army failed to crush the “pot”, including due to the lack of air support due to bad weather. April 7, 1944, the Germans were able to escape from the ring, losing 5878 people and most of the equipment.

After that, the group IILLG 1 flew South to Odessa. From there, she participated in the evacuation of troops and goods from the Crimea. In this operation, first used in sanitary 242 on a stretcher, and specialized gliders – mobile workshops, command posts, communications centers, and other modifications.

At the final stage of the war the intensity of Go 242 decreased. Reason – lack of fuel, reducing the number of aircraft-towing, the loss of the material.

With regard to the use of aircraft Go 244 in March 1942 they received two groups: KGrzbV 104 in Greece and КGrzbV 106-on the island of Crete, flew to this on the aircraft three-engine Ju 52/ZM. Pilots were not enthusiastic about new technology. Flight data Go 244 was mediocre, manoeuvrability insufficient. All these defects were due to low capacity of the power plant, moreover, is quite capricious. The only positive feature is considered the simplicity of design and ease of maintenance. The first meeting in the air with enemy fighters showed that the chances of escape from attack at the “Goths” a little. So after the first loss, in November 1942, the group rearmed the huge transport aircraft Me 323 “Giant”. This machine was also created on the basis of the Me 321 glider by installing a six-cooled engine.

Another squadron, received the Go 244 in the second half of 1942, became 7/TG 4, operating in the South of Russia. In General comments were the same as in other parts, but here is still added difficulty during takeoff from rasciesa, poorly equipped airfields. Later 7/TG 4 has also replaced its Go 244 the Me 323. She handed in “Goths” were transferred to the territory of the Reich, where they were incorporated into the training units of the airborne troops. In the sky of Germany Go 244 was performed in emergency transportation and are applied for preparation (including parachute) paratroopers and transport pilots. In General, it can be concluded that the glider was more successful design.

K. KUZNETSOV

Recommend to read ADJUSTABLE STOOL Equally uncomfortable to sit and when feet do not reach the floor and if the seat is very low. I think everyone has noticed that, sitting behind the piano, the pianist is rotating the... “TREAT” TRACK Wow, what a shame — cracked and crumbled concrete path on your country station! To talk about the fact that slim was a layer of mortar or the soil slipped, too late... But you shouldn't...  Firm “Gather of waggonfabrik” (better known as just “goth”) at the end of the 1930s, released the first batch of ten-seat amphibious gliders DFS 230 was developed in the German Institute for the development of gliding (Deutches Forschungsanstalt für Segelflug, abbreviated DFS) under the direction of G. Jacobs. At the plant “goth” production of the DFS 230 was engaged in engineer A. Kalkert. Taking a series of DFS 230, Kalkert thought on creating a larger glider capable of carrying 20 soldiers with full equipment, and oversized cargo. He had to have a large hatch with size approximately equal to the cross section of the fuselage, and upper wing. The cargo hatch designer decided to make a hinged tail of the fuselage, as the nose of the glider could get damaged when landing (which often happens). This entailed the use of twin-boom tail. This layout was previously known, but was first applied to aircraft of this size.

Firm “Gather of waggonfabrik” (better known as just “goth”) at the end of the 1930s, released the first batch of ten-seat amphibious gliders DFS 230 was developed in the German Institute for the development of gliding (Deutches Forschungsanstalt für Segelflug, abbreviated DFS) under the direction of G. Jacobs. At the plant “goth” production of the DFS 230 was engaged in engineer A. Kalkert. Taking a series of DFS 230, Kalkert thought on creating a larger glider capable of carrying 20 soldiers with full equipment, and oversized cargo. He had to have a large hatch with size approximately equal to the cross section of the fuselage, and upper wing. The cargo hatch designer decided to make a hinged tail of the fuselage, as the nose of the glider could get damaged when landing (which often happens). This entailed the use of twin-boom tail. This layout was previously known, but was first applied to aircraft of this size.