Vertical take-off fighter RYAN X-13 VERTIJET. In our day, aviation experts, it is difficult to surprise aircraft with variable thrust vectoring, or with gas rudders and the vertical take-off planes. But few people know that all these solutions were first implemented on a small experimental plane X-13 VERTUET established aviation firm Ryan in the early 50-ies of the last century.

Vertical take-off fighter RYAN X-13 VERTIJET. In our day, aviation experts, it is difficult to surprise aircraft with variable thrust vectoring, or with gas rudders and the vertical take-off planes. But few people know that all these solutions were first implemented on a small experimental plane X-13 VERTUET established aviation firm Ryan in the early 50-ies of the last century.

The name of Claude Ryan, owner of Ryan Aeronautical company, has acquired international fame in 1927 by the aircraft NYP “Spirit of St. Louis” which Charles Lindbergh flew the Atlantic ocean. Another famous aircraft, his company became a carrier-based fighter with a combined power plant FR-1 FIREBALL built in 1944. In the rear the screw of the fighter was installed auxiliary turbojet engine J34-GE-3 with a thrust of 730 kgs, which included a pilot during takeoff or in combat. In November, 1945, serial FR-1 of squadron VF-66 was able to land on an aircraft carrier using only a jet engine.

Combined power plant FR-1 gave him a distinct advantage in speed and climb rate before the piston fighters of the time. Moreover, after reaching a certain amount of fuel from the internal tanks total thrust of the propeller and turbojet engine exceeded the weight of the aircraft. This unique feature lively discussion with the designers of the firm Ryan, which suggested that the FIREBALL is able to vertically hang in the air. Before the flight experiment is not reached, but that arose between the engineers discussion led by Claude Ryan thought about the possibility of creating a jet aircraft with vertical takeoff and landing. A feature of this aircraft was to become the high thrust obtained due to the minimum size and structural weight of the aircraft.

In 1946, Ryan shared the idea of creating such a plane with the head of the Bureau of Aeronautics of the Navy of the United States R. Stevens. Far-sighted state officials are seriously interested in the possibility of creating such a device in a post-war cuts in funding for the fleet when all the resources of postwar America were concentrated on the production of nuclear bombs and their delivery vehicles — giant bombers. The primary role of the Navy as the primary strategic strike force, conquered them in the Pacific ocean, was quickly forgotten, and in the higher echelons of power began to venture opinions on the uselessness of aircraft carriers and the subordination of carrier-based aircraft to the air force.

Trying to mitigate the effects of the upcoming reforms, the sailors began to find innovative ways of development of naval aviation. The aim of conducted research was the fighter able to operate from cargo ships, tankers, destroyers or cruisers.

First seen two different apparatus. The first was a light aircraft shipborne vertical position of the fuselage during takeoff and landing, equipped with turboprop engine is T40. The result of the work in this direction was the aircraft vertical takeoff and landing (VTOL) CONVAIR XFY-1 POGO and LOCKHEED XFV-1 SALMON, with large coaxial screws of opposite rotation. The second ship was a small fighter jet flying boat XFY-2 SEA DART Convair company, shreema and raised by crane to the ship. Later they added the third apparatus — proposed by Claude Ryan jet mini plane with vertical take-off and landing position of the fuselage. Given the small size and weight of the aircraft, the sailors were supposed to put it in submarines.

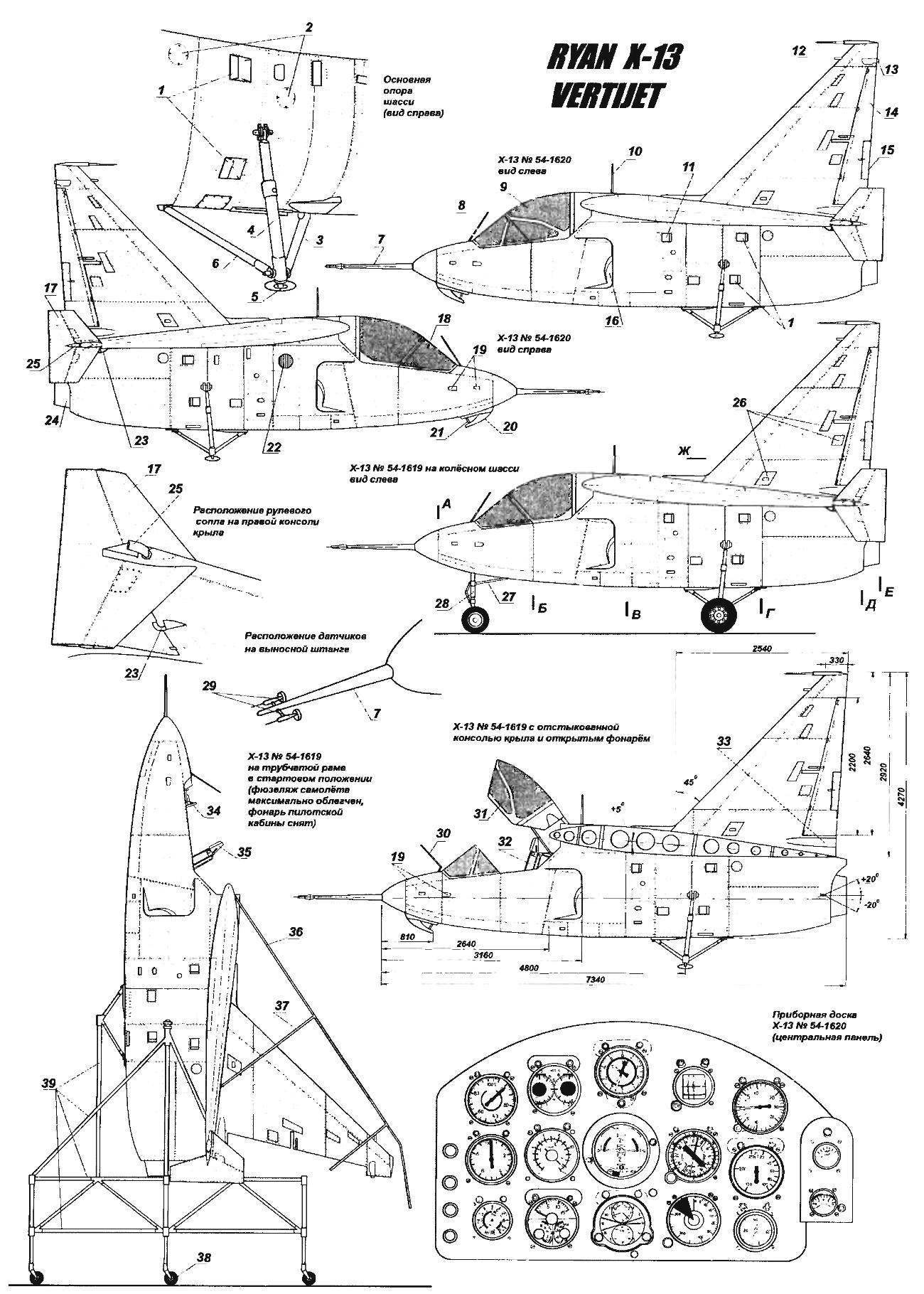

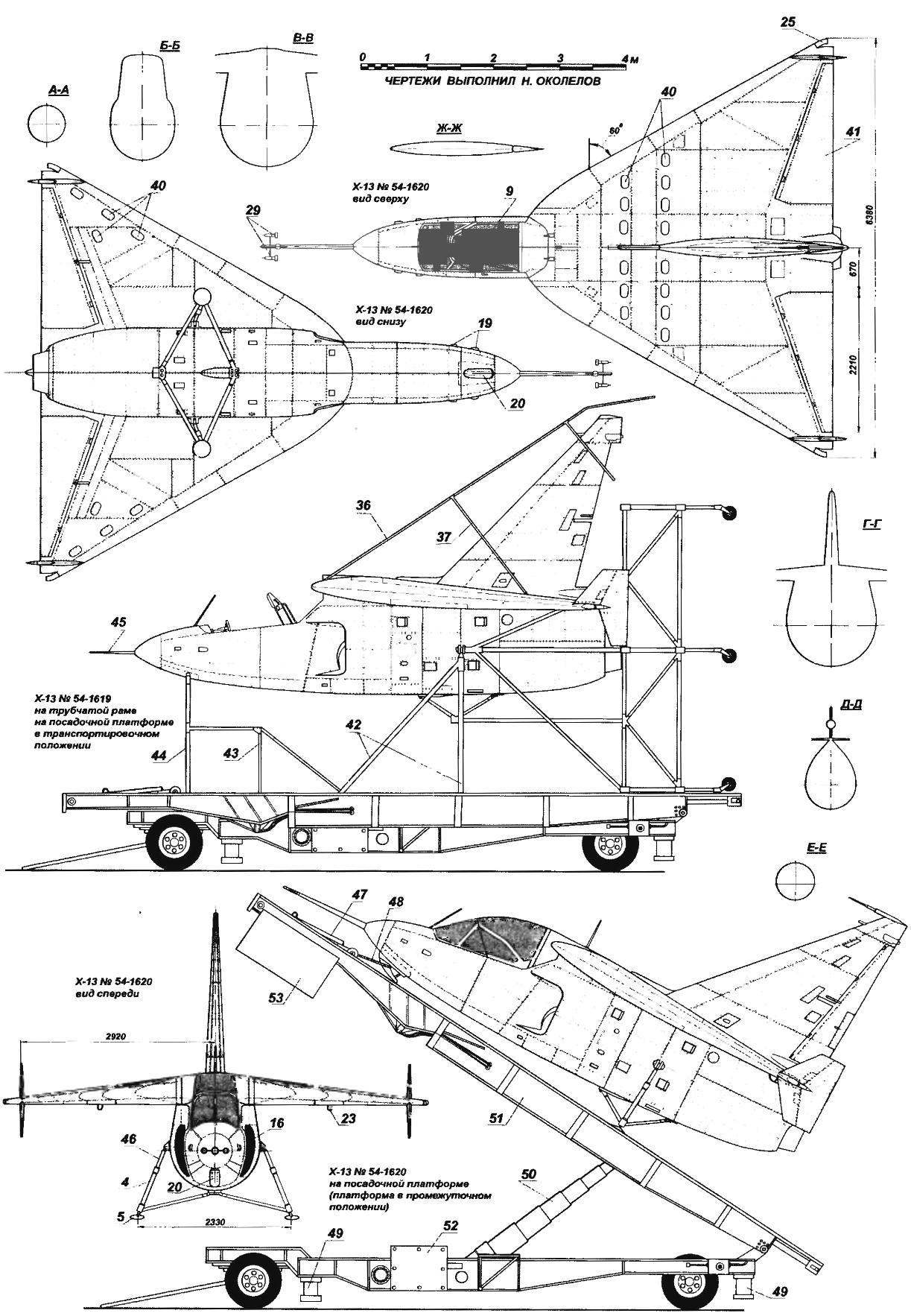

Aircraft vertical takeoff and landing RYAN X-13 VERTIJET:

1 — air intakes of the cooling system of the engine; 2 — performance hatches; 3 — front strut landing gear; 4 — hydraulic shock absorber; 5 — basic heel; 6 — rear strut landing gear; 7 — extension rod; 8 — antenna communication station with the operator in a flight position; 9 — modified the cockpit canopy; 10 — the radio antenna; 11 — air intake system pressurization of the fuel tanks; 12 — LDPE; 13 — keel steering gas nozzle; 14 — rudder; 15—trimmer of the rudder; 16— air intake; 17 — wing washer; 18 — visor canopy; 19 — the air intakes of the cooling system instrument module; 20 — a boarding hook; 21 — spring loaded safety lock; 22 — intake air turbine starter; 23 — rocking Aileron; 24 rotary nozzle; 25 — gas turning the steering wheel; 26 — maintenance access doors control system; 27 — the strut of the front landing gear; 28 — shock absorber of the nose landing gear; 29 — sensors; 30 — station antenna to communicate with an operator in the landing position; 31 — the canopy in the open position; 32 — pilot’s seat in flight position; 33 — drag chute container; 34 — instrument panel; 35 — a pilot’s seat in the declined position; 36 boarding ladder; 37 brace the ladder; 38 — casters; 39 — tubular frame; 40 — wing maintenance hatches; 41 —Aileron; 42 — the main tubular frame; 43 —environment fit; 44 — rear tubular cradle; 45 — LDPE; 46 — hour support; 47 — deflecting beams of the system of engagement; 48 — landing rope; 49 — support feet; 50 — hydraulic platform lift; 51 — off and landing platform; 52 container control units hydraulic cylinders of the lifting platform; 53 — cradle operator

In December 1946, the firm Ryan began developing a conceptual design of such an aircraft with a working designation of “Model 38”. The leading designer was appointed chief engineer Ben salmon, who began his work with search for a suitable engine. The main criterion for evaluating turbojet engine was its specific thrust — in other words, the ratio of the mass of the engine to its maximum thrust.

The most suitable engine could be NENE English company Rolls-Royce with a specific thrust of about 0.31 kg/kg, however, this TRD the company was not. Continuing the search and having about eight models of the American turbojet, salmon stayed on the J33 engine of the General Electric company with a specific thrust of 0.39 kg/kg.

January 10, 1947 a group of engineers have completed preliminary calculations of the characteristics of the “Model 38”. They showed that the curb weight of the plane will amount to as much as 7,500 pounds, or 3405 kg, and one J33 with traction 2090 kgs not cope with the vertical lifting of the apparatus into the air. The situation seemed hopeless, but the salmon decided to add to the thrust of the turbojet engine thrust four propellant JATO boosters. After takeoff. the pilot had to reset the accelerator and go into horizontal flight. After completing the task and returning to the starting place (and by this time most of the fuel will be produced) light weight aircraft can execute a vertical landing and no extra rocket engines.

Fearing that the version with boosters sailors may not like it, salmon assigns it the designation “38-1” and develops two alternative (hypothetical turbojet engine with a thrust of more than 3,500 kgs): “38-2” X-shaped tail and “38-3” Phillips plumage.

In March 1947 all three projects submitted in the office of the Navy During the Salmon report raised major problems that still had to be solved during the work on the “Model 38”. The most difficult was the problem of control of the craft in hover mode. If the aircraft firms Convaiг and Lockheed wing with the tail is blown a powerful stream of air from large propellers and aerodynamic control surfaces almost did not lose its effectiveness, on a jet plane at zero speed the rudders had become useless, and to control the position of the camera was possible only by changing the direction of thrust of the engine. During the discussion of the projects Ryan and Salmon managed to convince the military in the possibility of solving all the upcoming problems, resulting in $ 50,000 for research and the construction of a flying mock-jet vertical take-off aircraft. The corresponding contract was signed on 24 April 1947.

Theoretical studies lasted more than a year. In the end, June 24, 1948, salmon presented a draft of a flying stand with a remote control to conduct flight experiments. The design of the stand was a tubular frame with the engine J33. The main controls were deflected nozzle — its movable part joined to the extension pipe via a ball swivel. Part of the hot gases from the extension tube of the nozzle of the engine was given high-temperature pipelines to two small rotary steering nozzles with electro-pneumatic actuator —deflection of them turned the machine around its longitudinal axis. Engine control and gas rudder carried by cable. The first engine spent 20 October 1950, and the first “flight” with existing control system took place on 31 may 1951.

The experiments enabled the designers of the firm Ryan to proceed with the development of a full scale apparatus, however, the money was soon over, and the plane “38”, developed in 1946-1947, already obsolete.

Already on 21 September 1951 salmon suggested the Navy project vertical take-off aircraft, armed with four 20 mm guns, which was several times heavier than its predecessors. As the power plant was planned to be used, developed firm General Electric motor J53-GE-X10 with a thrust of 8000 kgs. The proposal did not arouse much interest, work on the project “Model 38” was finally stopped.

However, Ben salmon and never thought to give up. In the beginning of 1953, he finally managed to convince the military of the need to resume funding for research. New machine with a Delta wing and T-tail has received the designation “Model 38R”. It was calculated under the existing engine company Pratt & Whitney J57-PW-11 with a thrust of 6600 kgs. In February 1953, the Navy signed a contract with the Ryan company for preliminary studies and construction of flying models.

However, the company’s plans were never realized. In late summer 1953, with the beginning of the Korean war, the Navy sent Ryan a letter in which he reported the termination of its contract “due to the reduction in the number of research programs.” The military rightly considered that aircraft-generated firms Convair and Lockheed, they would be sufficient, especially because Convair had already begun flight tests of their flying boats XF2Y-1 Sea Dart and completed the construction of the VTOL aircraft XFY-1. Firm Lockheed is also not lagging behind, its flight of the XFV-1 was planned for the autumn of 1953.

Continuing to fight for the project, Claude Ryan turned to the competitors of the fleet air forces, with a request to consider the use of aircraft with vertical takeoff and landing in their interests. Members of the main staff of the air force agreed to Fund the program, which formally notified the company in August 1953.

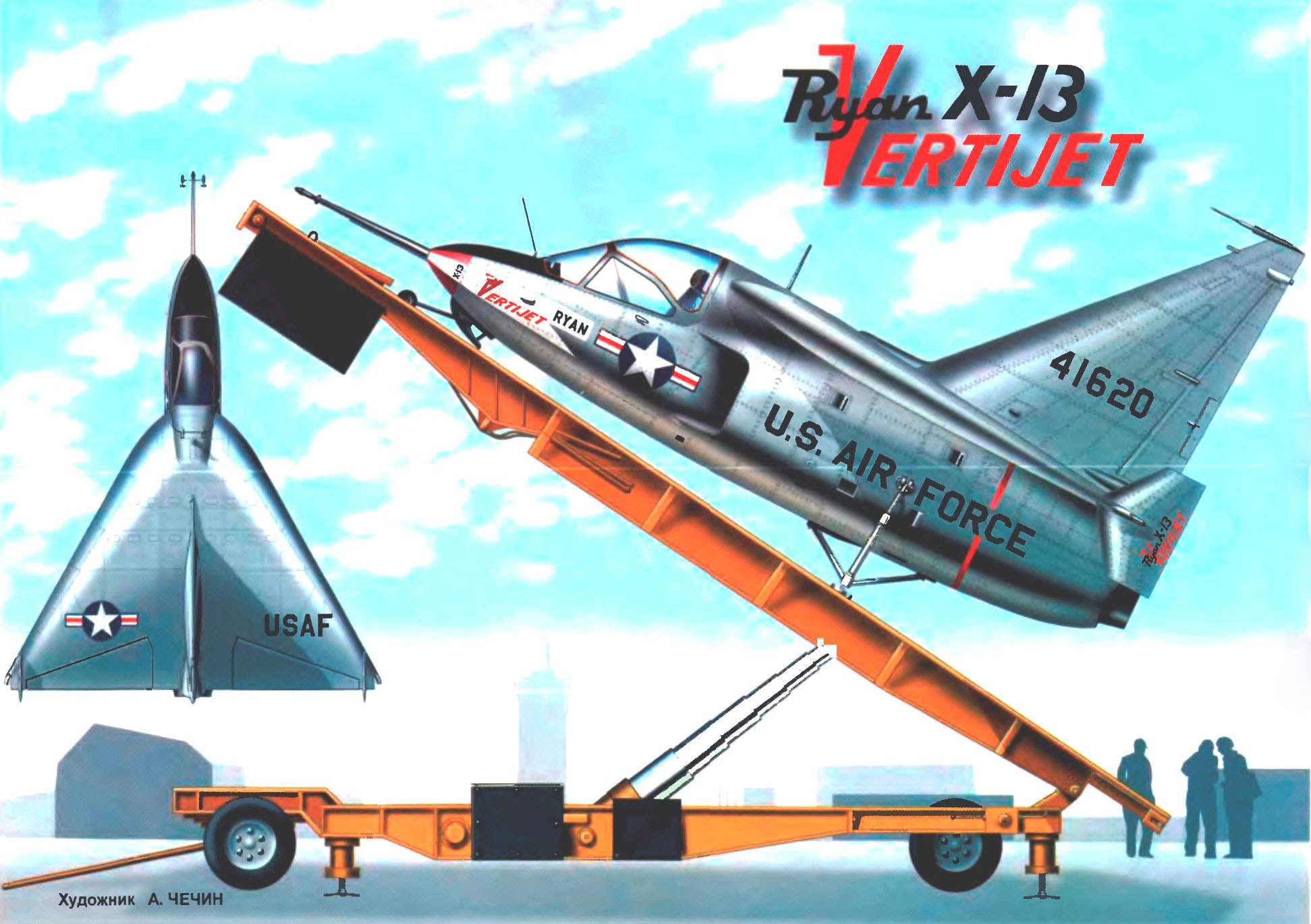

In accordance with the contract firm Ryan had to build two experimental aircraft (internal designation “Model 69”, the designation of an air force X-13 VERTIJET). The key to success was to become the English AVON engine company Rolls-Royce used at the time in most of the British planes and not without reason, considered one of the best in the world. The specific thrust of the Americans selected the modification AVON R. A. 28 was only 0.28 kg/kg and the maximum thrust was reached 4540 kgs.

The designers of the firm Ryan in the process of development of a new project had come back to his old flying stand five years ago, mounted at the rear of the businesses in San Diego.

Apparatus equipped with a makeshift cockpit for the pilot, having built it from an empty tank from the b-47, November 24, 1953, test pilot Peter Girard had tied off a rope machine from the ground and tested the operation of the control system. Was committed a few approach on a leash, in which the pilot was developed management skills unusual aircraft.

At this time a new group of planners of Ryan under the direction of chief engineer Curtiss Bates worked on the drawings X-13. For the aircraft were selected aerodynamic configuration “tailless”, the best in a weight ratio, combined with high Delta wing with clipped wingtips and a rounded front part. In the middle part of the fuselage was a turbojet engine, the air compressor flows through lateral intakes. In the forward fuselage housed the cockpit. To improve visibility in vertical position of the fuselage the pilot seat lean forward at 45 degrees. The aft fuselage was crowned with a huge triangular keel. In horizontal flight the aircraft was controlled by elevons and rudder. When the vertical position of the fuselage the main body had rejected the engine nozzle. To rotate the apparatus about the longitudinal axis was used differentially deflected gas rudders, which are now worked by compressed air taken from the compressor of the turbojet. Nozzle gas rudders located on the wing tips. Control system nozzle and gas rudders linked with the control stick and pedals of the aircraft that saved the pilot from having to make unusual manipulation during the vertical takeoff and landing.

After the wind tunnel it was found that when flying with high angles of attack, especially during the transition from horizontal flight to the vertical, the keel even as significant space will be partly obscured by the fuselage. Therefore, to maintain longitudinal stability at the wing tips X-13 VERTIJET has established additional vertical surface. Maximum design takeoff weight was 3630 kg, which allowed to obtain the thrust-weight ratio of 1.25 is more than sufficient for vertical take-off.

A unique feature of the X-13 was the complete absence of wheeled chassis. The plane was to take off and land vertically mounted metal platform. In the upper part of it was a hinged beams, between which is stretched a steel cable with a diameter of 25 mm — VERTIJET was suspended for it with a nasal hook. During takeoff, the pilot slowly increased engine thrust, the plane rose up and hook out of engagement with the rope. After that, the pilot took the machine from the platform at a safe distance, gained height and went into horizontal flight. For landing, the pilot translated the device in a vertical position and approached the platform and clung to the hook of the rope. Further, the pilot reduced engine thrust and the VERTIJET was hanging on the rope, the tail of the aircraft thus relied on platform two bumpers pyramidal shape. A beam with a rope was being turned down and pressed the rope to the platform, locking the bow of the X-13. In the stowed position and when servicing of the aircraft platform has taken a horizontal position. Lifting and lowering of the platform was carried out by two telescopic hydraulic jacks. Platform mounted on four-wheeled chassis and could be shipped by truck.

The Assembly of the first instance of X-13 VERTUET with serial number 54-1619 began on January 20, 1954; full training to fly the machine was only at the end of 1955. For starters, the designers decided to put the X-13 ordinary tricycle wheeled chassis and to fly around it, all of the planes way.

On the morning of 10 December 1955, after a few trial runs Peter Girard has raised the X-13 into the air. The pilot quickly discovered that the aircraft has serious problems with handling. Despite the difficulties in piloting Girard stayed in the air for about 7 minutes, then made a successful landing.

In the next phase of testing was to verify the characteristics of the X-13 during vertical takeoff and landing. Full confidence in the predictable behavior of the aircraft in the hover mode of Bates and Girard-Yes, there was. In this situation, the apparatus, it is desirable to stay as far away from the landing platform, so I decided to temporarily abandon her, securing the aircraft vertically, on a tubular four-wheeled frame.

May 28, 1956, Girard made the first vertical takeoff. Reaching a height of 15 meters with a small horizontal velocity began to decline and the successful landing of the aircraft. The only remark was made by the pilot to the engine: the pilot had to work intensively control handle ORES, however, the thrust of turbojet engines has changed since the big delay. This problem was solved fairly quickly by the installation of remote control system that coordinated the speed of movement of the ORE with the rate of change of the engine thrust.

Next flight, the pilot praised the adequacy of control: hovering in the air X-13 VERTUET behaved steadily and confidently managed.

The day of the first vertical rise of the test program involved second prototype X-13 with serial number 54-1620. In the first flight aircraft X-13 No. 2 ran a test pilot Lou Everett. Later began to work out a method of approach to the platform and land on it.

During the test, Girard, focusing on clues from the earth, demonstrated the accuracy of the output of X-13 in a predetermined spatial position with an accuracy of 0.1 m (in the horizontal plane).

After these flights, the test team gained full confidence in the success and began to prepare for the implementation of the first take-off from the platform with the standard landing “on the rope”.

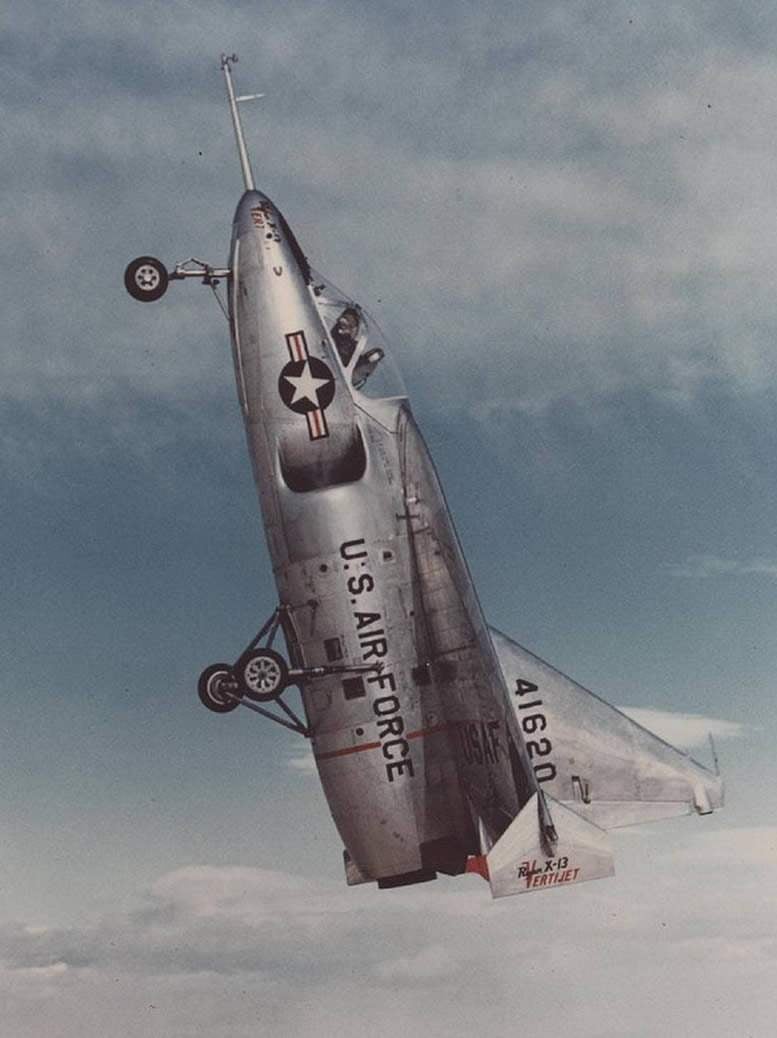

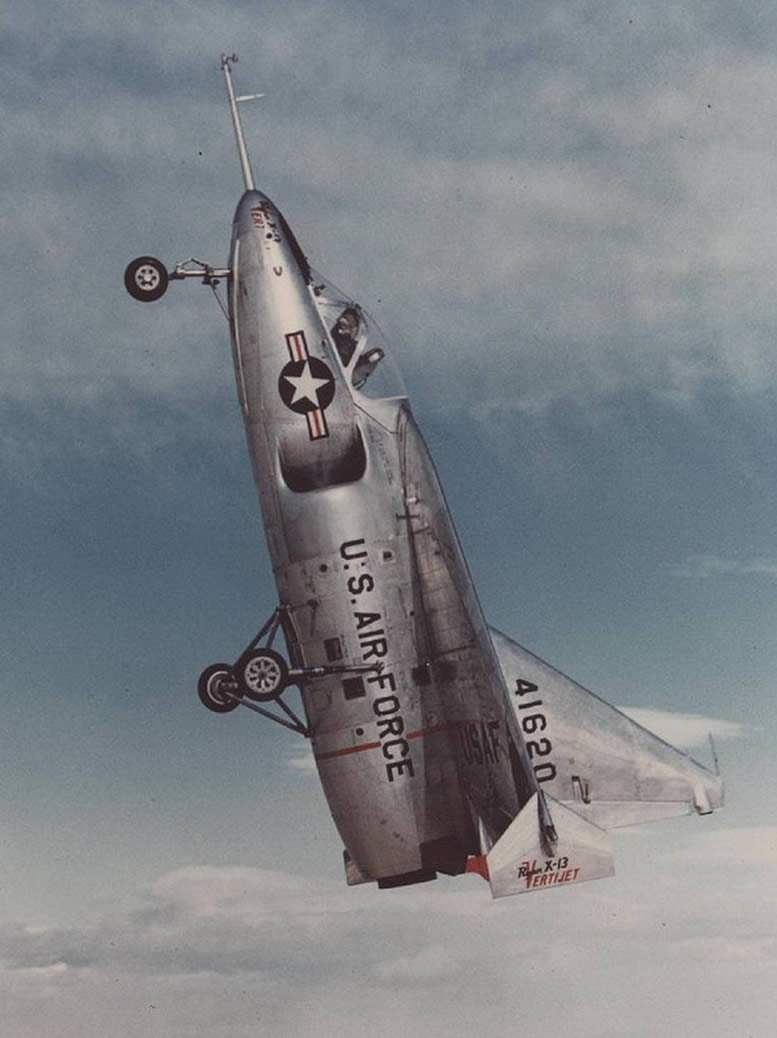

In the fall of 1956, the first X-13 VERTUET again equipped with a wheeled chassis. After a few preliminary flights of Peter Girard for the first time in the history of jet aircraft made the transition from horizontal flight to vertical. Powys is a few seconds in the air at an altitude of 1800 m, he returned to X-13 to a horizontal position and made a successful landing on the runway “on an aircraft”. This historic event occurred on 28 November 1956.

Followed by training flights, in which Girard and Everett learned to cling inch line strung between the two searchlight towers. The exact output plane on the cable provided with commands from earth. The only outstanding problem remained podpet of the aircraft to the platform. When the vertical position of the fuselage the pilot not seen the platform, to evaluate distance and speed of approach he needed a reference point. They became a six-metre pole with red and white Popoli attached to one of the rope holding beams. In addition, next to the platform has set high the ladder of the landing, prompting the pilot to radio his location and control beams, between which stretched rope. At the right moment, he suddenly raised the beam at an angle of about 20 degrees and “hooked” a hovering X-13. Together with the beams went up and painted the pole, signaling to the pilot about the attached.

Improve the equipment and training of pilots graduated in the spring of 1957. April 11, the first sample X-13 installed on a platform. Prepared VERTUET had wheeled chassis with a hook at the front Desk. The presence of gear allowed in case of impossibility to cling to the hook to land in the traditional way. Peter Girard took his place in the cockpit and the platform set in the starting position. Increasing thrust, the pilot was released out of engagement with the rope and began slowly, “backwards”, away from the platform, holding the device at a height of three to four meters. Flying away for a couple of tens of meters, Girard launched X-13 180 degrees, gained altitude and moved in horizontal flight. The landing took place in reverse order. Approaching the platform at 5-6 meters, Girard found that striped pin is absolutely not visible — it overshadowed the back of the cabin, located opposite the head. Had to completely rely on the operator’s command. Clinging to the rope, Girard has reduced cravings and the car touched the platform. The historic flight ended.

Performance characteristics of American VTOL vertical position of the fuselage

After this flight, the canopy was altered, arranging it on the left side of the window to monitor the pin. This was the end of the pilot phase in the test program of the aircraft X-13. Company Ryan deservedly celebrated its success: after all, VERTUET was deprived of most of the drawbacks of the screw VTOL aircraft companies Lockheed and Convair. For example, the vibrations of the propellers and the power plant, the effects of ground proximity, etc. in addition, the process of landing the X-13 took place easier and safer for the XFY-1 pilot did not see where and how it sits. Thus, the X-13 was a more likely prototype of a tactical VTOL than the XFV-1 and XFY-1. It remains to convince the military, well after a demonstration of the aircraft.

The first public demonstration of the X-13 was designed by Ryan in the best American tradition. June 28 at Andrews air force base near Washington, invited more than 3,000 soldiers and journalists. Specially prepared a second instance of X-13 could not fly over the whole country, and its pre-sent to Washington by ship. Beating around America via Panama canal, on the morning of 28 June, the pilots Girard and Everett made several demonstration flights using the platform to anyone not previously seen before the plane, prompting rave reviews from the audience. VERTUET sat on the platform, clinging to it with his hook, easily, like a fly on the wall. And still no plane in the world can do such things.

Specifically for this flight platform was finalized. To put next to it a ladder for the operator of the landing was undignified, and for him the upper-right corner of the platform is secured a square cradle, painted black. The culmination of the show was the flight X13 base Andrews to the Pentagon landing near this famous building. The plane flew to the Pentagon in a vertical position by the Potomac river in the cloud of water spray, producing a lasting impression. However, Girard is located in the cockpit, was not thinking about the impression produced, and the fuel stock which inexorably ended. The water spray settled on the lantern, bringing “zero” and without that a poor review Only because of the operator, he successfully landed the plane.

12 September 1957 X-13 No. 2 returned to base Edwards to join the first instance that were military test pilots. Nevertheless a good show and a successful test could not open “aluminum fly” the way to serial production. In September, the military pulled the funding and closed the program X-13. Were closed and other American program to develop VTOL vertical position of the fuselage. The main reason was all the one — complexity of uspet and landing for a pilot of average skill. X 13 “sinned” because a jet of gases from the turbojet it destroyed the concrete surface of the runway.

September 30, 1957, X-13 took to the air one last time. Some time the Americans took him for all aviation exhibition, exhibiting in the static display. In may 1959 VERTUET No. 2 deposited in the United States air force Museum in Dayton, and in 1960 the company Ryan gave VERTUET No. 1 together with the platform of the National aerospace Museum.

Design description X-13 VERTUET

Experimental aircraft vertical takeoff and landing X-13 VERTUET performed on the aerodynamic configuration “tailless” with the high-set Delta wing and single-fin tail.

The fuselage is semi-monocoque is structurally made of three parts. In the front were the pilot cabin and the main instrumentation. On the first power of the frames were fixed hook with lock type “carbine” for planting the device on the cable. In the case of use of a wheeled chassis hook shot, and his place was fixed nose controlled landing gear. In the middle part of the fuselage housed the fuel tank, hydraulic units, compressed air and power frame with the fixing points of the engine. To this frame is attached to the Central, most loaded damper of the bumper. In the rear fuselage housed the engine, an extension tube and swivel nozzle.

Fuselage is dural. In the area of the nozzle was applied to the plating of titanium alloys. In the cockpit, installed a set of pilot-navigating devices, including available control devices, reactive control system and the pointer of the angle of rotation of the nozzle.

The cockpit with a large area of glazing. Ejection seat could lean forward at a 45 degree angle to ensure proper operation of the vestibular apparatus of the pilot and to improve visibility in vertical position of the fuselage.

The two-spar wing, with front and rear longitudinal walls. Wing sweep on the leading edge of 60 degrees. The wing was a sealed design and is attached on top of the fuselage on the main power frames. At the ends of the wing fixed rotary gas handle bars and additional vertical surfaces. Compressed air from the compressor turbojet was fed to the wheels through the pipelines laid in the thickness of the wing. To control in horizontal flight, the roll and pitch was used on the wings elevons.

Keel triangular plane, a large area defined by the aerodynamic parameters of the aircraft. The height of the apparatus when it is mounted on a wheeled chassis was 4.62 m In the upper part of the keel was mounted a receiver air pressure and the nozzle of the gas booster. In the root of the keel was fixed to the container of a brake parachute, the only means of braking during landing X-13 on a wheeled chassis. The rudder was equipped with a trimmer.

As the power plant used engine Rolls-Royce AVON R. A. 28 axial 14-stage compressor and two stage turbine, develops a thrust to 4540 kgs. Engine length of 2.88 m, the maximum diameter of 1.05 m, weight 1312 kg. fuel Consumption at maximum capacity — about 65 l/min Armament on a plane could not be installed.

A. CHECHIN, N. Food reserve was