Our dacha plots are small. And when every square meter counts, allocating space for garages and utility buildings is no easy task. Tent structures can be a quite acceptable solution. Especially when considering the time, and even more so—material costs.

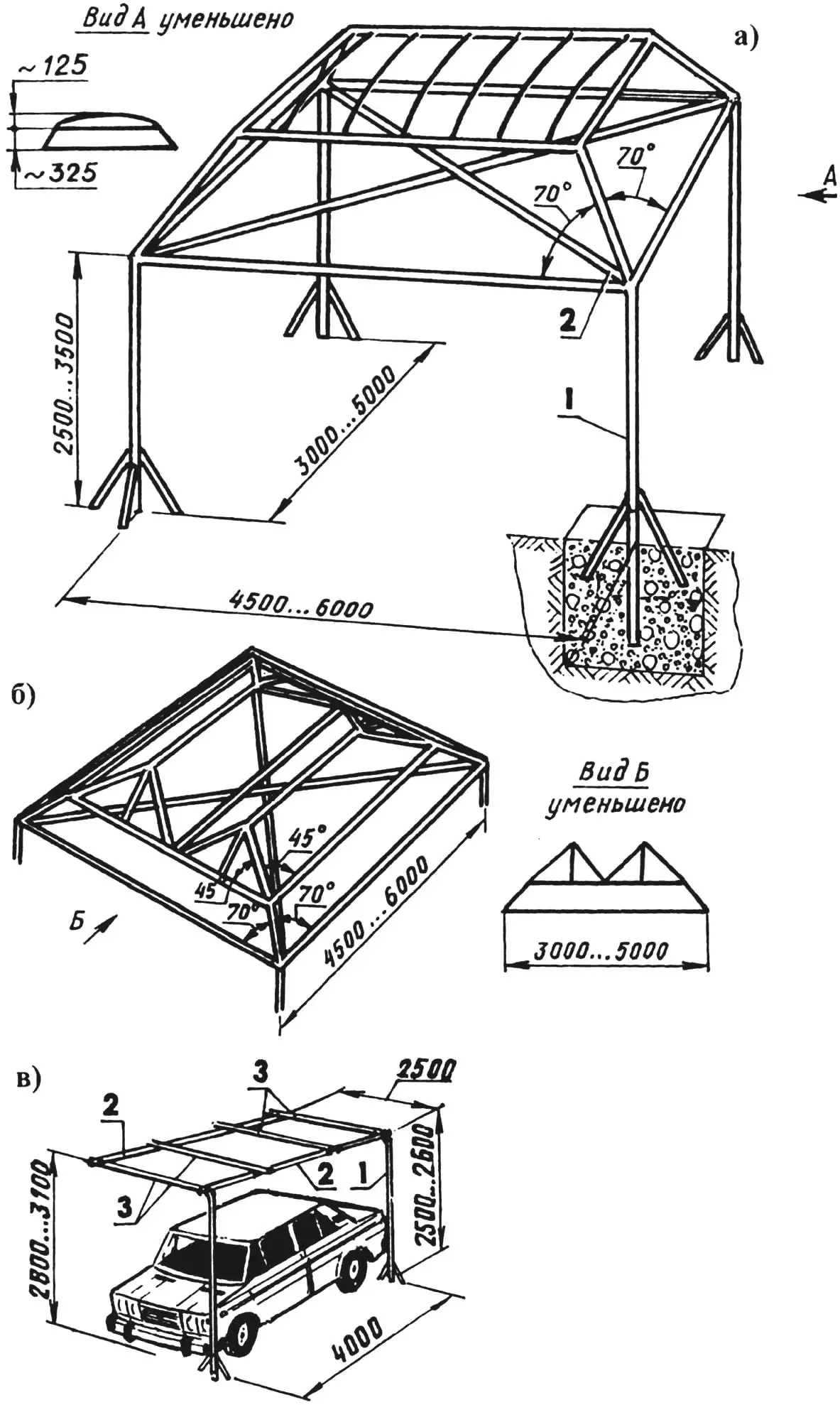

For assembling the frame of practically any of the three tent variants that have become most widespread here, anything at hand will do: wooden posts, beams, or even poles are acceptable. But it’s better to use steel pipe, angle iron, or other metal profiles for the frame. The dimensions should be such that the existing car fits easily under the future tent.

To prevent the tent from shading the yard, it’s advisable to cover the roof with transparent film, like in a greenhouse. However, in winter, the film covering cannot withstand snow loads, so it’s made removable or simply single-season.

It’s better to replace the lightweight film roofing with a metal or slate sheet. Such material is strong and durable. Moreover, installing such a stable covering won’t require much time and effort, although it will cost more.

a — with streamlined roof; b — with dual-ridge; c — with suspended covering:

1 — post dug or driven into the ground with braces; 2 — tie supports; 3 — cross members;

covering or sheathing conditionally not shown

The tent variant with streamlined roofing (a) is preferable in places where wind and precipitation are not rare occurrences. The dual-ridge covering (b) wins with increased strength (in cross-section, after all—solid triangles, which are geometrically rigid figures) and relatively small slope angles. But the presence of a longitudinal “trough” threatens accumulation of fallen leaves and other debris carried by the wind…

If a small-sized tent is required (for example, only to shelter a car), then the structure (c) is acceptable, consisting of two post-tubes, bent and connected to each other with ties with overlay wooden cross members for subsequent covering or sheathing. For such a tent-canopy, the side can also be partially closed with film.

Dug-in (driven, or even better—concreted) support posts must have side braces. Moreover, with an increase in the tent’s capacity (especially when lengthening it), the number of such sets must be increased.

In conclusion, a few words about the technology of covering the tent with film. Essentially, it’s no different from a similar operation for “glazing” greenhouses with double-layer polyethylene, which has been thoroughly and repeatedly described on the pages of “Modelist-Konstruktor” (see, for example, No. 3’99 and No. 6’2000 of the magazine). However, it’s worth reminding that the film should be nailed to the base beam not directly, but through a batten 3—4 mm thick. At the same time, one should not strive to achieve “drum-tight” tension. After all, the optimal covering is considered to be one done with barely noticeable sagging (otherwise the film, shrinking in the cold and losing its former elasticity, may burst).

Undoubtedly, a tent installed, say, over a repair area in a private yard or at a dacha is a good protector against weather whims. Having it, even in bad weather, one can use a workbench, welding equipment to carry out any repair work in more comfortable conditions than before.

V. RYBALKO