To obtain hot water in a bathhouse, a tank-register on the stove pipe (or a boiler in the stove itself) and an external tank in the washroom are often used. Water circulation between them is carried out by natural convection due to the difference in specific weight of hot and cold liquid at temperature differences.

Due to the small magnitude of natural pressure in such a system (100 – 300 Pa), it is recommended to use pipes with an internal diameter of at least 25 mm and a length of no more than 2.5 m, as well as to observe the slope of pipes from the external tank to the register tank. But even when following all the above recommendations for pipe installation, it is difficult to ensure more than a tenfold hourly water exchange in the external tank and, consequently, rapid heating of water in it.

Installing a circulation pump in the system, which provides forced circulation of water between the external tank and the register tank, allows accelerating the heating of liquid in the external tank by increasing the water exchange rate and simplifying pipe installation by reducing requirements for their length, diameters, and eliminating the need to observe slopes when laying them.

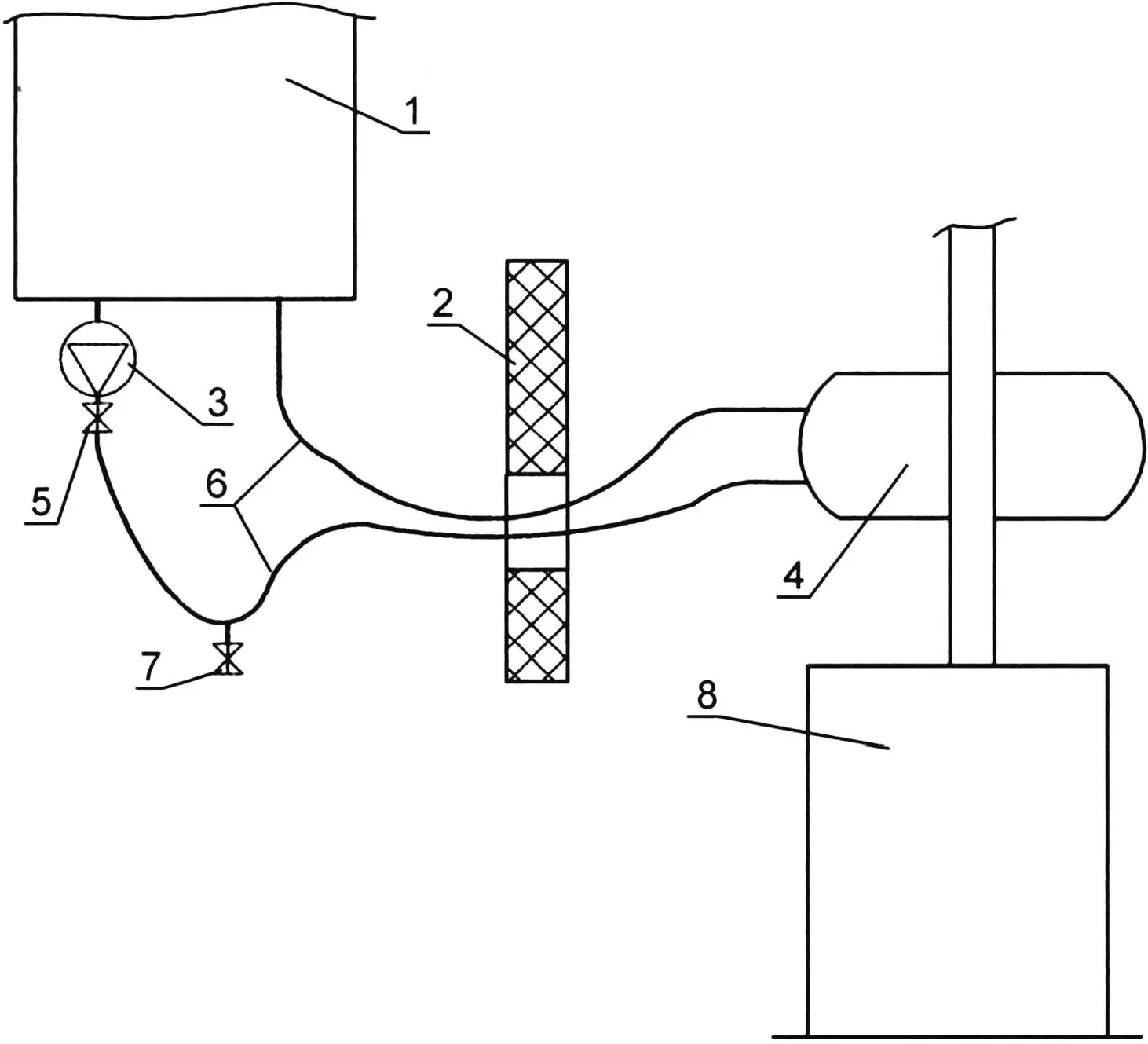

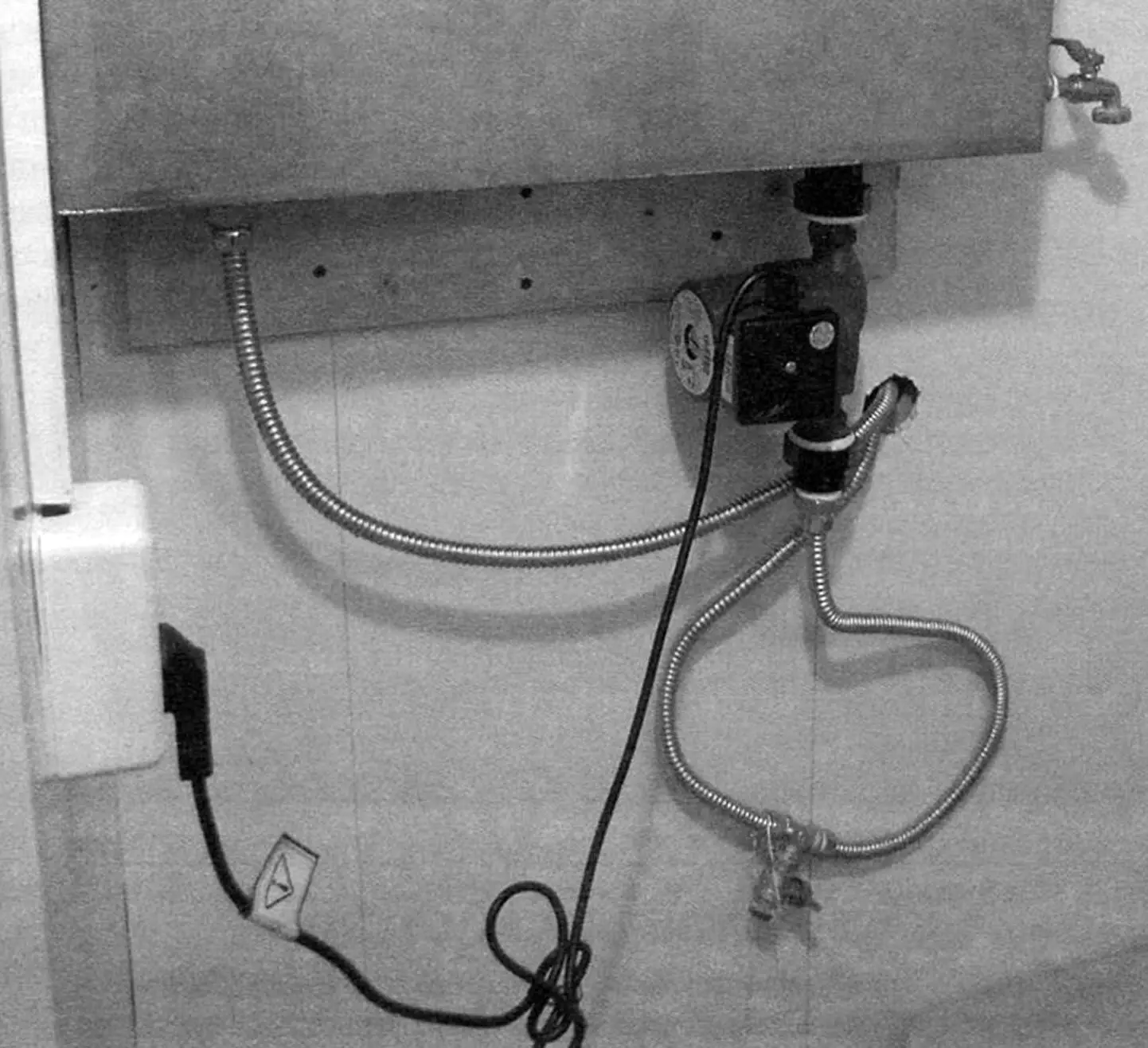

1 – external tank V=50 L; 2 – wall between steam room and washroom; 3 – circulation pump ELS25-4; 4 – register tank; 5 – regulating valve; 6 – pipes made of flexible corrugated stainless steel Ø20; 7 – water drain valve; 8 – stove-heater

Thus, installing the ELS25-4 circulation pump provides pressure in the system of about 1500 Pa and a hundredfold hourly water exchange in a 50-liter external tank.

If necessary, the water heating rate in the external tank can be additionally regulated both by changing the performance (rotation speed) of the circulation pump and by the opening degree of the regulating valve orifice.

Electrical safety in the bathhouse is ensured by using a residual current device and selecting electrical equipment with a protection class of at least IP44.

V. MIKHALITSYN