Every DIY enthusiast regularly faces cutting sheet metal and non-metallic materials. Using hand shears is inefficient (especially for large sheets): with high labor costs, the cutting quality leaves much to be desired.

At one time, I used factory-made lever shears for metal. However, unfortunately, they had a not very reliable design, and when trying to cut a 5-mm steel sheet, the cast iron body of the shears cracked. It was not possible to purchase a similar one: they were not available in stores and warehouses, and the manufacturer replied that their production had been discontinued. But I, as they say, “got hooked” on these shears and really didn’t want to return to the old grandfather’s method.

This prompted me to design and manufacture a device similar to the factory one, but only from simpler technological parts that require minimal use of machine metal-cutting equipment.

I think that the mechanical cutter offered to the attention of the magazine’s readers may interest many craftsmen.

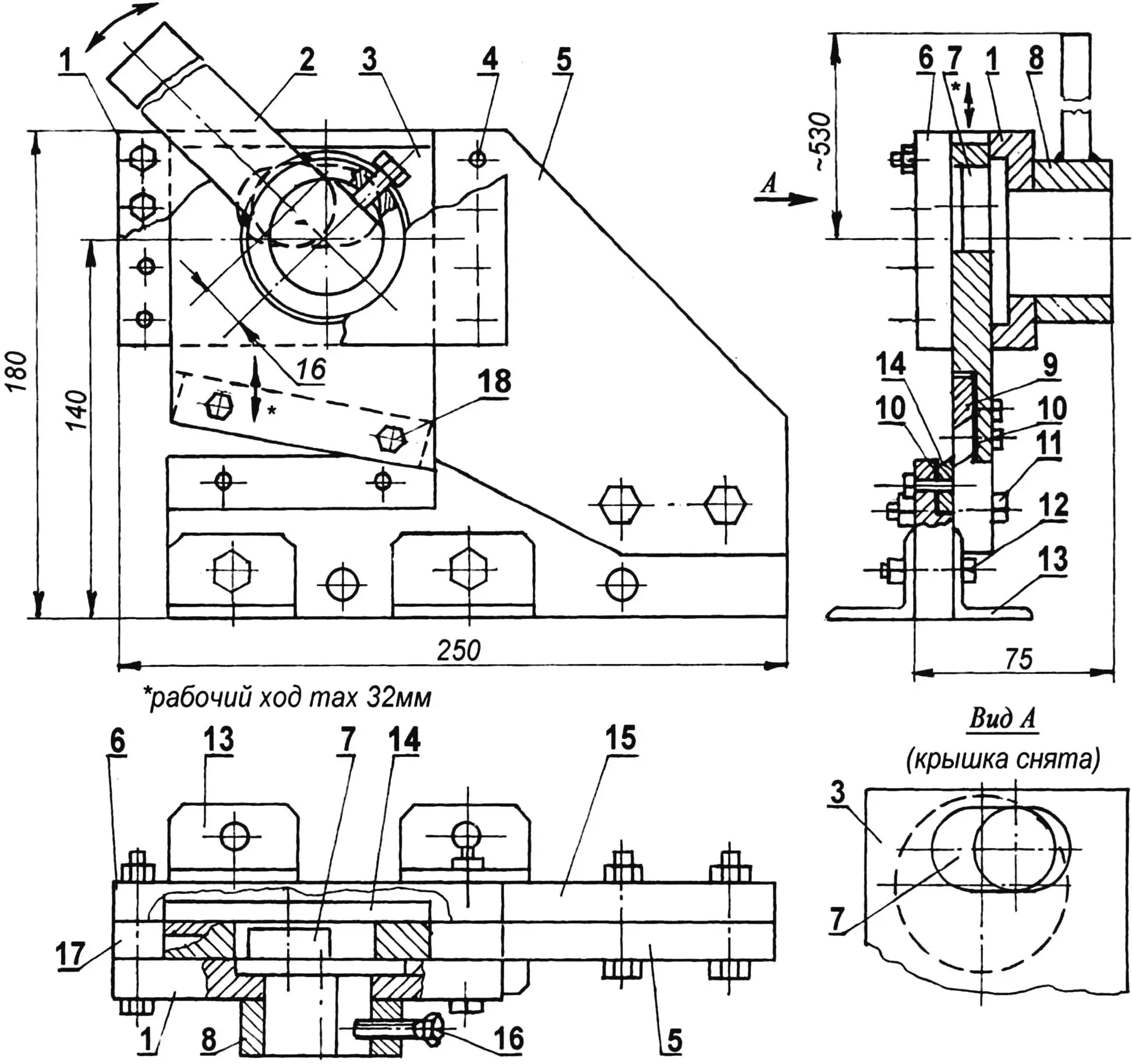

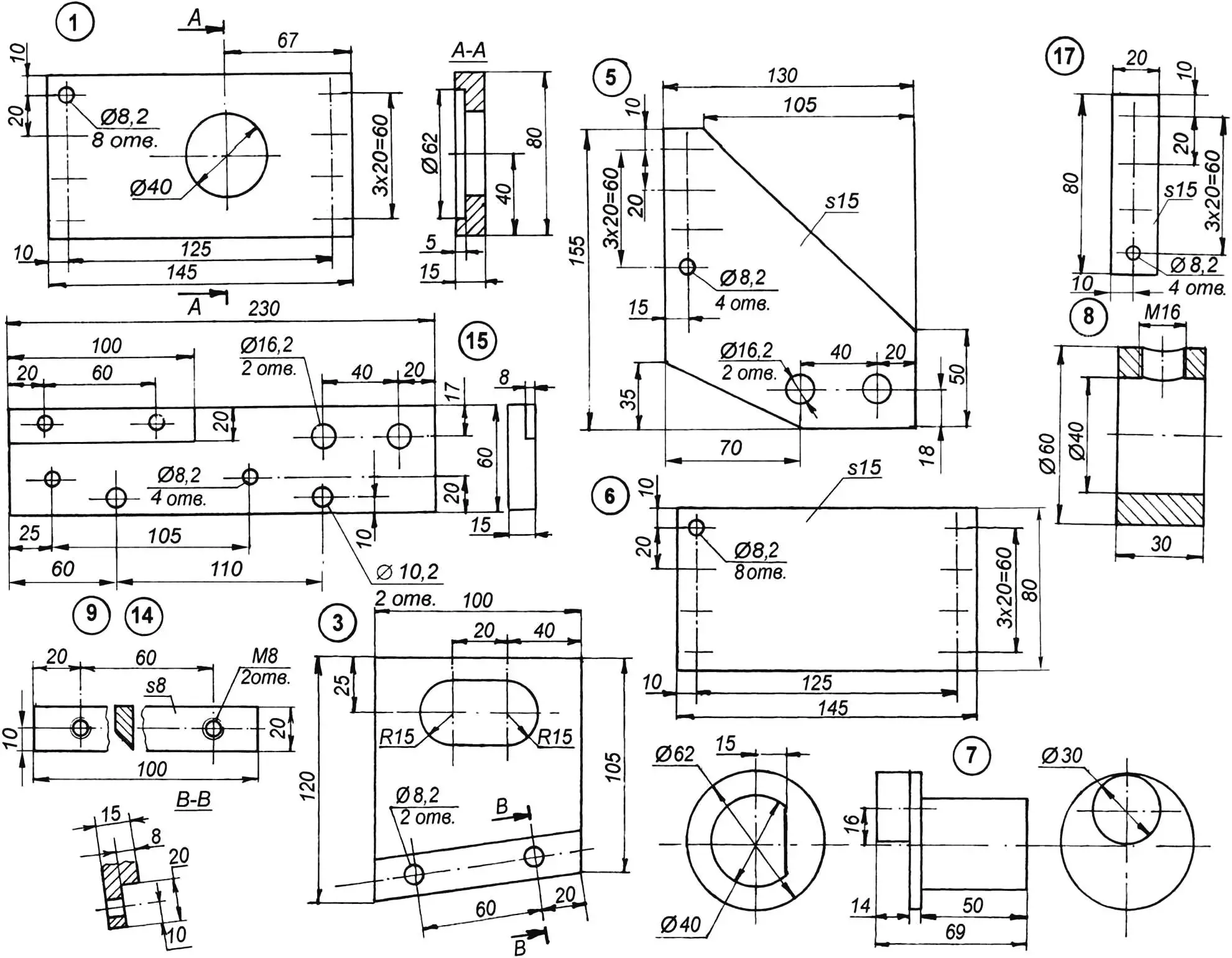

1 — cheek (sheet s15); 2 — handle (strip 10×30, L500); 3 — slide (sheet s15); 4 — cover fastening (bolt М8х55, 8 pcs.); 5 — bracket (sheet s15); 6 — cover (sheet s15); 7 — eccentric (round 62); 8 — handle bushing (round 60); 9,14 — movable and fixed blades (tool steel У8…У10; strip 8×20,5; L100); 10 — spacers; 11 — bracket to base fastening (bolt M16x50, 2 pcs.); 12 — leg fastening (bolt М8х30, 2 pcs.); 13 — leg (angle 35x35x5, 4 pcs.); 15 — base (sheet s15); 16 — stop screw (M16x25); 17 — spacer (strip 15×20, L100); 18 — blade fastening (screw М8х14, 4 pcs.); material of parts (except blades) — steel 40,45, 40Х, etc.; arrows show the direction of movement of the slide and handle during cutting

Metal cutting is performed by two 100-mm blades, one of which is fixed on a stationary base, and the other — on a movable slide. The slide feed is produced by a crank with an eccentricity of 16 mm (maximum working stroke 32 mm), on the tail of which a handle is fixed. With its length of 500 mm, the applied force increases more than 30 times, which allows cutting a steel sheet up to 3 mm thick quite easily.

The gap adjustment between the blades is performed by selecting spacers installed in the grooves of the base and slide. Also, with the help of spacers, the smoothness of the slide movement is adjusted.

Depending on the volume of work performed, the shears can be portable or stationary. In the first case, they are attached to the workbench using bar clamps from a hand circular saw kit. For this, two holes with a diameter of 10.2 mm are drilled in the base. The legs in this case serve as additional supports. In a stationary position, the shears are fastened with M10 bolts through holes in the horizontal shelves of the legs.

All parts, except for the blades, should preferably be made from quality grades of steel 40, 45, 40У, etc. Blades — from tool steel У8…У10 or Р9, Р18.

The proposed device has been successfully operated for more than two years and causes no complaints. Naturally, no one now tries to cut a 5 mm thick steel sheet on it. But with a 3.5 mm sheet, the shears work excellently.

«Modelist-Konstruktor» No. 1’2006, I. DEMIN