The disadvantage of such pumps is that they generate strong enough vibrations that are transmitted through the water on groundwater borehole wall, that gradually leads to their shattering and zapilivanie bottom. The latter circumstance leads to the reduction of water discharge and turbidity during pumping. This water can be consumed only after long periods of settling. Even more significant disadvantage of these pumps is that they eat from a network 220 In, and this is a potential danger of electric shock. Another feature of vibration pumps — return valve does not allow water to leave the hose after turning off the pump. And if the pump needs everyday to get out of the hole and remove to prevent theft, it is necessary to remove the hose to the pump, filled with water, and then drain it somewhere.

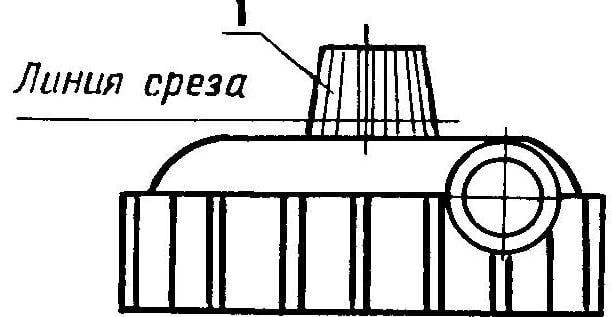

The revision covers the centrifugal pump:

1 — boss with a suction hole (cut to cut); 2 — outlet (to cut, hole to close up tightly)

Submersible centrifugal pump for lifting water from wells:

1 — power wire; 2 — rubber cover; 3 — housing; 4 — clamp; 5 — hinge; 6 — upgraded cover; 7 — tube; 8 —ring (rubber); 9 — rope (cable)

Finished cover:

1 — suction inlet; 2 — outlet; 3 — technological tides (self-hardening plastic); 4 — filter (fine nylon mesh)

Submersible pumps of centrifugal type are not creating vibration oscillations, but the industry specified diameter, they are hardly available. Besides, they work also from AC voltage of 220 V.

However, there is a simple and affordable way to solve this problem. For washing cars from scrap reservoirs (river, barrel, large puddle, etc.) is sold a special kit, called “wash”. It consists of submersible centrifugal electric pump, hose and power cord. Connects this system to the vehicle power supply or battery voltage of 12 V. the pump input power of about 100 watts, and the water pressure is sufficient to lift it through the hose to a height of 20 m. the supply Voltage is allowed to increase to 25 V, and the capacity of the pump is naturally increased.

In order to use this “wash” to lift water from a well, requires a slight modification of the pump. His cover need to remove the outlet fitting protruding sideways on a tangent, and the boss of the suction holes to install additional pipe (from nearretirees metal) with holes. The latter is necessary in order to be able to wrap a fine nylon mesh to filter water from large solid particles, which significantly reduces the resource of the pump (spoil the surface of the axle and oil seal). The outlet is cut at the sides of the cover, the hole is sealed thoroughly so that water comes out only in a new hole with a diameter of 8-9 mm which is drilled in the end caps where ends of a snail. On top of this hole is attached to the cut tube (copper, brass, aluminum or plastic) with a corresponding diameter, and the outer is such that it is tight to put on is not very thick a hose for supplying water to the surface.

For mounting parts to the lid is convenient to use a self-hardening plastic, which is used for the manufacture of dental prostheses (e.g., protakril or redont). With her pretty easy to work, and after final curing of the bonding turns solid, to divide them can only be broken with great effort.

After this upgrade “car wash” becomes convenient and efficient submersible centrifugal pump, which freely enters the bore with an internal diameter of 130 mm and above, since the outer diameter of the pump is only about 100 mm. to Lower it into the well should the rubber cover down and the power wire to bend up and press against the motor housing by rubber rings or tape. The pump itself is attached to the rope or cable with a clamp and loop of wire that holds the pump in a vertical position. The cowl covers the engine block just behind the lid and hinge can be screwed in place from the opposite side. The loop is tied to the rope (rope) and put the outlet hose. The result is output harness to the top rope, hose and power wires that need to be fastened with elastic bands in several places at intervals of about 1.5 m. as the power wires, you should use the cable in the rubber insulation and the wire cross section 2-3 mm2, i.e., slightly larger than the power cord.

To connect the pump to a household power rectifier applied power of about 300 watts with regulated output voltage and an ammeter to monitor current consumption. The rectifier, which makes the design a little uncomfortable, is also positive in the sense that the danger of electric shock is dramatically reduced, as an additional decoupling network, and the voltage 12-25 In the health and life of human is dangerous. If the country has no electricity, you can connect to the vehicle power supply or a battery.

As for pump reliability, it is sufficient for many years of use, subject to certain rules: not to pump water without filter mesh; do not leave the pump permanently in the well is idle; periodically, remove the rubber cover and inspect the engine, do not hit the water (eventually it’s bound to happen). By itself, the water inside the motor a few drops does not interfere with his work, but eventually from her salted the surface of the brushes and between them and the anchor worsens contact, there is arcing. The result is the brushes wear out quickly (by the way, they occasionally also need to see).

V. KHODYREV, G. P e R m s

Recommend to read

TO SHORTEN WITHOUT CUTTING OFF

TO SHORTEN WITHOUT CUTTING OFF

My bike is out of order camera of one of the wheels, and replace it was nothing, the store sold only camera larger diameter. However, the solution is found, and very simple. I brought... “NEIVA” – RURAL CAR

“NEIVA” – RURAL CAR

The idea to build a homemade car did not come to me right away, since I had a Moskvich. However, our terrain is such that you can’t get around in a passenger car, especially in muddy...

In any garden, each cottage or country house needs water, water in such places, as a rule, no. Dig a well if the water is deep, time-consuming and expensive. To arrange it is advisable when there are a-abstraction, i.e. in that case the well will benefit many people. Most owners want to have a small but private underground life-giving source and so does the casing of the well, with simple equipment, on their own.

In any garden, each cottage or country house needs water, water in such places, as a rule, no. Dig a well if the water is deep, time-consuming and expensive. To arrange it is advisable when there are a-abstraction, i.e. in that case the well will benefit many people. Most owners want to have a small but private underground life-giving source and so does the casing of the well, with simple equipment, on their own.