The figures represent two armchairs: one for a short rest during the day, and the second is for a night’s sleep. By the way, the mattress in the latter case, it is possible to fill a well-dried hay. Sleep on it — how in the hay! Just don’t forget to whip such a “feather bed”.

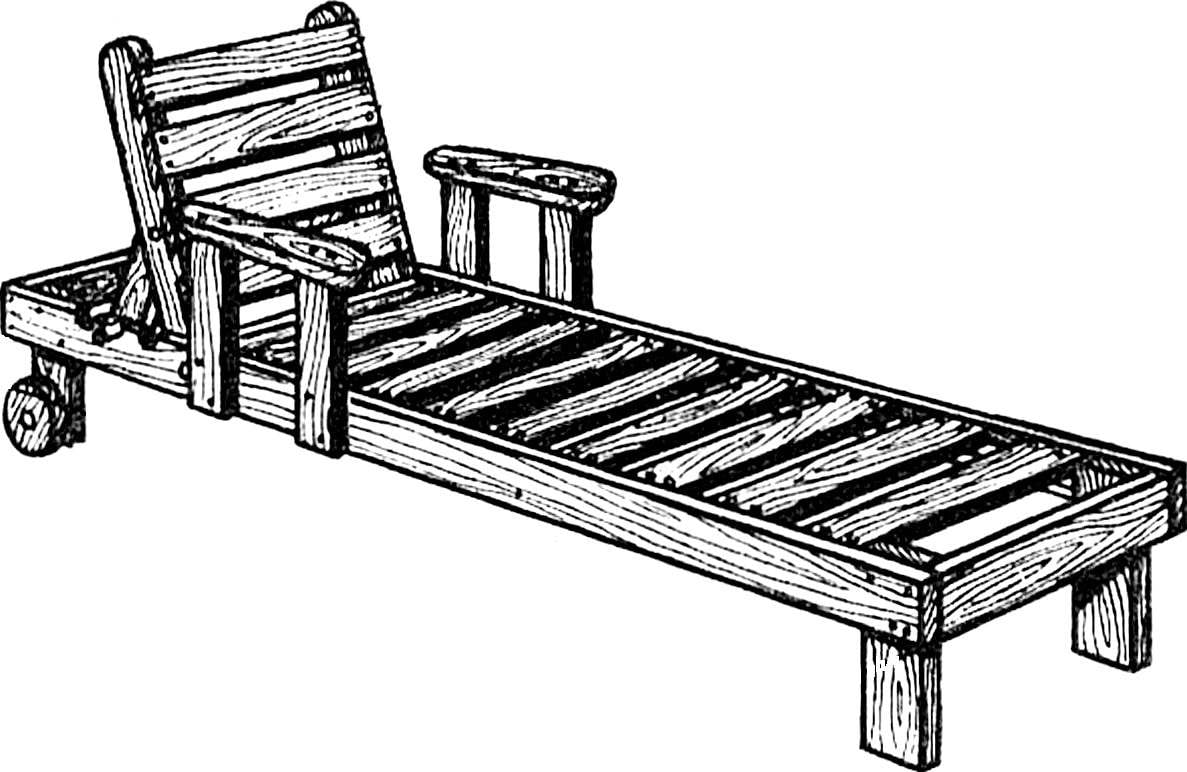

Fig. 1. Chair bed:

1, the longitudinal element of the frame (25Х75Х1000 mm, 2 PCs.), 2 — cross member (25X75X350 mm, 3 PCs.), 3 — leg front (25X75X300 mm, 2 PCs.), 4 — leg, rear (25X75X275 mm, 2 pieces), 5 — support bar (25X50X350 mm, 2 PCs.), 6 — cross member, seat (25Х75Х350 mm, 3 PCs.), 7 — front armrest (25X75X250 mm, 4 pieces), 8 — arm (25Х100Х400 mm, 2 PCs.) 9 backrest frame (25X75X600 mm, 2 pieces), 10 — cross member of the backrest (25X75X350 mm, 4 pieces) 11 — support of the backrest (25X50X275 mm, 2 PCs.), 12 — locking the backrest (Ø 25X450 mm), 13 — wheel (Ø 100X20 mm, 2 PCs.). A — Assembly of the back, B — Assembly of the armrest, In — build frame, G — installation of wheels, D — installation of crossbars of the seat.

For travel convenience the chair is fitted with wheels.

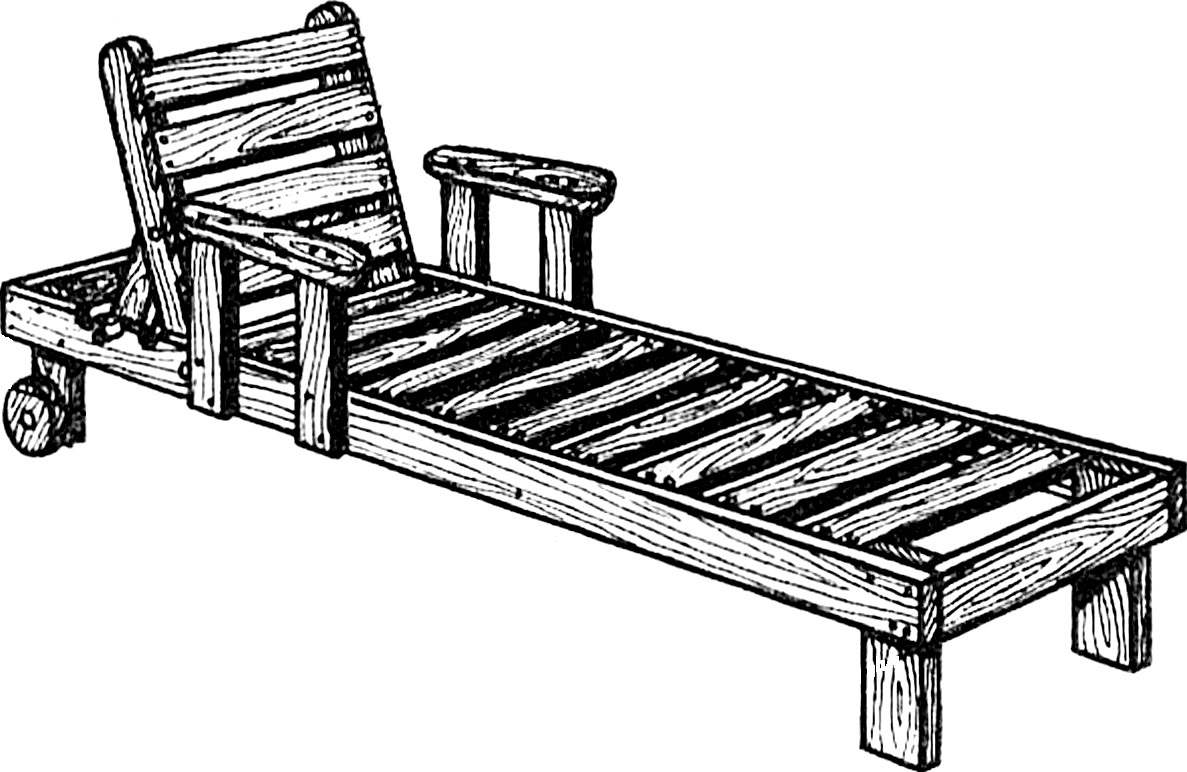

A simple chair

This design is simple and concise. Fabrication begins with the Assembly of the two side frames. The connection of elements is performed in the spike with spreading carpenter’s glue or epoxy. The frame parts of the seat are joined together by means of screws with countersunk heads. Of plates of the seat fit on the inside overhead rails and fixed against displacement by small nails or screws. Pretty important step — securing the backrest to the frame. For reliability it is better to apply the method with independent built-in cylindrical spikes on the glue.

Fig. 2. Easy chair:

1 — screed (25X75X380 mm, 2 PCs.), 2 — leg (25X75X625 mm, 4-piece), 3 element of the backrest (25X75X330 mm, 2 PCs.), 4 — cross member of the backrest (25X75X300 mm, 4-piece), 5 — a cross-tie (25Х75Х480 mm, 3 PCs.), 6 — cross member, seat (25X75X400 mm, 6 PCs.), 7 — a longitudinal element of the frame (25X70X450 mm, 2 pieces), 8 — support bar (25X50X450 mm, 2 PCs.).

Finished chairs is to cover them with polyester or nitrocellulose lacquer. They create durable and transparent surface film retains even more shows the wood texture. The paint is applied in three or four layers, with intermediate Vykurovanie. If coating is done manually, you can use the swab or sponge, making sure the coating uniformity and time removing stains. Using a sprayer will reduce the time. Of course, when you work with him you need to have a respirator.

Rocking chair

Recommend to read

“JEEP” FOR THE TWINS

“JEEP” FOR THE TWINS

The "toy" industry is developing in exactly the same way as "adult", and tries to use it to create new and new designs of many of the achievements of modern science and technology. This... SWITCH-BACKUP

SWITCH-BACKUP

It is very often necessary to turn off the light in the room from the hallway or corridor. I must say that this problem can be solved fairly well-known three-wire electric circuit;...

More and more citizens spend the summer months in the countryside, purchasing a gardens or as garden — houses in the villages.

More and more citizens spend the summer months in the countryside, purchasing a gardens or as garden — houses in the villages.