The front edge of the blade sharpened at 30° and lower than 60°. The blade has been welded to the lower part of the cutting — inch segment of water pipe with length of 1800 mm with the same stalk at a height of 400 mm welded eye made from the same steel sheet as the blade, with the lateral holes, the axis of thrust.

A tool for the processing of land:

1 — shingles (steel, sheet s); 2 — the handle (steel, pipe 1″); 3 — lug (steel, strip s); 4 — axis (M12); 5 — thrust (steel pipe 1/2″); 6 — Shoe (steel, sheet s); 7 — bushing (steel pipe 1/2″); 8 — plain bearing (bronze, PTFE)

The pull is made of half-inch water pipe, its ends slightly bent in opposite directions. One its end is welded a sleeve and the other end is slightly tapered and is welded to the plate support-Shoe.

The Shoe is made from the same steel sheet thickness 3 mm size of shoes (I have it with a length of 300 and a width of 120 mm side 20 mm walls). In front of the wall is slightly undercut from the bottom, and the nose of the Shoe are bent like skis. The rear part of the Shoe is bent at 90°, making the 30-mm focus. From the stop to the middle of the Shoe to the lower plane of welded, vertically steel strip-guide. The front and lower edge of the guide sharpened at an angle of 45° on both sides, and end at the same angle, but only from the front side.

A thrust Shoe using the axis-bolt M12 via spacer with bearing and yoke combined with the shovel-plow.

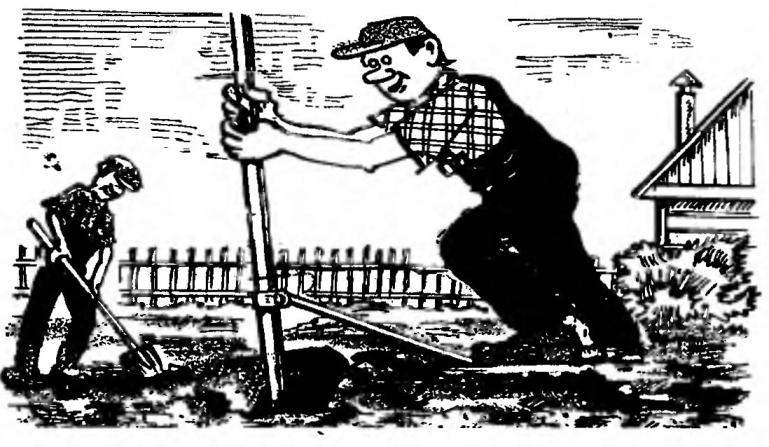

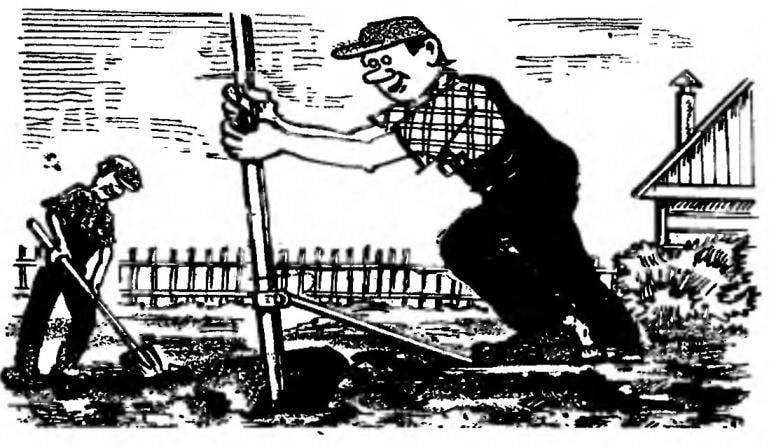

If conventional plough works on the principle of “pull” that, my weapon works on the principle of “pull”. For the cultivation of the soil, the shovel-plow is set to the original position, pushing the top of the cutting at arm’s length. Put the leg on a support, pushed her to the ground and pull the end of the cutting itself. The blade cuts into the soil and passes it to a depth of about 200 mm, Wrigley and turning over soil.

Then I crossed the free foot forward and shifting her body weight, pushing the stalk from itself. Pivotally mounted thrust while the prop pulls from the ground and pulls her forward. Further movement is repeated. If the shingles are distracted to the side, moving the support leg can be used to adjust the position of the blade, thereby straightened to its “course”.

With the help of this tools has planted potatoes: after furrow, put it in the tubers and bury them next to which runs a furrow, leaving it empty. Following furrow planting again, and so continue to work on.

A. SAMOKHIN, Lipetsk