As a tank used five-liter plastic bottle from under drinking water. In the bottom cut a rectangular hole (about 100×80 mm). The bottle is secured with two wire strands on a wooden rack.

Unscrewed the lid and it produced a gate node of the washstand.

The base part of the locking node — shank of steel rod with a diameter of 5 mm, length 180 — 190 mm.

The upper end of the rod with a hacksaw cut along the axis and a screwdriver to spread the ends. At a distance of approximately 65 — 70 mm from the end made two cross-cutting depth of 1 mm, and at the opposite end of the cut thread M5. On the rod put the washer and locking clip of twisted steel wire with a diameter of 2.5 — 3 mm. In bracket inserted the retention spring and an outer diameter of 10 mm and height 15 mm greater than the height of the staples. The spring in the clip was recorded by a split washer by inserting it into the notches on the rod. Then from the old autokamera cut a washer 10 mm in diameter, pierced in the center hole and put tension on the rod until the lock washer.

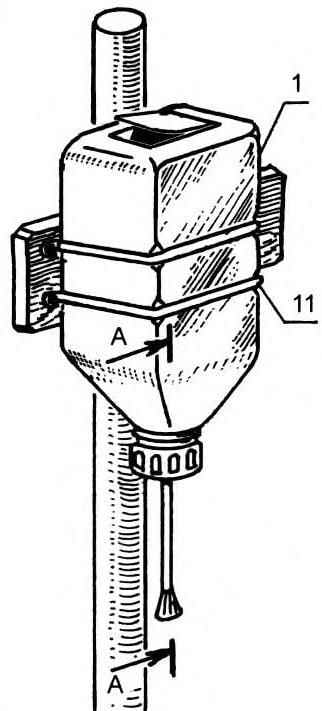

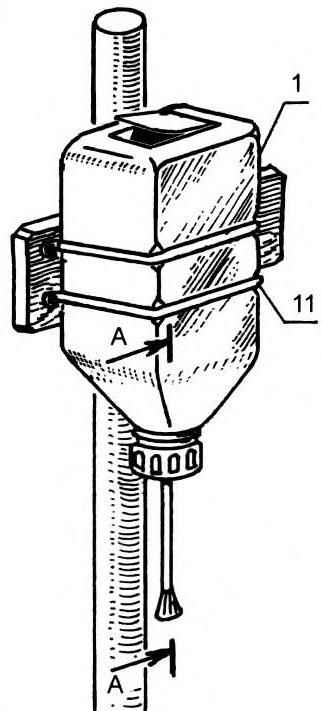

Washbasin out of the bottle:

1 — tank (a bottle of drinking water, 5 l); 2 — washer; 3 — fixing bracket (wire, d2,5 — 3); 4 — spring (steel wire type, OVS, d0,8); 5 — rod (a rod d5. L180); 6 — small locking washer (rubber); 7 — large locking washer (rubber); 8 — screw (2 pieces); 9 — the tip (the cap from a tube); 10 — lock washer; 11 — fastening the reservoir (the wire d2,5 — 3, 2 PCs.). On the section a — A Bank conventionally not shown

In the center of the lid from the bottle drilled a hole with a diameter of 8 mm and at the bottom put the puck out of the elastic rubber (used the same inner tube).

Then produced the final Assembly of the locking node: two screws attached to the cover fixing clip with filling, and the lower end of the stud screw cap from the tube of toothpaste.

For protection against corrosion all metal parts of the locking node, enameled, and after drying, set the node to the reservoir-the bottle.

All vanity is ready, you can pour water.

P. S. This vanity is not afraid of cold and will not burst, even if the winter will be water.

STEPANOV, G. And s t R a, Moscow region

Recommend to read SUPERIOR QUALITY — RELIABILITY Good modelers know how important it is to provide reliable stop screw rezinomotornaya model in the transition planning. Offer readers the design of the front boss with the stopper (Fig.... A LOT OF ONE — ON-ONE For suits and dresses, shirts and blouses, even pants and skirts in the wardrobe find appropriate hangers. But the smaller accessories such as ties, kerchiefs and scarves are usually...

It so happened that a winter forgot to drain the water from the washstand in the garden. Came spring, and the frost broke. Without the washstand in the country bad. A trip to the hardware store proved fruitless. At the time nothing suitable in the sale were not available. Then decided to make a vanity myself, out of scrap materials.

It so happened that a winter forgot to drain the water from the washstand in the garden. Came spring, and the frost broke. Without the washstand in the country bad. A trip to the hardware store proved fruitless. At the time nothing suitable in the sale were not available. Then decided to make a vanity myself, out of scrap materials.