When there is a need in the trailer for transportation of household goods, there is the problem of choosing which trailer to buy, good this choice was. That’s the only difference in price is not really felt, although the price was quite high. In the end I thought — and whether it is worth it to buy? So it’s not that complex device that was not able to do it myself. And the money will come in handy for something else. Of course, with this trailer is more of a hassle at check in, but the savings are worth it.

When there is a need in the trailer for transportation of household goods, there is the problem of choosing which trailer to buy, good this choice was. That’s the only difference in price is not really felt, although the price was quite high. In the end I thought — and whether it is worth it to buy? So it’s not that complex device that was not able to do it myself. And the money will come in handy for something else. Of course, with this trailer is more of a hassle at check in, but the savings are worth it.

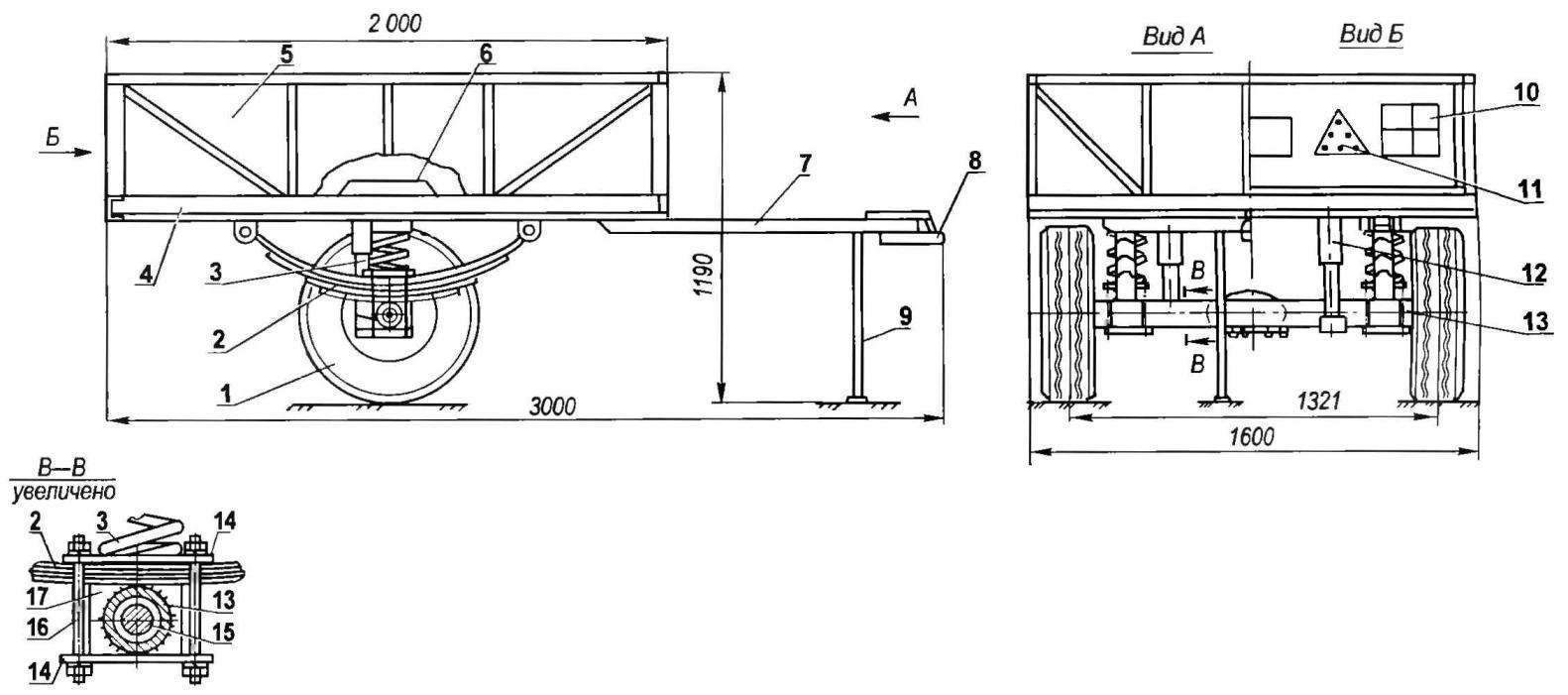

The trailer is two-wheeled, single-axle, payload up to 1000 kg. Wheels with a rim diameter of 13″ — such as the “Lada” and “Muscovites” of previous releases. By the way, even as the axis (or beams) used rear axle Lada: removed main gear with the differential and axle shaft left (their inner ends mounted in bearings 305). The hole that was previously covered shank main gear, killed steel sheet 2 mm thick, attached by regular screws to the beam. The very beam turned 90° so that the convex protective cap Carter was at the top, thus increasing ground clearance.

The trailer suspension combo. Trucks for “mitigation progress” in empty mileage and increase load capacity at the suspension set pair of damping: leaf springs with podreczniki. In my own trailer is another pair – spring and coil spring from the car “Moskvich”. With spring in full force and effect starts to work only when the spring can no longer bear the load and SAG badly.

The trailer for passenger car or mini-tractor:

1 — the wheel (from the car “Lada”, 2); 2 — spring (from the car “Moskvich”, 2); 3 — spring (from the car “Moskvich”); 4 — frame; 5 — lining the sides of the body (duralumin sheet s2); 6 — wheeled niche in the floor of the car body (steel plate s1, 2); 7 — pole; 8 — hitch (industrial manufacture); 9 — leg (steel pipe Ø16); 10 – signal lamp (2 PCs); 11 — the sign of emergency stop (2); 12 — the shock (from the car “Lada”, 2); 13 – beam (the rear axle of the car “Lada”); 14 upper and lower plate (steel sheet s5, 4x); 15 driveshaft (from the car “Lada”, 2); 16 — pin M12 with lock washers and nuts (8 sets; 17 — Shoe (steel sheet s3, 2 PCs.)

For mounting the springs to the beam is welded platform boots, a mount carried by four M12 studs with two plates: one set on the bottom of the Shoe and the other on top of the springs. The latter serves as a cradle for the spring, the upper part of which is fixed in the Cup that is welded to the spar. The front ends of the springs through bushings rigidly secured in the brackets also welded to the longerons. The rear ends of side members connected with the pivotally— through earrings.

To ensure the smooth running of the trailer suspension equipped with shock absorbers — “Zhigulevskoe”. Support on the beam for them, used regular, only welded them into place.

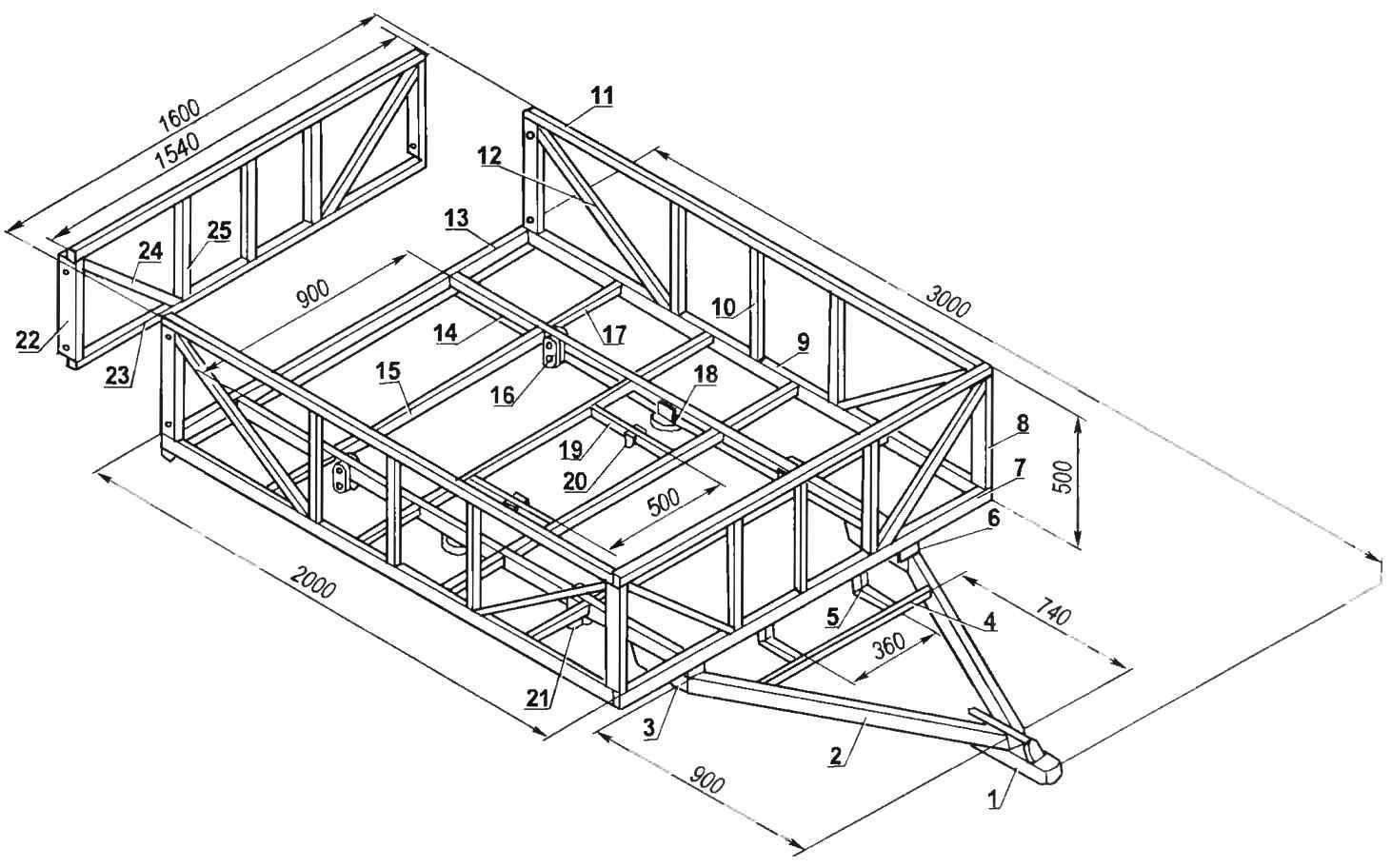

Skeleton (skeleton) of the body of the trailer — frame construction: it is formed by the power components of the body bottom and frame sides the First is the two longitudinal members are made of extruded steel channel 80x40x3 mm. In the place of installation of the earrings and cups channels strengthened by overlays (in the drawing not shown) welded to opposite edges of the shelves. The side members are also welded (or screwed bolts) mounts suspension: leaf springs and coil springs.

The frame of the trailer (parts of POS. 4, 5, 10, 11, 12, 17, 19, 23, 24, 25 made of steel square pipe 25x25x2):

1 — locking device (industrial manufacturing), 2 — beam beam (tube 50×25, 2); 3 — ending beam of the drawbar (tube 50×25. 2 pieces) 4 — cross member of the drawbar; 5 — tool tray spare wheel (2); 6 — plate (steel sheet s3, 2 pieces); 7 — front cross member (tube 40×20); 8 — corner front side (tube 40×20. 4 PCs ); 9 — longitudinal beam (pipe 40×20, 2); 21 — bracket suspension spring (steel sheet s5, 4x), 22 — front side frame rear side (pipe 40×20, 2); 23 — rail frame rear side (2 PCs ); 24 — strut tailgate (2 PCs); 25 — front rear side (3 PCs.)

Between the four side members welded cross member from a rectangular tube 40×20. Connections are reinforced with gussets from 2 mm steel sheet (in the drawing not shown — they are very visible in the photo). Between the two middle cross members welded a couple short longitudinal elements — they are used to mount the upper support of shock-absorbers.

To the side members at the sides, the outer side is welded several short cross pieces of square pipe 25×25 mm. Free (outer) ends of the crossbars are connected to the longitudinal beams (made from a rectangular tube 40×20 mm), which were both lower studs of the side walls, and formed of a lattice — basis of expanding the bottom of the platforms. To the ends of the longitudinal members (in the corners of the pad) is welded to the corner post of a rectangular tube 40×20, with the struts (tubes 25×25) and in between a few member posts the same pipe as the struts. On the perimeter (except tailgate) top of the rack are connected by a harness from the same pipe 25×25 mm

At the front side of the lower rail of the frame is the front cross member. Tailgate — hinged and removable; it has a separate frame.

The shaft is made of steel rectangular pipes 50x25x3 in the form of rays of an acute angle, the ends of which are rigidly connected (welded) with the spars through the extensions at a distance of about 250 mm.

…If you look under the bottom

In place of gathering rays of the drawbar to it welded to the hitch (it industrial manufacturing — IED prohibited technical requirements) Here hinged leg that supports the rich on “vacation” and the wiring connector for the rear signal lights mounted on the rear Board (as this Board is detachable, the back under the bottom there is another connector).

The bottom of the trailer is closed by galvanized steel sheet thickness of 1 mm. For the wheels arranged in small niches with a height of 80 mm.

All sides trimmed shaped dural sheet with a thickness of 2 mm.

The trailer was made actually to work in tandem with the car “Lada” and now he is tractor tractor. But no alterations to the trailer not required — only on the tractor mounted car drag hook with ball

V. WHEELS