Screwdriver is a tool, which, perhaps, to the greatest extent characterizes the “homebrew”. Any self-respecting “handy” invent to themselves “personal” screwdriver, unlike any previously seen.

Screwdriver is a tool, which, perhaps, to the greatest extent characterizes the “homebrew”. Any self-respecting “handy” invent to themselves “personal” screwdriver, unlike any previously seen.

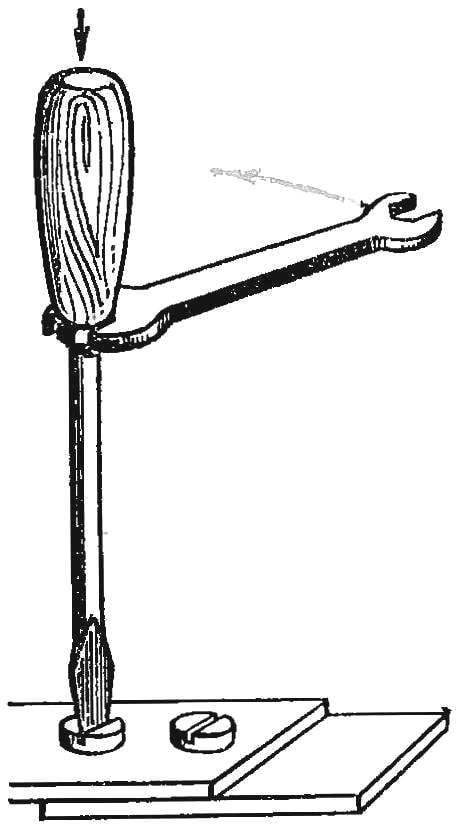

What you will not find any fixtures to the screwdriver! And simple as, for example, welded to the base stud hex nut for loosening the most stubborn screws with a wrench (Fig. 1). And complex, make that only a qualified specialist. Try it and you will benefit from the experience of craftsmen.

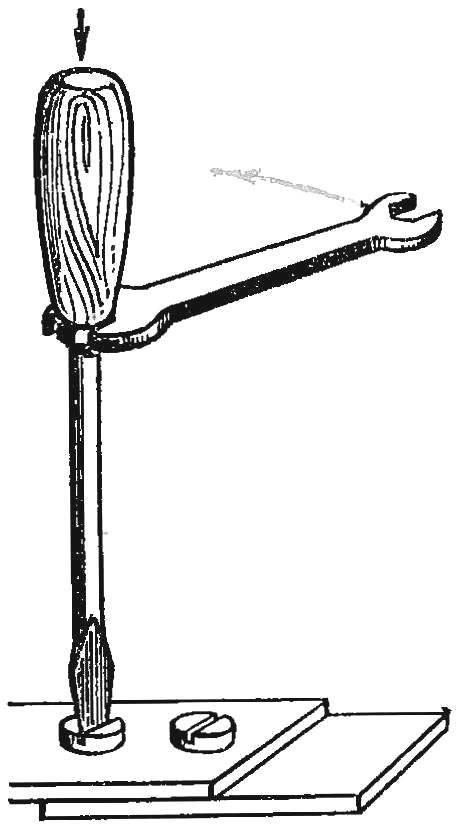

A permanent magnet built into the handle of a screwdriver (Fig. 2), can greatly facilitate the work when the need arises to screw in an inaccessible place. Movement of the button is “turned on” magnetization stinger tool and the screw is thus “glued” to it.

The handle is machined from wood or PCB; spring, tension, circumferential steel wire Ø 0,5 mm., the contacting surface of the magnet and of the shaft of the screwdriver needs to be carefully adjusted to each other. The same effect can be achieved if the magnetization be carried out using coil-solenoid, the core of which is the stem (Fig. 3). The electromagnet is activated the button that moves the battery.

To keep the screw can be purely mechanical way — using the inside of the rod screwdriver round rod Ø 3 mm (Fig. 4). The capture of the screw head by rotating the latter at a small angle using the lever situated on the handle.

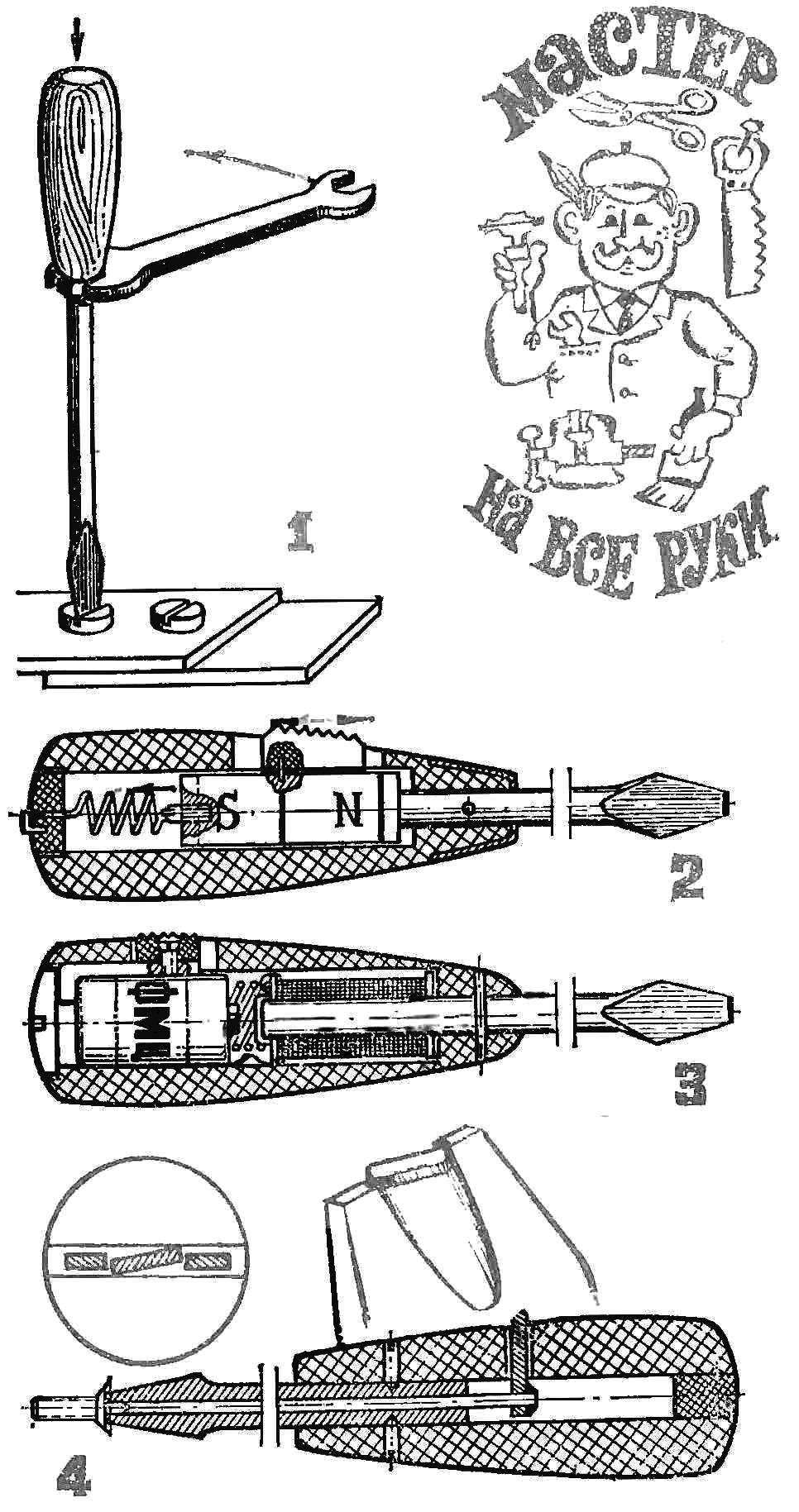

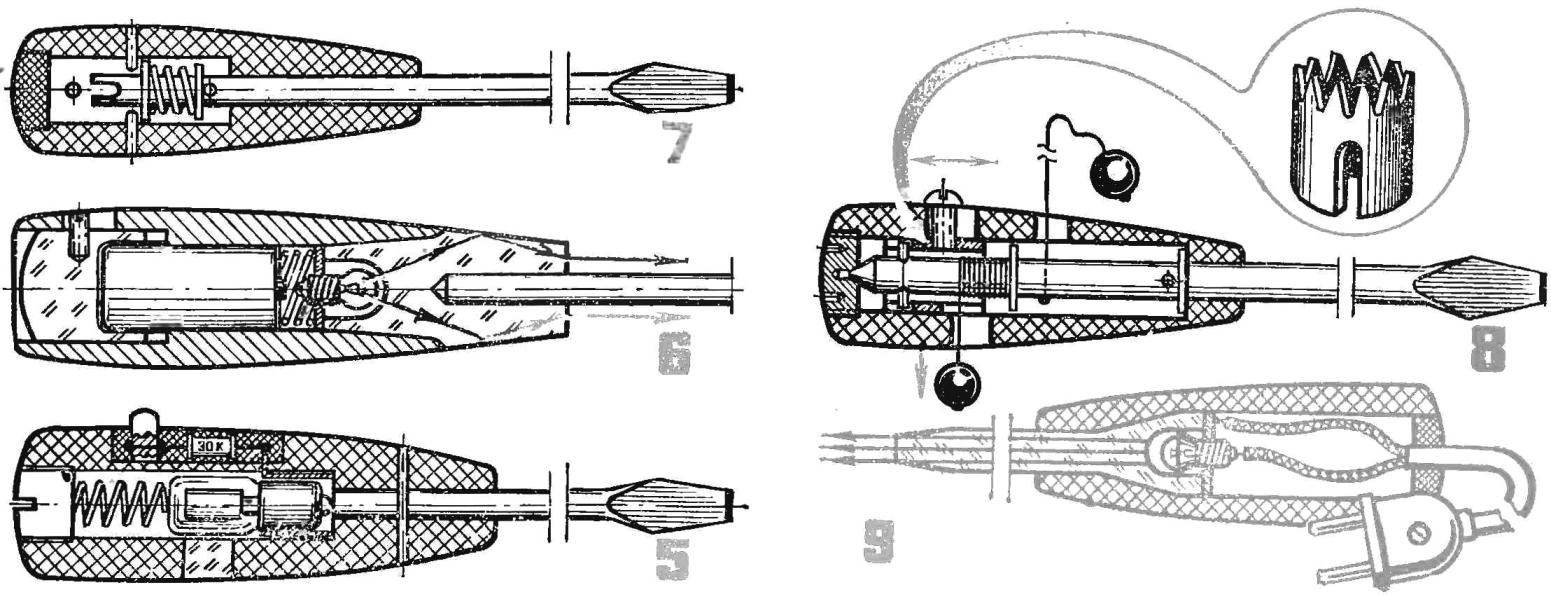

The simplest indicator of the voltage on the neon lamp built into the handle of the tool (Fig. 5), will warn you about the presence of voltage when you replace, for example, switch. For this you need the tip to touch the contact, and by protruding the rod hand. The value of the additional resistor 22 — 100 ohms.

Screwdriver, shown in figure 6, will help you if the screws are in a dark place. In the handle are a battery, a bulb from a pocket lantern, and the switching device.

The light passes through machined from organic ^ glass and carefully polished the adapter light guide.

For use with screws of small diameter, use the design shown in figure 7. Rotating a movable rod, with a stationary handle wrap or loosen the screw without risking to “lose” the slot. Sting stopped by pressing on the handle until it stops.

“Bystrovany” — so you can call the next tool (Fig. 8). Even a very long screw wrapped with it in a few seconds. This advantage manifests itself most clearly when a lot of screws. “Reach” screws ~ at the fixed rod, which engine stopper must be moved to the left.

And finally, on the eve of the first of April, we offer you the latest in our selection tool (Fig. 9). Similar in appearance to a screwdriver, it is not it.

Figure portable laser torch, which is convenient to unsolder the elements of electronic circuits on printed circuit boards. The technological revolution (NTR), which caused rapid growth of laser technology has allowed to create a portable generator of light pulses available to the radio Amateur of average skill.

The main detail of this simple laser-soldering iron — carefully polished rod of organic glass.

When the length of the rod 176,4 mm (end to end) temperature at 20 mm from the emitting end is about 200 °C.

“Paging” is performed by using conventional filament lamps for a voltage of 3.5—4.5 V. it is Important role in the formation of the laser beam plays a made of aluminum foil reflector-reflector.

On the lamp, “paging” there are rectangular voltage pulses with amplitude In 117,4, a repetition rate of 31.4 Hz and a duty cycle of 0.001.

Readers wishing to make a portable laser soldering, the editorial congratulates the first of April and… encourages all to make it to illuminate the shadowed parts of the radiomontazh when soldering parts.