(The end. Beginning at No. 8 and 9,’02)

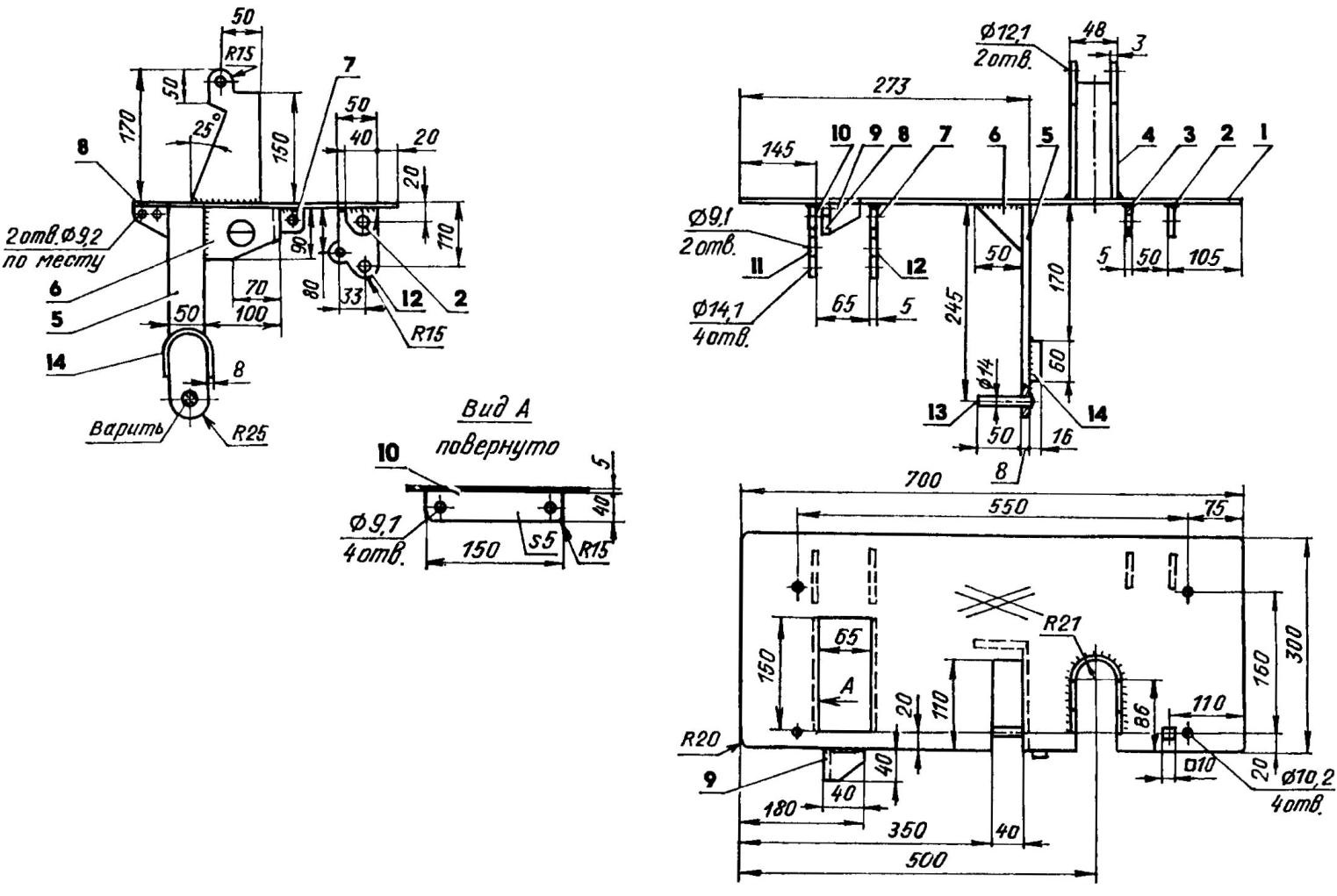

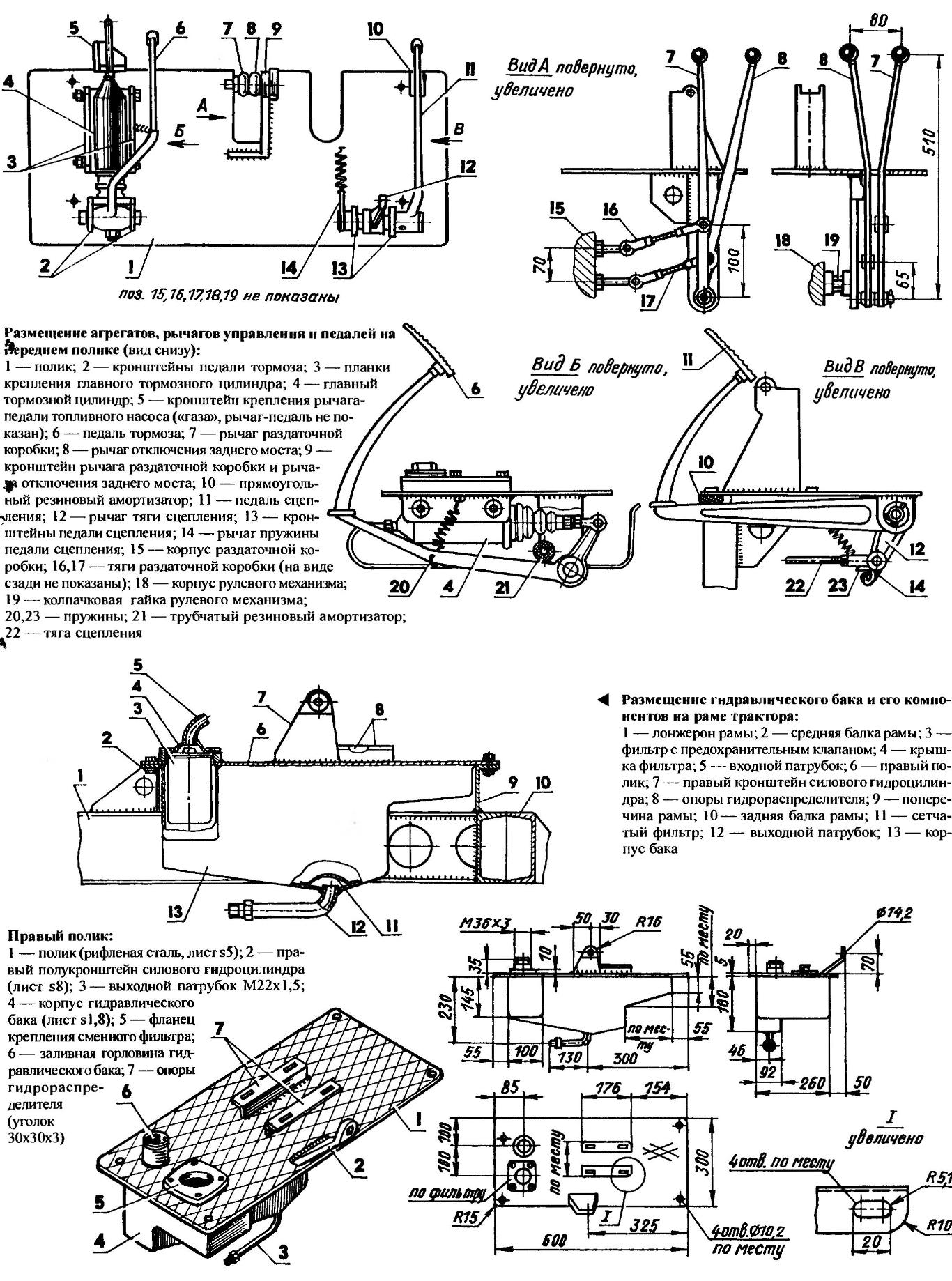

(The end. Beginning at No. 8 and 9,’02) FRONT PANELS the front has cutouts for the levers transfer case and the inclusion of the rear axle, under the steering column and cut a window under the main brake cylinder (GHZ). From top to Polycom welded bracket for additional securing the steering column, opposite the window under the GTZ — bracket-lever-pedal control rack of the fuel pump (“gas”). The bottom is welded strap attachment GTZ, brackets, brake and clutch levers for the transfer case and the inclusion of the rear axle.

To the frame of the tractor, the front panels with screws M10 head under the wrench.

RIGHT POLIK, as already noted, structurally designed in concert with the oil tank of the hydraulic system. From the top, in the center of Polycom, welded angle supports for installation of the valve R75-23, ahead of the mounting flange of the filter cartridge and filler neck, left — right Polynesian power cylinder.

POLYCOM has LEFT in the middle of a dozen threaded holes M10 for permutations or, in other words, adjustment of the location of the driver’s seat. Polycom welded the bottom to the box that serves as tool box, top right —left half-bracket power cylinder.

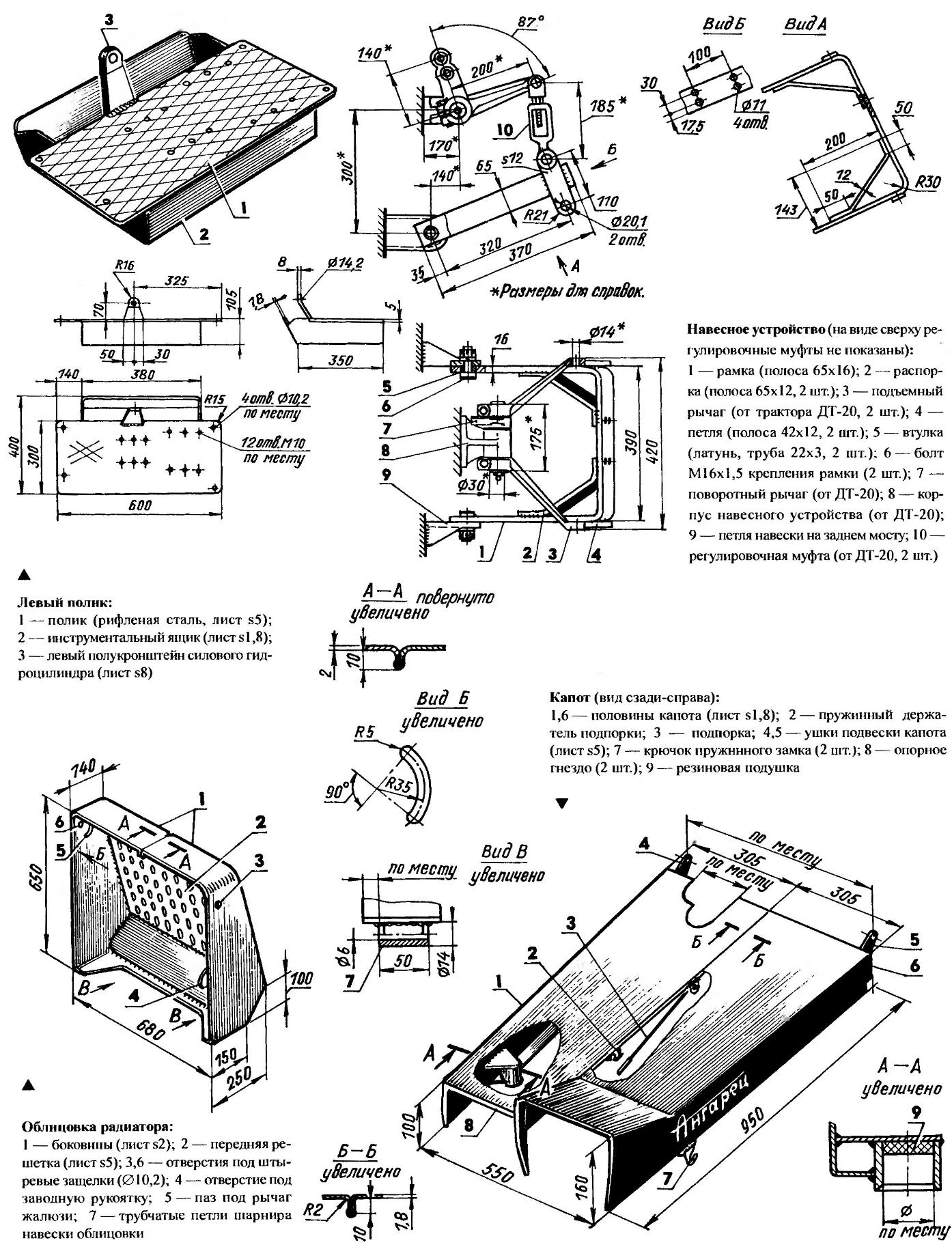

Hitch is a combination of several improvised parts and components factory made, in particular, from the trailer of the adaptation of the tractors DT-20.

The SEAT of the tractor assembled from elements of the sea;:the first cars of different brands. It’s adjustable, suspension, with hydraulic shock-absorber of a motorcycle “Minsk”.

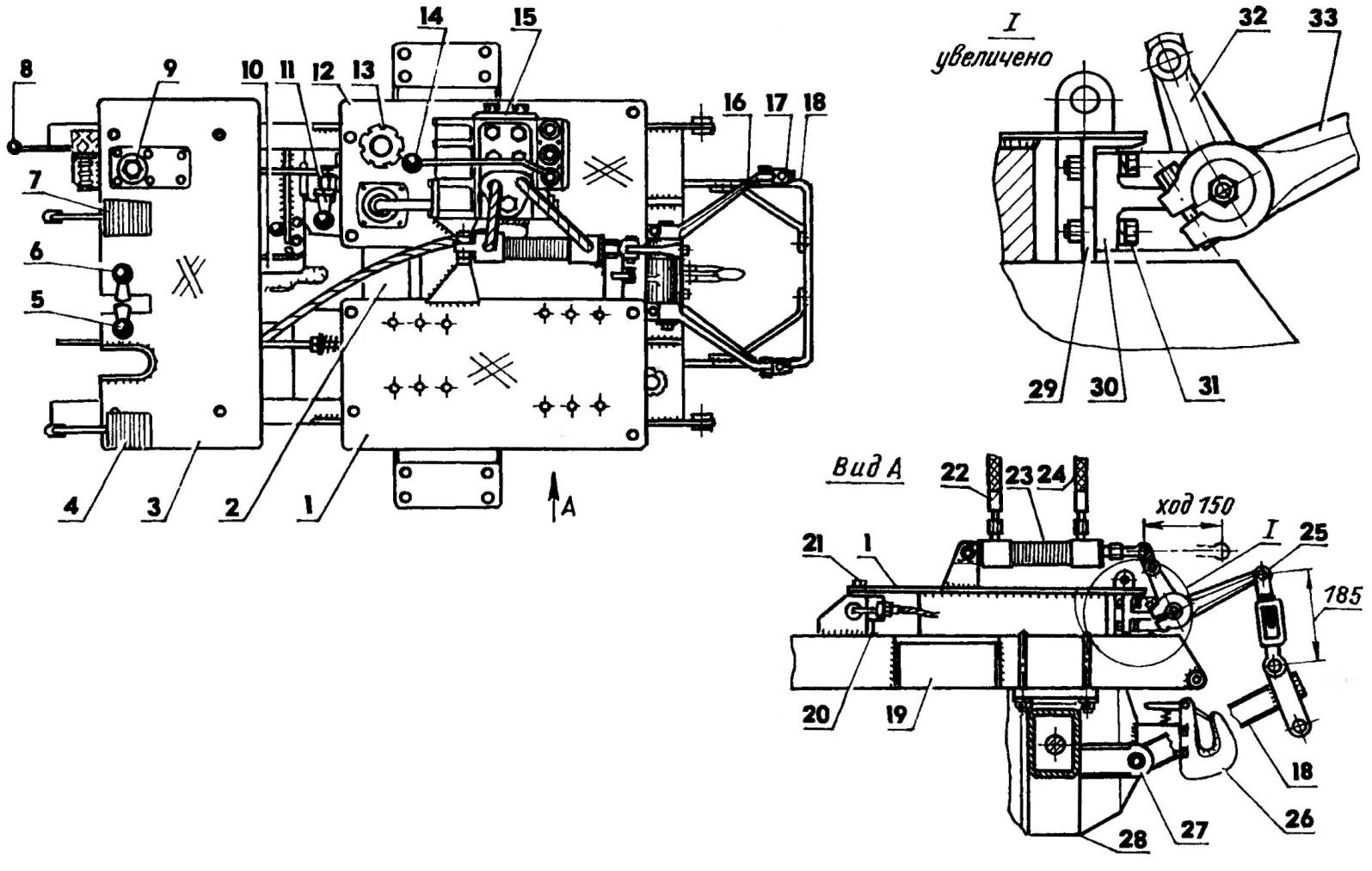

Accommodation Polycom, controls, main components of hydraulic system and attachment device on the rear of the frame of the tractor:

1 — left panels; 2 — brake drum hand (Parking) brake; 3 — front toe; 4 clutch pedal; 5 — the lever off of the rear axle; 6 — lever transfer case; 7 — a brake pedal; 8 — lever-pedal fuel pump (“gas”); 9 — brake master cylinder; 10 — transfer case; 11 — the lever of a box of selection of power; 12 — right polik; 13 — screw plug hydraulic tank; 14 — lever valve; 15 — the valve R75-23; 16,33 — lifting arms; 17,25 — adjusting clutch; 18 — frame attachment device; 19 — the frame of the tractor; 20 — the middle beam of the frame; 21 — a bolt of fastening of the left M10 Polycom; 22 — high pressure hose; 23 — hydraulic power cylinder; 24 — low pressure hose; 26 — towing hook; 27 — the left hinge on the rear axle housing to frame attachment device; 28 — rear axle housing; 29 — crossmember rear beam frame; 30 — body attachment device; 31 — M12 mounting bracket (4 PCs); 32 — the rotary lever; And, Fig. 13,14,15 conventionally not shown

Front panels:

1 — panels (corrugated steel, sheet s5); 2,3 — brackets clutch pedal (sheet s5); 4 — bracket fixing the steering column (sheet s3); 5 — lever bracket transfer box and lever off the rear axle (band 50×8); 6 — backup (sheet s8); 7,10 — scope mounts brake master cylinder (sheet s5); 8 — bracket-lever-pedal fuel pump (sheet s8); 9 — solitaire (sheet s5); 11,12 — brackets brake pedal (sheet s5); 13 — lever axle transfer gearbox and lever off the rear axle (the rod has ø 14-ø); 14 — clip-retainer acorn nut steering gear (strip 16×8)

RADIATOR liquid cooling system of the engine together with the standard frame and shutters — from the GAZ-53.

Grille components: its front grille from the tractor DT-75 and the sidewall is self-made from steel sheet of thickness 2 and 5 mm. Cladding is mounted on two horizontal hinges, lugs which are welded to the front beam of the frame of the tractor, and attached to the radiator with two bolts M10. After unscrewing these bolts, it can be opened all the way down to the ring and opens access blinds shutters and radiator.

The HOOD is cut from 2-mm sheet steel. On the tractor it is connected by two hinges to the radiator. In the raised position, the hood prop is retained in a closed rest their rubber cushions on the frame stand fuel tank and clipped two spring locks. Thus between the hood and the dashboard remains a necessary air gap of 5-6 mm.

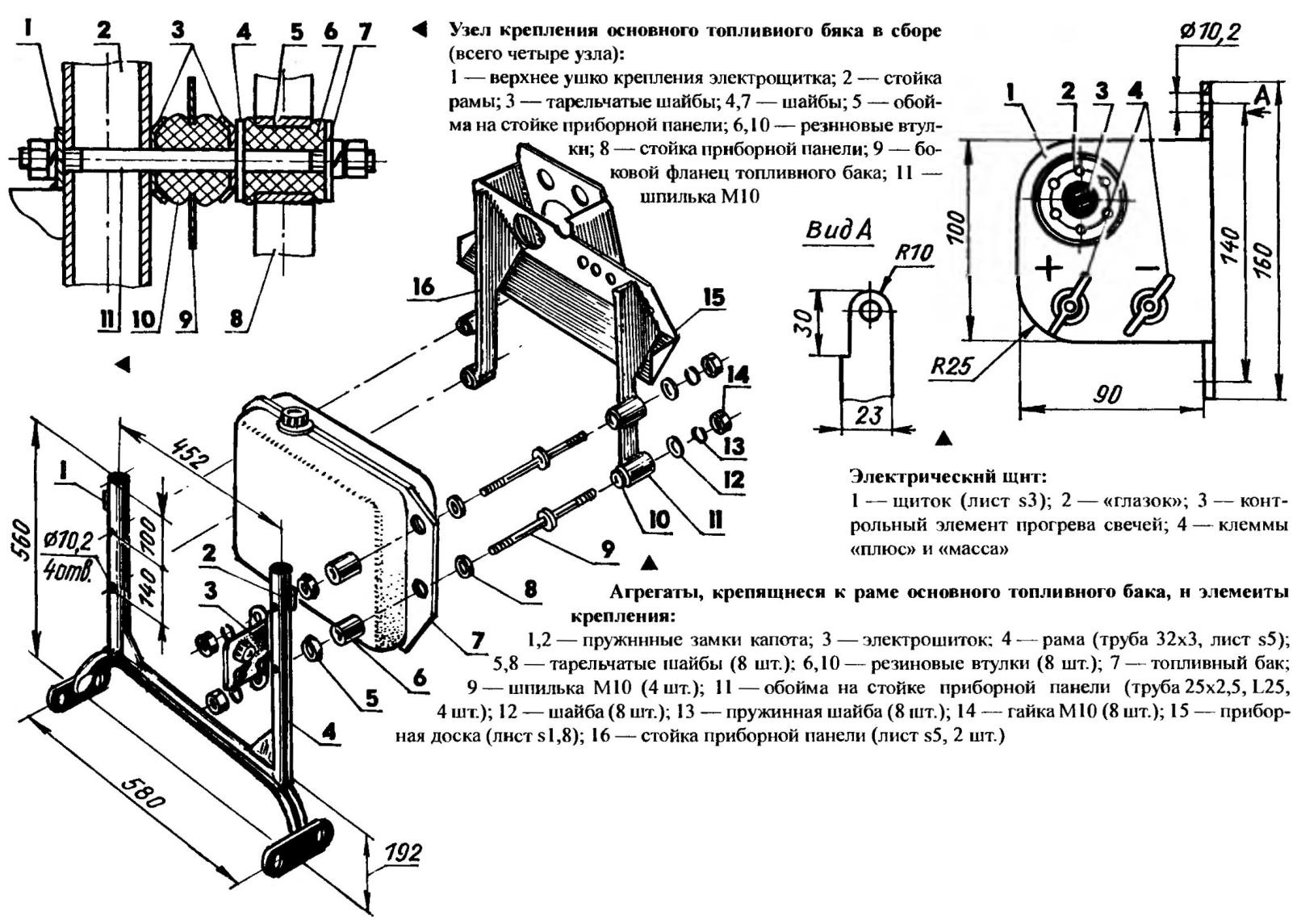

FUEL TANKS. Main tank — fire pump. Capacity (25 l), as well as the capacity of the front and rear beams and the additional tank placed right on the frame of the tractor, enough for 24 hours of continuous engine operation. Centrifugal regulator maintains within specified limits a predetermined number of rotations of the engine, avoids the stop with any load changes, including sudden.

MUFFLER—a motorcycle “Minsk”, adapted to the engine “Angara”.

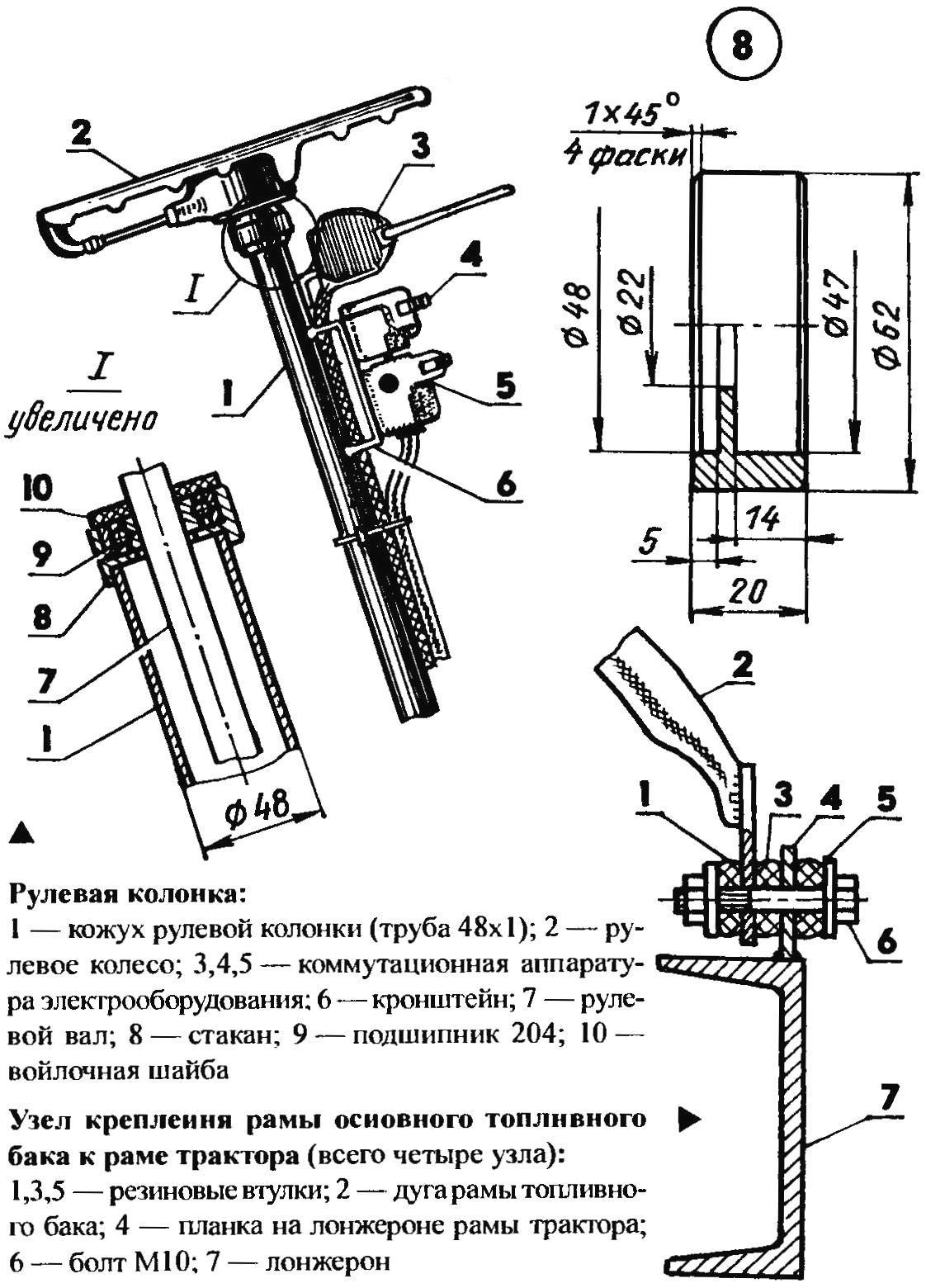

The STEERING MECHANISM and the longitudinal tie — rod- from the GAZ-51. Steering column a bit shorter, and instead of the standard bearing in its Cup is inserted the bearing 204.

Steering wheel — from the GAZ-24. Under it, the bracket that is welded to the pipe of the steering column, placed switchgear electrical equipment of the tractor, partly borrowed from the car “Zaporozhets”, and partly from a motorcycle “IZH”.

DASHBOARD. It is fitted with a tachometer, pressure gauges and oil temperature, water temperature in the engine cooling system, fuel level and current, and light control circuits.

COLOR. After a thorough cleaning, degreasing and priming of all surfaces of the tractor is painted in Golden yellow color of nitro NC-25.

I will repeat it again. “Angrez” is quite universal and suitable for the most diverse farming operations. Experience of continuous operation of the tractor as a whole confirmed the correctness of many of the technical solutions incorporated in its design. However, in order to address the car did not have any complaints, something needs to be improved.

In particular, change the installation place muffler for exhaust system not up (gusts of wind exhausts sometimes throws the driver in the face), and under the skid down and back. And yet, instead of a two-stage transfer gearbox with gear ratios low gear i = 1,963 and direct transmission i = 1.0 to apply a two-step reverse gear, possibly homemade, with ratio equal to, respectively, 3.0 and 2.0. This change would dramatically expand the range of operating speeds of the tractor.

V. PETROV, Krasnoyarsk Krai