THE WIND IN THE CONTEXT OF

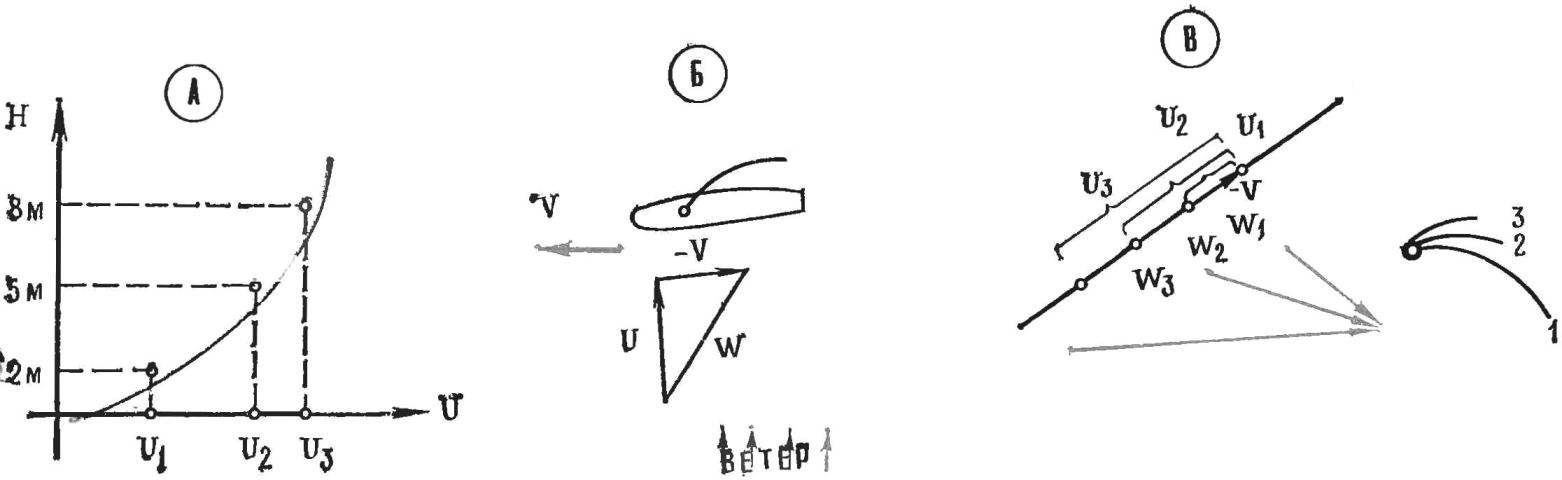

THE WIND IN THE CONTEXT OF The sail of the windsurfer is not the only element that produces thrust, but “the wheel” for manoeuvring. The air flow at the surface and water has a lower speed than the wind at a height of, say, three meters. Therefore, the load on the sail (corresponding speed) are proportional to the height from the water level and each overlying section of the sail will receive a certain twist in relation to the underlying (Fig. 1A).

Another concept that will be useful in further arguments, — the “apparent wind” W (Fig. 1B). The vector of its velocity is obtained by adding vectors of natural air flow U and the true speed of the windsurfer with the opposite sign V. When the speed of the air flow with height of the apparent wind not only increases your speed, but also to some extent changes the direction. This leads to the conventional twist of the sail, that is, the phenomenon in which lying above each section of the sail is blown by the air flow with its vector (Fig. 1B).

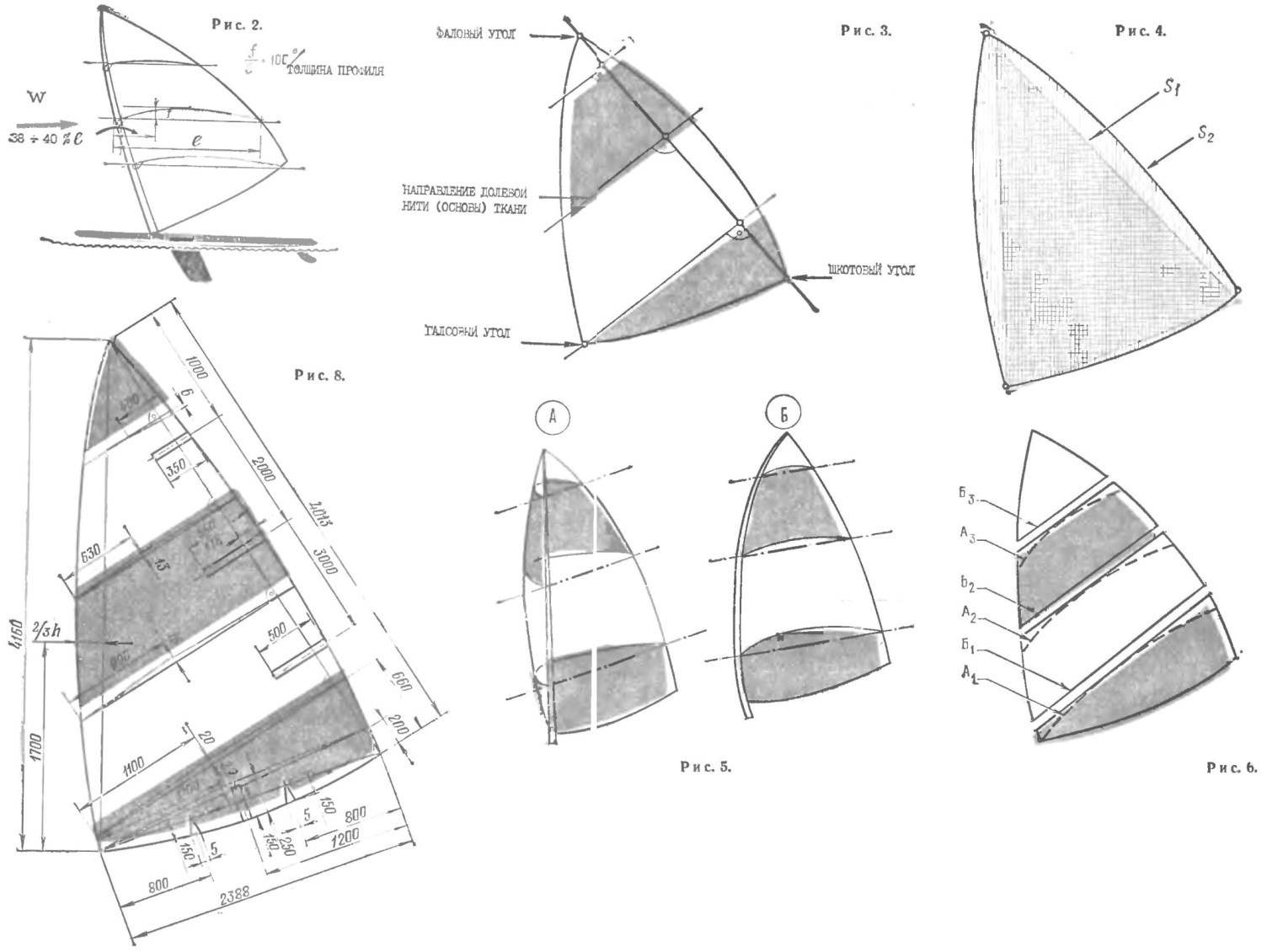

To sail as the wing of the plane, the applicable characteristics such as “thickness profile”, which is the ratio of the greatest profile thickness to the chord length. In our case, the profile thickness is usually about 6-8%.

MEMO TO THE CUTTER

Good performance of the rider largely depends on the proper cutting of the sails. Based on the properties of the fabric, use two methods.

If the fabric has considerable stretch on the diagonal (percale, cotton fabrics, Bologna), used equity cutting: panel unfolds on equity the thread perpendicular to a line connecting flowy and sheet corners (Fig. 3). When building patterns, the maximum profile thickness of each piece of cloth lies at a distance of 38-40% from luff point.

Fig. 1: A — dependence of wind speed with height above the surface; B — scheme of formation of the apparent wind; In the conditional twist of the sail of the windsurfer.

Fig. 2. Location of point of maximum thickness on the chord of the sail.

Fig. 3. The basis of the location of tissue at the Plaza of the sail.

Fig. 4. The scheme of measurement of the sail:

S1 is the area of the sail with direct skatinami, S2 is an area of the sail.

Fig. 5. Deformation of the sail depending on the bending of the mast:

A — mast video (a big “belly” of the sail); B — the mast is curved (flatter sail).

The sail of the windsurfer is formed by convex curves on all katarinam, it allows you to get the largest area for the same mast (Fig. 4). The curvature of the luff point to the same allows the sail to change shape depending on the bending of the mast. In light winds the mast is straight and the “belly” of the sail is increased, thereby increasing the thrust (Fig. 5A), strong winds, the mast bends and the sail becomes flatter, which reduces the load on the hands of the athlete (Fig. 5B). And yet, despite such “bootstrapping”, we do not suggest to use very “pot-bellied” sail with medium to strong wind: increases the resistance of the sail, and consequently, decreases its “quality”. Plus the growing stress on the hands.

Sewing the sail it is best to have ready the mast so that when cutting the fabric was known for its deflection. For fabrics, virtually no stretching on the diagonal (polyester), easy radial cutting of cloth, wherein the cloth has a slope proportional thread relative to the previous panels. The total scan panels may be 45°, depending on the properties of fabric. This camerasread sail with the wind.

NOW FOR THE LAYOUT…

On a flat stretch of floor with a tape measure or long ruler to mark up the corners of the sail and the length of skinoren. In the corners of the Plaza hammered clove and pulled the rope between them so as to obtain a triangle with sides equal to these lengths. At the respective skinoren put off the size of sickles, and planned with smooth curves the maximum dimensions of the sail. From the bottom (tack) corner of the sail hold perpendicular to the line connecting the upper (flowy) and rear (sheet) angles, thus get the direction of equity of threads of the fabric.

When pre-cutting pieces of fabric should not only take into account the seam allowance on the hem of katarin, but leave about 50 mm on each side of a piece tailored fit fabric for sewing.

…AND A SEWING MACHINE

To make the sail aerodynamic shape of the cloth are sewn together along curve lines (see drawings of the sails), which are applied or marker * colored pencil on the edges of pieces of cloth with a long wooden or metal ruler. After marking of the cloth are sewn together at the butt so that the edge B coincides with the line And the adjacent panels.

Sewing the sail better on the car zigzag: this seam does not create excessive stress concentrations and has no mobility, it is necessary for “nursing” sails.

Sewn together panels re-stacked on Plaz for marking scatolin, laderman, Windows, rooms, intensifying overlays in the corners, etc.

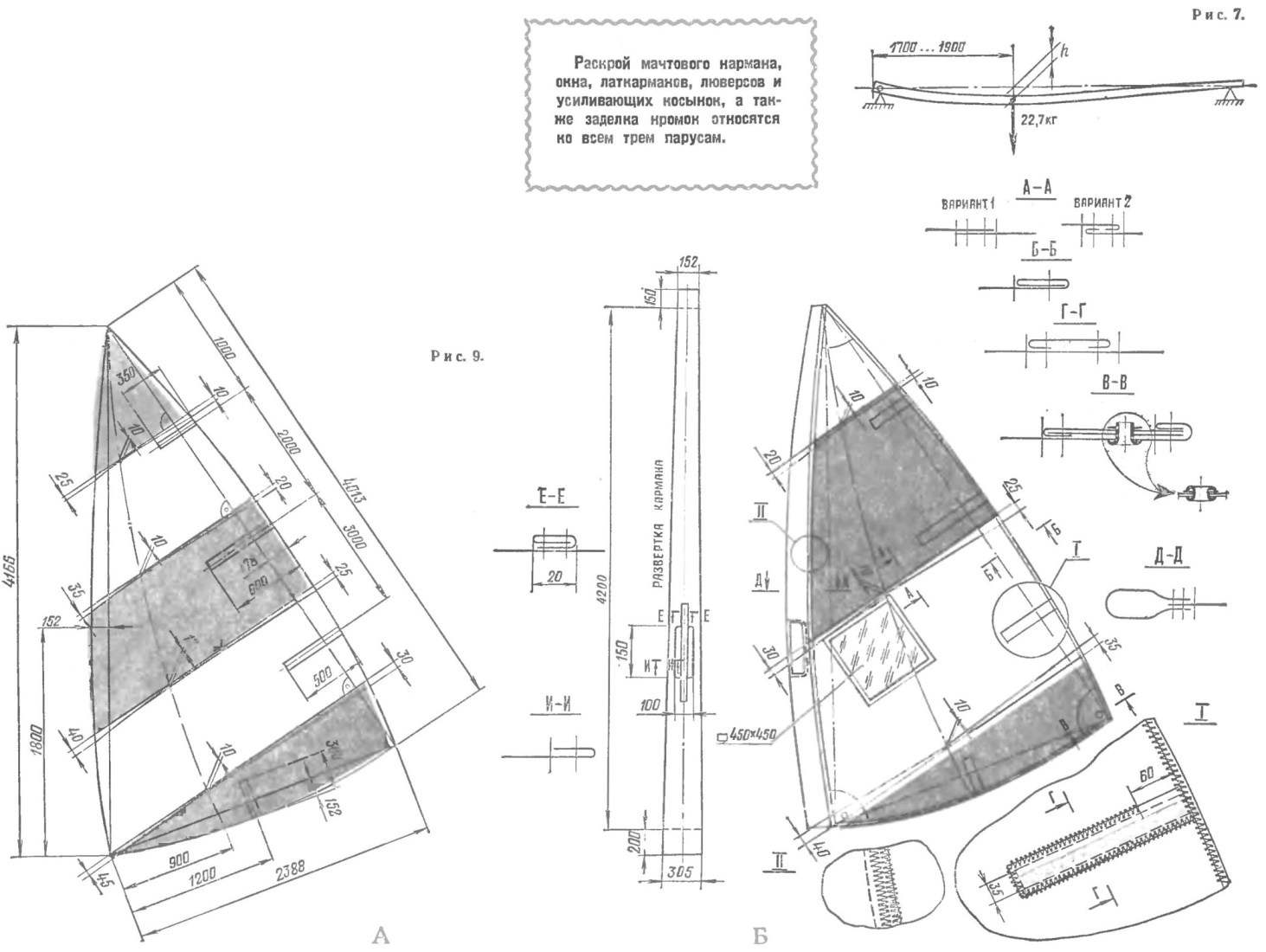

Special attention should be paid to the choice of the magnitude of the sickle luff point. For this pre-determined deflection of the mast (Fig. 7). The magnitude of the sickle luff point should correspond to 2/3 of the magnitude of deflection, and the nature of the curve — shaped deflection of the mast. It is necessary to invigorate joint work of the sails and masts.

Fig. 6. The formation of stitches on the cut sheets.

Fig. 7. Determination of the nominal deflection of the mast.

Fig. 8. The drawing of the sail, developed by silver medalist at the Rome Olympics he Chuchelov (lavsan or Dacron 90 cm wide).

Fig. 9. The sails, designed by A. and G. Arbuzova:

And polyester, percale or linen with a width of 90 cm, B — percale with a width of 135 cm

To the luff of a sail is sewn a pocket for a mast. Its design and sealing of joints, reinforcement of corners, laderman and other elements shown in figures 8 and 9.

The window of the Mylar film with a thickness of 0.05 mm is sewn using the fabric reinforcing edges of a rectangular hole in the sail should be cut only after it is sewn on film. This will eliminate the distortions.

So that the sail is not twisted and had “hammer” on the back foot laderman sewn fabric lining for elastic wooden or plastic plate — armor.

Angles should be reinforced with gussets from more durable fabric.

For attaching the sail to the boom and the mast in Shkotovo and galbavy corners are inserted eyelets — copper or aluminum rivets with a hole for the sheet.

Race number can be obtained through the Federation of sailing hectares of the city (Republic) or through the Committee on Windsurfing sailing Federation of the USSR (121069, Moscow, Skatertny pereulok, 5).

New sail percale linen and other fabrics you want to “go out”, that is to give him the opportunity to stretch out II to acquire the correct form.

During this period, it is necessary to be afraid of strong wind and not to pull (to touch) sail – it may not be able to stretch it, to spoil the form. The sail upholstered, try to fix the defects inevitable in the cutting — strut failed seams and restore the corresponding adjustment.

(Continued. Beginning in № 1-2, 1977)(to be continued)

A. ARBUZOV, Serhiy ARBUZOV