As the title of the motor, its working volume — 700 cm3, power — 40 HP by the Way, the latter characteristic is obtained not only by calculation, but for bench testing, the engine speed in this case was…5100 5600 min-1. The weight of the engine without propeller, electric starter, gear wreath and the electronic ignition is only 30 kg — that is less than one kilogram per horsepower.

Crankshaft. The cheeks of the crankshaft is of steel 30KHGSA. First on the lathe handled three identical blanks — their diameter is 140mm, thickness is 23.5 mm. the resulting “pancakes” hardened to HRC 33…38, after which they are sanded to a thickness of 23 mm.

The holes in the cheeks and 25Н7 Ø Ø 35Н7 chiseled on a jig boring machine. At the same time to achieve should be minimum deviations in the tolerances in the direction of increasing diameter.

Axle crankshaft — steel 40ХНВА. Raw stock machined with an allowance for the diameter of 0.5…0.7 mm, the cylindrical zone Ø 40 mm and cone — with an allowance of 1.5 mm. the workpieces are milled keyways and drilled the safety hole, then these details thermoablative up to HRC 48…54. Note that less hardness of axles, the seals quickly “eat” the shaft. Hardened work pieces are processed in the installation blasting, then polished cylindrical sections with diameters 35И8, 43, 18 and 12 mm of Thread should be cut into resubstitution the machine.

The lower connecting rod fingers of steel SHKH15. The workpiece should be termoobrabotki up to HRC 62…65.

The Assembly of the crankshaft — the operation is very responsible. It begins with the fact that the lower connecting rod fingers deeply cooled in liquid nitrogen and using a screw or hydraulic press is pressed into the middle of the cheek of the crankshaft.

Fig. 1. The unit “shaft-the Carter” two-cylinder boxer engine DD-700/40 (connecting rods conventionally not shown):

1 — a cranked shaft, 2 — bolt M6, 3 — washer 4 — front cover (steel 30KHGSA), 5 — front gasket (to put on bakelite varnish), 6 — Carter (D16T), 7 — back strip (to put on bakelite varnish), 8 — back cover (D16T), 9 — oil seal 40Х57Х10 mm (from the engine VAZ), 10 — M6 screws, 11 — bearing No. 2208, 12 — bearing No. 36208, 13 — ring 80X70X2 (steel 20), 14 — the bearing № 208.

Then one of the fingers going the connecting rod bearing and the connecting rod with the side washers. Below the rollers are not scattered, they are fixed in any way. Cheek with a rod is also cooled in liquid nitrogen, and in the middle hole, cheeks, inserted the tube; the groove should face toward the rod. Then the tube is put on the outer cheek, in this case will serve as a guide, on which when pressing begin to slide the outer cheek. So as not to crease the cheeks and do not bend connecting rod fingers, when pressing between the cheeks invested faceted spacers with a thickness of 19 mm.

The same operation is repeated for the second outer cheek of the crankshaft. Distracting first tube and inserted in the middle of the cheek on the other side, followed by deep cooling of the already collected two cheeks with rods and zapressovka second outer cheeks.

Assembled crankshaft proshlifovyvayutsya in the centers of a grinding machine. Then on a lathe pritachivajut cheeks to Ø 135 mm the runout of the shaft where the bearings should not exceed 0,02 mm.

Fig. 2. Crankshaft:

1 — front axle (steel 40ХНВА), 2 — finger crank (steel SH-15), 3 — the outer cheek of the crankshaft (2 PCs steel 30KHGSA), 4 — rod (finished product type IZH-P), 5 — bearing number 822906, 6 — side washer bearing, 7 — inner cheek of the crankshaft (steel 30KHGSA), 8 — rear axle (steel 40ХНВА).

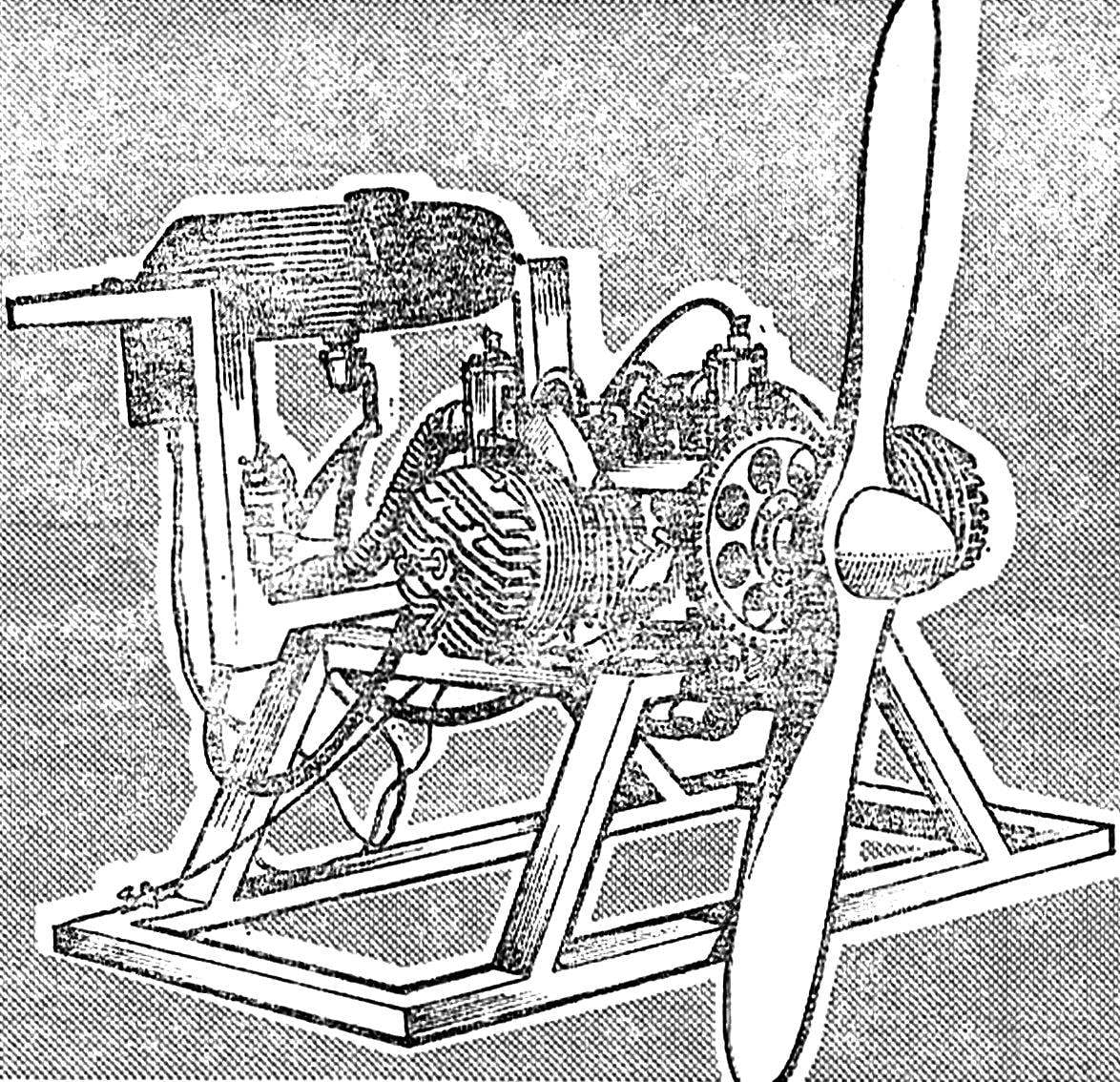

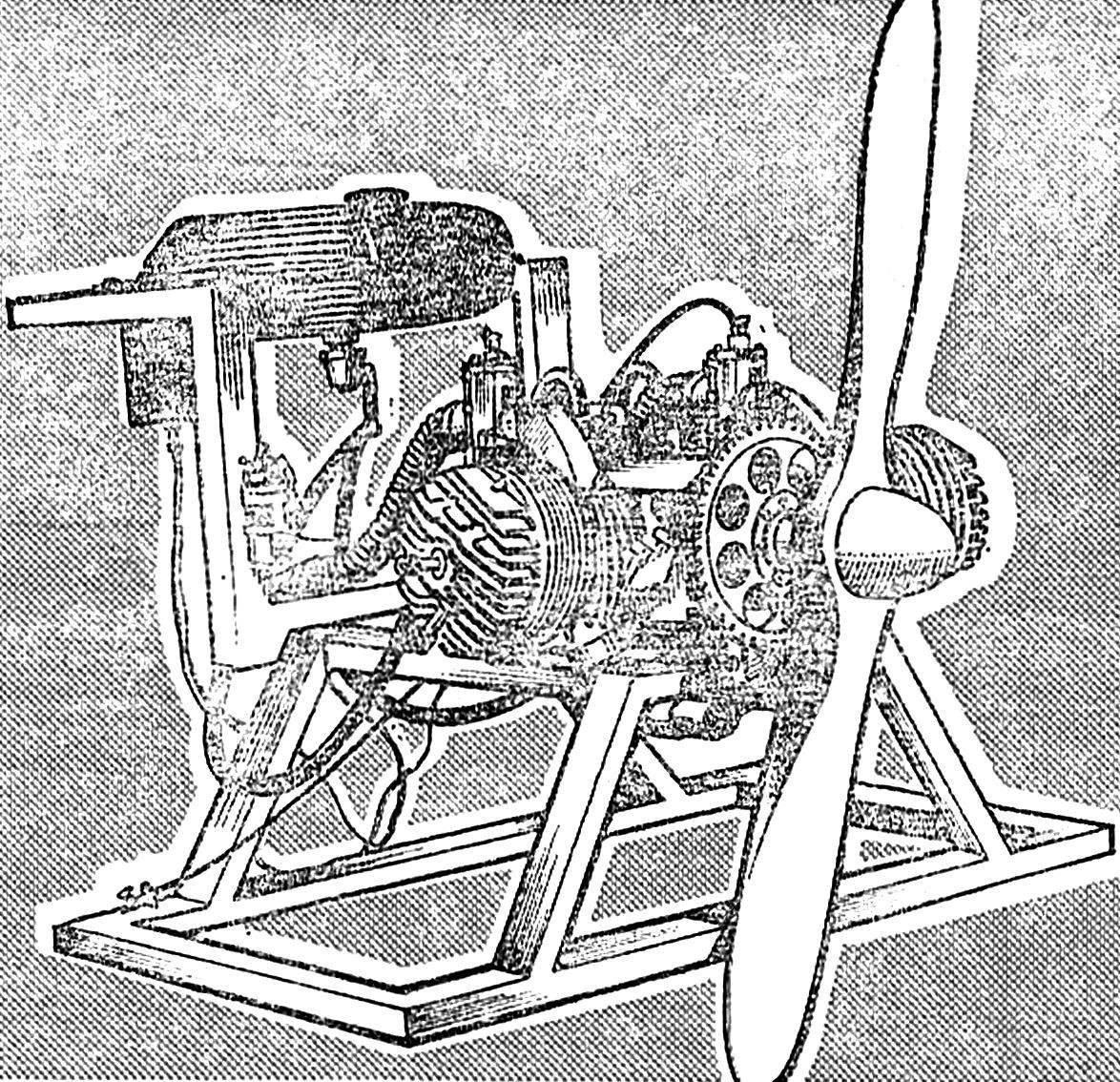

This two-cylinder engine, which received the name DD-700/40, designed and built the head of the public design Bureau “Aerocam” George Dorfman. The motor turned very good: reliable, relatively simple, easy enough.

This two-cylinder engine, which received the name DD-700/40, designed and built the head of the public design Bureau “Aerocam” George Dorfman. The motor turned very good: reliable, relatively simple, easy enough.