NOT YET — HIS HANDS

NOT YET — HIS HANDS To build a car from beginning to end with their hands — a tempting idea, but hardly feasible. The main aggregates should take ready, the serial and only in rare cases to make design changes in accordance with the layout of the car. The main attention should be paid to rational “folding” machines of prefabricated elements, the creation of separate parts and units of chassis and bodies, particularly the body, and in the design of the last is also desirable to use the finished part.

It seems that the only way that will succeed in a relatively short period of time to build efficient, comfortable, safer and attractive car.

This, of course, does not mean that under especially favorable conditions can be done, for example, the original automatic transmission. However, the inevitable lot of work to design, manufacture and especially the so-called “fine-tuning” of the original mechanism can permanently push back the first exit “in the light” of your car.

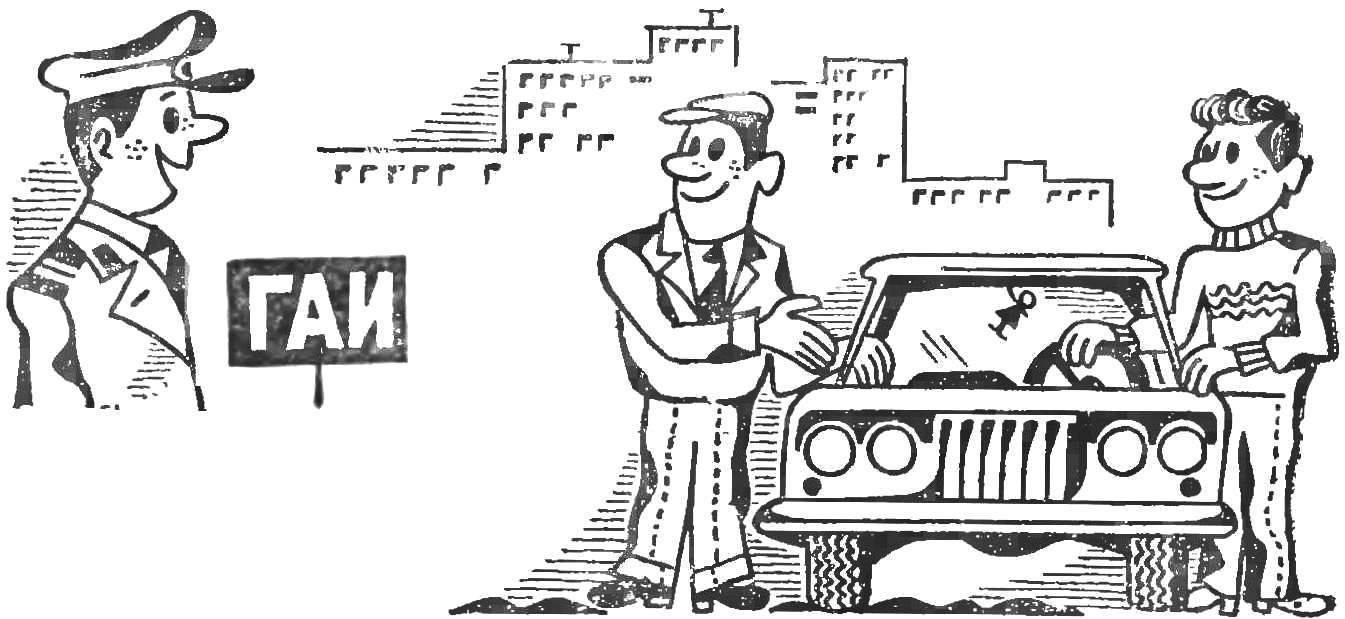

The choice produced by the domestic industry of engines, suitable for self-made cars, small, but sufficient. As already mentioned in our articles, for twin machines are suitable engines Izhevsk motorcycles, scooters Tula and Serpukhov sidecar (modification of the Izhevsk motor), quadruple engines Irbit and Kiev motorcycles and cars “Zaporozhets”.

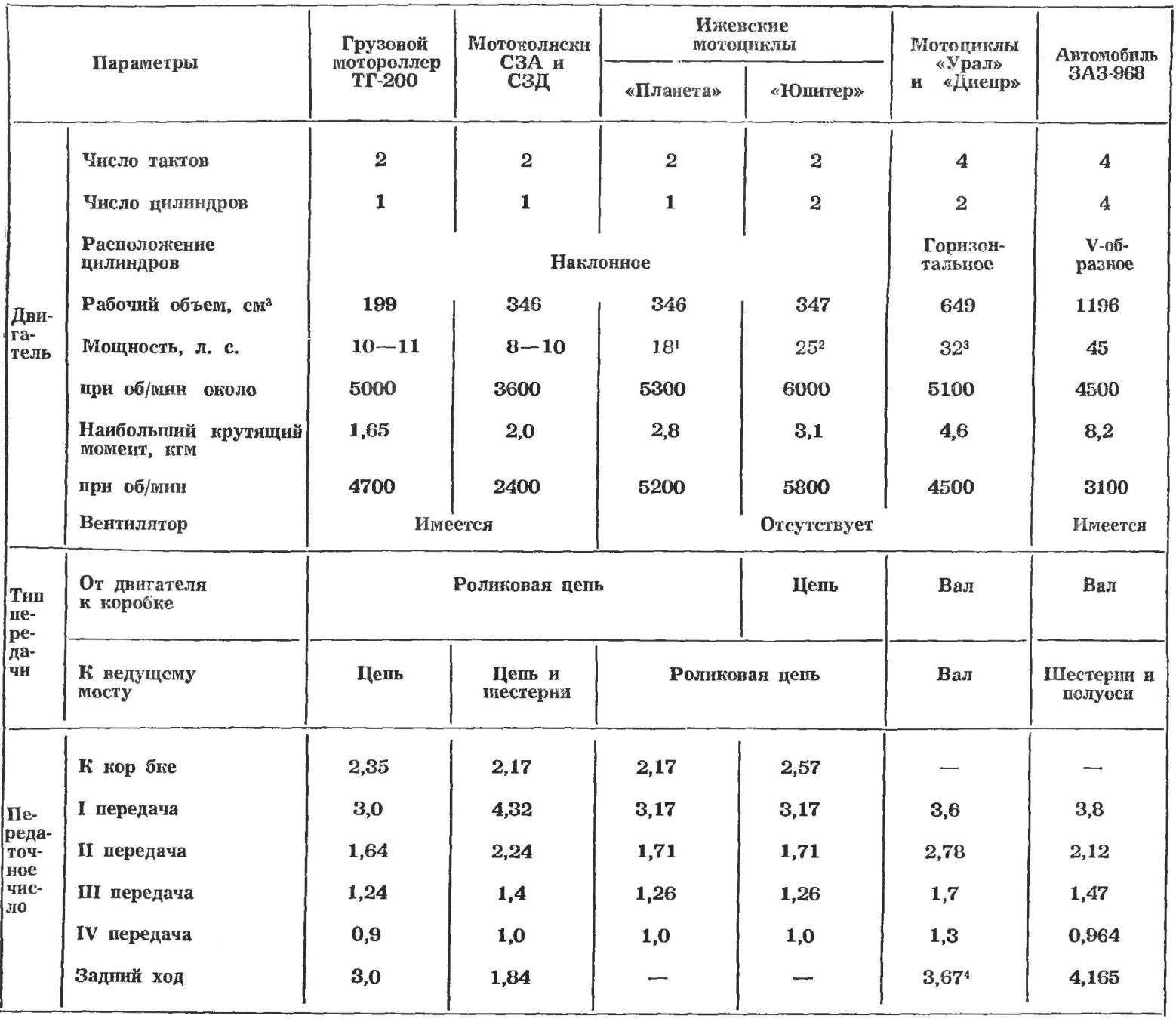

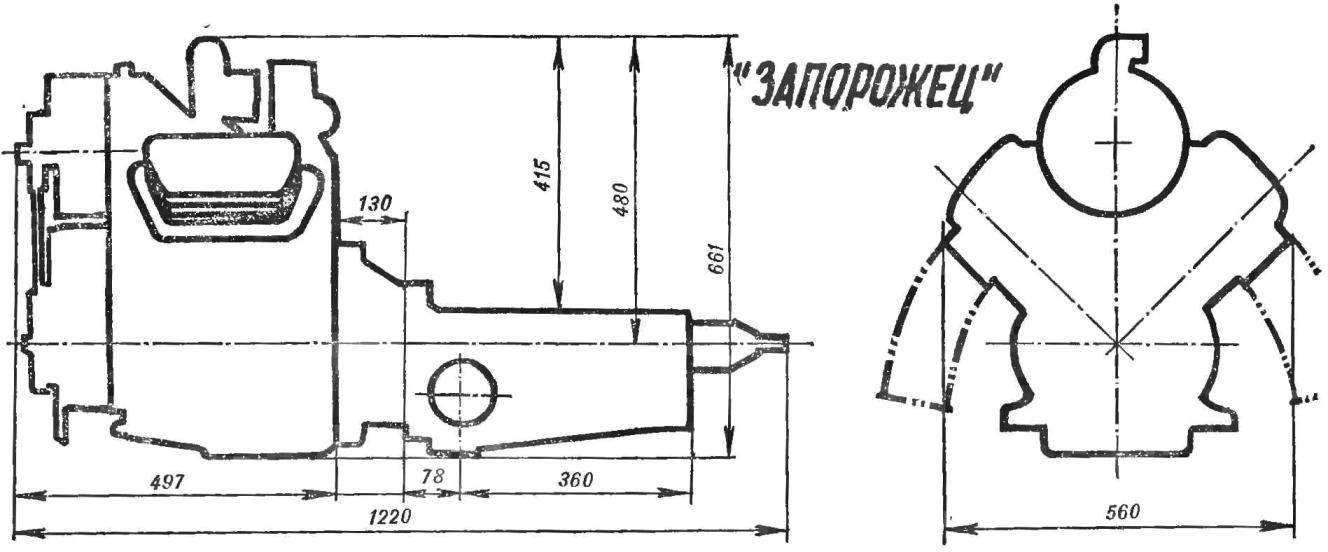

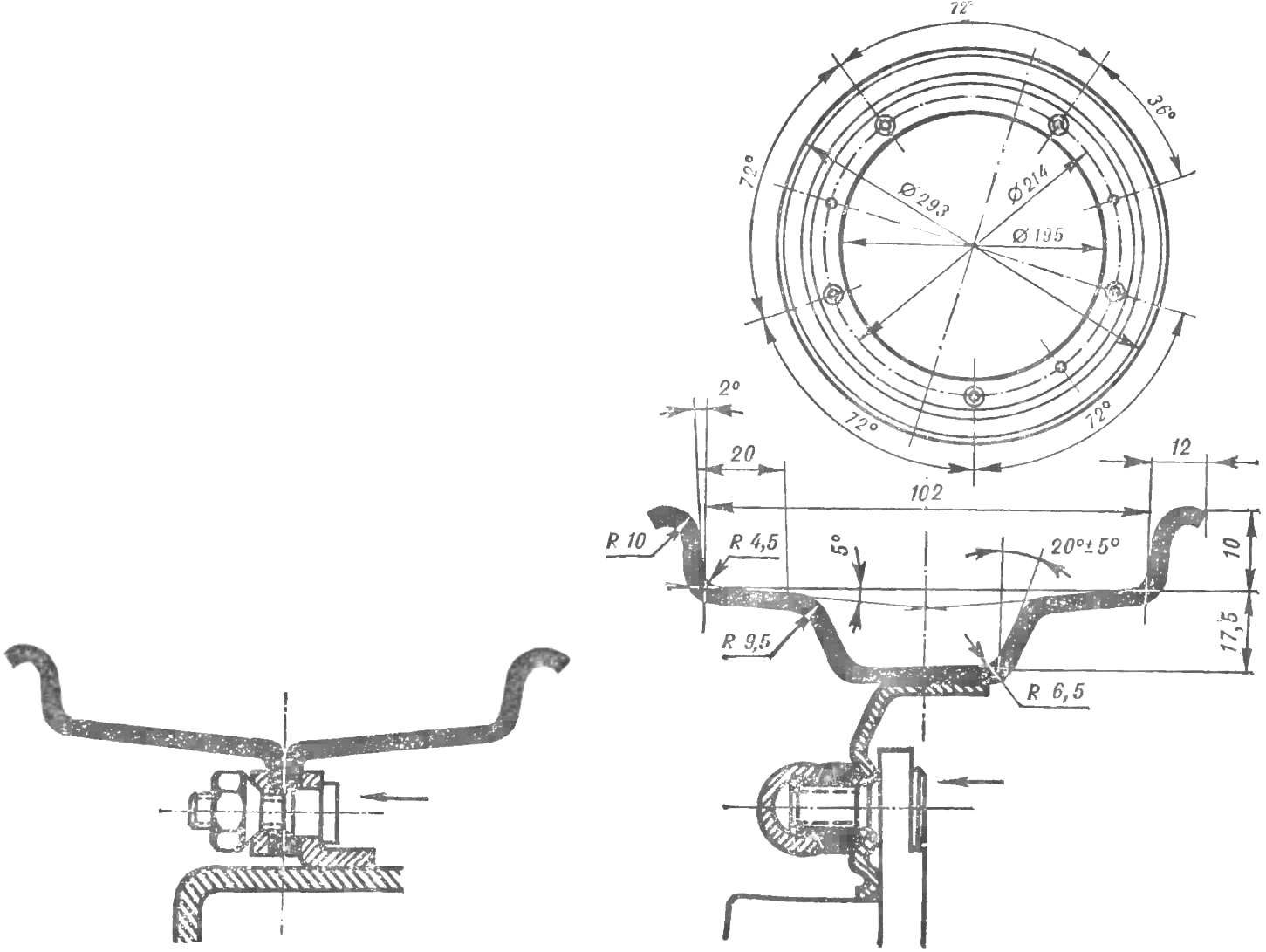

Table 1 shows brief specifications of these engines, and figure 1 — form and data but install on the frame or body.

Table 1. DATA FOR POWER UNIT

1. Planeta-2 early release: 15,5 HP at 4600 rpm, 2,5 KGM at 3400 rpm; gear ratio of the gearbox — see С3А.

2. “Jupiter-2”: 19-20 HP at 5000 rpm, the 2.7 KGM at 4500 Rev/Inn.

3. “Ural-2” (M-63) — 28 HP

4. Only the motorcycle “Dnepr-MT-10”.

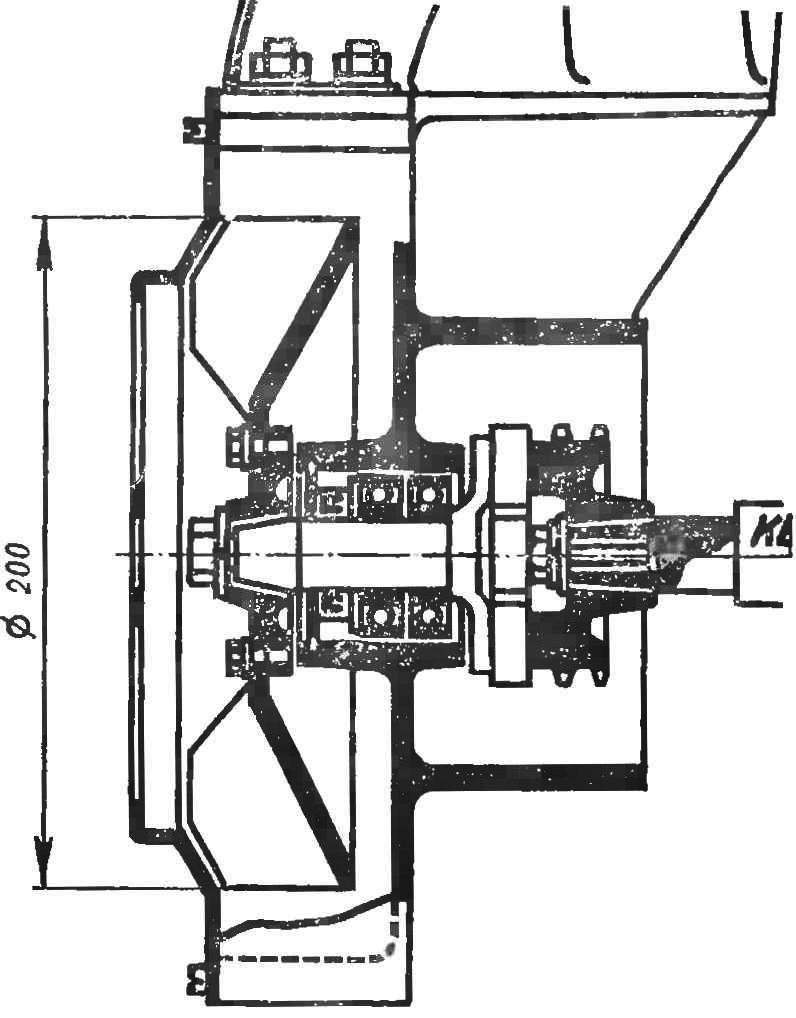

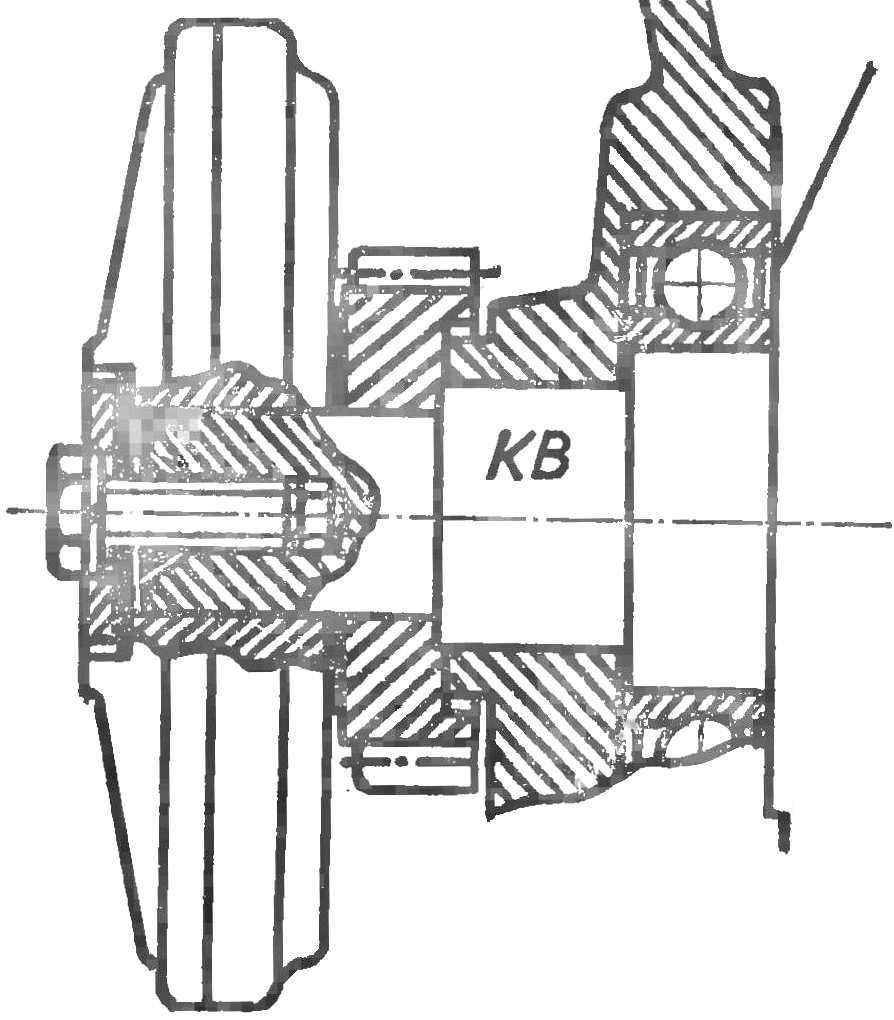

The engines of scooters, motorized wheelchairs and “Zaporozhets” is equipped with a fan that allows you to install them in the rear, without compromising cooling. Engines Izhevsk motorcycles require revision — install the blower the same way as is done on the scooter (Fig. 2). To ensure Irbit and Kiev motors forced cooling, it is also necessary to provide them with a blower either placed on the end of the crankshaft (KV), or driven by belt from pulley (Fig. 4) on this shaft. The impeller blower should have an outer diameter of 200 — 220 mm and a capacity of at least 1000 m3 of air per hour. For the nozzle it is necessary to lengthen the crankshaft of the engine. In the neck of the shaft of the drill hole and make a groove for the dowel; the extension of the shaft are pressed into the socket and pull the screw.

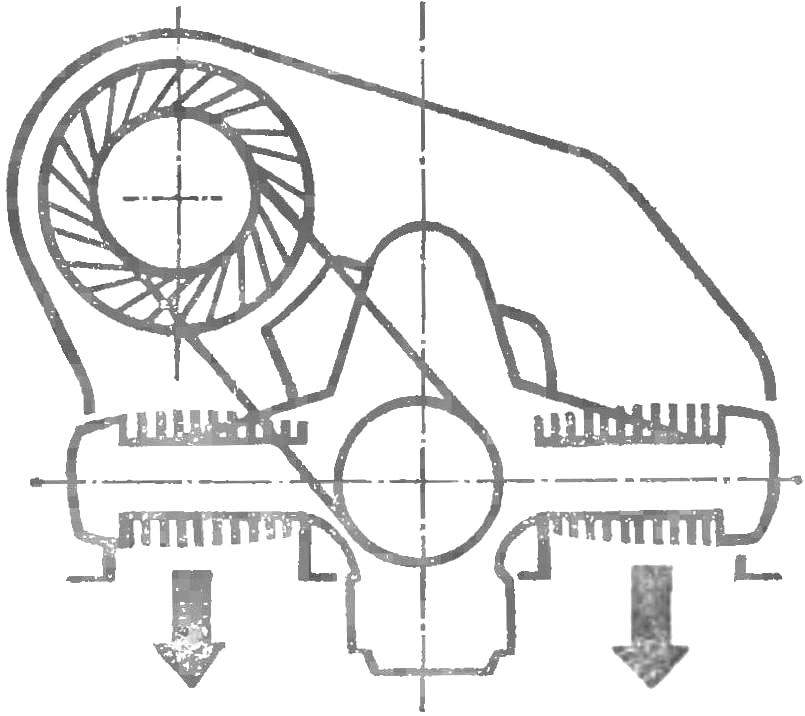

The casing of the blower (Fig. 4) must be sufficiently rigid, with smooth contours and is removable. It is best to do it out of sheet aluminum with a thickness of 0.5 — 1.0 mm, hinged hinged with snap type locks (like portable gramophones) or fixed with screws. A special pipe for admission of air to the blower is not obligatory, but must be provided in the side of the body or, preferably, on the top of the cover matousek holes, the total cross-sectional area which must be somewhat larger than the area round the blower.

When linking the vehicle with the front engine cooling the latter can be achieved by the flow of oncoming air. The hole in the veneer the front end should be large enough, and the edges of it is rounded, not creating turbulence. If the hole is covered with bars or mesh, Windows (cells) between the bars should not be small. Great importance has free exhaust air from matousek; it is best to take the air under the body (also rear engined) or through openings in its sidewalls.

Fig. 1. Dimensions and fixing points power units for micro cars.

Fig. 2. Design blower motorized Serpukhov plant

Fig. 3. The knot of fastening of a centrifuge lubrication system on a motorcycle “Dnepr-MT-10”: as it is possible to lengthen the shaft if you install a pulley

Fig. 4. Casing of blower for boxer motorcycle engine.

It is not recommended to overlap the pallet crankcase and the lower rows of ribs of the cylinders. The lower half of the crankcase, it is advisable to replace finned for efficient cooling of lubricating oil.

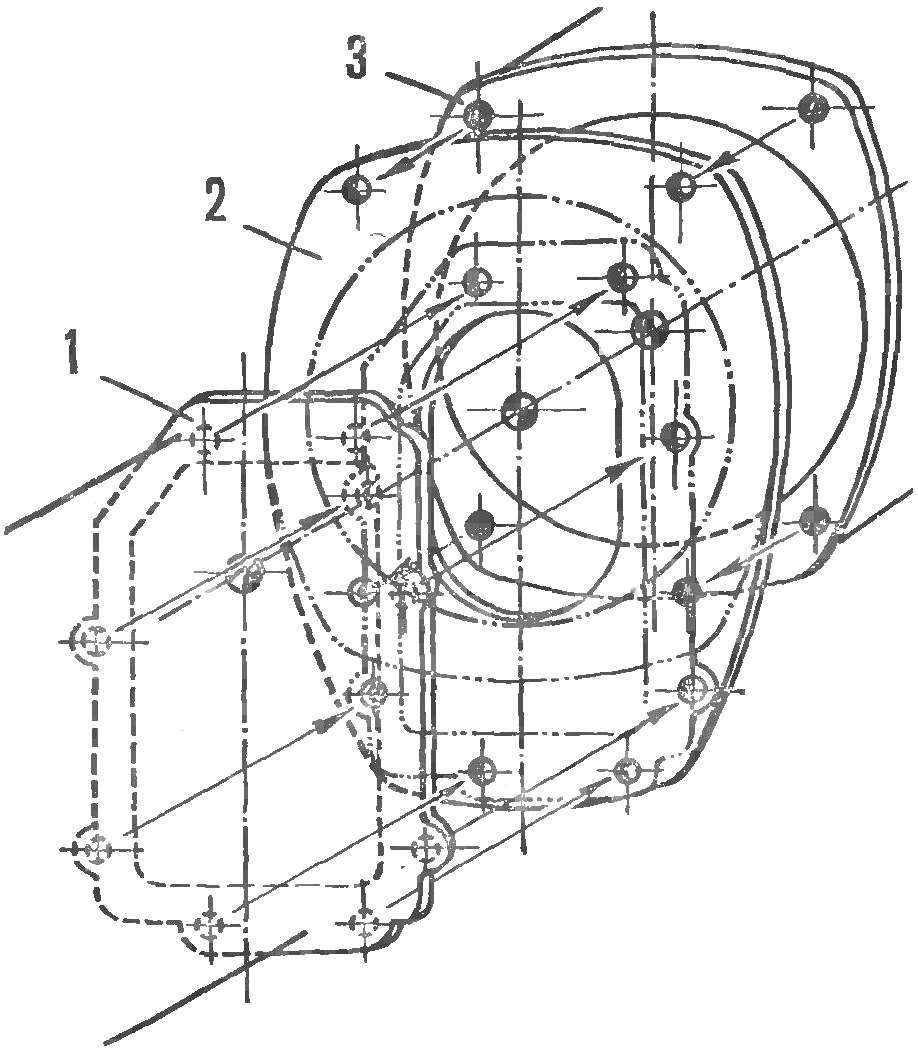

Motorcycle engines are usually sold with the clutch and transmission. In this form they retain when installed on the car. Possible mismatch of gear ratios in the gearbox and the desirable dynamic characteristics of the vehicle will be compensated by the selection of the gear ratios of the main transmission, additional gearbox, if provided in the layout (see the third article), and tires. Replacement motor gear box of any car, for example from “the Muscovite” makes sense only if you are installing Irbit and Kiev of the engine on relatively large (four-seater) car. Then to connect the housings of the transmission and engine need to provide for a transition sheet metal (Fig. 6) that serves as a cover at the same time for both the crankcases. On the worksheet, mark the holes, removing the imprint (impression) with the flanges of the housings on heavy paper.

Application automotive gear box ensure the machine in reverse, which, as you know, there is many motorcycles. The requirements of the traffic police admit self-made vehicles without reverse gear, if Palpa vehicle weight (loaded) does not exceed 600 kg (double machine). When used in heavier construction motorcycle engine car transmission it is necessary to incorporate a reverse gear. It applies any additional gear or main gear, similar to how it’s done on the scooter Serpukhov plant.

Carburetor, ignition devices, exhaust silencer and other equipment — from a standard engine. The exception is the starter, which is better accomplished by the actuator from the vehicle. For the engine located at the rear, needs starter, remote electrical enable (push button or key ignition) automotive type.

The power unit of “Zaporozhets”, it is advisable to use a whole — along with a transmission and sump of the main transmission, and the axles and suspension.

Fig. 5. Dimensions of wheel rim tire 5.00-10 and its attachment.

Fig. 6. Install the intermediate sheet between the engine and the transmission:

1 — transmission, 2 — transition worksheet 3 — a crankcase.

A very important element of the car — the tires. We already know that there are some tire sizes, suitable for improvised structures. Figure 5 shows the configuration of the corresponding wheel rims. Form latest need to withstand very accurately to tire easily and correctly mounted.

In the absence of the finished wheels they are easy to make, if you take a composite wheel design (Fig. 5) of the two discs, each of which forms a half of the rim. Composite wheel can be done in the following way: a template profile made of sheet steel or aluminum. Machined bar made of beech or aluminum and is installed along with the billet of steel sheet thickness 2— 3 mm on the lathe. The machine in this case is pressure. As the extrusion of the drive roller, mounted in the caliper, it applied the template to check. Should keep the builders from selecting too thin of material for the wheels, so that the edges of the rim exposed at certain moments of great pressure and, in addition, it is possible the strikes of the rim on the rocks or the edge of the sidewalk. And yet — in the manufacture of disk “photochrome” material at the folds, in the sky, purifies. In the thinnest areas the thickness of the disc must not be less than 1.5 mm.

Composite wheels can be heavier than the welded or riveted (which drives the rim is welded or riveted to each other). But they, in addition to simplicity of manufacture, convenient to mount the tires, especially the small size of the disks stacked on the sides of the tire and pull together established three small bolts, then the tire is inflated.

The inner and outer disks are doing the same, join together, centruum, and then mark and drill the hole for the wheel studs. For a small car only three or four pins Ø 10 mm on each wheel. To tighten nut, good to put or even welded to the outer discs, washers, countersink, or run a countersink in the outer disks. Facilitating the wheel is achieved by drilling holes. Changing the diameter of the holes can be well balanced its weight.

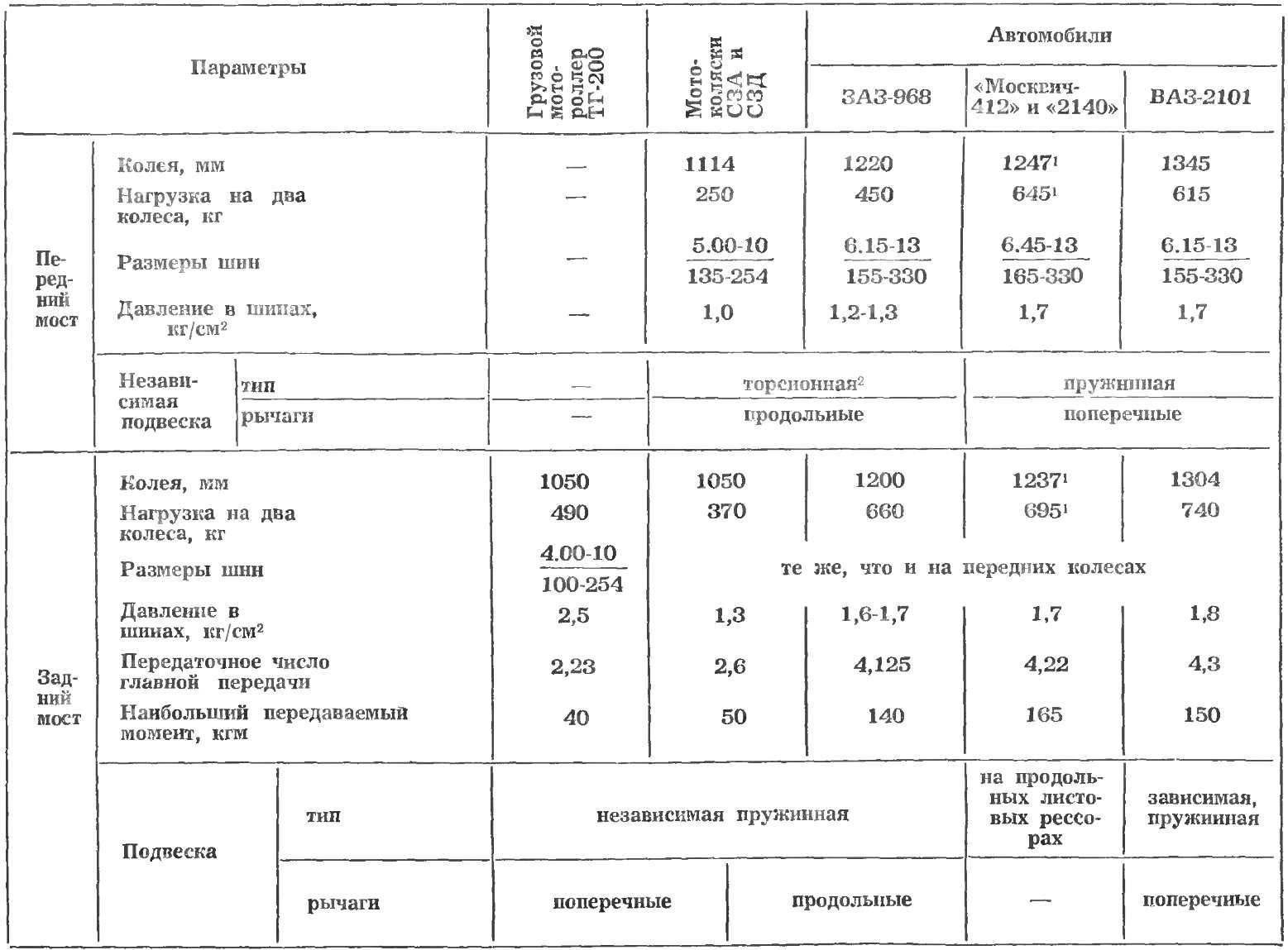

Table 2. DATA FOR FRONT AND REAR BRIDGES

The finished items are recommended to be used in the systems of steering management, a suspension, brakes and drive. In detail, these systems will be discussed below, but for now, looking ahead, it may be noted that in the construction of home-made cars use the suspension front and rear wheels of motorcycles assembled with shock absorbers, springs, motorcycle trailers strollers, not to mention the parts and components of suspension sidecar С3Д, trucks, scooters and the car “Zaporozhets”. Chassis parts and controls last even can serve as a good basis for suspension of the micro-car, only (table. 2). From motorcycles you can borrow brake drums and other brake parts, cables.; from cars “Moskvich” and “Lada” from different editions — the steering gear, threaded clevises and other parts of the steering gear, the hydraulic system of the brakes and Clutch, shock absorbers. Of course, electrical equipment and appliances improvised car assembled with prefabricated elements, and not always items small cars are most suitable. Some great car control and lighting are very compact and lightweight.

Y. DOLMATOVSKIY, candidate of technical Sciences