In our home the garage there is a well-worn snowmobile “Buran”. I’m not going to Express their attitude to it in General, because the views of the owners on this issue diverge. However, the work of his heart — the motor always caused not only anxiety, but also from year to year required surgery. Every summer, making these “sleighs” for the winter season, in the engine due to wear and something changed: the rings, liners, pistons.

In our home the garage there is a well-worn snowmobile “Buran”. I’m not going to Express their attitude to it in General, because the views of the owners on this issue diverge. However, the work of his heart — the motor always caused not only anxiety, but also from year to year required surgery. Every summer, making these “sleighs” for the winter season, in the engine due to wear and something changed: the rings, liners, pistons. As far as I know, these problems occur during operation of the engine RMZ-600, do not give sleep to other owners of “storms”, and the motor hitherto for several decades excites the minds of domestic Kulibin, trying to bring the design to mind. We went different path, deciding to replace the stock power unit to others, enjoy your stay.

The idea of installing motor pumps MP-80 on a snowmobile “Buran” belongs to my son, Vladimir, as operated and repaired it mostly it. The son, however, and picked up necessary spare parts for the new motor, because at the moment of occurrence of ideas were available, only the cylinders and the block-crankcase. He basically performed and the alteration, and I only helped him when he didn’t have enough time or skills to manufacture complex individual parts.

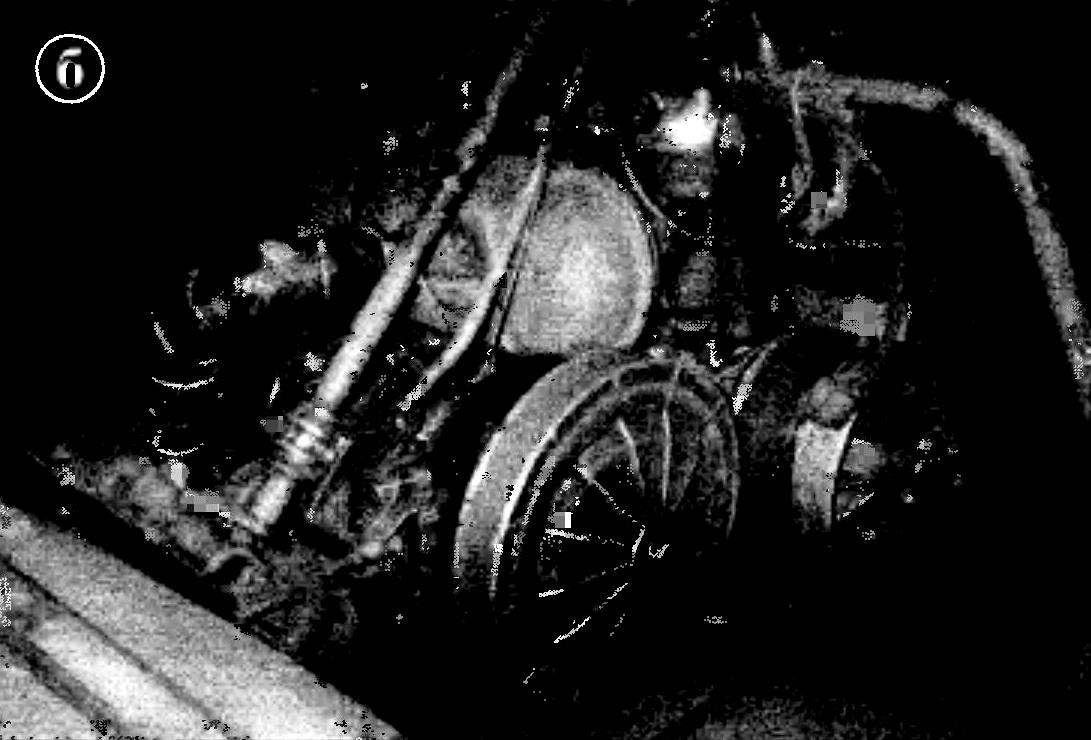

About the engine from the motor-pump MP-80. This two-cylinder, two-stroke engine working volume of 700 cm3 (at 349 cm3 in each cylinder) and a power of 28 HP liquid-cooled (the heat from the cylinders were sampled channel download water). Maximum speed — 4800 min. Its crankshaft — chetyrehosnyj Packed into a powerful roller bearings. Well thought out system of lubrication. The lower part of the connecting rod is installed on the main journals is also in a roller bearing. And rollers without cages, recruited close to each other. This decision connecting rod bearing unit I used previously when modifying the engines (for example, when mating two motors “IZH-the planet” — see “modelist-Konstruktor” No. 2, 2003). In this node the blow of the rod is not directed towards the one roller, and distributed among several. The motor is very unpretentious and may be for days to pump water.

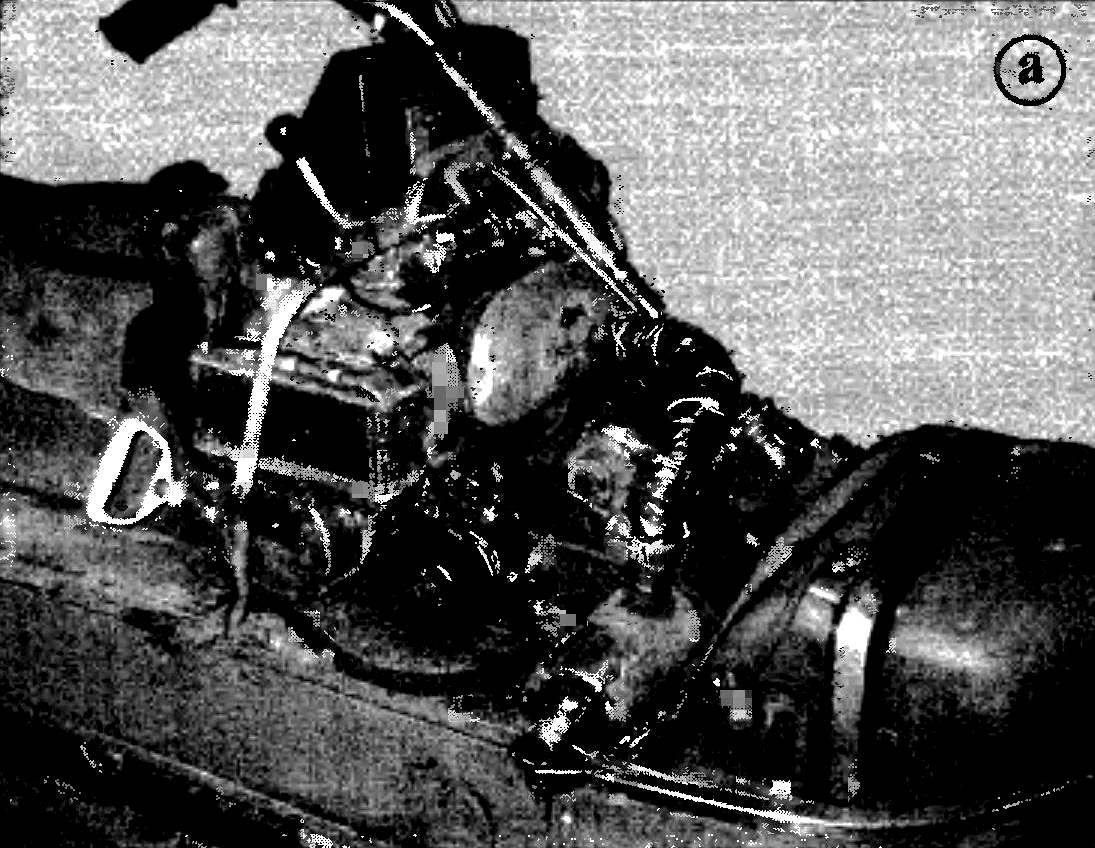

The power unit of the pumps MP-80 on a snowmobile “Buran”:

a — right side view (in direction); b — on the left (on the go).

Pistons for engine MP-80 came from a motorcycle “IZH-Planeta”. By the way, they are five times cheaper “buranovskiye”, though the latter inferior in quality, even burned. The piston rings were tighter than expected, but eventually got used.

Motor MP-80 was calculated to operate on gasoline A-66 or A 72. Now that gasoline at the pump simply no. Therefore, the cylinder head had to “shlifanut” one millimeter to reduce the volume of the combustion chamber and to adapt them for gasoline AI-80. Measurement of the change of power is not produced, but due to this boost it should, of course, increase.

The muffler of the engine left the staff — from the MP-80, but it was improved, but rather added a homemade tank-resonator, connected to a muffler via a flexible corrugated sleeve. With this new engine, and the additional cavity are compacted under the standard hood.

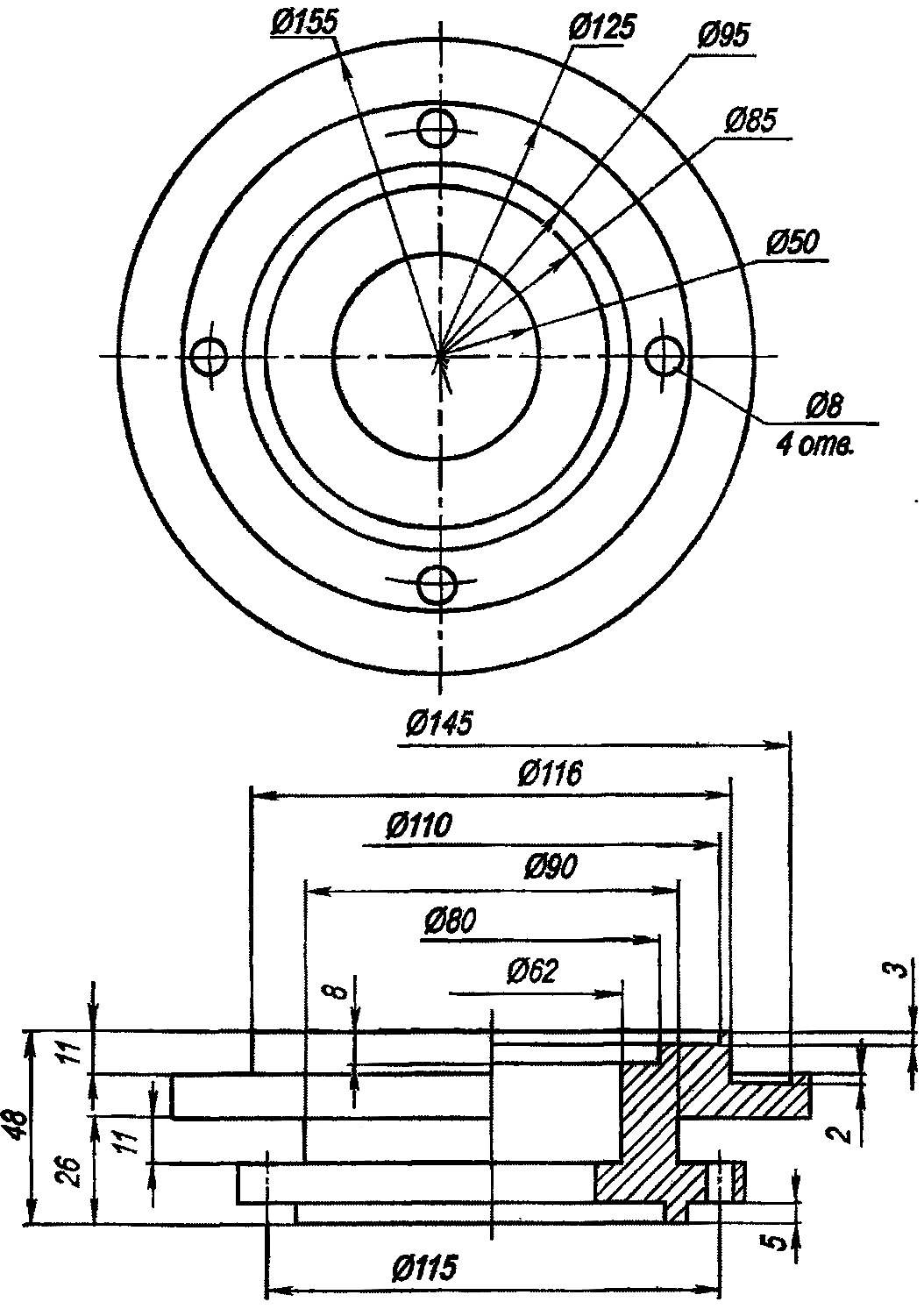

Upgraded the crankshaft of the power unit of the pumps MP-80, adapted for snowmobile “Buran” in the Assembly:

1—left (in the direction) the axle shaft; 2—thrust bearing 8207; 3—42207 roller bearing; 4—outer (solid) cheeks of the connecting rod; 5—connecting rod; 6—roller bearings 2306; 7—internal (cut) cheek of the connecting rod; 8—ratchet clutch of kickstarter; 9—helical gear kick starter; 10—magneto coupling; 11—the right axle shaft; 12—coupling bolt (2 PCs); 13—the Central shaft; 14—remote coupler; 15—native neck of the connecting rod (2 PCs.); 16—the rollers are full complement bearings (needs 2 sets.).

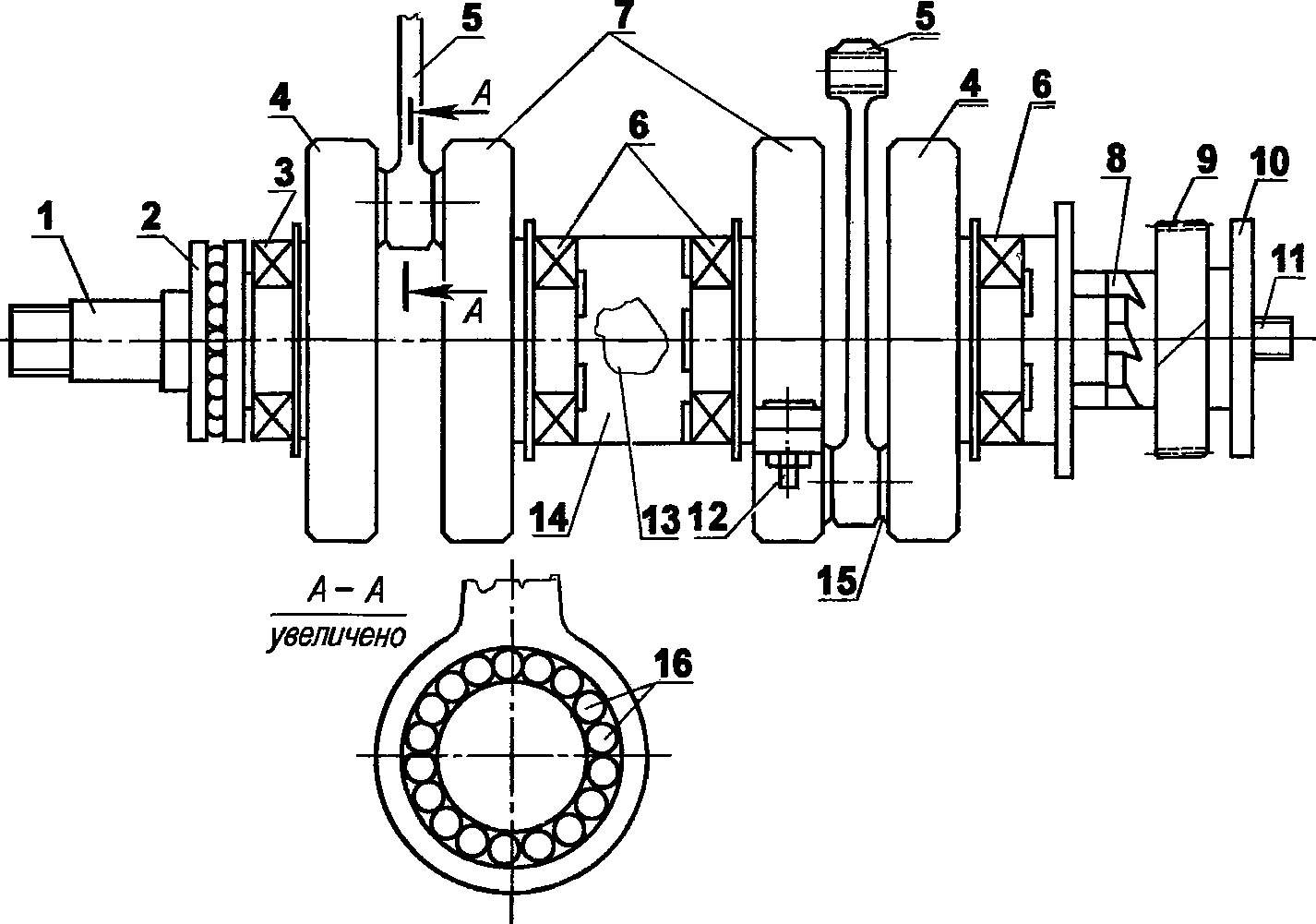

Axle crankshaft:

a — right; b — left; dash-dotted line shows the outline of the original part — full-time axle.

Looking ahead, I note that the exhaust is softer and can be compared with the exhaust stroke of the engine. The operation of the engine at medium rpm is not audible at a distance of 40 m, and at idle is 7-8 m. But the main advantage was another. So, in the “Buran”, the exhaust gases are directed through the muffler body of the snowmobile down there is always formed ice, pieces of which had to travel to beat up. Now the exhaust gases exit from the starboard side to the side not getting on the driver and passenger. The old hole in the muffler housing closed welded overlay.

Important improvised an additional item — special flange, which are mounted on the generator (magneto instead of the standard MP-80) and the trigger from the “Buran”. The flange not only had to sharpen on a lathe, but to cast him a blank, as have never found the right massive presets.

Material for blanks was the old aluminum pistons, which are chopped and melted in a ladle made of tin. The diameter of the bucket about 220 mm and a height of almost 90 mm was Melted in the forge at the end of the shift, leaving the melt in the ladle in the fading fire all night. The next morning the bucket with solidified metal cut grinder, tore the wall “a rose”, and pulled out a disc. Casting had a different structure: porous and in the upper layer and dense (approximately 2/3 of the height) in the lower layers, which was used for the manufacture of the flange.

Here I note that the flange is seated on the M8 studs and nuts fastened to the block-crankcase. When installing the flange it is necessary first to impose it on the studs so that they only slightly protrude from the holes. Then all the studs slightly loosely install the nuts and tighten them evenly.

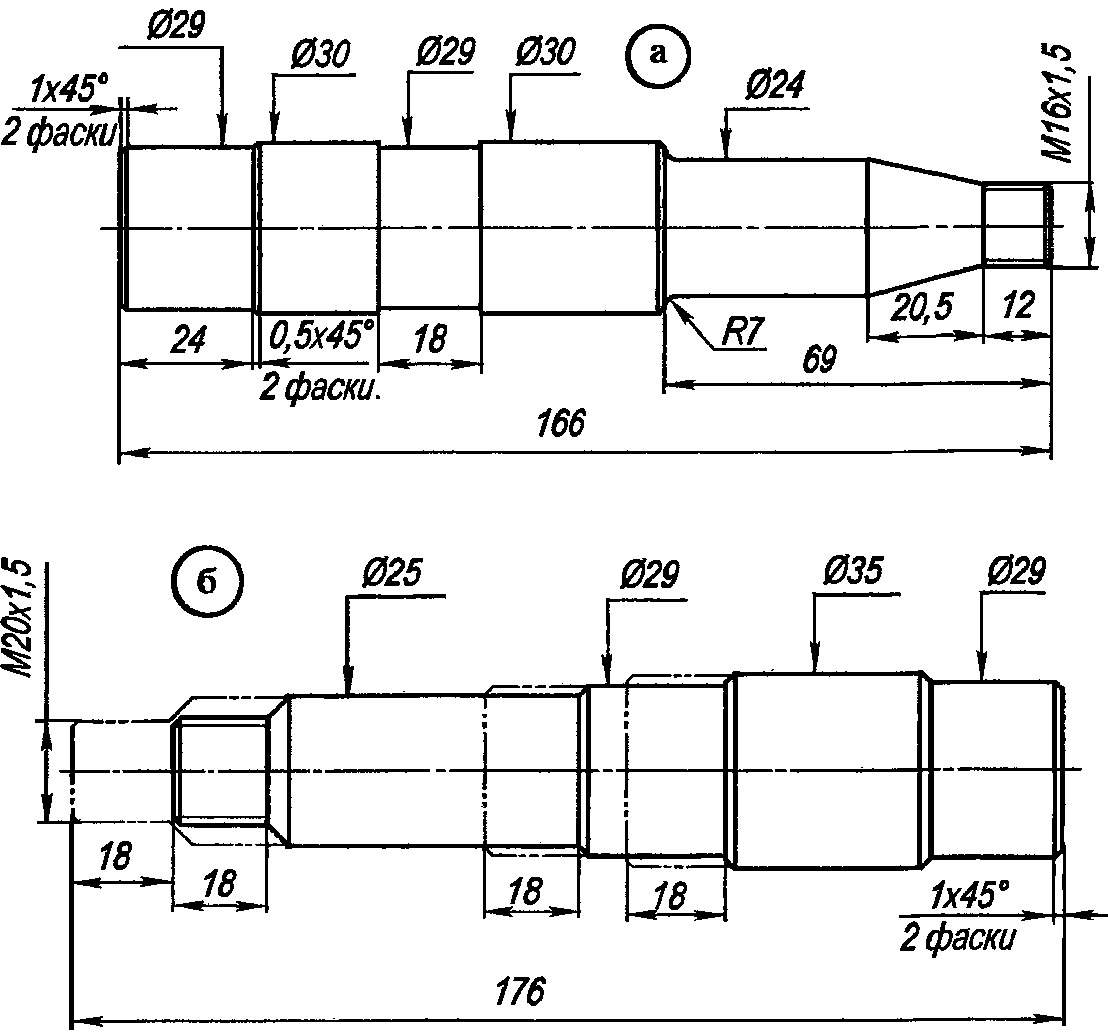

Drive (V-belt drive) cooling fan, liquid pump and generator (not visible in launcher device).

Radiator engine cooling system of the snowmobile.

Even in the flanges in place drilled a hole under the wire and run two diametrically opposite groove for screws M5. The grooves in the eroded screws allow you to rotate the flange clockwise (or counterclockwise) that gives the opportunity to install an earlier (or later) the ignition — change the angle of the closed state of the breaker contacts.

Special flange.

In addition to the cylinder head modifications undergone and some other engine parts MP-80. First of all it concerns its crankshaft, or rather its first and last parts (we call them conditional rod-right and left, guided by the course). The engine was disassembled: removed the cylinders block crank case “raspolovinit”.

Let’s start with the left axle shaft. In the factory version for MT-80 designer, as if anticipating that his motor will put on the “Buran”. And therefore left in place both of her bearing: roller bearing 42207, and ball thrust 8207. It would be possible to preserve the same and the length of the axis. But then it would have been too long its console the protruding portion, the displacement of the pulley of the variator would cause additional load on the bearings. Besides, had would have to redo the node of the driven pulley.

So decided driveshaft to be shortened, although not by much — only 18 mm, moving, respectively, the transverse and longitudinal dimensions with the shaft end inside. When determining the length of the cantilever part of the axis “danced” from the ends of the studs stuffing box, after the overmolding of the right drive pulley onto the axle shaft until it stops at the shoulder, he still should not reach the ends of the studs at least 3 mm.

The factory driveshaft has a centering hole of the socket, so the processing end of the cantilever part of the difficulty is not caused, although required to strictly maintain the tolerances for the landing right of the drive pulley and the bearing 205 idle speed variator. On the threaded end of the axle is screwed buranovskaya bushing left side of the drive pulley with weights variator.

Now’s about the right axle shaft. First of all it removed all the sitting on it part. Free the axle shaft is clipped at the root of the cheeks of the crank. Then on the other side of cheeks (there is a centering nest) drilled hole with a diameter of 28 mm, and then rastaquouere diameter 29 — 0,05 mm.

The right drive axle legacyvisa new (its size is shown in the drawing) is first with margins 2 mm, and then accurately to size. For planting cheeks onto the axle shaft cheek warmed. After checked the runout of the complete crankshaft and eliminated redundant. Next, by setting the crank to the right connecting rod in the position of the upper dead point, on the half-line was profesionaly keyway for the rotor of the generator.

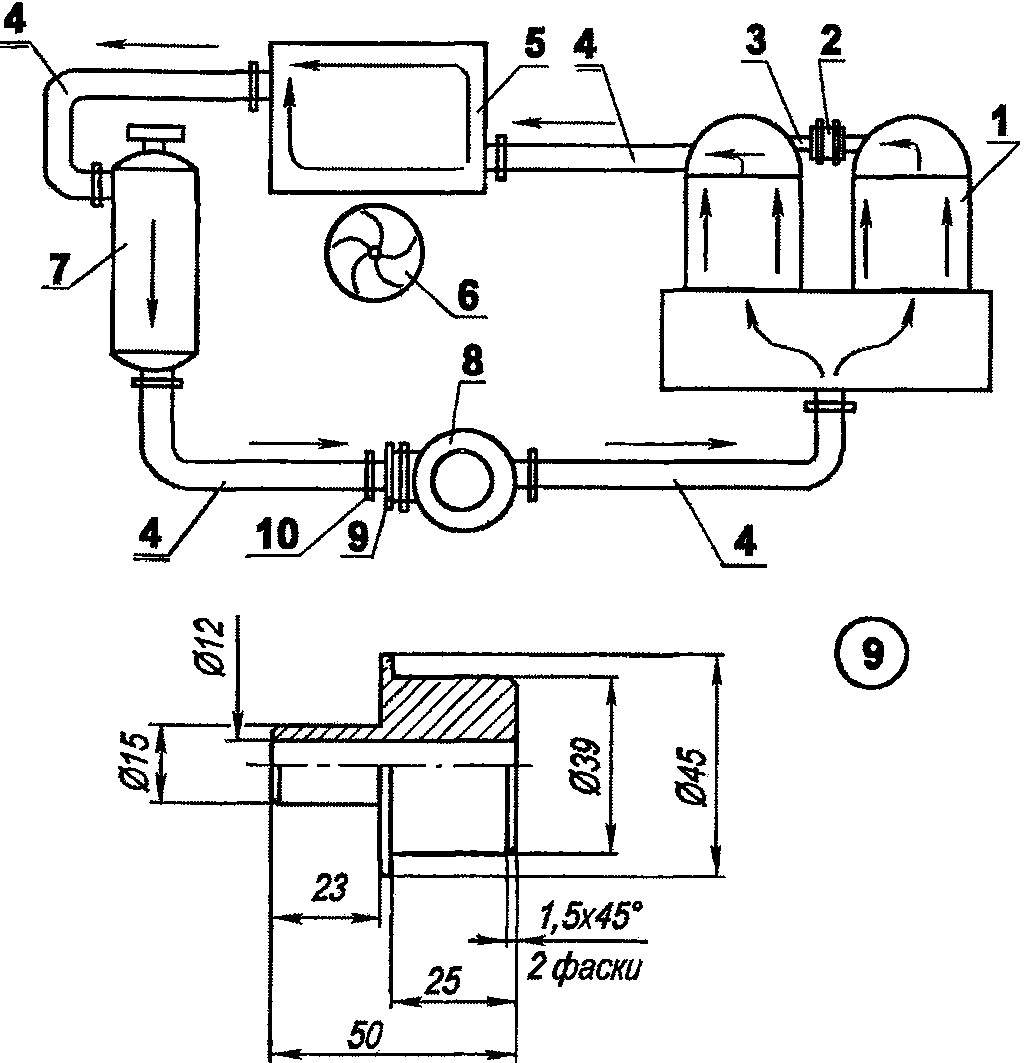

The cooling system of the motor in the pump MT-80 were very simple — a cylinder cooling flow of the injected water. So for use on a snowmobile cooling system had to be designed anew. The main difficulty with this was that it (the system) needs to be compact and to fit together with the engine under the standard bonnet. But this problem was solved, even with those component nodes that were available or that were able to get.

Diagram liquid-cooled engine MP-80 on a snowmobile “Buran-plus”:

1 — engine; 2—clutch (cut a rubber tube); 3—tube (regular, cut); 4—hoses (rubber tube Ø EXT. 14); 5—radiator (stove from tractor DT-75); 6 — fan (from a snowmobile “Buran”); 7—extender (the gas tank from the starter DT-75); 8—pump (pump from the car VAZ-2101); 9—adapter (steel, lap 45); 10—a clamp (9 PCs.).

The most voluminous part (or Assembly) — radiator. In his capacity adapted a heater (stove) from the tractor DT-75 with virtually no alterations. And the expander was the tank starting the engine the same tractor. Only in the system of cooling it is set “to bottom” (vertically). Since the radiator is located under the hood, but still sideways to the direction of motion (and hence to the counter air flow), it still provided a fan, which is positioned between the radiator and the right cylinder, attaching the housing to the crankcase. The rotation of the fan along with a pump carried by the crankshaft through pulleys and V-belt transmission.

The pump is used from the car VAZ-2101. It had to be refined: to drown the opening at the end of a 3 mm steel plate using a rubber gasket and drilled opposite the receiving inlet hole with a diameter of 12 mm, to weld a pipe — section of the tube outer diameter of 15 mm. As the suction bend is designed for a hose diameter of 40 mm, and all the pipelines of the new system have an inner diameter of 14 mm, then had to make an adapter.

The pump is attached to the radiator fan bracket with a slot (from the generator VAZ-2101) and the angled bracket with shaft (bushing welded to the plug of the pump) to the crankcase. The pump has the ability to turn on a small (but sufficient for tensioning of the drive V-belt) angle.

The cylinder heads have gaskets which had only one hole near each cylinder. Had to punch special punch another six holes (excluding attachment fittings) that the fluid followed the path of least resistance and will flow around the whole cylinder head.

The cylinder head is connected by an aluminum tube. The tube is cut, reamed to a diameter of 10 mm and was connected by a cut rubber hose by tightening its clamps. This alteration will prevent the depressurization of the connection tube and the cylinder head from vibration during engine operation.

To blow out the radiator to effectively cool the circulating fluid, independently of the speed and temperature of the environment, installed the impeller (fan). She is from a snowmobile “Buran”, where it was used for forced air cooling of the cylinders. The rotation of the impeller, and the pump (the pump), provided from the crankshaft via the pulley belt transmission. And that the impeller is not driven in the air past the radiator, it is enclosed in a casing, and all the cracks in the radiator and between it and the casing of the impeller sealed white tin.

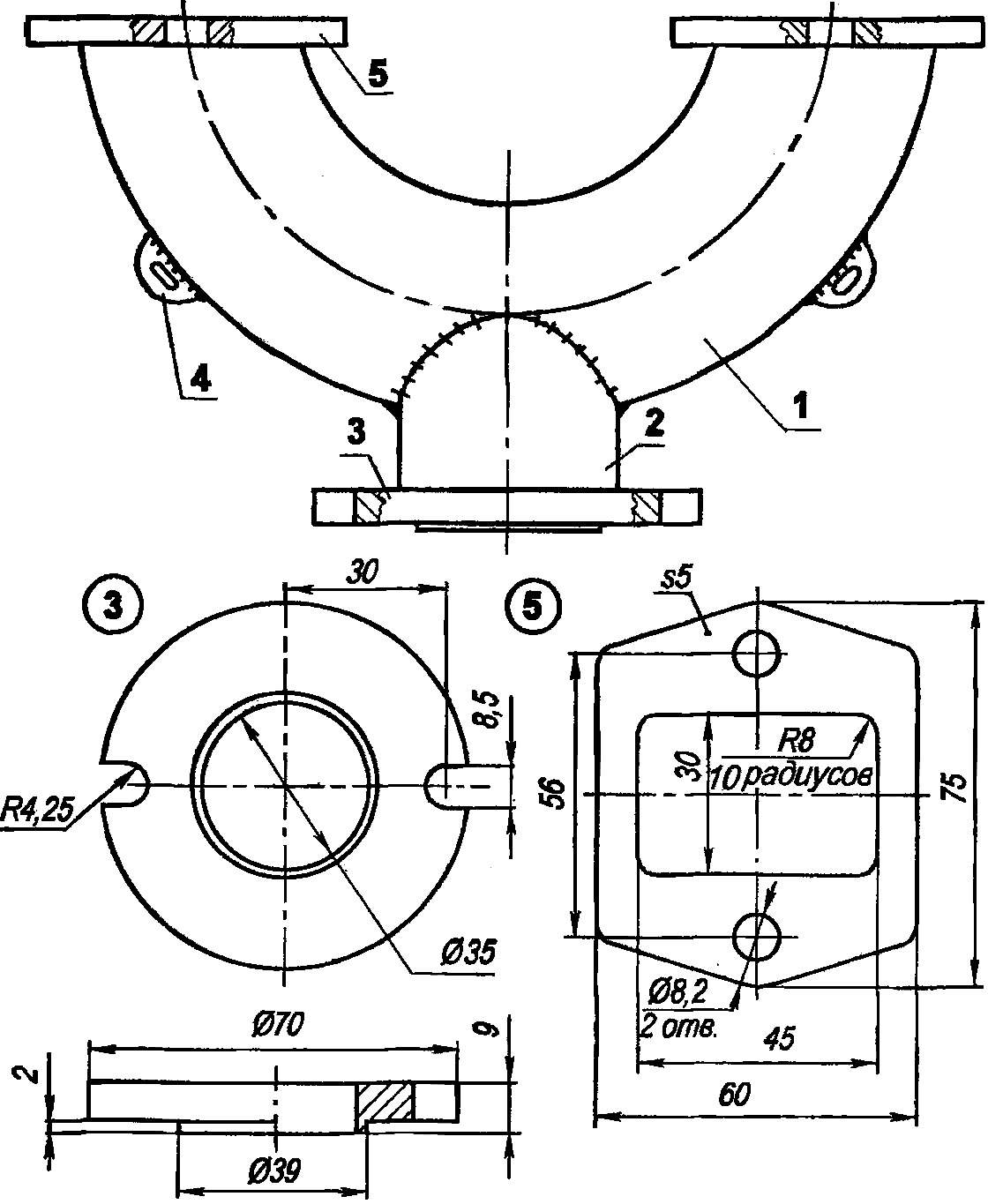

Intake manifold:

1—ports of the cylinders (from the exhaust pipe of the motorcycle “IZH-Planeta”); 2—a branch pipe of the carburettor (from the same tube); 3—carburetor flange (steel sheet s6); 4—eyelet carb (steel sheet s3. 2); 5—flange of cylinder Assembly (sheet s5).

For engine MP-80 bought a new carburetor K-68 “Pekar”. For it had to do from the exhaust pipe of the motorcycle “IZH-Jupiter” a different intake manifold.

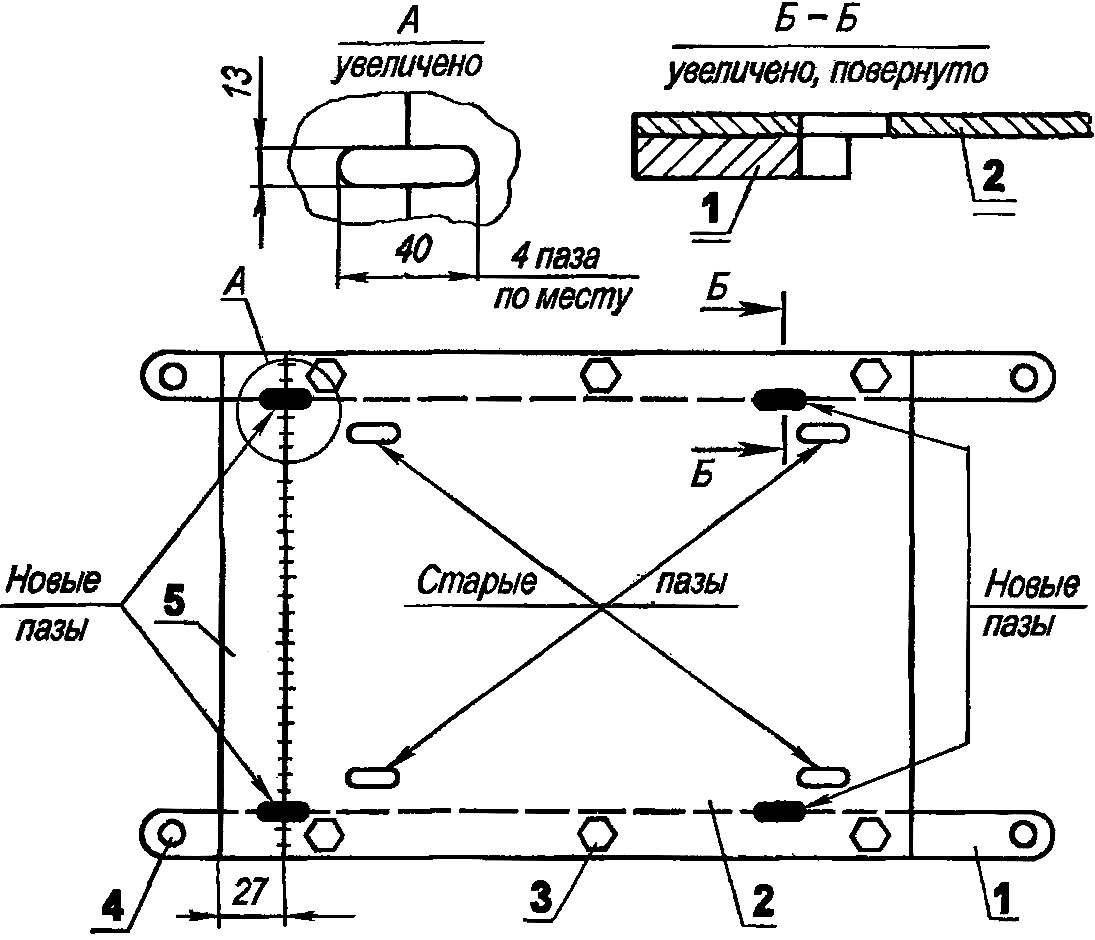

Finalization of sub sites:

1—spring (2 PCs); 2—deck (sheet s3); 3—mounting pads to the spring (M8 screws, 6 PCs); 4—pillow (rubber, 4 pieces); 5—the additional plate (sheet s3).

For consolidation of the new power unit on the sub site of the “Buran” had to lengthen (incremental transverse weld plate) is 27 mm, and make a new slot and adjust its location with the aim of matching the plane of rotation of the variator and the pulley of the gearbox. In this case a little bit, but inevitably preservability the edges of the leaf springs (which, in General, not scary). To the studs and power unit (or rather, their nuts and washers) is not twisted, place the cut ends of the leaves to the bottom platform welded the same thickness of the plate.

Another change on the snowmobile’s more concerned about his appearance (that is to say, design) than the design is the reworking of the fairing. His “tailored” of the two, with the second headlight, giving the snowmobile a more impressive look. Staff spotlight shifted to the right in this case (in the course), and it has remained as a track (fixed). The second has the ability to turn in its socket and even be removed from it if necessary, and used as a searchlight.

In conclusion, we note the advantages, which acquired the old “Buran” after the equipment of his engine from the motor-pump MP-80.

Firstly, liquid cooling of the motor ensures stable thermal conditions with an operating temperature of about 85°C. secondly, the increased traction of a snowmobile, enabling him to easily overcome steeper obstacles, but also to tow the heavily Laden sled (already up to 800 kg). Third, spare parts are available and cheap, which is also important.

Maybe fell the maximum speed. But a snowmobile is not designed for racing across the plains and steppes. The terrain we crossed, but still with forests, where 45 km/h speed is already prohibitive. And our “Buran-plus” and can roll faster.

VITALI and Wladimir PRONINA, Krasnoslobodsk, Mordovia