When winter comes, the main individual off-road transport in much of our country be the snowmobiles. Unfortunately, they have a significant drawback in terms of comfort snowmobiles do not differ from the motorcycle, and the frost does not go far.

When winter comes, the main individual off-road transport in much of our country be the snowmobiles. Unfortunately, they have a significant drawback in terms of comfort snowmobiles do not differ from the motorcycle, and the frost does not go far.

It would be nice to equip a snowmobile with a heated cab, but it would have been a completely different car. The snowmobile equipment designers went the other way, creating a ski-track machines comfortable trailers-compartments for the carriage of them two or three passengers.

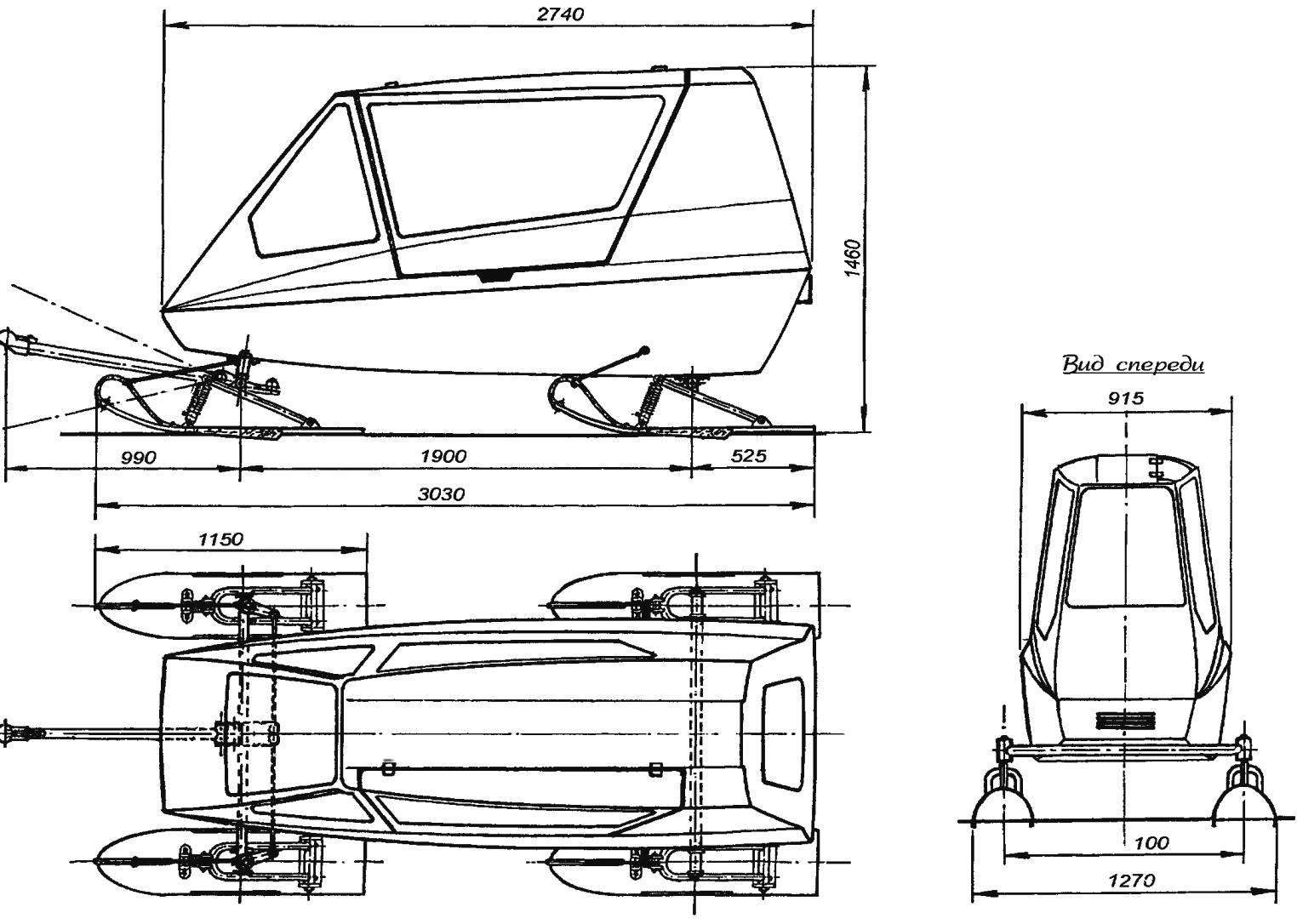

For readers of the journal “modelist-Konstruktor” creating a non-motorized vehicle — is not the most difficult. Therefore we offer you the double trailer the compartment to the snowmobile with an engine capacity of not less than 20 HP, designed by the reader of the journal by I. Horoshavin.

Trailer coupe is chetyrehlistnyj sled with a glazed passenger cabin, equipped with Autonomous heating and lighting shades. The cabin has a single side door, flip-up. Seat made on the basis of office chairs can swivel in the transport position, the passengers are arranged in tandem, and the Parking lot they can sit facing each other. If necessary, between the seats, you can install the flip top.

The passenger cabin is mostly wooden. The basis of it is the lower (power) cabin panel, which is a kind of sandwich.

Double trailer for snowmobile coupe

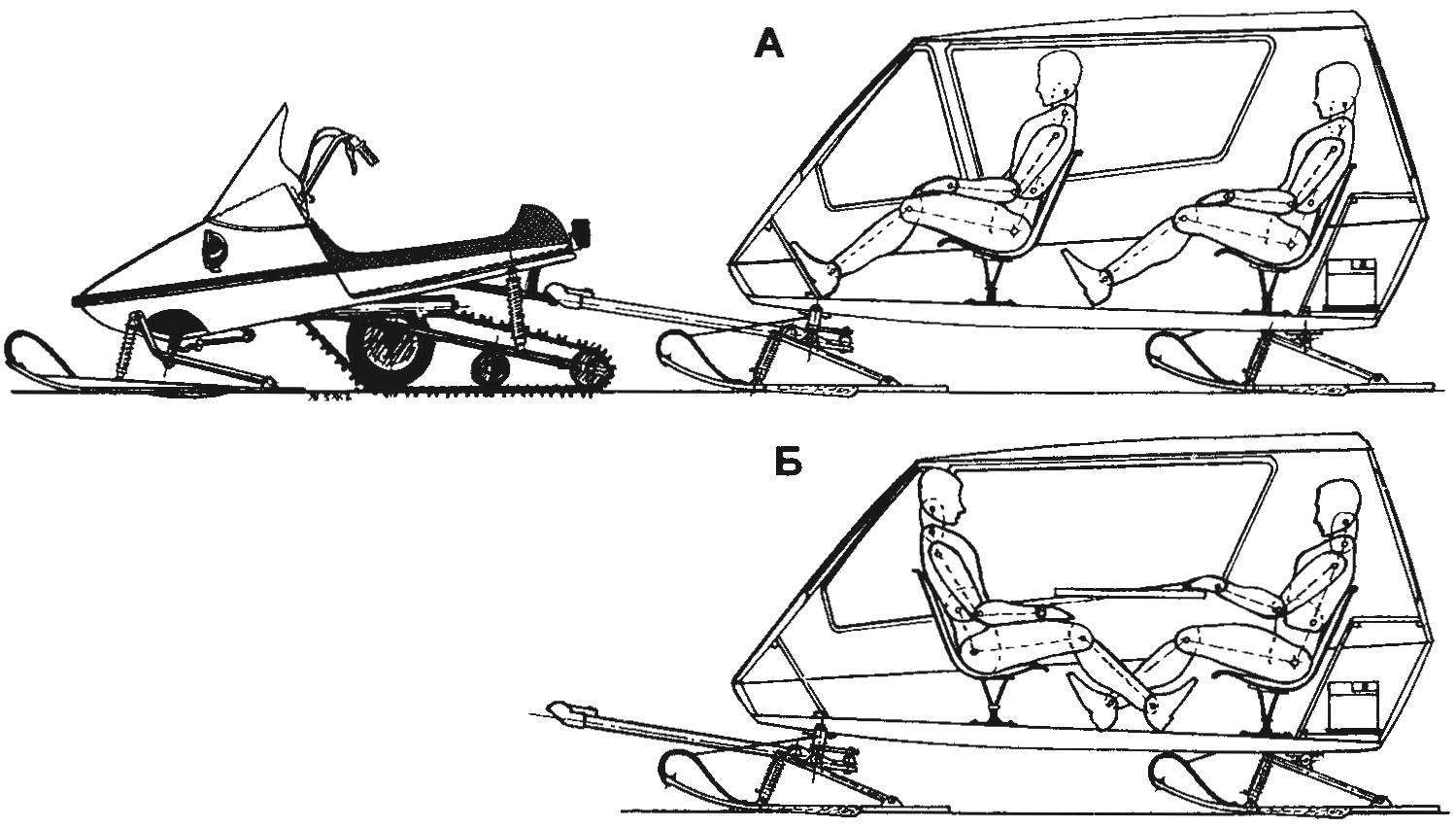

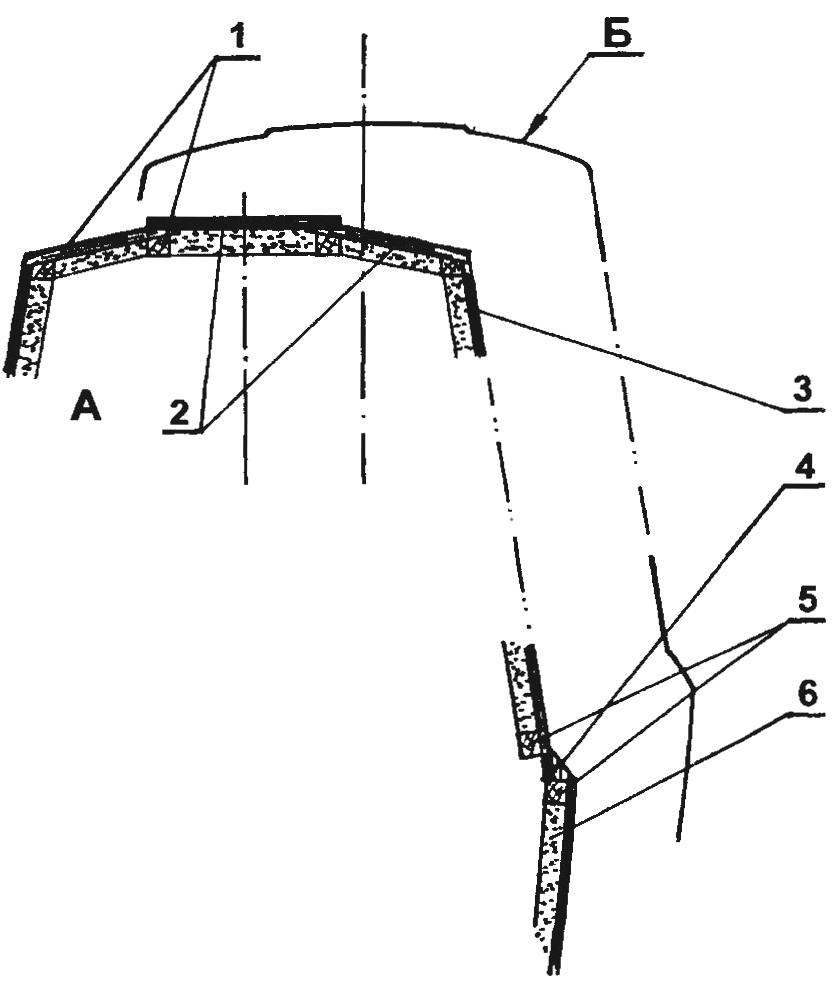

Options for the accommodation of the passengers in the trailer compartment (when towing, a B — in the Parking lot)

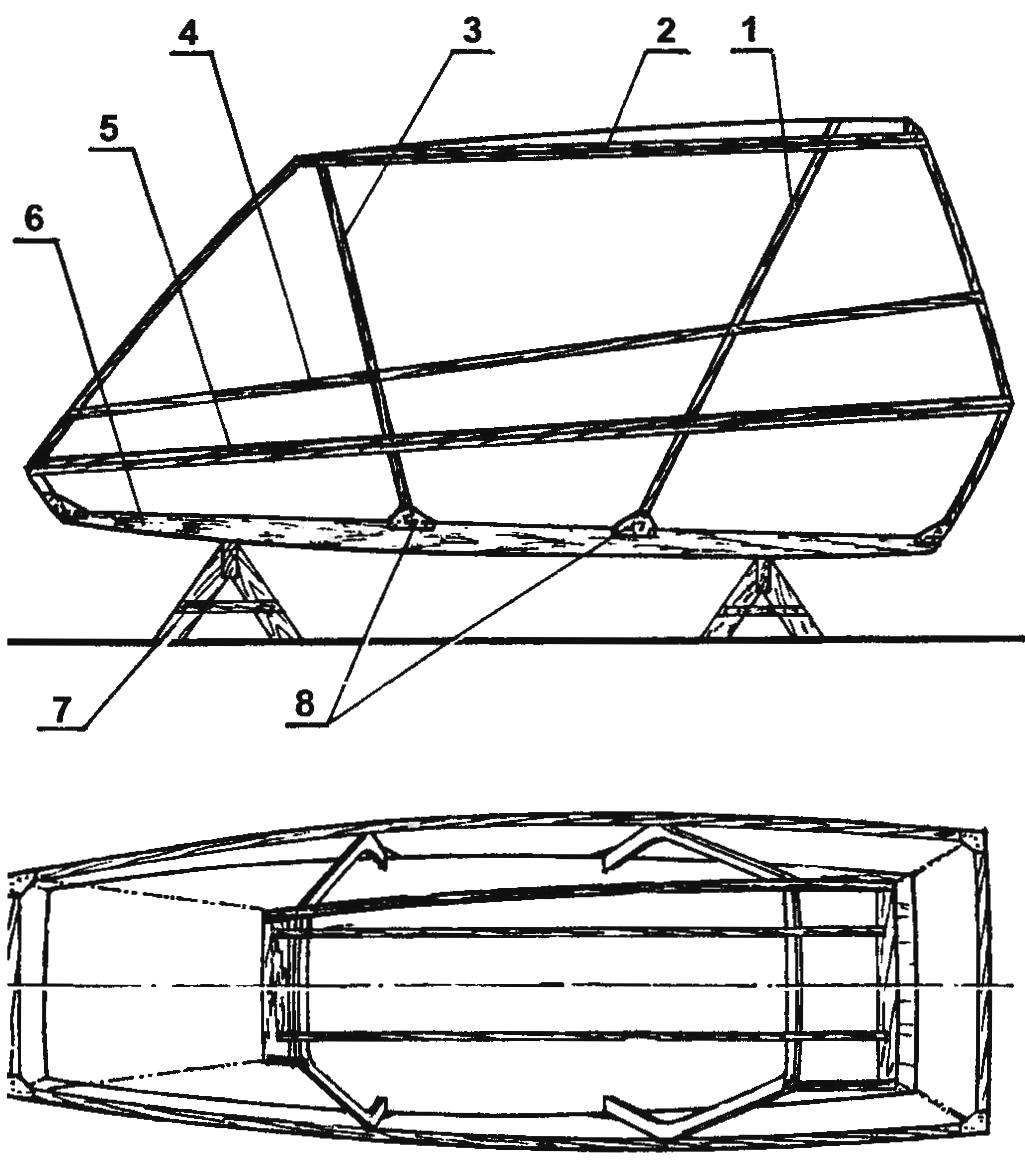

Assembly diagram frame cabin (plan projection of the front and rear inclined frame elements conventionally not shown):

1,3 — sloping frames (plywood, s12); 2 — roof panel; 4 — additional stringers (pine, whetstone 20×20); 5 — middle belt; 6 — the bottom (power) panel; 7 tragus; 8 — reinforcing the gusset plate (plywood s4)

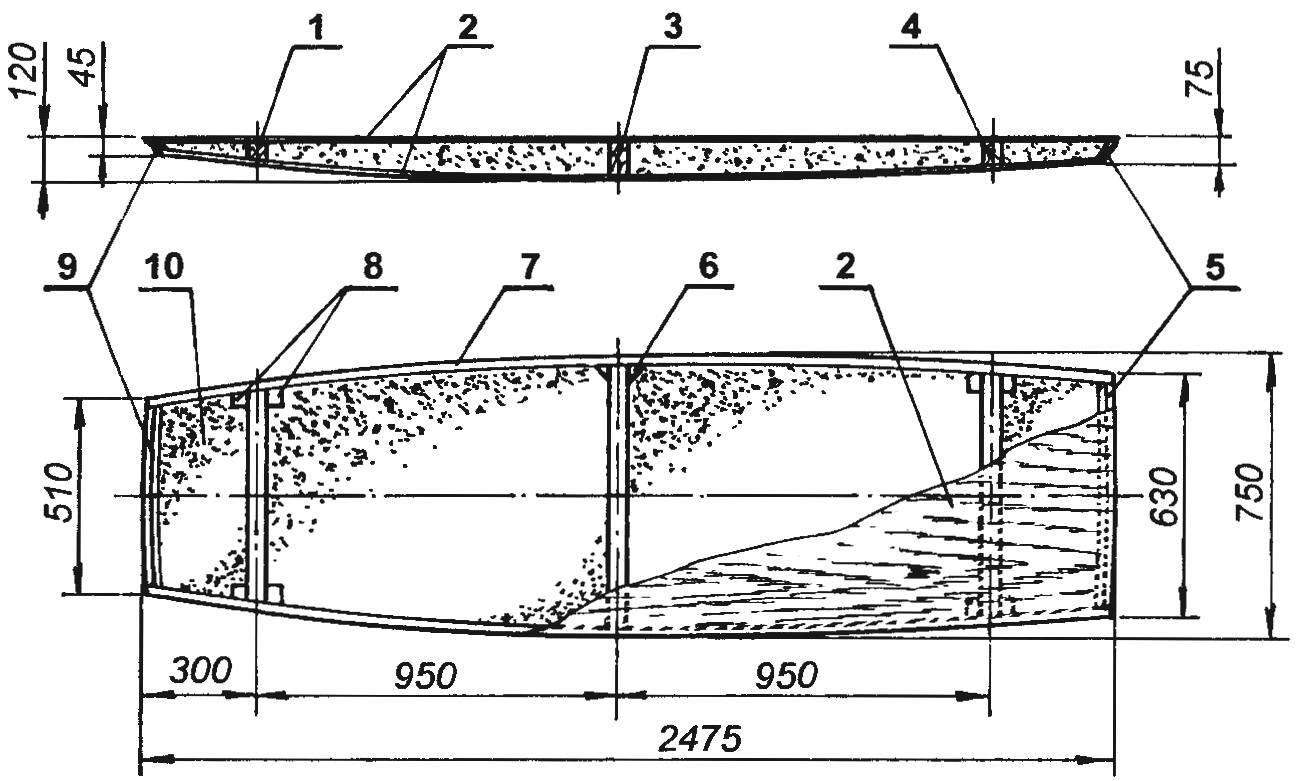

Inside the power panel is a frame consisting of cross bars and the sidewalls. Top and bottom panel are covered with 4 mm plywood; the voids between the bars of the frame filled with construction foam. Such a panel with a relatively small thickness and low weight has a significant stiffness as torsional and bending. For cross members should be selected straight grained boards 40 mm thick, which are pieces of the required sizes, the width of the largest (middle) the tie bar is 110 mm. For the sides will need a Board with a thickness of 20 mm.

Frame, power panels assembled on epoxy glue. Using the same binder in the frame are pasted blocks of construction foam, and fixed paneling of 5 mm plywood.

Cabin is going on a ready basis. The most appropriate scheme following its installation. To start at the bottom (power), the body panel is going to frame krysheval panel and the middle belt. Next lower panel is installed on the trestles in the original (operating) position, then all three elements of the frame (the bottom and the roof panel, and the average zone) are connected by means of two inclined frames cut from 12mm plywood. The result is a rather rigid structure, which can be extended in-place — mount the longitudinal stringers, install the crossmember and additional lightweight frames.

In the thus prepared skeleton frame fixed front, rear and side Windows, as well as forming the frame of the doorway. By the way, the door to the trailer compartment only one left. Ready to glass the cockpit to pick up quite difficult, so it’s easier to cut them from plexiglass.

Then the frame is sheathed on the outside with 3mm plywood. It should be noted that the sheathing frame together with the door, and after the curing of the epoxy adhesive to remove it from the frame, cut the plywood sheathing with a jigsaw. The space between the frames is filled with foam blocks. After alignment of the foam flush with the ribs glued inside the cabin is artificial leather.

Outside the cabin is formed by the surfaces of single curvature, which, as a rule, give the vehicles a “home-grown” look. However, there are many techniques to give the plywood shells of double curvature. One of such techniques is shown by the example of crisenoy panel is formed of three strips of plywood. After viskazivaniya and pasting fiberglass, such a surface does not differ from the panels with double curvature. In principle, the same technique can be used when forming the lower part of the cabin — from her belt.

Outside the cabin is glued a layer of fiberglass cloth on the epoxy binder, and then leveled a two-component autosplice and painted first a layer of primer and then two layers of enamel.

The ski is glued on an epoxy binder strips of 3 mm plywood and stainless steel band with a thickness of 0.8 mm, the total thickness of the package is 20 mm. Before gluing it is necessary to make the simplest slipway, having fixed on a wooden beam a few cross-beams; in front of the pile height should gradually decrease in accordance with the curvature of the sock of the ski. When gluing veneer strips pressed to the cross the pile with staples, bent from steel rod in the form of the letter “P”, “legs” where you tapped. You will also need a wooden yoke with drilled holes in them, which are the “legs” of the clips; the clip is carried out with the nuts.

In the middle part of each ski set the direction undercuts from stainless steel sheet with a thickness of 3 mm. On a ski pivotally secured to the pendulum suspension — arm, bent steel pipe with a diameter of 22 mm. In front of its part of the arc rests on the spring-hydraulic damper of the wheelchair motorcycle “IZH” in the rear — bearing capacity of cut steel channel.

The power panel of the cockpit:

1,3,4 — sleepers (pine, boards, s40), 2 — sheathing (plywood s4); 5 — rear cross member (pine, Board s20); 6 — reinforcing pad (pine, block 30×30); 7 — side panel, (pine, Board s20); 8 — support tubular cross-members (birch, bar 40×40); 9 — front cross member (pine, Board s20); 10 — fill (construction foam)

Pattern formation surface of the cabin (A design environment; B — the final contour of the shell):

1, the longitudinal bars of crisenoy panel (pine, whetstone 20×30); 2 — roof (plywood, s4); 3 sheathing Board (plywood s3); 4 — bevel (pine, block 30×30); 5 — stringers middle belt (pine, 20×20); 6 — filling (building foam)

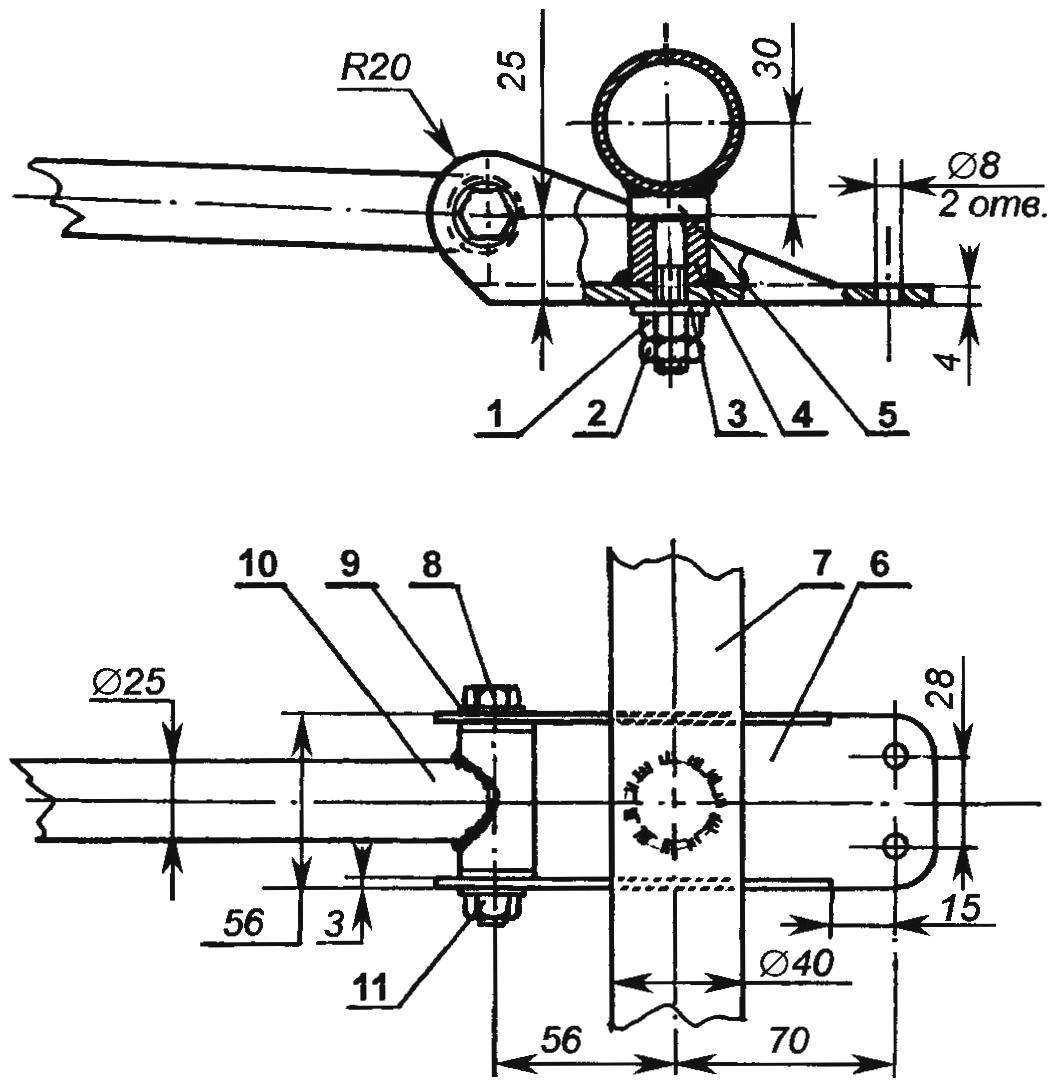

Tow-steering gear:

1 — nut M12 2 — M12 lock nut; 3 — spacer; 4 — bushing (steel); 5 — axle (steel); 6 — pendulum (steel, channel 40×56); 7 — front tubular crossmember (steel, pipe 40×2,5); 8 — the axis of the towing drawbar (bolt M10); 9 — washer; 10 — pole (steel, pipe 25×2,5); 11 — nut M10

Steering gear:

1 — nut M12 2 — M12 lock nut; 3 — spacer; 4 — bushing (caprolon); 5 — axle (steel); 6 — area of attachment of the tubular crossmember (steel, sheet s5); 7 — steering arm (steel, sheet s5); 8 — tubular cross member (steel, pipe 40×2,5); 9 — the case of the steering joint (steel pipe 40×2,5)

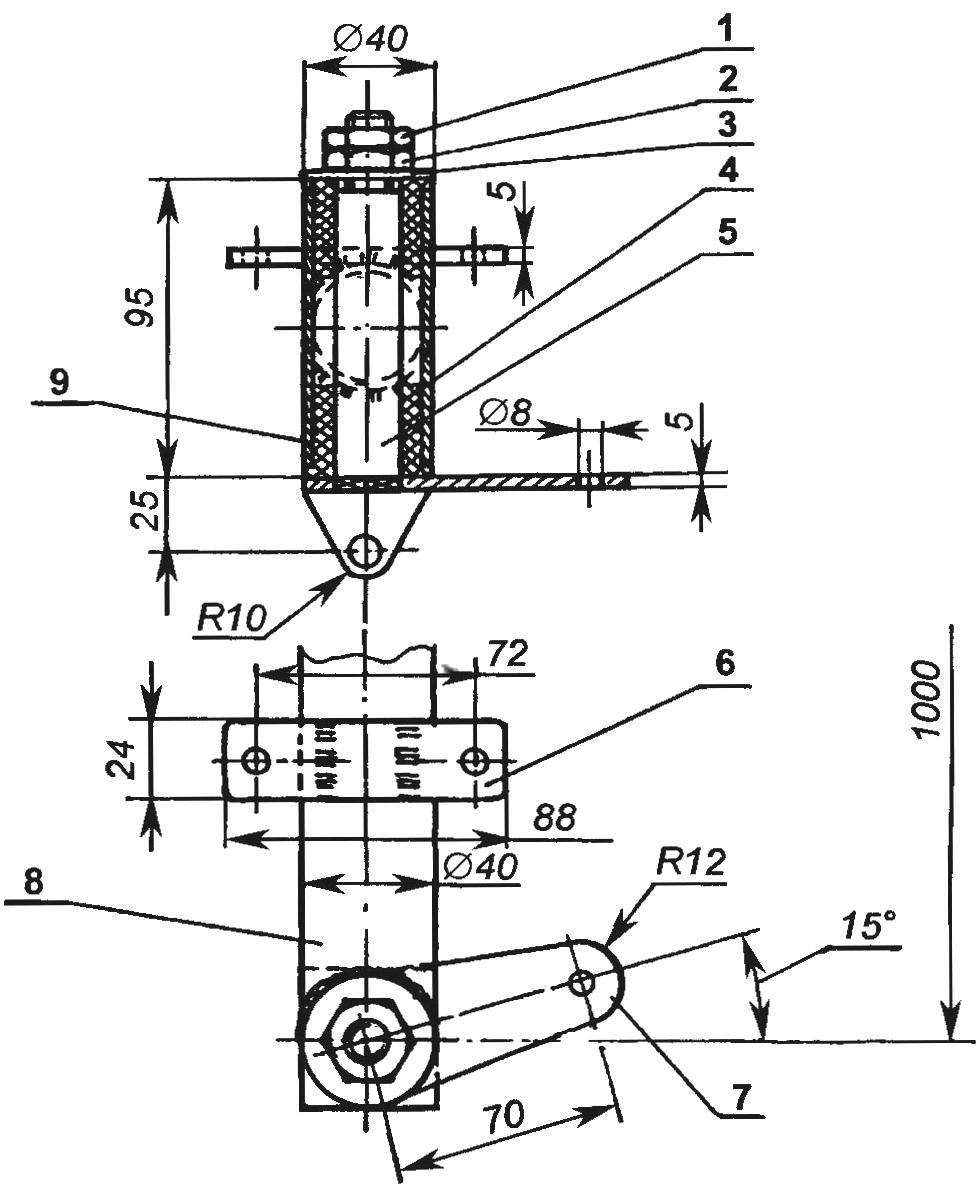

Ski:

1 — suspension bracket of a pendulum (steel, channel); 2 — axis pendulum (steel, stud M 16×1); 3 — pendulum suspension (steel, pipe 22×2,5); 4 — spring-hydraulic shock absorber (from a motorcycle “Ural”); 5 — safety arc (steel, pipe 16×2,5); 6 — fastening of the pipe (the bolt of M6 with nut and washer); 7 — the base of the ski (gluing of strips of plywood and stainless steel band s0,8); 8 — fastening of the safety arc (self-tapping screw Ø5); 9 — the case of the hinge of the pendulum suspension (steel, pipe 30×2); 10 — bushing hinge (caprolon); 11 — bracket (steel, sheet s4); 12 — mounting for shock absorber (bolt M8 with nut and washer); 13 — undercut (stainless steel s3); 14 — shock mount (M8 bolt with nut and washer); 15 — shock absorber bearing (steel)

Structurally, the front and rear skis are the same. And those and others pivotally mounted on tubular cross members, which are in turn fixed on the power panel of the cab. The front ski swivel, steering rods pivotally connected with the drawbar by which the cabin compartment is connected to the snowmobile-tug. Ski socks are pulled up by rubber shock absorber cord with a diameter of 8-10 mm. Tow hitch — standard automotive, ball, ball diameter 50 mm.

At the rear of the cabin is the compartment in which is fixed a car battery for lighting the cab, two rear position lamps and the drive of the auxiliary heater (from the car “Zaporozhets”). The latter is located in the front compartment of the cab. The air intake for the heater is carried out through the blinds at the front of the cabin. Wiring wise to do so that when driving at circuit of the snowmobile towing include a trailer battery.

And the last one. Passenger trailer shall be equipped with Parking stopper — in the simplest case, it could be a couple of pins, bury in the snow through the holes in the rear ski.

I. KHOROSHEV