Everyone has their own dreams. Some dream of one thing, others of another, but Sergei Dmitrievich Rudenko, an employee of the city station of young technicians in Slutsk, Minsk Region, dreams of a children’s technical park. And he not only cherishes this dream but also quietly fulfills it. His main helpers in this are children, all the local kids. Together they create the foundation of the future park — technology. In the teenage club of amateur constructors “Original,” which Sergei Dmitrievich runs on a volunteer basis, about a dozen unusual machines have already been built: from a moped to a hydromotodeltaplane. All machines have one purpose: to serve children’s interests. So the young craftsmen design, build, and ride themselves.

And it all started with the aquaped “Dolphin,” which S.D. Rudenko came up with so that kids would have an interesting way to spend time on the lake in summer.

We nurtured the idea of the aquaped for two years: we estimated, calculated, drew the design, selected materials. When the image of the “Dolphin” was finally formed, we got down to business. And although the workshop at that time had neither a lathe nor a welding machine — only an electric drill, a vise, and ordinary metalworking tools, the construction took only two weeks.

The aquaped turned out to be stable on water, convenient to operate, and quite spacious (five seats on board). It’s pleasant to take water trips and fish on it. The “Dolphin” will also come in handy for rescue work and for towing boats. At the same time, it itself requires no maintenance.

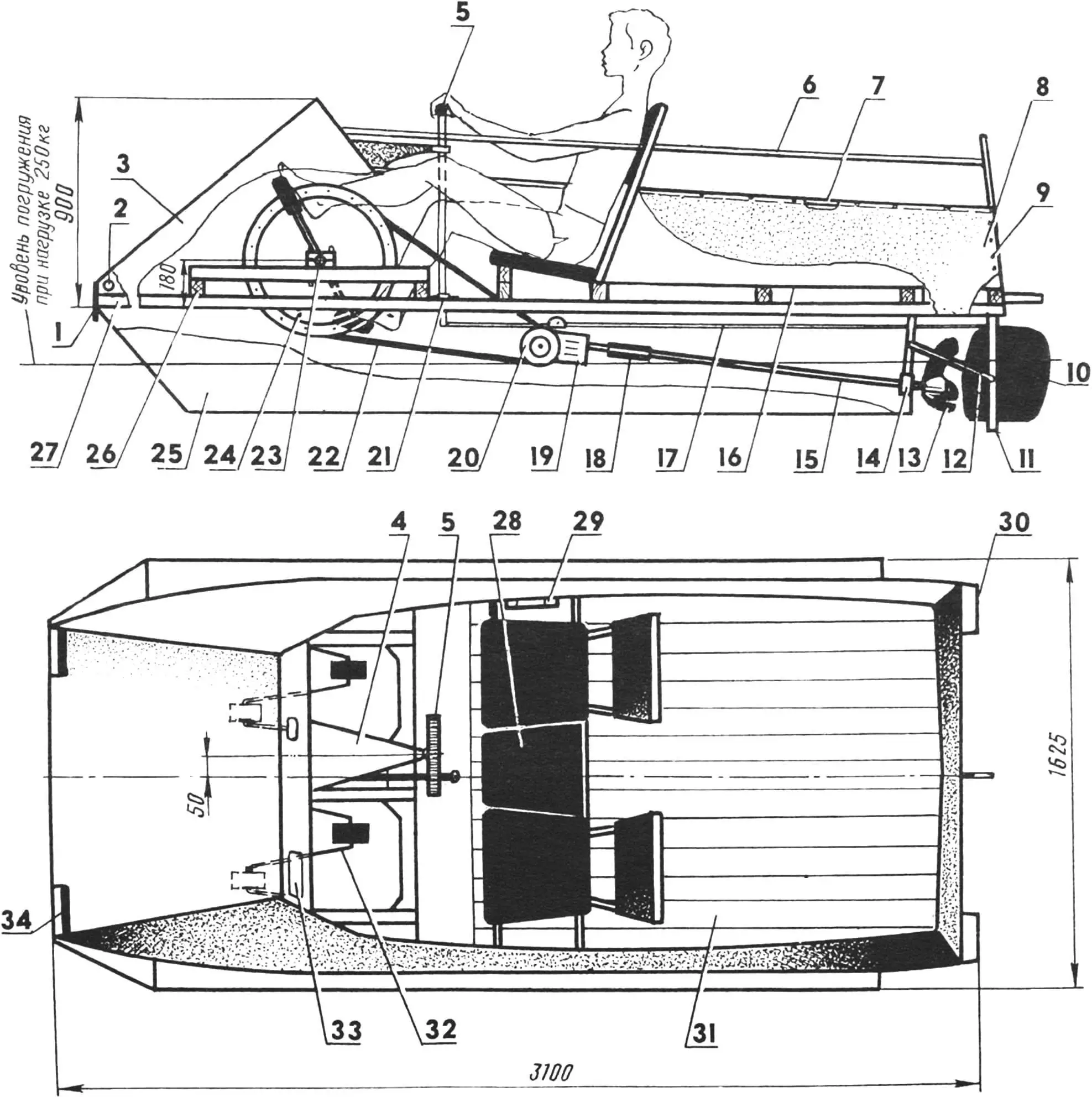

1 — bumper, 2 — cross member (tube Ø 30), 3 — nose fairing, 4, 21 — steering post brackets, 5 — steering wheel, 6 — guardrail (tube Ø 30), 7 — sheathing frame (angle 15×15), 8 — sheathing, 9 — bolt M4, 10 — rudder blade, 11 — rudder blade bracket, 12 — strut (2 pcs.), 13 — propeller, 14 — propeller bracket, 15 — propeller shaft, 16 — floor (plywood), 17 — steering rod, 18 — coupling (rubber tube), 19 — reducer, 20 — driven pulley, 22 — V-belt, 23 — crank bearing, 24 — drive pulley, 25 — left float, 26 — deck transverse rail, 27 — deck longitudinal rail, 28 — hatch-seat, 29 — anchor hoist wheel, 30, 34 — handles for carrying the aquaped, 31 — deck, 32 — crank (pedal unit), 33 — instrument board (road headlight conventionally not shown).

The watercraft’s design is quite simple, so I don’t think there’s a need to describe it in detail. And hardly anyone will take on building a copy. I think it’s enough to use the main idea and take into account the shortcomings that appeared during operation.

The “Dolphin” consists of two floats, a deck, and a body, on which a windshield and a roof-tent can be easily installed in a matter of minutes.

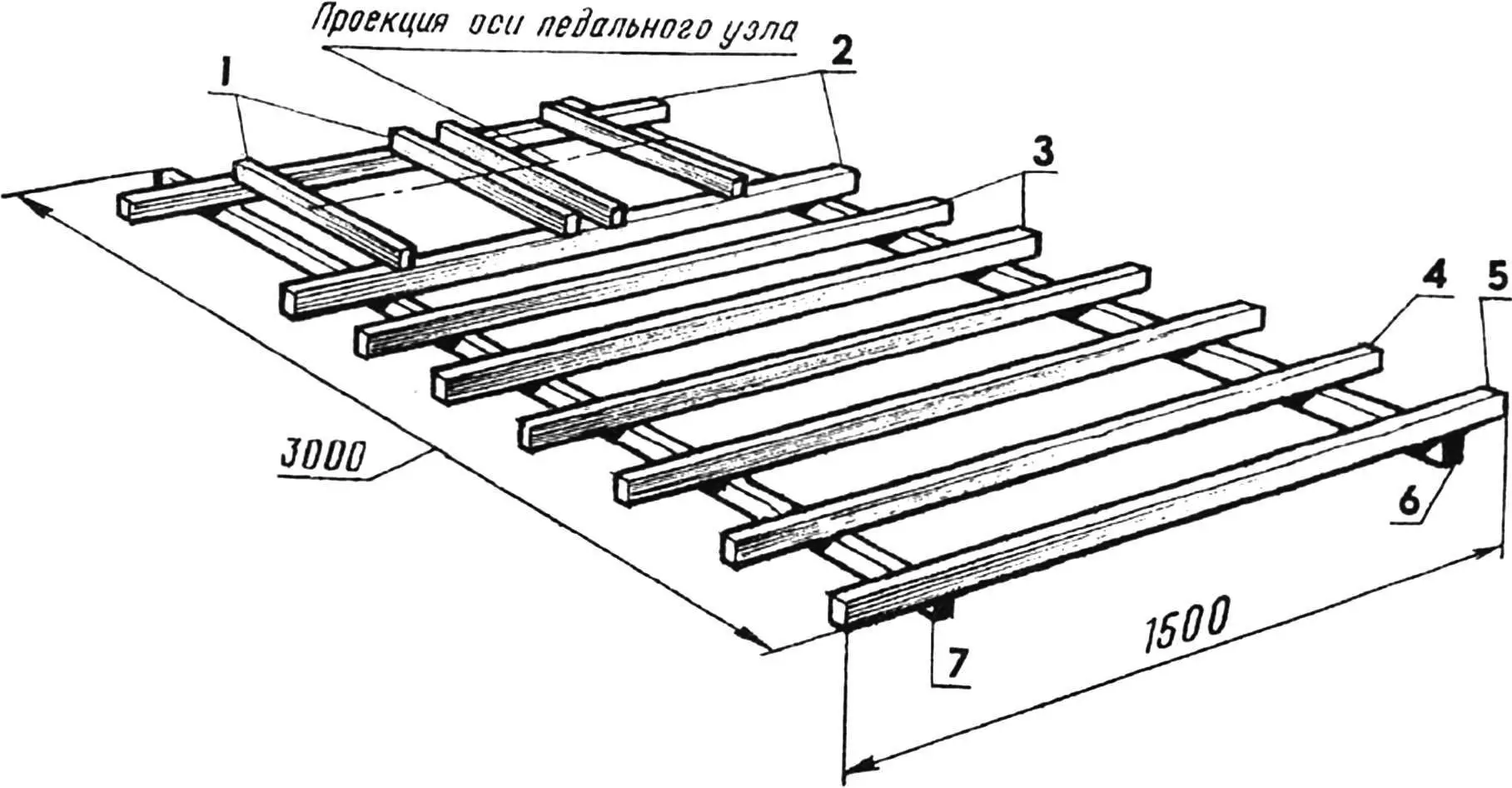

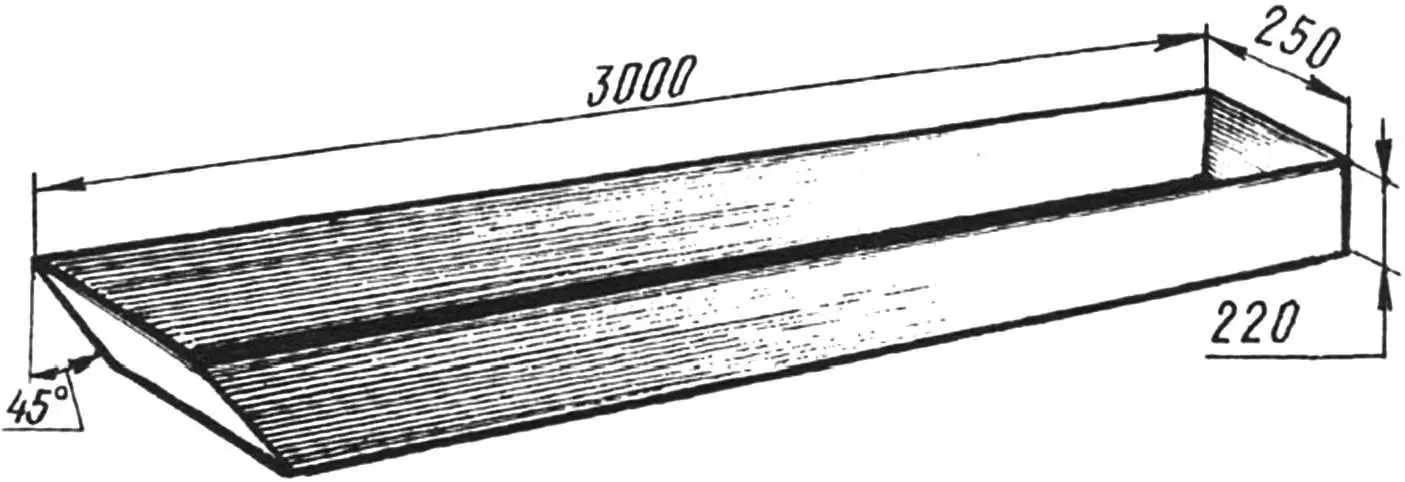

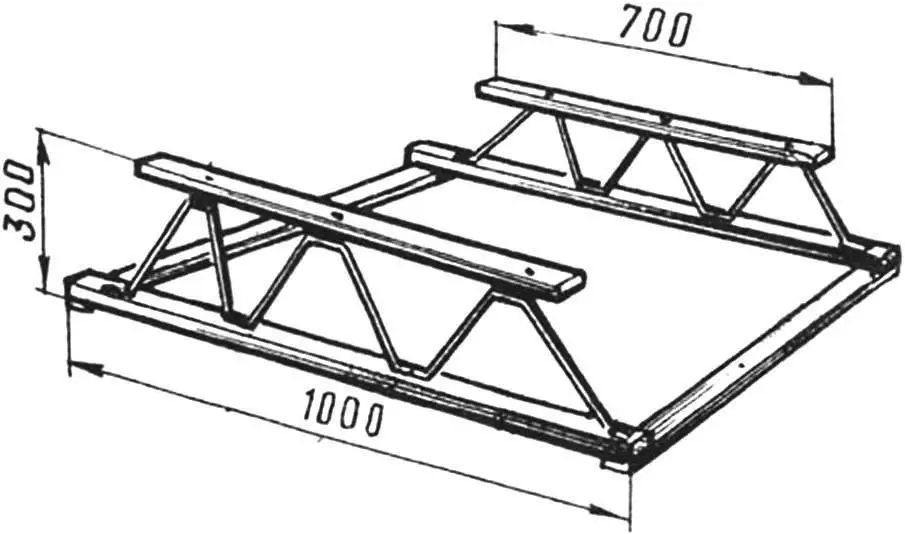

The deck is assembled from longitudinal and transverse wooden rails connected with screws, with cross-sections of 40×30 and 50×30 mm respectively, and covered on top with 3-mm plywood. The seats are made folding from 10-mm thick plywood, covered with foam rubber and oilcloth. Under the left seat is a box with the road headlight battery, under the right — a tool box. The middle seat serves as a hatch cover, through which the reducer can be inspected or the drive belt tension adjusted.

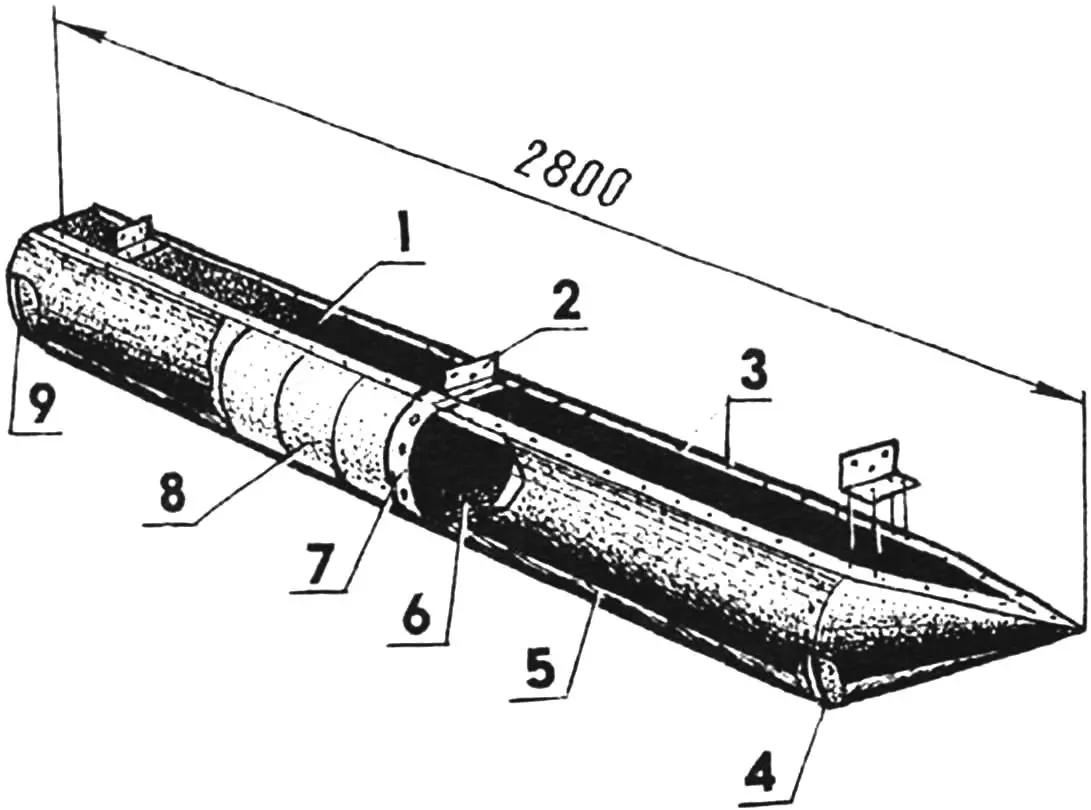

The body frame is assembled from duralumin angles and tubes (some of them are ski poles) and sheathed with thin duralumin sheets. Fastening — with M4 bolts. The front of the body is reinforced with a transverse 30-mm diameter duralumin tube, the ends of which serve as handles for carrying the aquaped (two other handles are at the rear), and a bumper — a 10-mm plywood overlay.

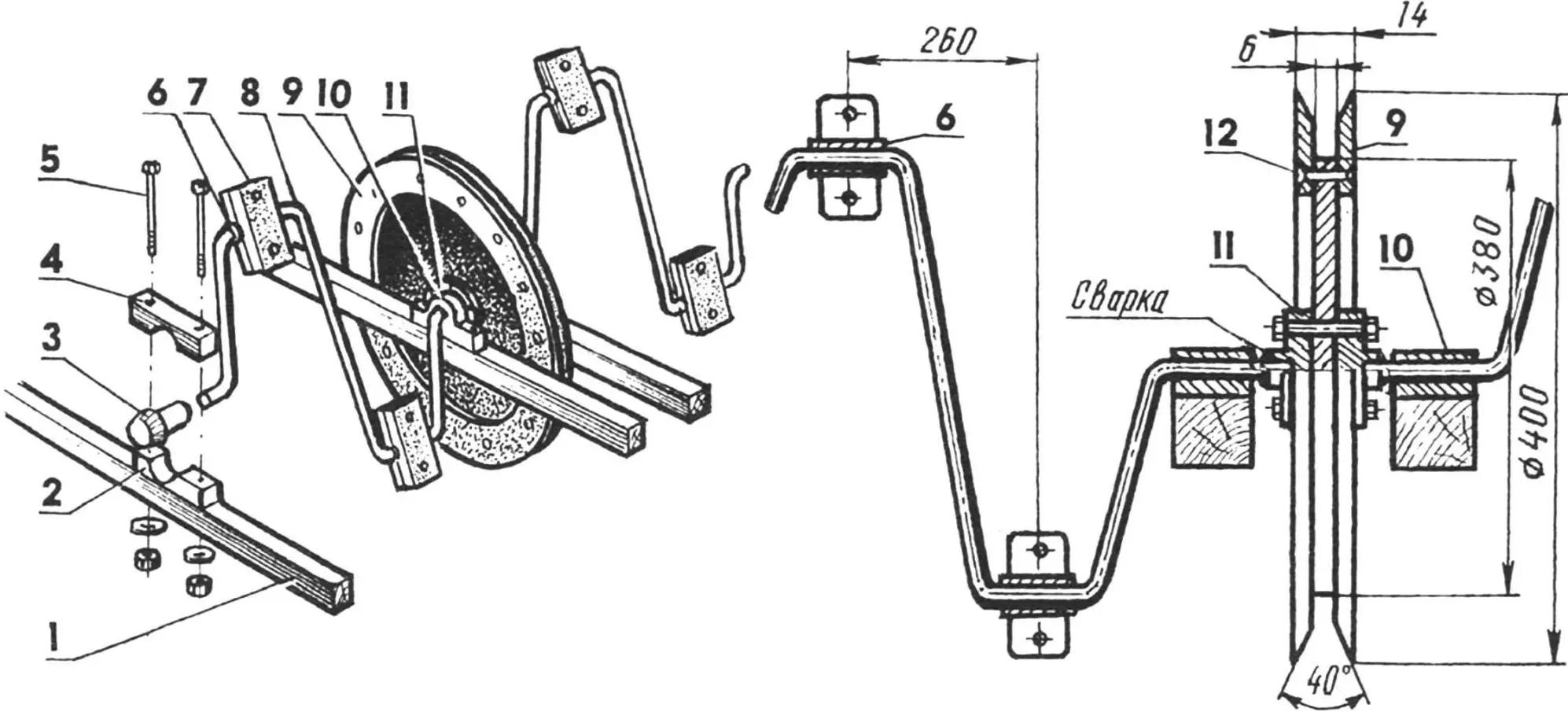

1 — longitudinal support, 2, 4 — crank bearing housing halves, 3 — bearing (polyethylene plug), 5 — bolts M8, 6 — pedal bearing (tube), 7 — pedal, 8 — crank (rod Ø 14), 9 — drive pulley (conventionally increased in thickness), 10 — pulley bearing race, 11 — flange, 12 — rivet.

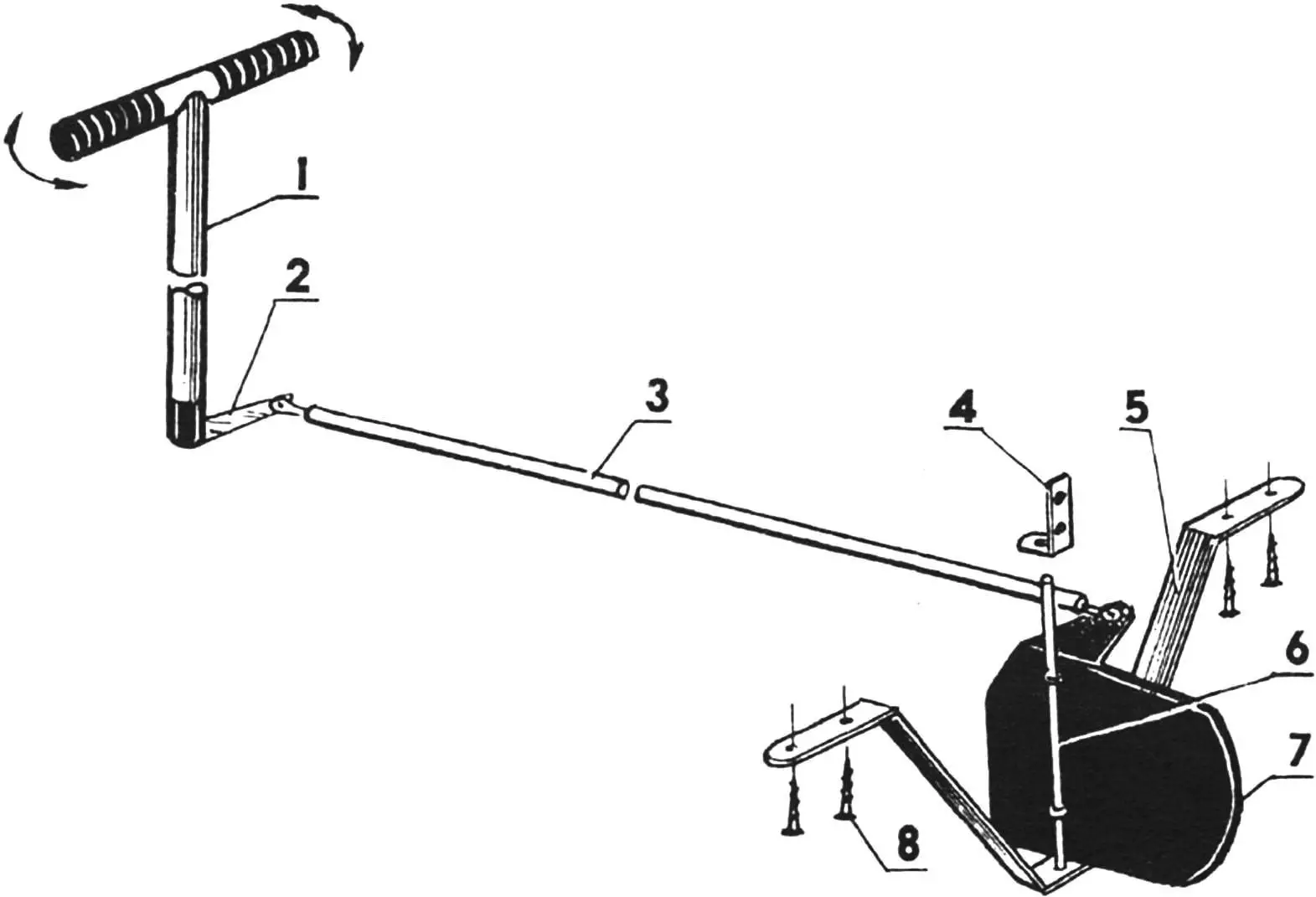

The aquaped moves by the muscular power of one or two people seated on the seats. The effort from the legs is transmitted to the propeller — a three-blade propeller 270 mm in diameter — through the pedal drive, V-belt transmission, and reducer. The V-belt transmission ratio is 1:3.9, the reducer — 1:2. Thus, for one revolution of the pedal drive, the propeller rotates around its axis almost eight times. This is quite enough for the aquaped to move at an acceptable speed — about 7 km/h. And backward almost as well as forward.

Both cranks of the pedal drive are bent from 14-mm diameter stainless steel rods. Before bending, two 80-mm long steel tubes each are put on the rods, to which wooden pedals are then attached. The ends of the cranks facing the sides are equipped with bearings — polyethylene plugs from champagne bottles. Flanges for mounting the drive pulley of the V-belt transmission are welded to the other ends.

1,2 — longitudinal and transverse pedal unit supports (rails 50×30), 3 — seat supports (rails 50×30), 4 — propeller bracket holder (rail 50×30), 5 — rudder blade bracket holder (rail 50×30), 6,7 — longitudinal load-bearing supports (rails 30×40).

The drive pulley is riveted from three aluminum discs with a total thickness of 14 mm, profiled to match the cross-section of a type A V-belt.

The driven pulley (100 mm in diameter) is plastic. It is installed on the reducer’s input shaft. As the latter, the mechanism of an electric grinding machine was used, from which only the housing, gears, and armature shaft were left. The reducer’s output shaft is connected by a piece of rubber hose to a thin-walled 20-mm diameter duralumin tube — the propeller shaft.

1 — steering column, 2 — rocker, 3 — rod, 4, 5 — upper and lower brackets, 6 — axis, 7 — rudder blade, 8 — screw.

The aquaped is controlled manually. The driver, turning the steering column around the vertical axis, transmits force to the rudder blade through rockers and a rod. The column and its handles are made from 30-mm diameter duralumin tube, the rod — from a ski pole, the rocker, both rudder blade brackets, and the blade itself — from a 4-mm thick aluminum plate.

All wooden and metal surfaces of the aquaped are carefully painted to protect against water exposure.

Things weren’t so simple with the floats. The first set was made from 10-mm plywood, foam plastic, and fiberglass.

The main structural element of the float is a plywood longeron. Three angles made of thick galvanized sheet metal — brackets for attachment to the deck — are screwed to it from above with screws, and three plywood discs from below, with the spaces between them filled with foam plastic. The entire product is covered with epoxy resin, wrapped in fiberglass, and painted. Its weight is about 5 kgf.

However, the main advantage of the floats — low weight — could not outweigh their significant drawback — fragility. Even the structural features of the deck, which takes on the lion’s share of the loads, didn’t help. We had to replace the fiberglass float hulls, first with duralumin ones, and later — with steel ones, riveted (with sealed rivet seams) from thin (0.4 mm) sheet steel. The rectangular hulls are filled with foam plastic and closed with steel covers, which have plywood longerons inside and angle brackets for attachment to the deck on top.

1 — longeron (plywood, s10), 2 — brackets for attachment to deck transverse rails (3 pcs.), 3 — screws, 4, 6, 9 — bow, middle, and stern discs (plywood, s10, Ø 250), 5 — sheathing (fiberglass), 7 — foam plastic disc holder (duralumin strip), 8 — filler (foam plastic).

The new floats noticeably gained weight. But their strength became incomparably higher. We weren’t even afraid to drop the aquaped on grass or sand when carrying it to the water.

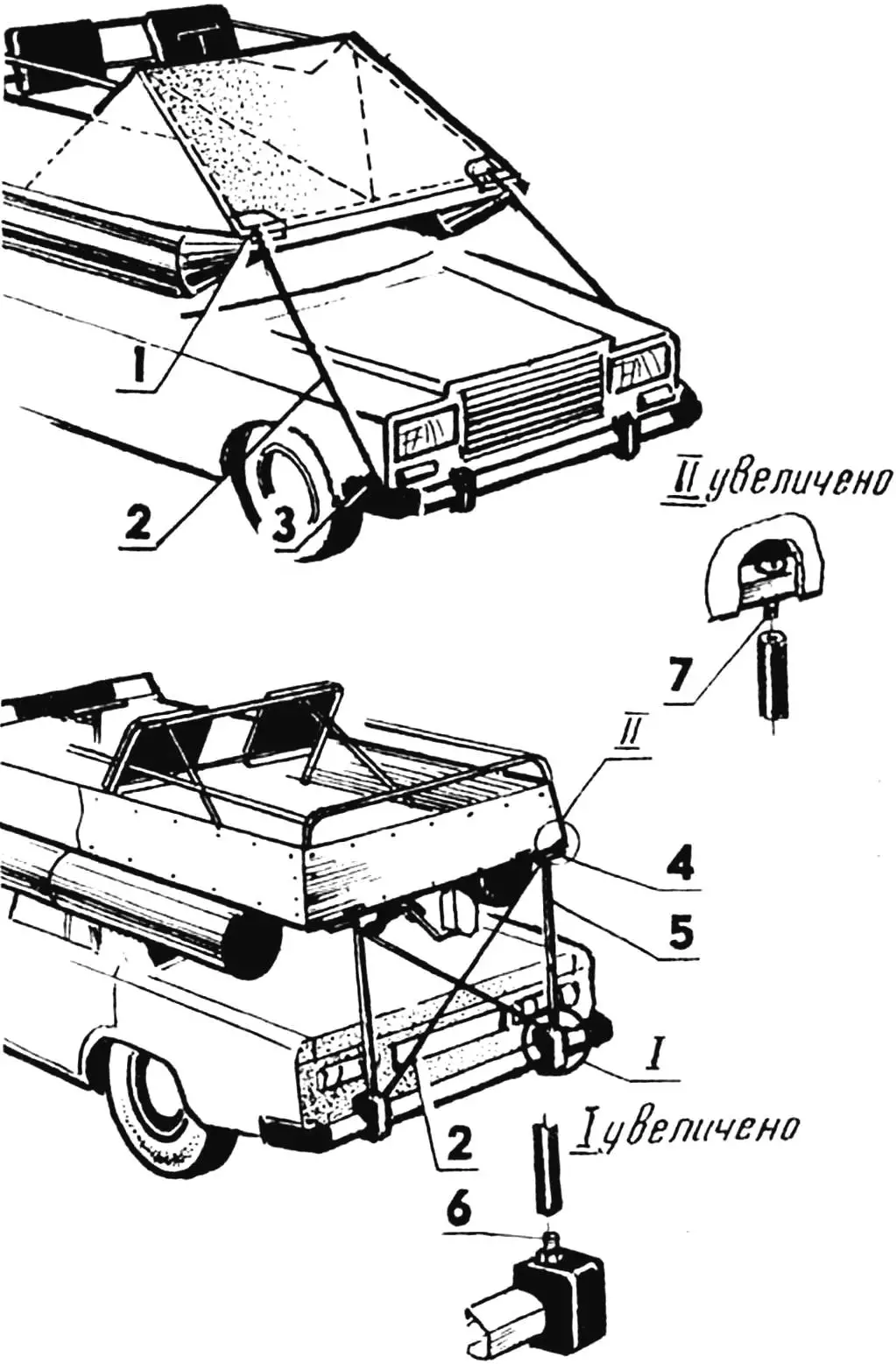

How did the “Dolphin,” with its impressive dimensions and weight, get from the city garage to the lake shore? It was transported on the roof of a car. For this, it was necessary to make a special rack for the roof rack from wooden rails and 18-mm diameter copper tubes, purchase four strong synthetic cords with hooks, and two duralumin tubes for attaching the aquaped to the front and rear bumpers.

1,4 — front and rear handles for carrying the aquaped, 2 — synthetic cord, 3 — hook, 5 — support (duralumin tube), 6, 7 — support fixing bolts.

Of course, it’s impossible to load such a behemoth weighing more than 70 kgf onto a car alone. It requires the efforts of three or four adult men. Therefore, it makes sense to take it to the water body only when a large group gathers. But the pleasure of riding the aquaped is unforgettable!

“Modelist-Konstruktor” No. 6’97, S. RUDENKO, Slutsk, Minsk Region