The idea to use as a vehicle motor wheel is tempting. She became interested in members of the laboratory design of compact machines Cute Siberian branch of the USSR ninth-graders Sasha Titarenko and Vitaliy Molchanov. They were attracted by the compact device, no transmission and therefore no loss of mechanical energy in the intermediate links, that is, a higher efficiency motor wheel converting input electrical energy into mechanical energy and the transfer of the latter directly on the propeller — wheel.

The idea to use as a vehicle motor wheel is tempting. She became interested in members of the laboratory design of compact machines Cute Siberian branch of the USSR ninth-graders Sasha Titarenko and Vitaliy Molchanov. They were attracted by the compact device, no transmission and therefore no loss of mechanical energy in the intermediate links, that is, a higher efficiency motor wheel converting input electrical energy into mechanical energy and the transfer of the latter directly on the propeller — wheel.

All this they tried to use when designing your two wheeled machine. Turned electroboiler with both leading wheels, and engines mounted directly in the wheel hubs. Unusual the machine is moving at a speed of 20 km/h for 30 min, power Source is car battery with a capacity of 68 Ah/h, which is not enough for a long drive. A greater number of lead batteries dramatically increases the weight of electrosolar. But this is a “world problem”: until now, there is still a massive cheap, lightweight and energy-intensive batteries. Nevertheless, from the point of view of technical experiment design electroboiler with the use of motor-wheels, of course, will be of interest to readers of the journal.

6 wheel size 400X100 mm used from a decommissioned machine for mowing lawns, it is Desirable to use wheels with a smaller outer diameter, then substantially improve the dynamics of electroboiler

Electroboiler both wheels driving. As the power unit used two ministarter GS scooter T-200, located in the wheel hubs. This electric DC motors with serial excitation. Their advantage is that they are not afraid to overload and develop a large torque when starting off.

The use of ministarter DC as the power unit for the motor wheel caused by its design. If conventional electric motor is placed outside the stationary portion, and inside is rotating, then ministarter the opposite: the rotating part is placed outside, fixed inside the motor that is best suited for the motor-wheel.

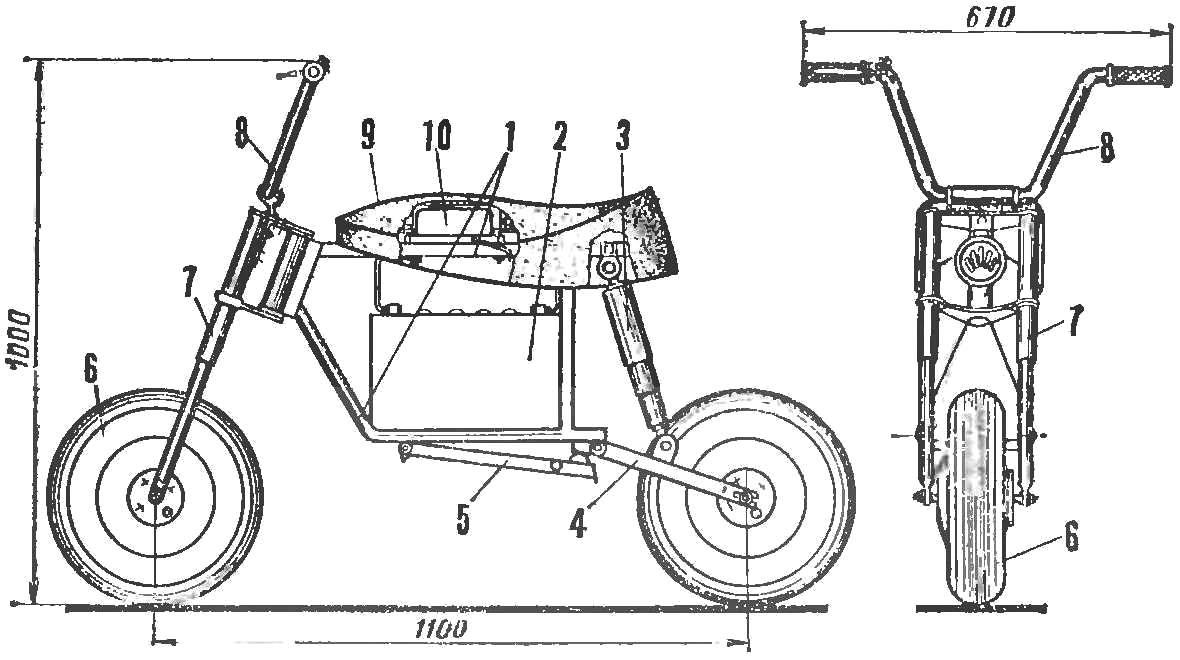

Fig. 1. Electroboiler, side view to the front:

1 — frame 2 — battery; 3 — absorber; 4 — way fork; 5 — step; 6 — motor-wheel; 7 — front fork; 8 — wheel; 9 — seat; 10 — start relay.

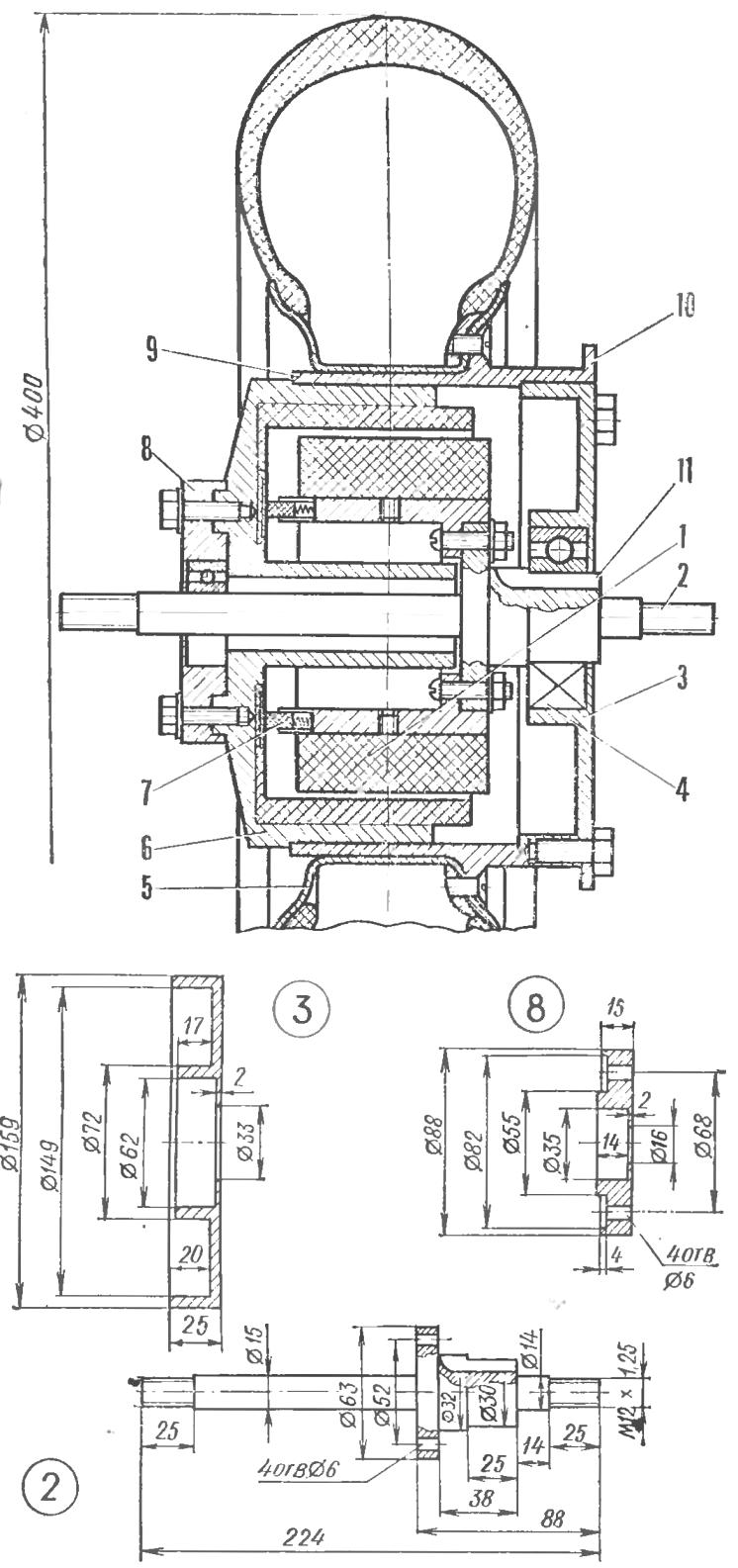

Ministarter mounted directly in the wheel hub (Fig. 2). This required to make only a few parts: finish machining the axis 2, the large lid 3, the case 8 and the glass 9. In a glass pressed on the rotor ministarter. In the axis profiterole groove 11 of the power wires of the motor.

The Assembly is conducted to the rotor of ministarter bolts M8 case 8 with the bearing No. 202. The stator is inserted in axis 2 and is fixed with M6 bolts. Now the axis with the stator is inserted into the rotor. Axle worn cover 3 with the bearing 4 (No. 206) is attached to the glass by bolts M8. Finally, the entire engine Assembly is inserted into the rim 5 of the wheel and fastened with screws M6.

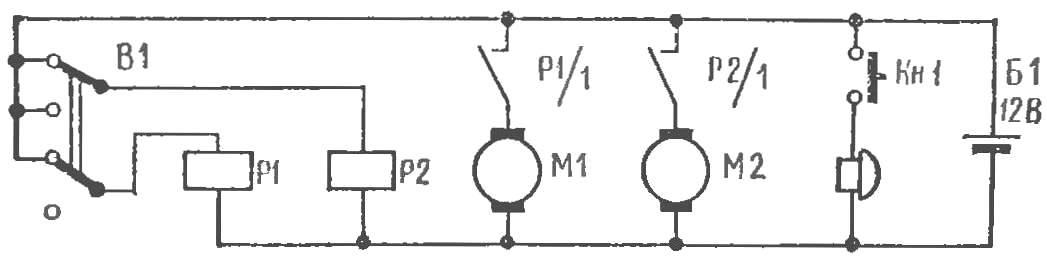

To turn on the engines used in the two start relays P1 and P2 (Fig. 3) from the written-off relay-regulator RR-121 motoroller T-200. They connect the motor winding with the battery. Relays are mounted on a plastic panel, closed lid from PP-121 and fixed to the frame under the seat. Controlled by the starting relay lever light switch B1 of the scooter T-200. This switch only closes the circuit of the crank relay, and through it passes a small current.

Switch mounted on handlebar on the right and has three positions: “off”, “on the front of the engine, on both engines”.

Fig. 2. Motor wheel:

1 — stator of ministarter; 2 — axle; 3 — large cover; 4 — the bearing № 206; 5 — wheel rim; 6 — ministarter rotor; 7 — brush; 8 — body; 9 — glass; 10 — restrictive collar for band brake, 11 — groove for the wire.

At the first click of the switch closes the circuit from the battery through the switch, the coil of the first relay — to ground (minus of the battery is connected to ground). The core relay is magnetized, attracts the anchor with a movable contact. Current from the battery through closed contacts will be held in the motor winding the front wheel. To improve acceleration, move the switch on the click of the switches in the same way the engine of the rear wheels. After the dissolution of the switch moves to click the back — the rear engine is shut off, just go to the front of the engine.

Use as a drive wheel in front, pulling, rather than the rear pushing, like a motorcycle greatly improves stability when driving on slippery land, eliminates drifts.

Brake belt type — only on the rear wheel, which on the glass of the engine there is a special collar (see Fig. 2, POS, 10) holding the belt from slipping off. The drive of the brake cable through the lever on the right handlebar.

With this design, the motor we use only seriesnow winding of ministarter consuming a lot of current. Probably to save power you can use and cost-effective shunt winding Dina-starter, and switch on it after overclocking.

Fig. 3. The circuit diagram:

B1 — switch; R1, R2 relay; P1/1, P2/1 — relay; KN1 — button; M1, M2 — motors; B1 battery.

“Dear editors!

In No. 4 of your journal this year, under the Competition of ideas” was published article “Electroboiler”. This idea is, of course, rational. However, when designing Masha you need to consider the following calculations.

On electrosolderie proposed power plant with a capacity of 350 W is 0,475 HP, or, rounding, — 0,5 HP If you use batteries 6ST-42, giving a voltage of 12 V, E-42A/h, the total weight will consist of the weight of the driver is 70 kg, the battery weight is 40 kg and the tare weight of electroboiler — 60 kg total 170 kg. And it is certainly less than happens in reality, but it is possible.

Then the machine at a power of 0.5 HP can reach speeds of 7-10 km/HR, not 45— 50 km/h. it is Known that logs traffic police cars and motorcycles with a power / weight 20-25 HP This means that our handmade will have the total weight reduced to 25 kg, that’s impossible!

Otherwise, all the modes are well matched. The discharge current of ZOA, the most favorable for our case. However, you will increase the power of electroboiler because that will put two of the engine? I would like to know about the structures and experiences of other readers who are building electroboiler”.

D. ORLOV, mechanic, Naberezhnye Chelny

“Having read in your journal a proposal to make electroboiler, we decided to create our own design. On the first test was obtained speed of 36 km/h with power of 0.6 HP motor, the power Reserve on one lead for the battery is 5 km away.

Frame — double (duplex), made from a tube 19X1.5 mm, lightweight and durable. Wheels: rear — 2,50X16, front 2,25X19. Its total weight is 63 kg.

Would be grateful if you in the journal will tell you about other designs.”

S. STEPANOV, A. LUNEV, Voronezh

A. TITARENKO, V. MOLCHANOV