Once upon a time, according to the Bible, Noah built an ark and saved his family from the Flood, and at the same time all life on Earth. I, of course, cannot in any way compare myself with him. However, after the first month spent in self-isolation this spring, I began to seriously think about whether I should put my wife, son and daughter on a boat, and sail with them somewhere far away from Moscow with its viruses, masks and gloves, mayoral decrees, passes and fines. For example, go on a trip to the Karelian lakes for the whole summer, live on the shore, eat caught fish, teach children to communicate with nature. And so that there are no all-knowing TV doctors nearby, no TVs at all, no phones, no Internet, no ghost of a pandemic wandering around the world.

I wanted to start planning the details of the route and the transfers to it, but I remembered in time that… eh, I don’t have a boat! There used to be a homemade sailing “inflatable”, but it burned down six months ago along with a motorcycle, equipment, a bunch of camping equipment, and the motorcycle club itself, where all this stuff was stored (it’s good that the hang-glider was at the airfield at that time, that saved it). And it is unlikely that the family budget, which has been greatly undermined in the current quarantine situation, will withstand the acquisition of this entire farm. I was upset, of course, but the thought of a new watercraft stuck firmly in my head…

And one day, walking with my son through the nearby forest, I suddenly clearly saw a solution to the problem. Point one: you don’t need to buy a boat, but make it yourself. The second point is to make it using the most accessible, even primitive, materials, that is, the same walnut rods (for how I made a children’s chair from walnut sticks – see “M-K” No. 7-2020 ), connected in frame and covered with something that does not allow water to pass through as a shell. It will look like an Eskimo kayak or an Indian canoe.

As a technical person with a systematic approach to all issues, returning home from a walk, I delved into the search for analogues of the intended design: after all, someone has probably already studied this topic, so why abandon the experience of predecessors. And, of course, I found such examples. And quite a lot. At first glance, judging by the videos on YouTube, everything is really simple and cheap. Even very simple and very cheap. We knit a frame of twigs with ropes and wrap it with stretch packaging film purchased at the nearest hardware store. You will need one or two rolls of film and a skein of synthetic twine. Next, we cut a hole in the “deck”, fix the edges with tape – that’s the whole technology.

On the whole, I liked the concept of a boat “out of nothing,” but a more detailed analysis of “Internet designs” showed that almost all of them do not meet my goals. Some of them were made as “survival tools”, not intended for long-term or even repeated use (they swam across a river or reached civilization and threw them away). It is clear that with such an “extreme” approach there is no time for choosing materials and exquisite forms – use what is at hand, the main thing is not to drown. Other homemade products, and the majority of them are on the Internet, are even worse. It’s unlikely that after filming the exciting video they were launched into the water again. And they were made solely for the sake of “likes” and “hype,” as they say now (increasing the number of views on the author’s channel and “hype from scratch,” if translated into normal Russian).

My requirements for the craft (except for cheapness and simplicity – with this the “film ship” is really all right) were the following.

First, I need a “reusable” boat that is designed to last at least one season. Or more: replace the shell after a year and you’re done! Consequently, the frame must be made thoroughly: not on branches tied with bows, but according to the classical rules of shipbuilding, which require full-fledged longitudinal and transverse structural elements.

Secondly, since such a boat is non-dismountable, a certain “living space” is required for its storage. I don’t have the opportunity to allocate a separate room or at least half of the balcony for this purpose. This means that I need to try to make her “fit” into my apartment.

Well, thirdly, which is also important for me, is the engineering, innovative and aesthetic component of the project, which should instill in my children (my son and daughter are still very young) a craving for creativity. In other words, the boat must be original, technically and beautifully designed.

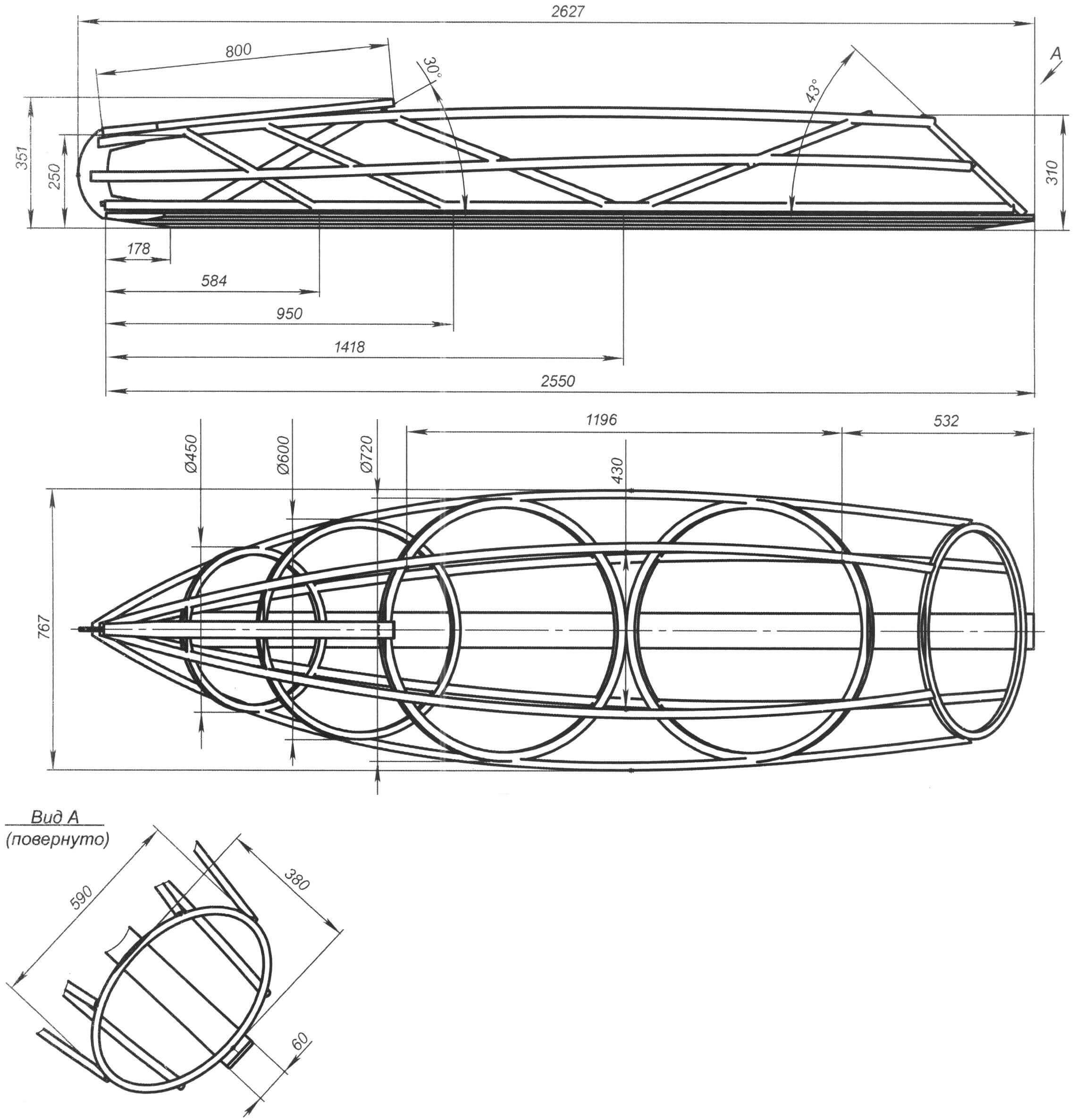

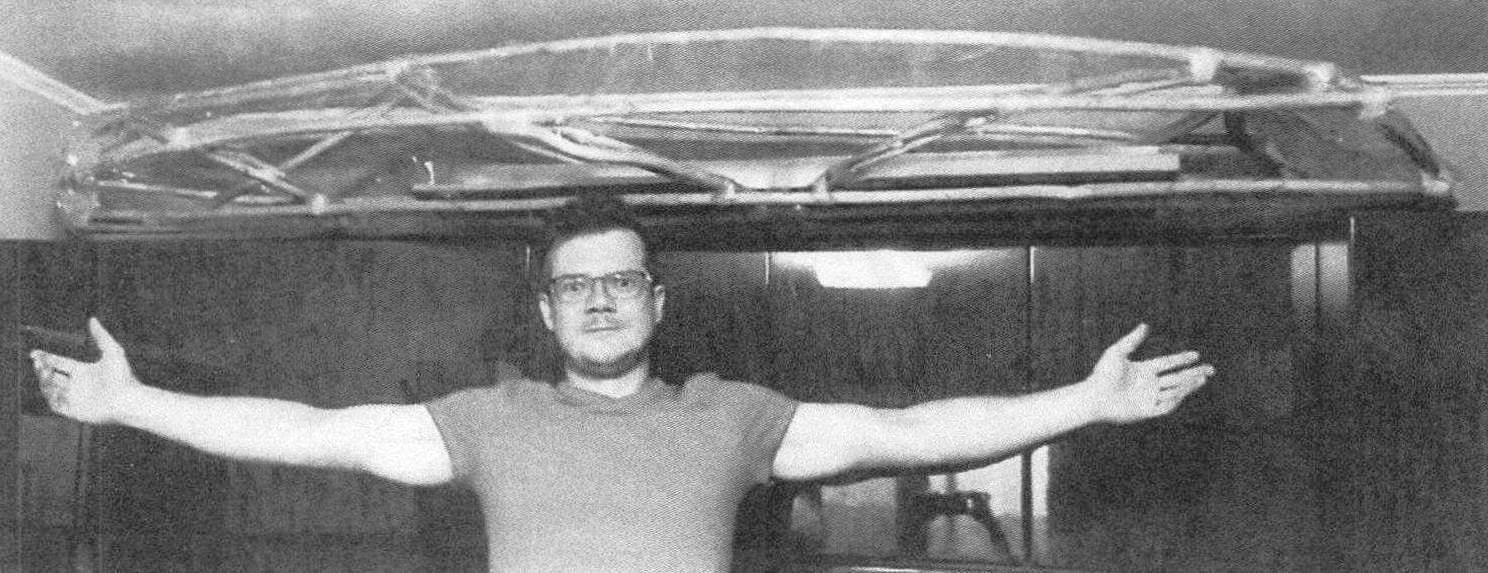

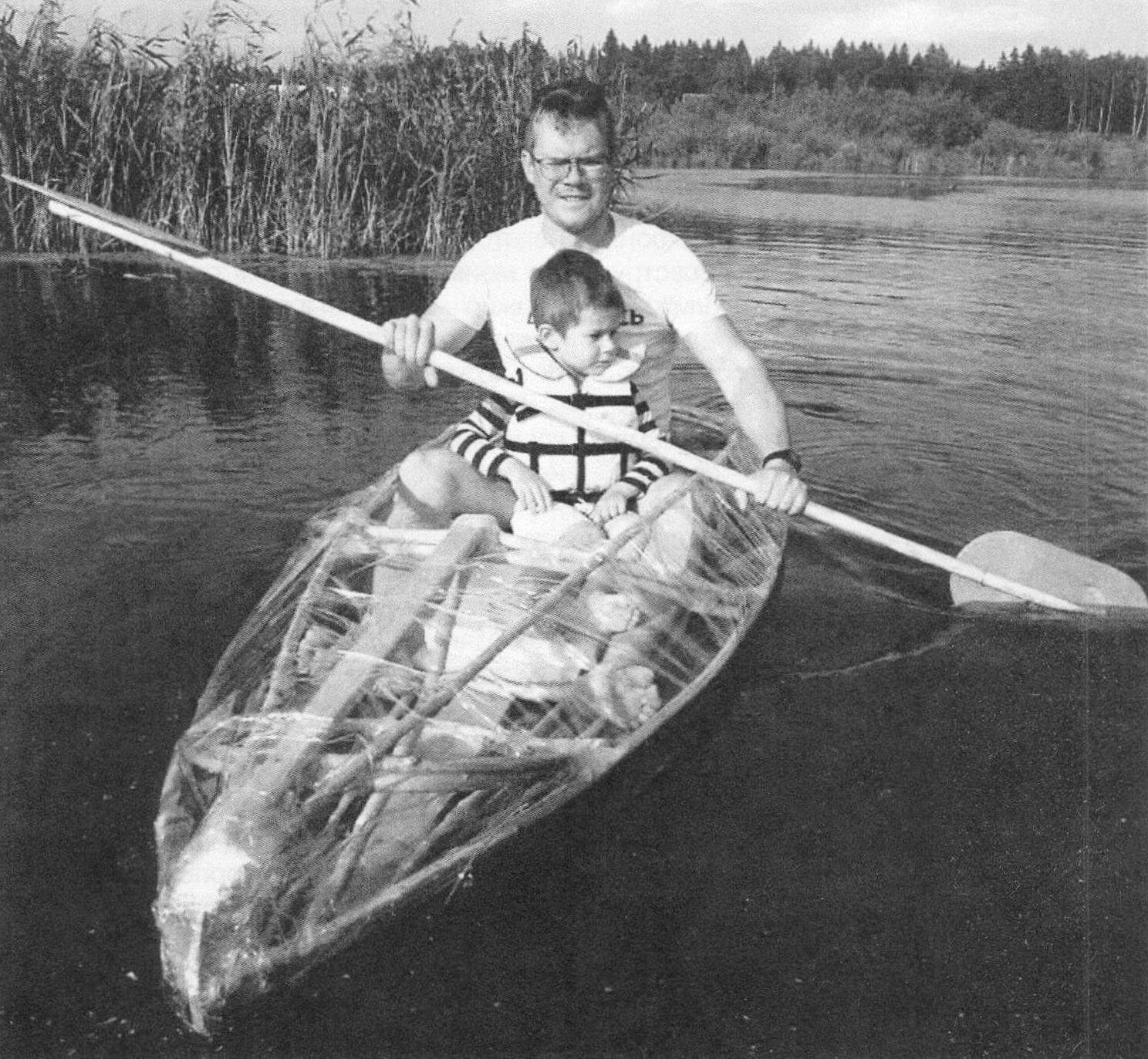

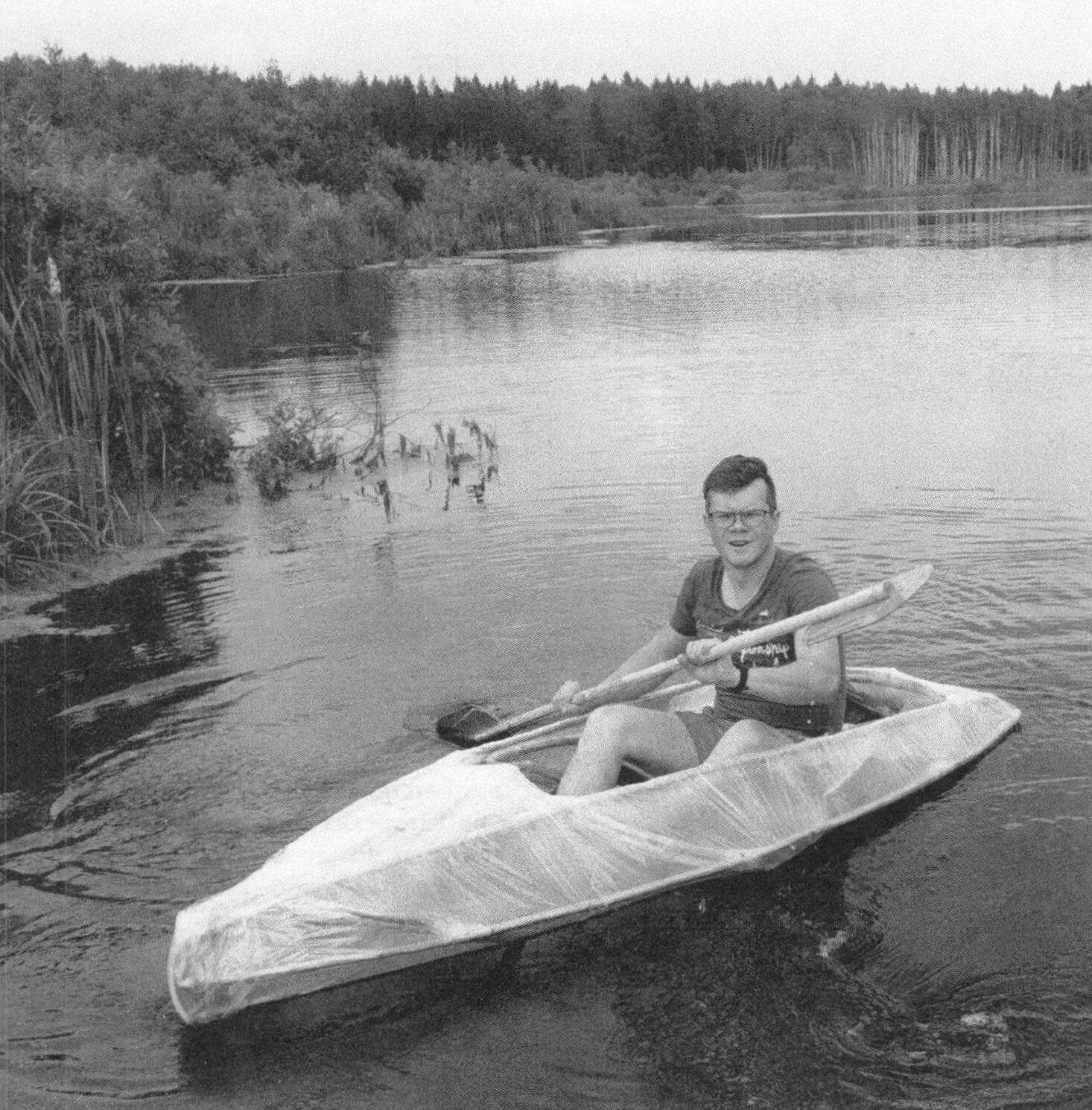

Thus, based on the specified requirements of the technical specifications, even before the start of construction of the vessel, its dimensions were determined: length – 2650 mm, width – 750 mm, height – 350 mm. I would love to start building a larger ship, but such small dimensions were dictated by its storage location – in a room in a city apartment, lying under the ceiling on a Soviet-era furniture wall. The need to transport it by freight elevator, as well as delivery to the nearest body of water using the “shoulder” method, was also taken into account. Doing this with a long boat would be much more difficult.

But the width of the hull was determined based on the desire to get not a single-seater boat, but a “one and a half” boat, so that you could take a child on board. By the way, even at the stage of getting acquainted with various options for such structures, I immediately noticed the narrow mounting holes in them – these definitely do not suit me. And they are unsafe in case of overkill: you can get caught, get tangled with your feet and not get out. And all sorts of water-slalom “Eskimo coups” are not for us yet.

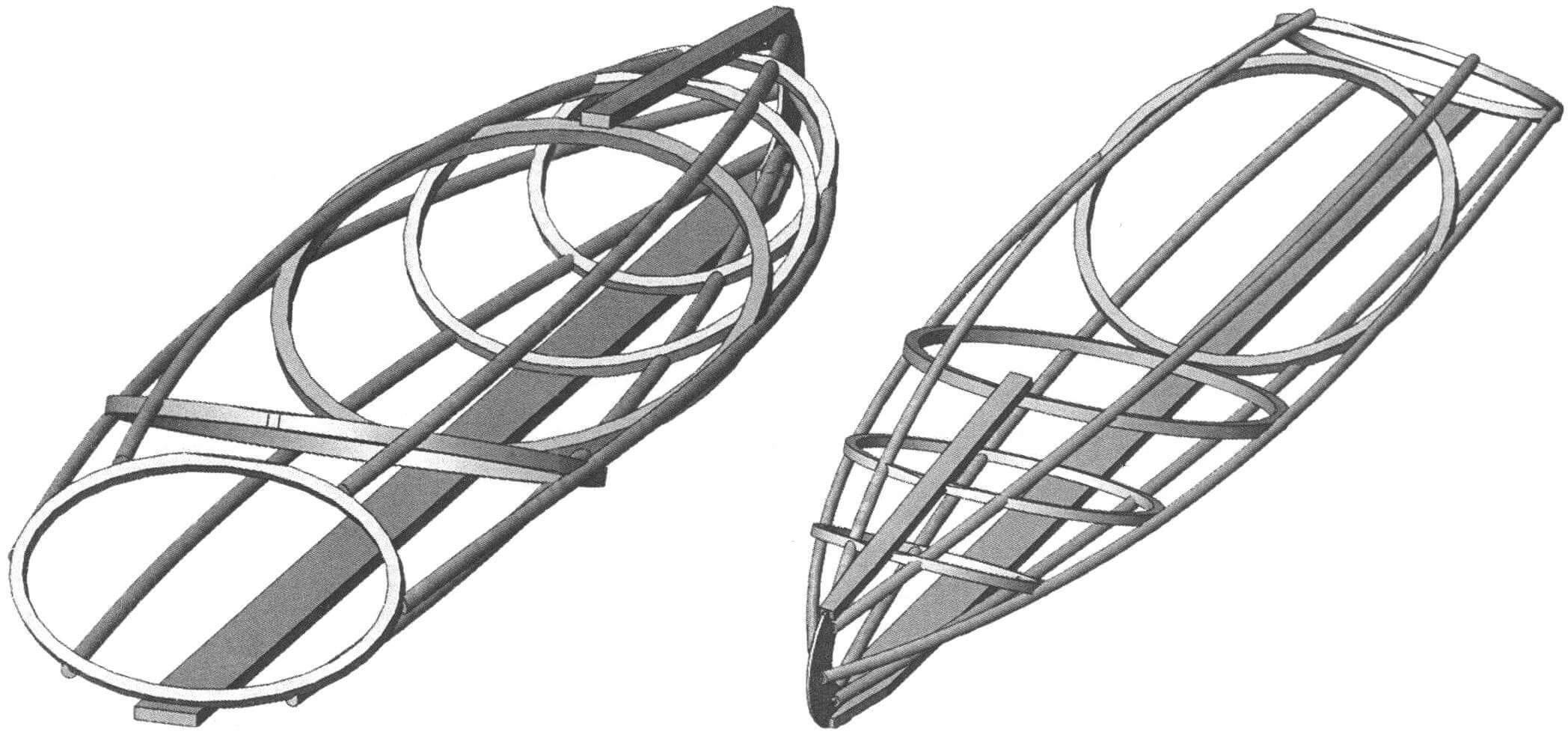

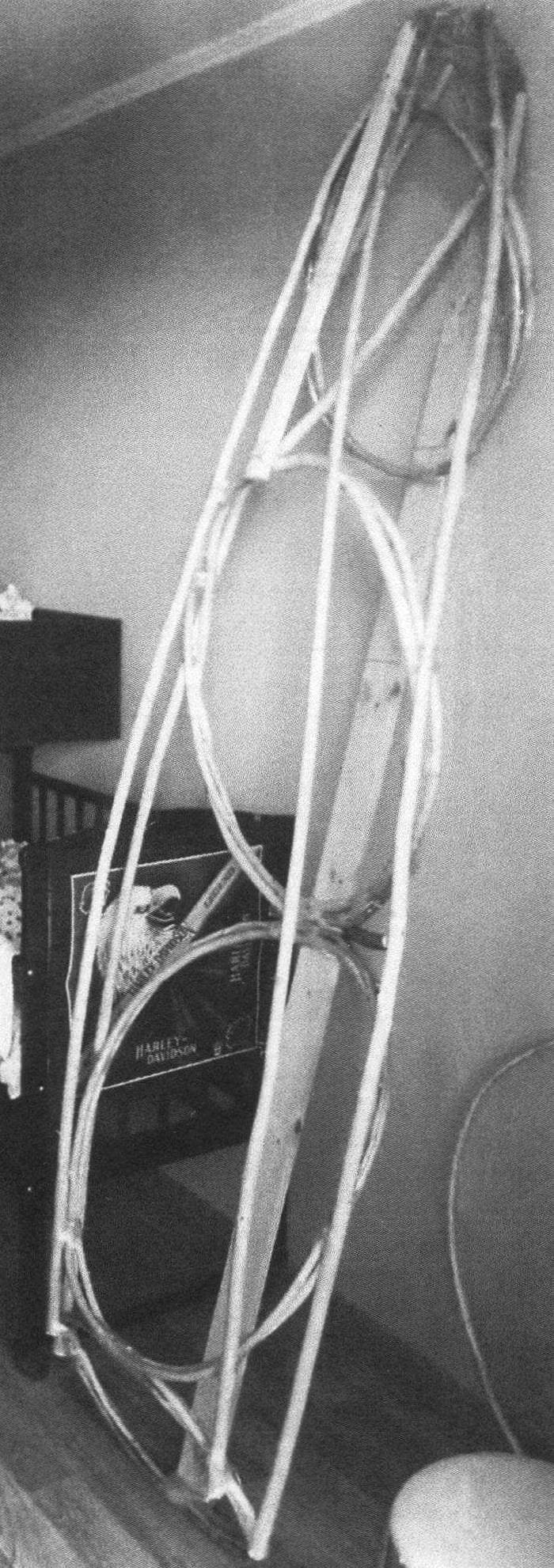

Having decided on the fundamental points, I moved on to the actual design. I drew several options for 3D models of the frame, which can be rotated on the computer screen, selecting the desired contours of the body and taking measurements obtained “on the spot.” Please note: for greater reliability of the design, it was decided to make all transverse elements of the set (frames and transom) closed, and located diagonally with fixation among themselves. In connection with the longitudinal elements, they form a fairly rigid spatial truss with minimal weight.

As the main material for the manufacture of stringers (longitudinal elements of the frame), the choice fell on hazel trunks with a diameter at the base of approximately 25 mm. So that the “green defenders” do not worry, I will repeat what was said in the last issue: in our forest there are whole thickets of them, which no one is thinning out. So, there is plenty to choose from, and the forest will be cleaner. After a short search, I cut out six straight rods as blanks for the bottom stringers and frames for the cockpit, and a couple more a little thicker – these will go to the fender. But the keelson (the power “backbone” of the boat) was made from a flat pine board with a cross-section of 96×20 mm – this will be more reliable, given the possibility of sailing with a child. The same board served as a base (something like a slipway) for installing and fastening the elements of the set.

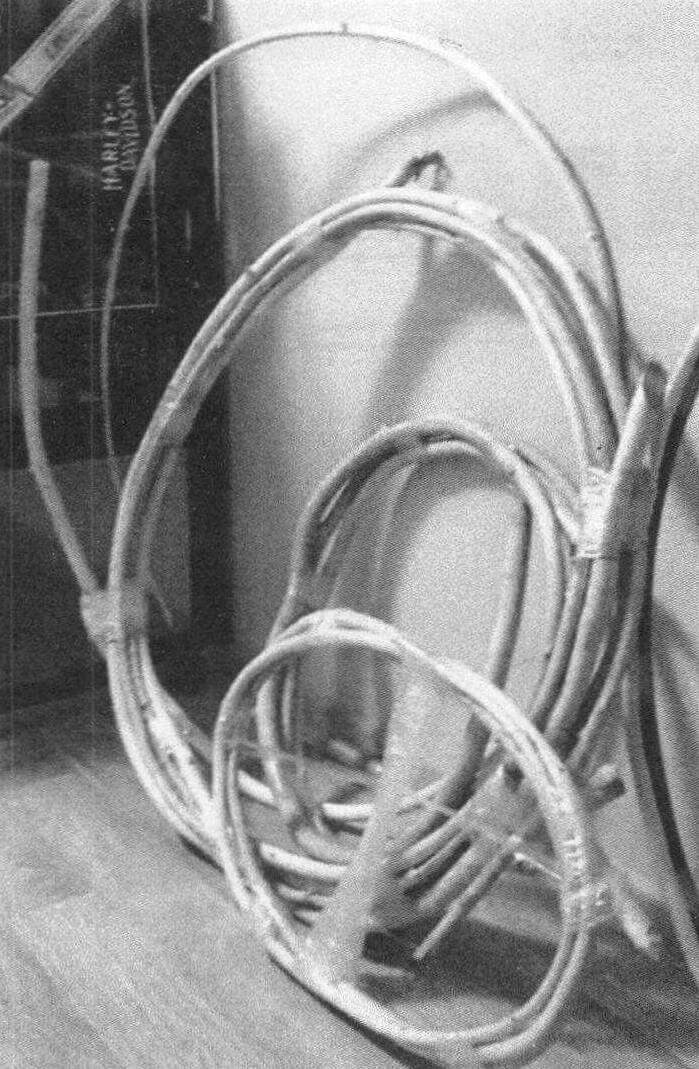

Rowan rods were used for the frames, transom and stem – they are more flexible than walnut rods. Immediately after sanding, they were formed into rings of the required diameter, fixed in this form and dried.

Having previously been accustomed to working mainly with metals and plastics, the anisotropy of wood and the peculiarities of working with it became a discovery for me. For example, we know very well, from childhood experience, that in order to wind a metal wire on a certain base, it is necessary to fix one end of it and, holding the other, wind it onto the base with a good tension. This trick doesn’t work with a tree! To perform such an operation with it, you must avoid creating a pulling force. Also, when bent, wood fibers compress perfectly even in their raw, unsteamed form up to 25%, but in the same state they can only elongate by 3%. Thus, when bending a workpiece, it is absolutely unacceptable to stretch it. If I had known this “trick” before starting work, I could have saved effort and time by avoiding a large number of broken parts.

Before bending a wooden rod into a ring, it is advisable to slightly deform its inner surface. For example, place the workpiece on the ground and, stepping on it with the outer edge of the boot, simultaneously pull the free ends upward. As a result of this operation, small creases are formed on the internal fibers of the rod, which will help in the future to bend it without cracking.

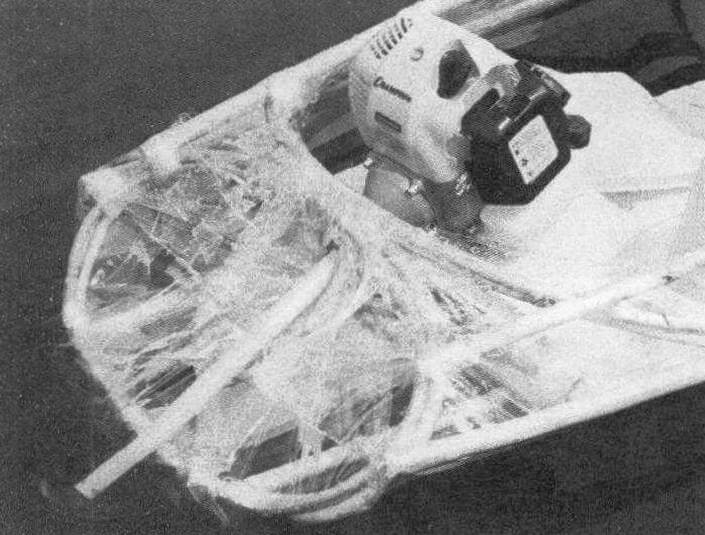

The parts of the set were fixed together using the aforementioned synthetic twine – it is strong and soft (it will not pierce the shell), and then the joints were wrapped with tape. No other fastenings were used. Although, in principle, ropes and wires are also suitable for connecting frames and stringers, they can only be used for binding pre-dried materials. The beauty of adhesive tape, in addition to its ease of use, lies in its elasticity. When the dimensions of parts change due to different levels of humidity, the place of their connection, wrapped with tape, will not be disturbed.

Having achieved almost perfectly symmetrical shapes of the frame, I started “covering” it, or rather, wrapping it with film. But not everything turned out to be as simple as first thought. Experiments were needed. As a result, three types of shells were tested in practice. The most useless of them was the stretch film, praised by all bloggers. When cutting the cockpit hole, the film tension drops and leaks appear between the layers. Polyethylene film for greenhouses behaved much better – in terms of price/quality ratio, it became a leader. Well, the most interesting choice seemed to me to be the use of PVC film with a thickness of 0.5 mm – it has exceptional transparency and is very durable. I settled on this option.

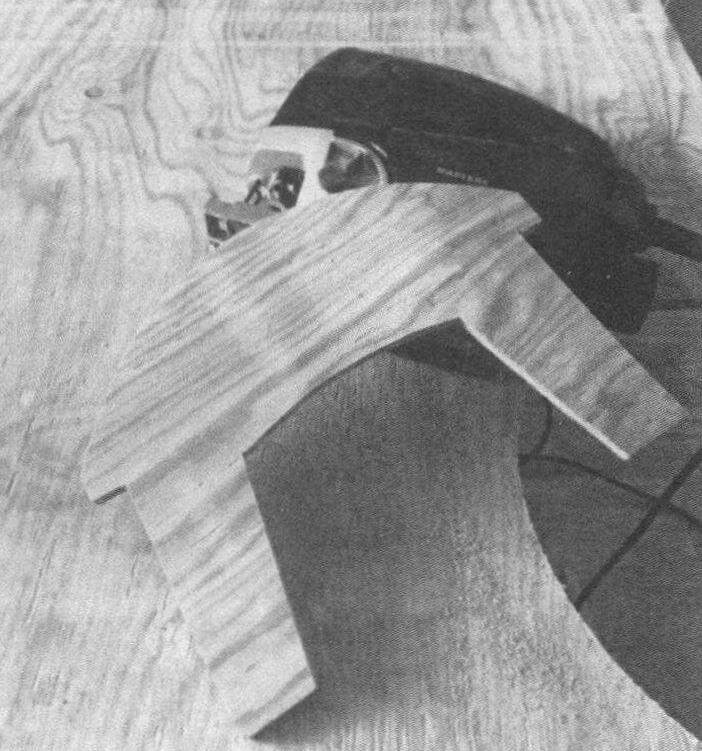

Polystyrene foam and a camping mat were used to make a “seat” can to accommodate the crew. They were tailored to the location so that it was convenient. The paddle is also homemade, made from a stick and two plywood blades held on with self-tapping screws.

It only remains to add that the boat presented here is intended for operation exclusively on calm water near the shore; the presence of life jackets is strictly required!

Well, we didn’t go to Karelia this summer – there was something to do close to home!

Vasily FENOGENOV