a deep fascination with the technique came to me in youthful years, when he began not only to repair the scooter, but to collect them from different old parts. Then, growing up, over to the motorcycles, have altered their own way: faced on your own taste (the word “design” then in my everyday life were not), made easier, more fashionable, more powerful, more comfortable.

a deep fascination with the technique came to me in youthful years, when he began not only to repair the scooter, but to collect them from different old parts. Then, growing up, over to the motorcycles, have altered their own way: faced on your own taste (the word “design” then in my everyday life were not), made easier, more fashionable, more powerful, more comfortable.

After serving in the army, in 1985 was acquired VAZ-2108 “Sputnik”. At the time the car was not studied, it reluctantly took on the service station, but because the repair had mostly himself, delving into her device, and it is even more “tied” me to the technique.

The fares on the “eight” for two years, started the car “tuned”: redid the bumpers, installed the spoilers — then it’s only became fashionable. The machine began to look attractive, to stand out among his fellows, and leave her for the night near the house became unsafe. The garage I was far away, and get up for work I had before, when public transport did not go. Then I decided to buy on the cheap an old ZAZ-965 (the”humpbacked” “Zaporozhets”), 1965 edition, which, sleeping under the window in the morning, rolled me to the garage, and in the evening back. I looked over, adjusted, and in the course and learned how to say, to death.

Got it I got in any frost, but the stove is almost not heated. Tried to reinvent its gas-powered machine, but the desired effect was not achieved. And then we have decided to put in “Zaporozhets” liquid-cooled engine from VAZ-2103, time to solve the problem.

Preliminary estimations showed that the Zhigulevsk engine fits in the Zaporozhye engine compartment, but the hood will still have to redo it. The increased weight required strengthening the suspension, and increased power amplification of the drive wheels and increase the efficiency of the brakes and the wheels themselves had to be changed to such that would meet the engine.

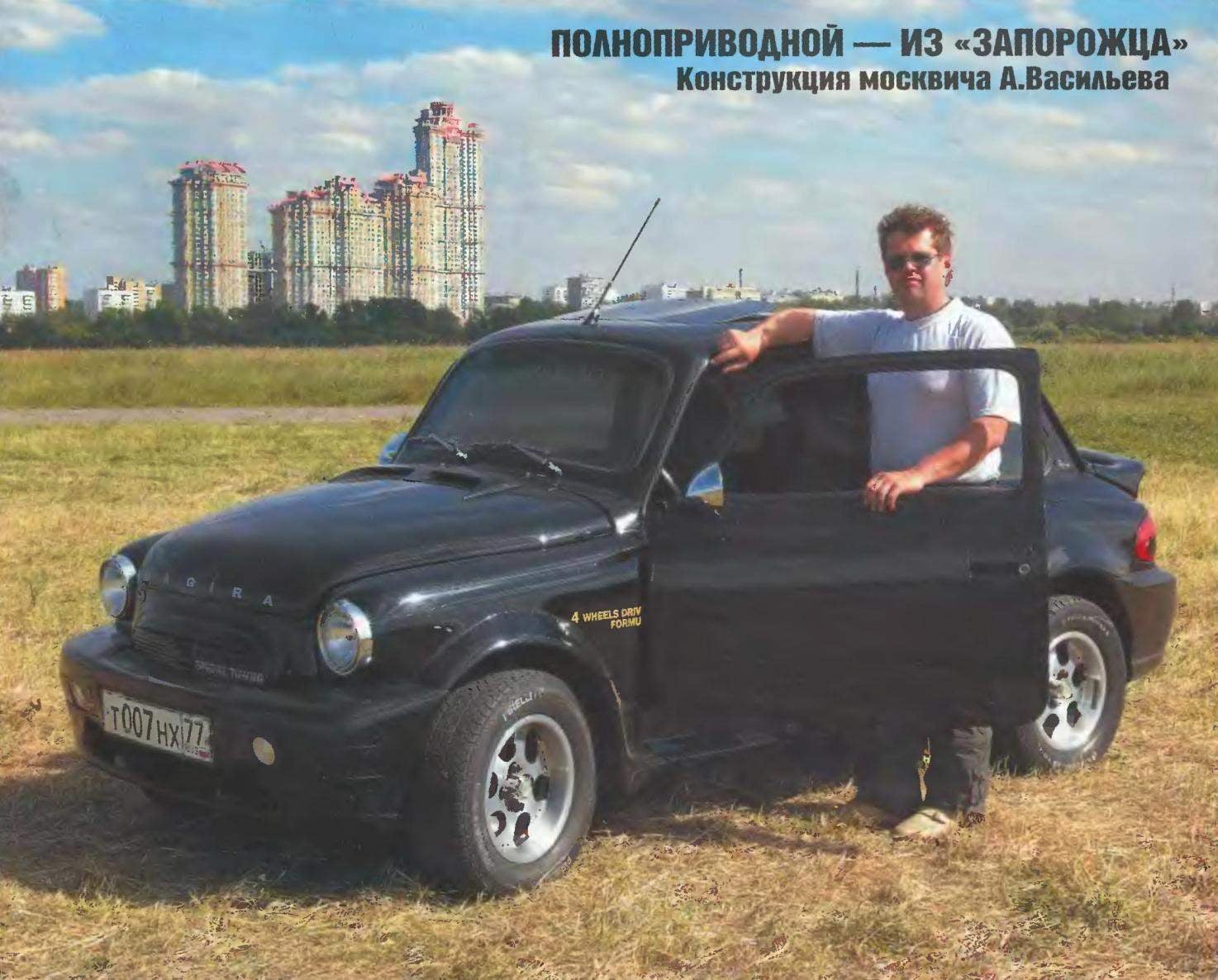

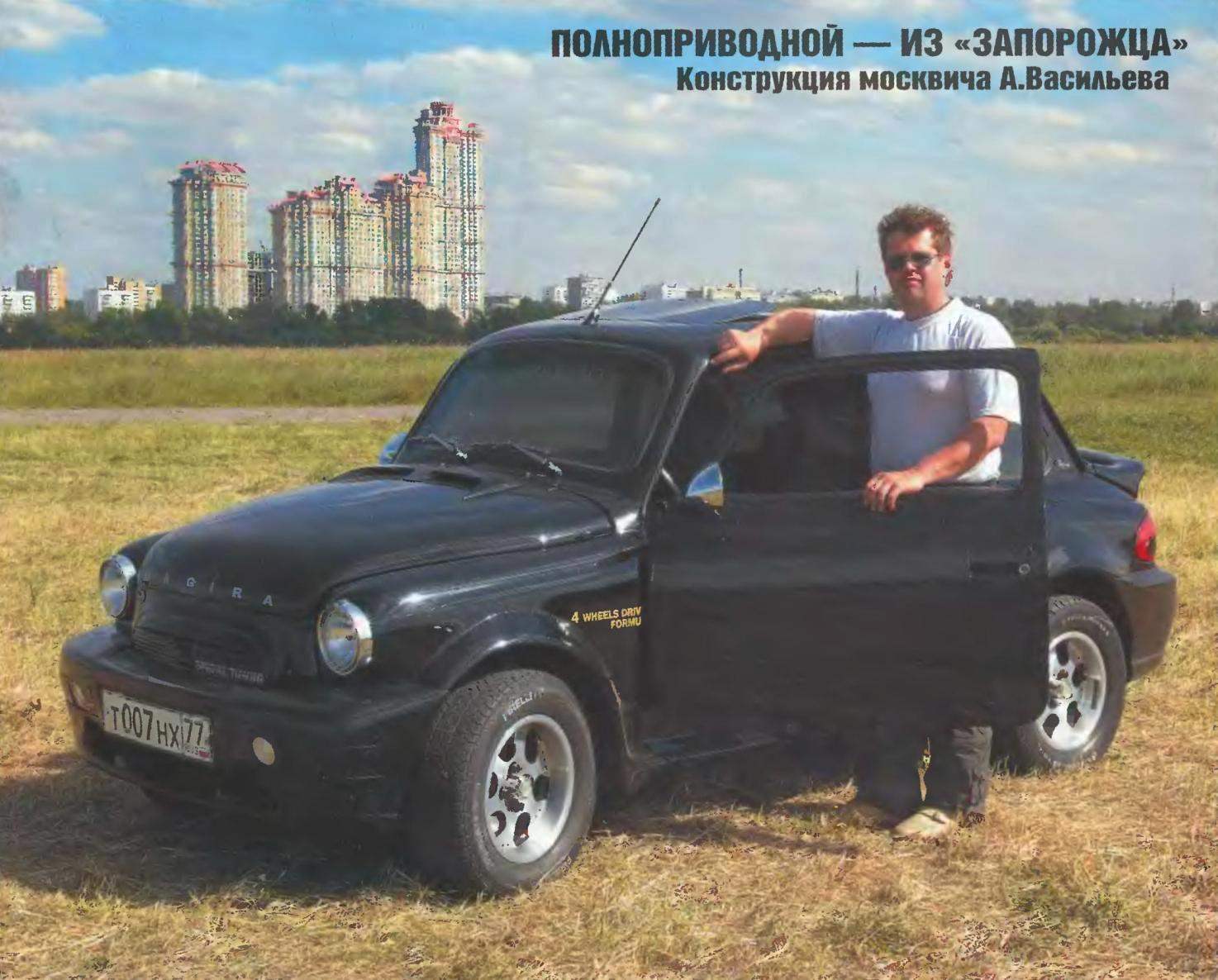

Car “Bagheera”:

1—wheel / tyre 205/60-R13 (5 PCs); 2 — front bumper-spoiler (fiberglass), 3 — front hood — trunk lid (from ZAZ-965, extended); 4 — front fender (from ZAZ-965, elongated); 5 — front air intake (fiberglass); 6 — a windshield (laminated glass, custom); 7 — antenna (purchased product); 8 — hatch; 9 — window door (2 pieces, order); 10 — the body (from ZAZ-965, modified); 11 —window body (the ZAZ-965, 2); 12 — rear window (ZAZ-965); 13 — rear spoiler (fiberglass), 14 — rear hood 15, and the rear signal lights (2 PCs); 16 — rear bumper (fiberglass); 17 — lateral air intake (fiberglass, 2-piece), 18 — door (from ZAZ-965, modified, 2 PCs); 19 — the knob (Honda-civic, 2 PCs); 20 — nut (GRP, 2); 21 —windshield wipers (VAZ-2108); 22 — halogen headlights (from the VAZ-2106, with the rims from the “Java”, modified), 23 — fog lamp (from the BMW 5-series); 24 — a radiator grille (ZAZ-965); 25 — a reversing lamp (homemade, 2 pieces); 26 — exhaust muffler pipe (stainless steel, 2 PCs.)

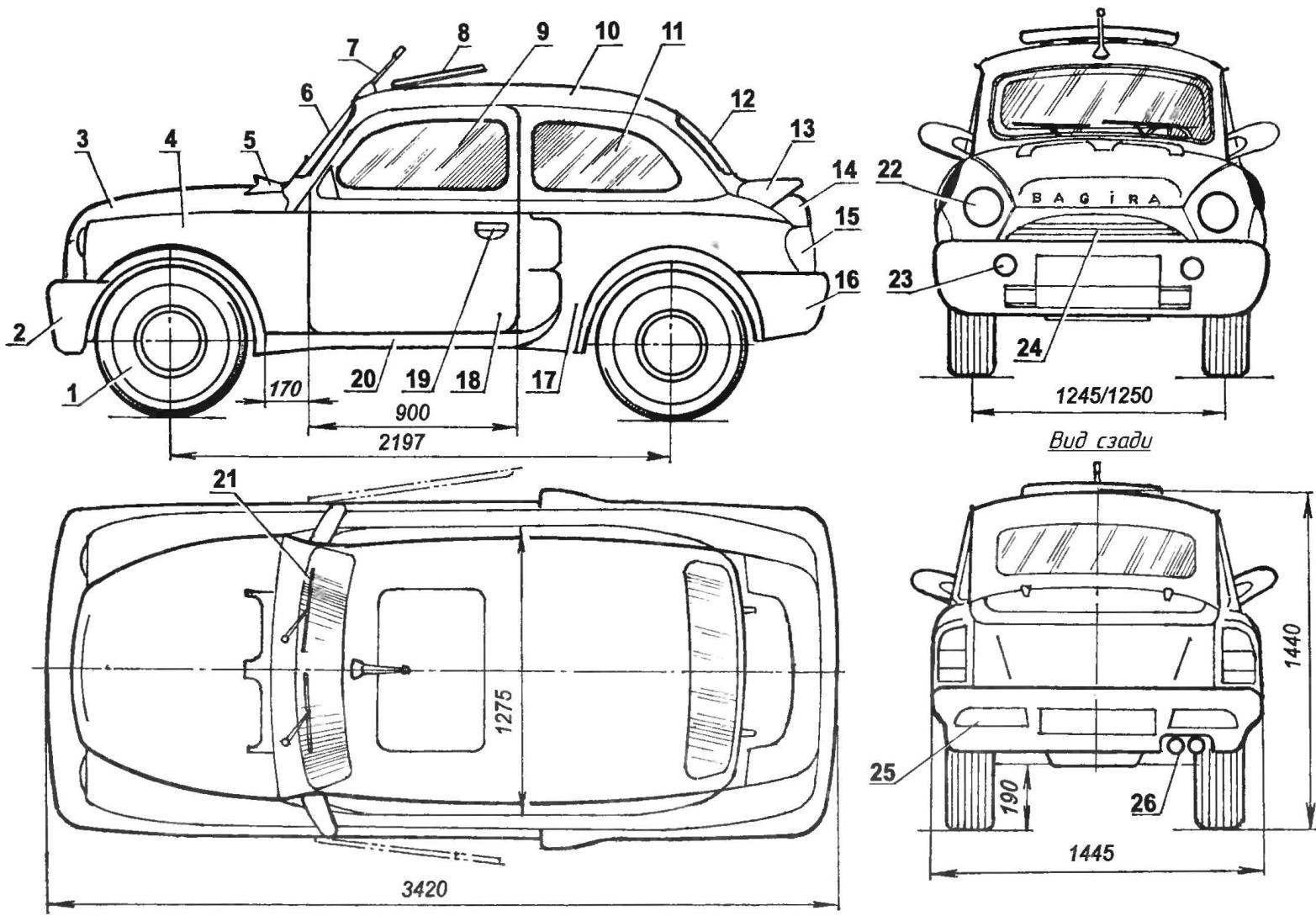

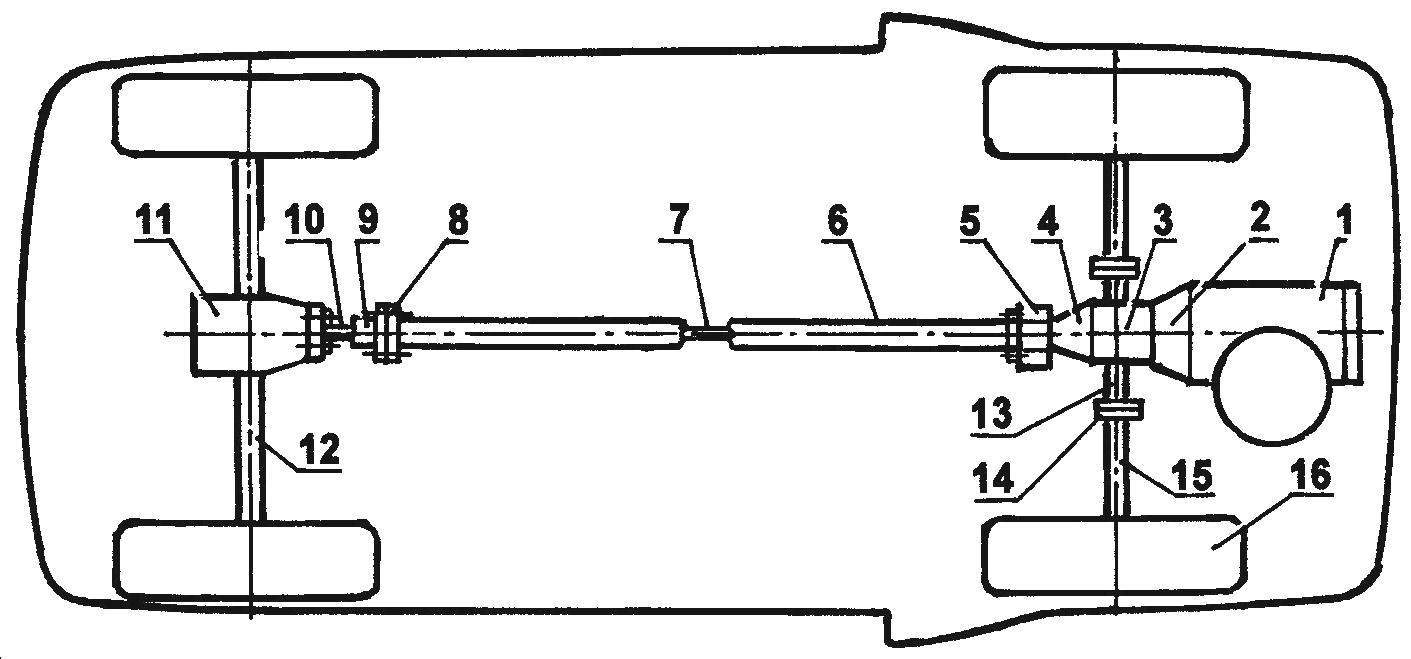

Layout of the car “Bagheera”:

1 — spare wheel 205/60R13, 2 — fuel tank capacity 60 l; 3 — front suspension strut (from the VAZ-2108, 2); 4 — mipagina bulkhead (steel sheet s0,8), 5 — a coupling pedal; 6 — Parking brake pedal; 7 — the service brake pedal; 8 — wheel; 9 — the lever connecting the front axle drive; 10 — front seat (from the VAZ-2108, 2 PCs), 11 —back seat (homemade) 12 — rear of the oven with a reversing fan, 13 — left radiator (half from the radiator GAZ-53); 14 — left supply fan (purchased product); 15 — engine (VAZ-2108), 16 — damper; 17 — ventilation bulkhead (fiberglass); 18 — the right supply fan (purchased product); 19 — right radiator (half from the radiator GAZ-53); 20 — partition of the engine compartment (homemade); 21 — the lever of a gear change; 22 — front stove (VAZ-2108), 23 — the boot partition (homemade); 24 — battery (purchase the product); 25 — pedal “gas”

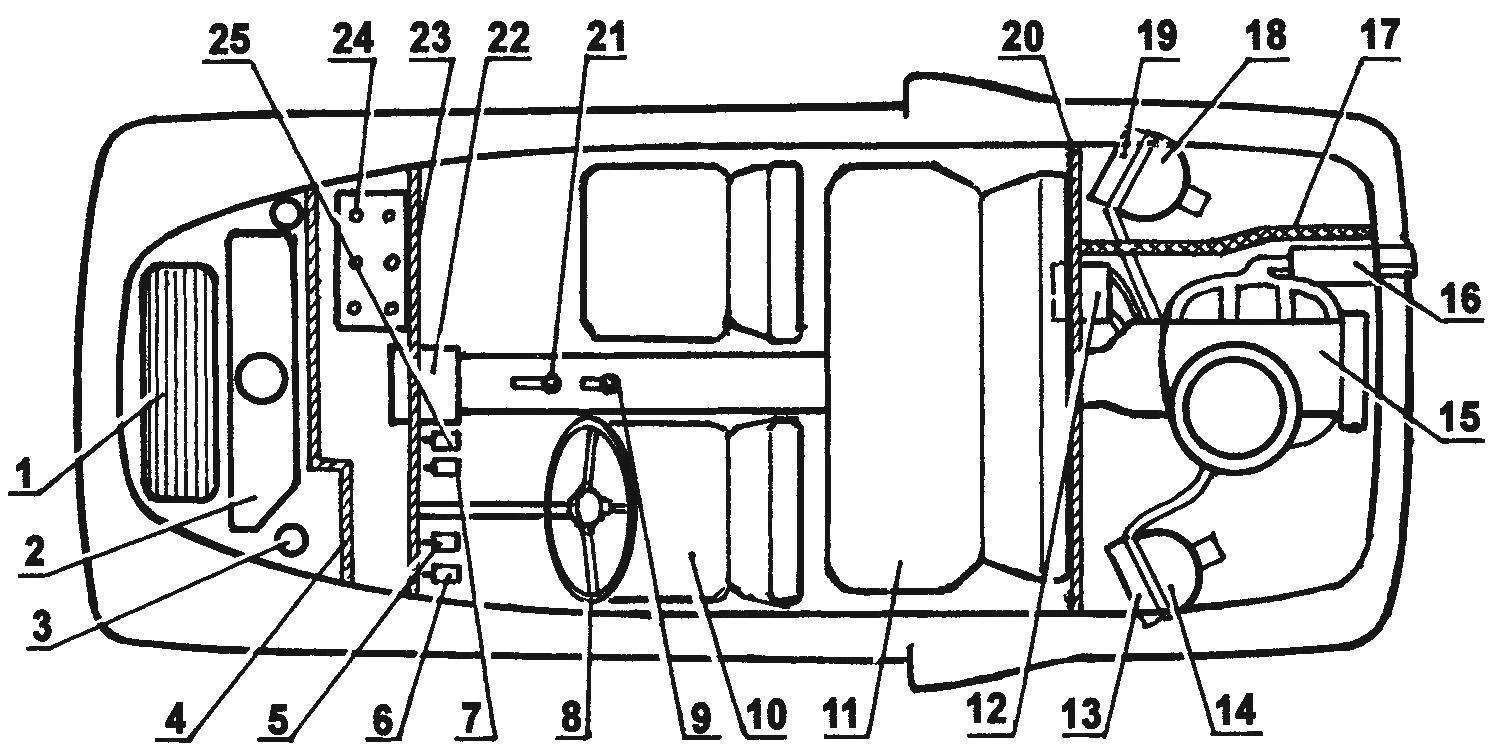

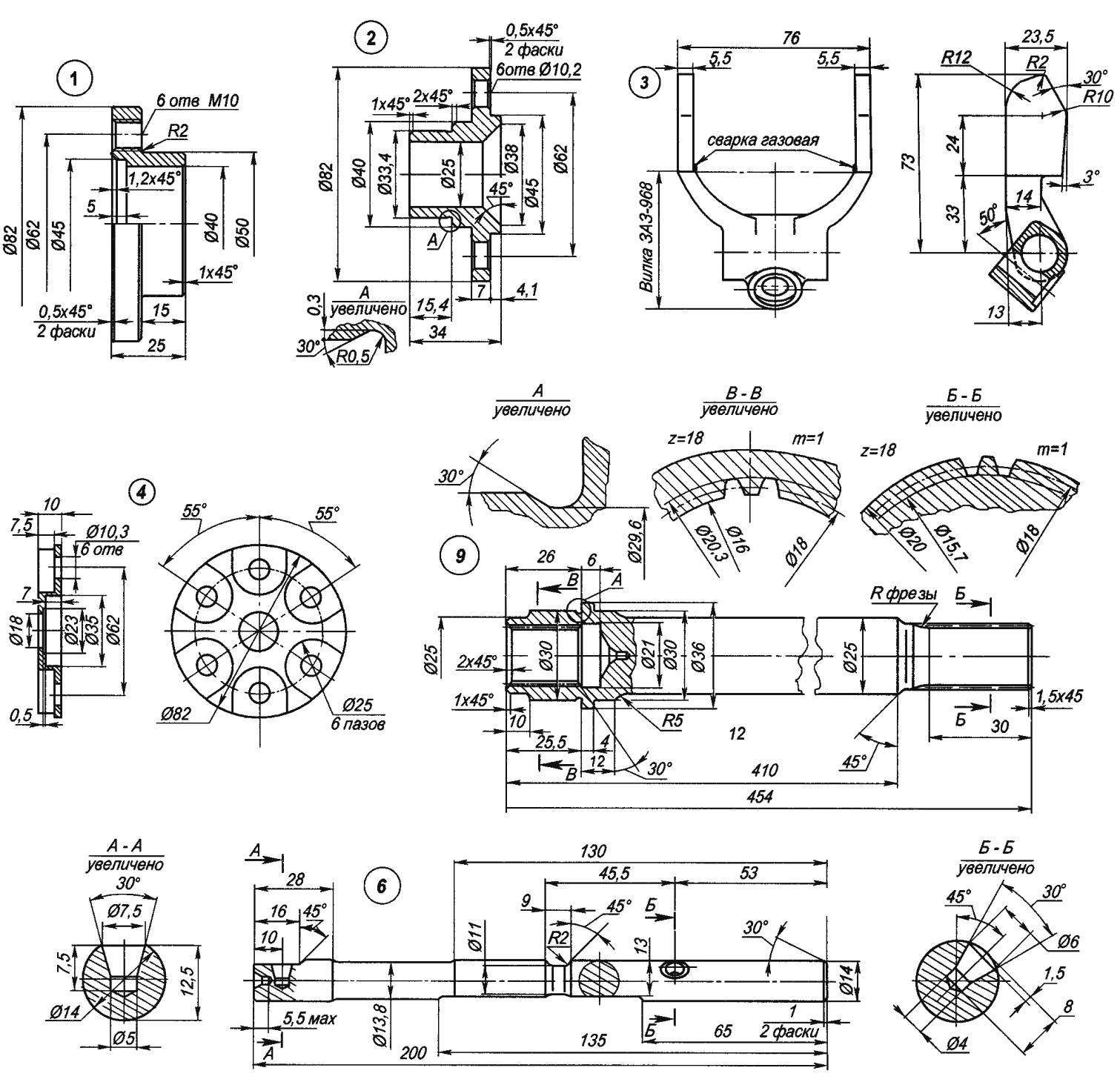

diagram of the powertrain:

1 —the engine (VAZ-2108), 2 — grip (VAZ-2108), 3 — gear shift (from Loiza); 4 — dual (Luisa), 5 — transfer case (Luisa), 6 — tube drive shaft front axle (from Loiza, oblong), 7 — drive shaft (from Loiza, extended); 8 — a connecting node of the main and additional pipes 9 — of the additional tube; 10 — additional shaft; 11 — main gear (Luisa) with differential front wheel drive (VAZ-2108); 12 — axles-front wheel drive (from VAZ-2108, 2); 13 — the short part of the rear axle (from VAZ-2108, 2); 14 — connecting node (flanges) short and long parts rear axle, 15 — long portion of the rear axle (from VAZ-2108, 2 items); 16 — driving wheel (4 PCs)

The reworking of the bonnet, although the required accuracy, the big hassle is not delivered. It is much more difficult to connect the base engine and Zaporizhia transmission unit, and more specifically its clutch housing. Carry out the connection via the transitional plate (flat ring). Its thickness 24 mm, but the location of the holes do not even dare to reproduce on the drawing is all done “in place”, according to platovym prints on the engine block and the clutch housing. The task was complicated by the fact that this also had to include the holes and the notch for the custom mounting of the starter. Besides, I had to make a special plug and ball bearing.

Details and knots of brake system and the front hubs and rear axles shortened was “borrowed” the car VAZ-2101. Wheels with tires in size 175/70 R13 used from the VAZ five.

Reinforced front suspension parts from a ZAZ-968, installing new torsion bars, steering knuckles, shock absorbers and other components — a staff remained only the crossbeam. Replaced and steering trapezoid. In relation to the rear suspension initially to take drastic measures did not — only made it harder Yes, slightly reduced its speed.

The main formulation in solving problems of heating itself became secondary. But it decided to go for quite successfully by putting the front under the dash Zhiguli stove. However, the tube inlet (hot) and return (cold) water main had to stretch from the engine through the interior

On the trunk lid (I call it the front hood) installed a homemade plastic air intake. In the roof cut out the hatch with a sliding cover. Thus the cabin is not only well heated in cold weather, but also effectively ventilated in the heat

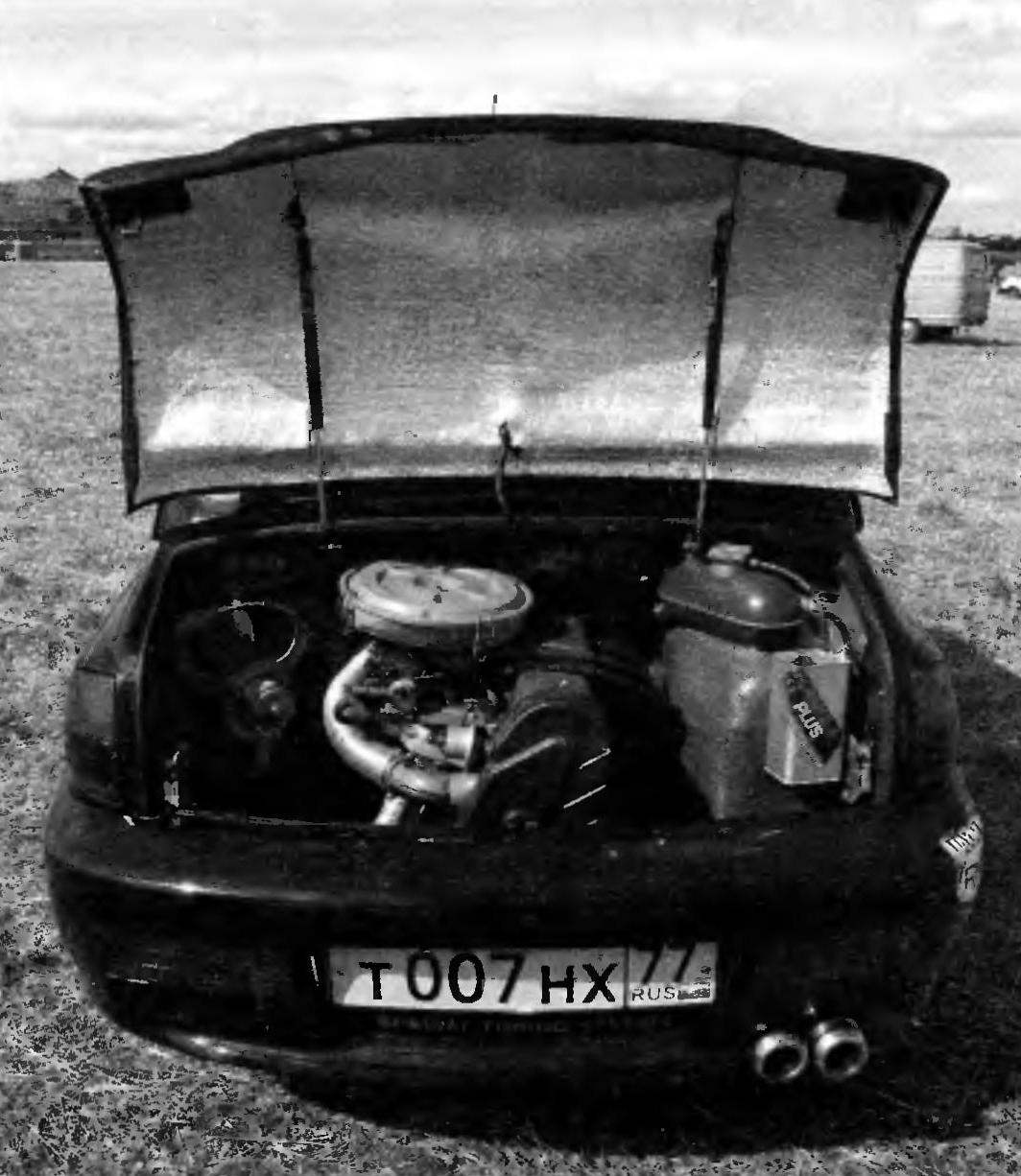

But with the cooling system it didn’t work out successfully First of all I was not able to mount the radiator in the nose of the car So I took the radiator from the truck GAZ-53 and cut it lengthwise in half, set halves in the engine compartment on both sides of the engine. But later the operation turned out that in hot weather the engine overheated. This disadvantage is partially eliminated by installing a homemade side (fiberglass epoxy glue) the air intakes on the rear fenders, and partly by changing the angle of installation of the radiators in relation to the incident flow of cooling air. The design of The machine work is not planned, but, however, the installation of new intakes spodvignulo and it vykleili new bumpers and sills made of fiberglass.

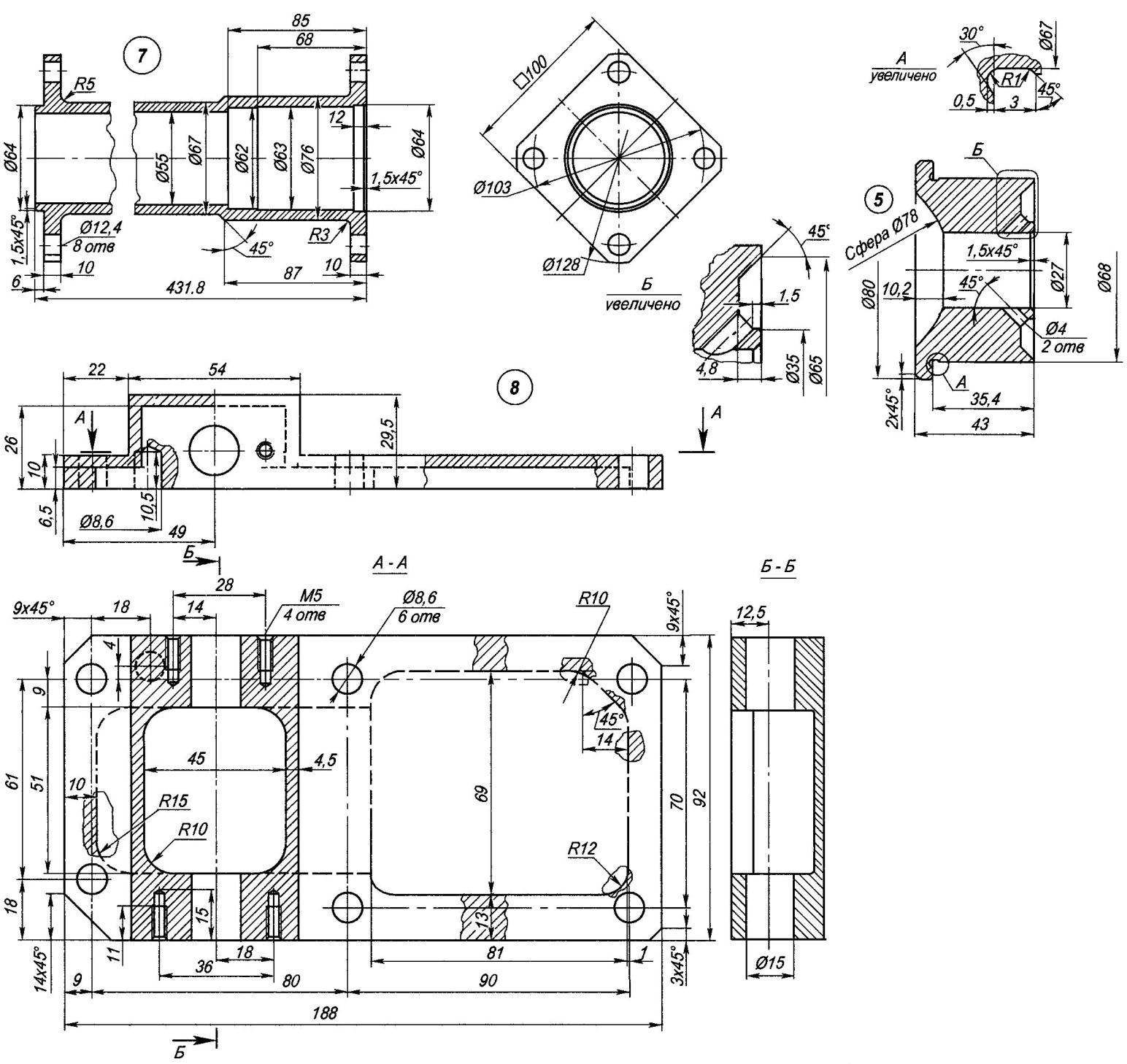

Special items ordered by the experts:

1 is the short flange of the rear axle (steel 45, range 82, 2 PCs); 2 — flange long rear axle (steel 45. circle 82, 2 PCs), 3 — a plug of deenergizing of clutch, 4 — centering yoke bearing flywheel (steel 40X, the circle 82), 5 — the sleeve is the differential housing (steel 20KH, circle 80,4 PCs.); 6 — the control rod gearbox (steel 45, round 14), 7 — additional tube front drive shaft (duralumin D16, circle 128), 8 — a cover of the Carter d:the s installation guide rods downshift and connect the front axle drive, 9 — additional front drive shaft (steel 40X, round 36)

All the alterations it took me a year, and exploited the car then almost three years (1989 to 1991) Mileage during this time amounted to 54 thousand km: it is now on the “zaporozhtse” I went not only to the garage, but working trips. It was funny and flattering to see the puzzled or admiring the views of the partners of the movement, the owners of more powerful machines — as this little old “Zaporozhets” so rapidly goes forward, “starting” with them from a traffic light. Interested and curious were many: on the market, at the service station the machine has always had the people around him. This, of course, flattered

The machine I am not re-registered, but because there were problems with the traffic police. Helped that most of the inspectors know a lot about technology, so too has shown a keen interest in unusual design. Well, after almost intimate conversations — in which the inspector, tell, rise, “the sword”?

However, the increased power and increased performance (top speed reached 140 km/h) like Mao, and an old body with pereletnyi the bottom, and the details of the suspensions and powertrain. Their failure occurred quite often: as due to corrosion and metal fatigue, and dynamic overloads.

In the end I have matured the idea to upgrade the machine to make it a reliable and dynamic car, from the modern units, having, so to speak, “the wolf in sheep’s clothing” Body “drone” ZAZ-965 suitable for this well.

According to first estimates, the new car was to be driven only on the rear wheels. Many ideas came up while working on it, something even altered. But starting work, I knew exactly what color car is black, and even came up with her name — “Chantelle”.

Modernization of the machine began to stand, it took her all units and components, and the body lengthening cut across in front (rear) wall. Despite the desire to maintain similarity, it would still expand the field of view for the driver, that is, for myself (as well as front passenger), to make the cabin more comfortable and appearance more modern. At the site of incision on the sides have waril stand and perenosil them door — now they open in the course of the car, not “against the grain”.

For the reconstruction of the body, but also to determine the points of attachment thereto of the power unit transmission assemblies and suspensions had to mount something like a pile of steel of various profiles. Floor front of the cabin, from the “eight”. He was mounted and seat from the same machine.

To replace rotten body parts made bending machine with manual lever actuator. On the same machine arching cut from 2-mm sheet steel elements wishbone rear suspension, which is then welded into a single part. By the way, levers are made oblique, the kind that has the BMW 3-series — with mounting angle to the transverse axis of the vehicle 13°. The rear springs from the “Moskvich-2141”, and the shock absorbers — from a ZAZ-968. Suspension stroke is about 200 mm.

With front suspension for a long time could not decide which car to use. Clearly there was one — “Zaporizhia” will be impossible: too often she’s let me down in the road. Again, as in the case with the power unit, the balance is tilting in favor of the “vomeracea” (VAZ-2108), but it had greatly to modify — because it was constructed under the drive wheels. It was then that I came up with the idea to make “Zaporozhets” all-wheel drive. But more on that later.

It is clear that no alterations not done. Since the load on the front axle of my “drone” is much less than the “eight”, needed softer springs. So how to choose the appropriate finish, and especially new navit I couldn’t have done something simpler: from the outside of the springs on all coils soshlifovat with a round bar in the flats to a depth of 2.8 mm, having the desired rigidity. Since the track “plows” less than the gauge of the VAZ-2108, it had to be shortened and the stabilizer bar.

For the new version of the machine has chosen a different powerplant — the engine with the clutch basket from the car VAZ-2108. Was guided in this by the fact that to have two machines with the same spare parts is still better. Besides “wasmerely” engine is easier, more efficient and smaller than a “troechniki”. True, he had to cook another pan (the smaller), to alter musopriani.

to 30-horsepower engine ZAZ-965 took forced up to 92 HP engine VAZ-2108. The left first radiator with the supply fan; a second radiator with another fan under ablative fiberglass cover

Front-wheel drive: gear final drive with the main couple from Loiza, and differential and constant velocity joints — from the VAZ-2108. Suspension and steering components, too, from the VAZ-2108

Under the front hood in the trunk free space is almost gone: here compactly housed generalist spare wheel, 60 litre gas tank, battery and driver’s tool

Front panel and instrument panel combination can be recruited from different cars. Next to the usual pedals: clutch, brake, “gas” left appeared another — of the Parking brake. Arms between seats — two: gear and connections front axle drive

Transmission units, box changes gear, the reduction gear (shift stage), and transfer box — used from Loiza. In all of these units had to redo the control mechanisms (inclusion or switching) — because on my machine compared to the base car, they are “backwards” (rotated by 180°). Drives include mechanisms mounted on the pipe drive shaft of the front axle. Still had to redo the pinion shaft of the speedometer, as this device from the VAZ-2106 and it showed a speed about 1.6 times smaller (as noted by my consultant and manufacturer of original parts drawings design engineer with the automobile “Moskvich” Alexei Dzhigurda — sure in miles). So, gear ordered 19-bevel and the counter — 30-bevel. The module of both gears m = 1. By the way, non-standard parts that require high precision and quality of execution, ordered the experts of them, in my opinion, the most important quote in the material

But the main change involved the differentials, both front and rear because all-wheel drive has been used a shortened half shafts with constant velocity joints from the VAZ-2108. In addition, the axle of the rear wheels is made of multiple (split flanges) for easy dismantling of the transmission, if necessary, the differential is assembled from gears axle shafts from the VAZ-2108 and intermediate gears from the differential VAZ-2101, with a homemade spherical inserts and crankcase covers.

Brake system, as in “eight”: on the front — discs, rear — drums. Hub rear wheel had to make a special since they too become leading. Under the left foot except on the clutch pedal, there is another “hand” brake with two provisions. First, as a Parking brake, and the second for braking in the course of only the rear wheels. Steering — from VAZ-2108, revised.

The cooling system is still two radiator with electric fans, only the air flows to them and they are now separated. But in the heating system there is another stove — back, improvised with reversing fan. She blows rear and side Windows of the body and, if necessary, serves as a hood. Front stove the redesigned dampers.

Wiring — improvised, carried out in non-combustible sleeve: to all consumers including fuses, and powerful — connected via a relay. A separate fuse installed on power wire from the battery to the starter.

Now Tselikov Door (without vent Windows) Windows and have electric Windows and locks.

Rear signal lights — from “Volga-3110″—modified, and anti-fog and reverse — homemade. The wipers actually from ZAZ-968, but have 3 working speed, as in “eight.”

The muffler is their own design from stainless steel with vytaskivanija “flutes”.

The front panel is glued together from parts of different cars. Devices — from the VAZ-2106 and VAZ-2105, revised.

“Bagira” now spinning wheels with low-profile tires width of 205mm. them special made For discs: each disc is welded of two ordinary Zhiguli wheels, taking from them only the halves with wide shelves.

Front and rear bumpers, wheel arches, front and side air intakes, rear spoiler laminated of fiberglass epoxy resin. For their production directly into the car out of plasticine clung the master model, which was featured in the matrix, and was wileyways products.

Ahead, in the Luggage compartment placed fuel tank 60 liters made of stainless steel, the battery and spare wheel, tool so free seats are almost gone.

Lead technical specifications “Bagheera”. The number of places, as in “Zaporozhets”, — four, but now even the rear passengers are much freer. Curb weight — 850 kg top speed — 180 km/h and acceleration from standstill to 100 km/h is 12 seconds. Fuel consumption in city mode is about 8 l/100 km and on the highway — 6.5 liters/100 km. the Engine is located behind the longitudinal axis of the machine, it is slightly boosted, and now its capacity is around 90 HP Drive all-wheel, front — disable. Transmission — combination: a gearbox from ZAZ-968, transfer case, reduction gearing, a main transmission (rear and front)— Luisa redone with differentials from the VAZ-2108; axle shafts — CV joints from the VAZ-2108 — modified, adhesion — from VAZ-2108.

All work on the creation of “Bagheera”, including painting, have been conducted in a normal metal garage.

The work lasted six years. But now “Bagheera” is used mainly for ceremonial trips, and for everyday — “the eight”.

VASILIEV

EDITORIAL

The story of The creation of “Bagheera” would not be complete if, at least briefly, to imagine its Creator—Alexander Vasiliev. And because here is the opinion of him by his friend and associate and assistant in the creation of “Bagheera” — Alexei Dzhigurda — professional automotive designer with the former AZLK.

“Alexander — the wizard universal car and he can do everything from the welding of revealing, refinement of engines and transmissions, vyklicky fiberglass panels to make the original electricians: all of them very carefully, at a high level, and where necessary, and tasteful. Practice and self-education helped him quite professionally to find the right solution. It is thanks to listed as h got a car “Bashir,” which was facilitated by another feature of his character: perseverance bordering on fanaticism in achieving the goal.”