These guys have a lot in common. They all live in the Serpukhov district, their parents — farmers. But most importantly — they are all involved in the circle of technical creativity of the regional House of pioneers with the wonderful teacher Yevgeny Diligentia.

These guys have a lot in common. They all live in the Serpukhov district, their parents — farmers. But most importantly — they are all involved in the circle of technical creativity of the regional House of pioneers with the wonderful teacher Yevgeny Diligentia.

More than a quarter century gave this man the lesson with the children technical creativity. In recent years he was fascinated by the design of fixtures and assemblies to facilitate agricultural labor.

Evgeny Nikolaevich tries to instill in its members a thoughtful, creative approach to seemingly simple, operations. And success was not long in coming. Five members of the group and the head became laureates of the Central NTTM exhibition and exhibition of the USSR for the development of original devices for harvesting cabbage. We talked about this in our journal (see # 7, 1975).

Several exhibits were presented by the children and at the Moscow regional exhibition NTTM. The jury members and visitors unanimously noted the great work being done by serpuchovskay for mechanization of manual labor in agriculture.

It is easy to understand, where are the origins of the agricultural orientation of technical creativity of these guys. Because every day, they see the work their parents do in the summer working at the farm, helping to harvest.

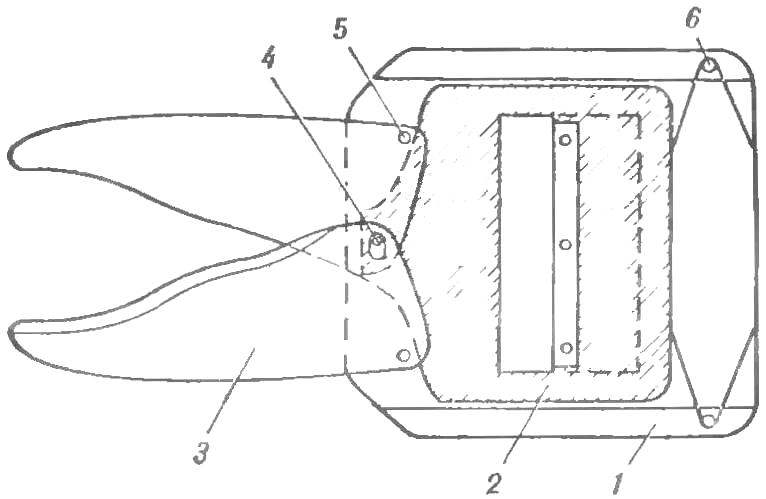

Fig. 1. Lever scissors to trim the carrot tops:

1 — frame, 2 — pen-drive with plates, 3 — blades, 4 — bolt, 5 — finger, 6 — return spring.

So, when cleaning carrots, beet guys noticed that the roots have to be cleared of foliage. This is done with a knife or scissors. But the work is not very productive and tiring quickly. Here members suggested several adaptations.

For the creation of a lever shear for cutting off the tops of the carrots the winners of the regional exhibitions NTTM became the eighth graders Dashkovskaya high school farm “Bolshevik” Valery Ryzhov, and Sergey Malkin.

Diplomas of the laureates of the exhibitions NTTM was marked and the work of the pupils of the 9th class of secondary school in Lipetsk farm “in zaokskiy” Sergei Smirnov, Alexander Klimov, Anatoly Klygina. They designed a lightweight portable machine for cutting the tops from beets.

All of these young inventors with a passion to work in the student’s KB under the direction of E. N. Diligentia.

Today we put the development of serpuhovka in our correspondence exhibition stand TVP-76.

The principle of scissors, the basis of the device (Fig. 1), which facilitates the pruning of the tops of the carrots. The main force element — frame made of plywood with thickness of 10 mm. Inside the frame is made of cut for the movement of the handle actuator is made of duralumin with a thickness of 2 mm. At one end of it fastened the bolt that translational movement of the handle is transmitted to the knives made out of saws on wood. The axes of rotation of the knives are the fingers of bronze, Ø 3 mm, fixed to the frame.

Return handle actuator, and hence the knife to its original position by two springs, made of steel wire Ø 1,5 mm. the sides of the frame are closed by pads made of plywood with thickness of 3 mm. Stroke of the pen-drive 25 — 30 mm.

To operate the fixture takes one rune and the other to the knives served carrots with tops. With your fingers push the handle, the drive force is transmitted to the knives, and the tops trimmed. In the place where the fingers press the pen-drive, riveted wooden plates to increase the area of contact.

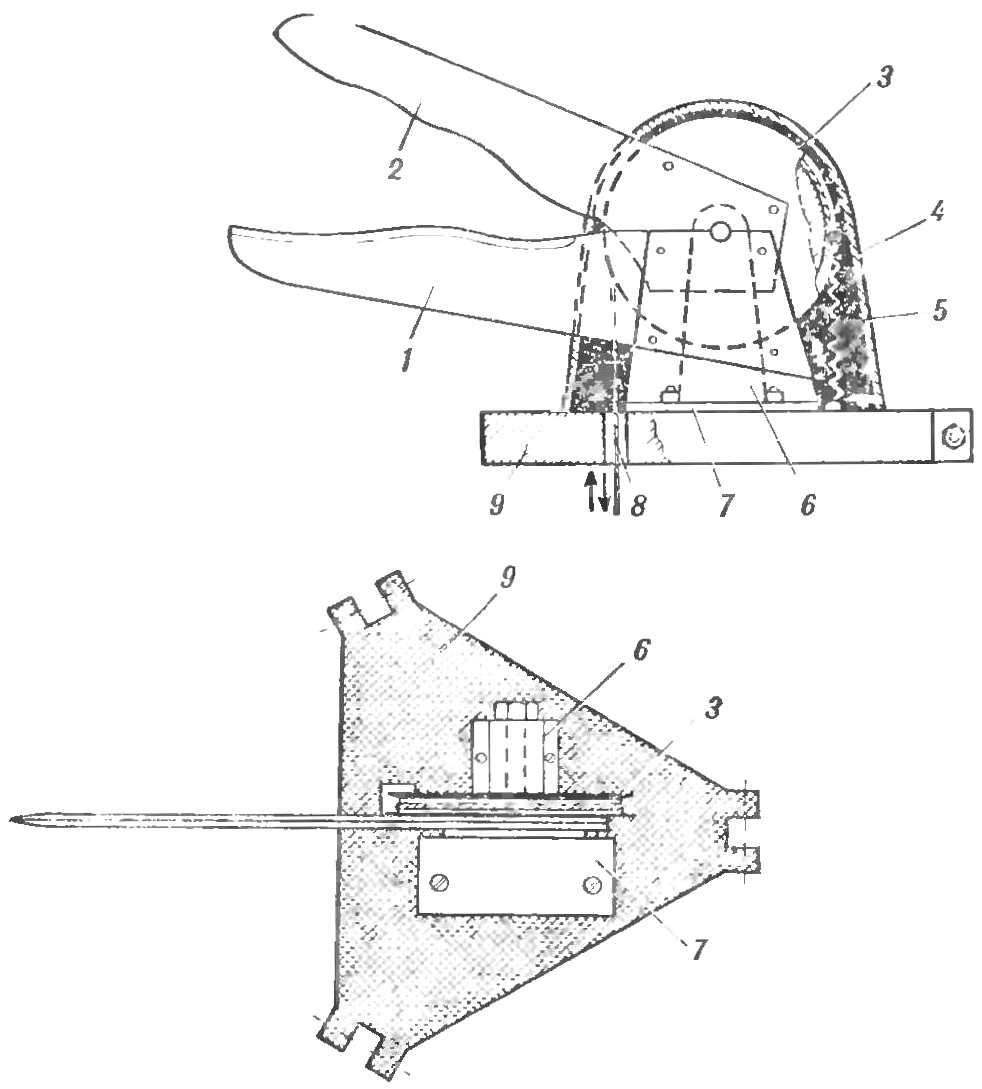

The same principle used in the device for cutting the tops from beets (Fig. 2).

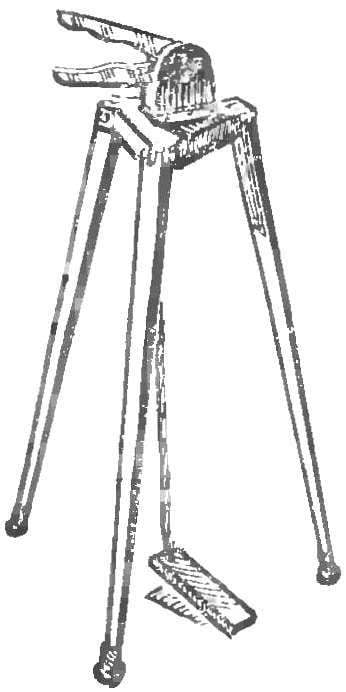

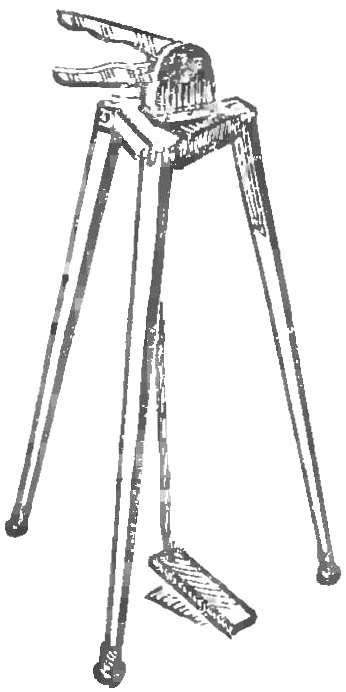

Fig. 2. The machine that facilitates cutting of the tops from the beets:

1 — fixed knife, 2 — movable knife, 3 — disk, 4 — housing, 5 — spring return, 6 — bearing, 7 — bracket 8 — cable, 9 — base (tripod)

All elements of this design are attached to the base, made of pine bar thickness of 20 mm. the Stationary blade of steel fixed by four rivets Ø 3 mm on the bracket made of aluminum that bolts connected to the base. Movable knife riveted to brass disc Ø 80 mm Shaft Ø 6 mm made with the disc as a whole. It rotates in a steel support. The disc has an annular groove for the cable connected to the pedal.

The entire fixture is mounted on a tripod that allows it to be installed at a height corresponding to the increase in operating. Pedal with one end stuck in the ground. Working with fixture two: one is located in the rear of the knives, the other side takes the beets. The first push on the pedal, and cut off the tops poured down. The peeled roots are placed in the basket.