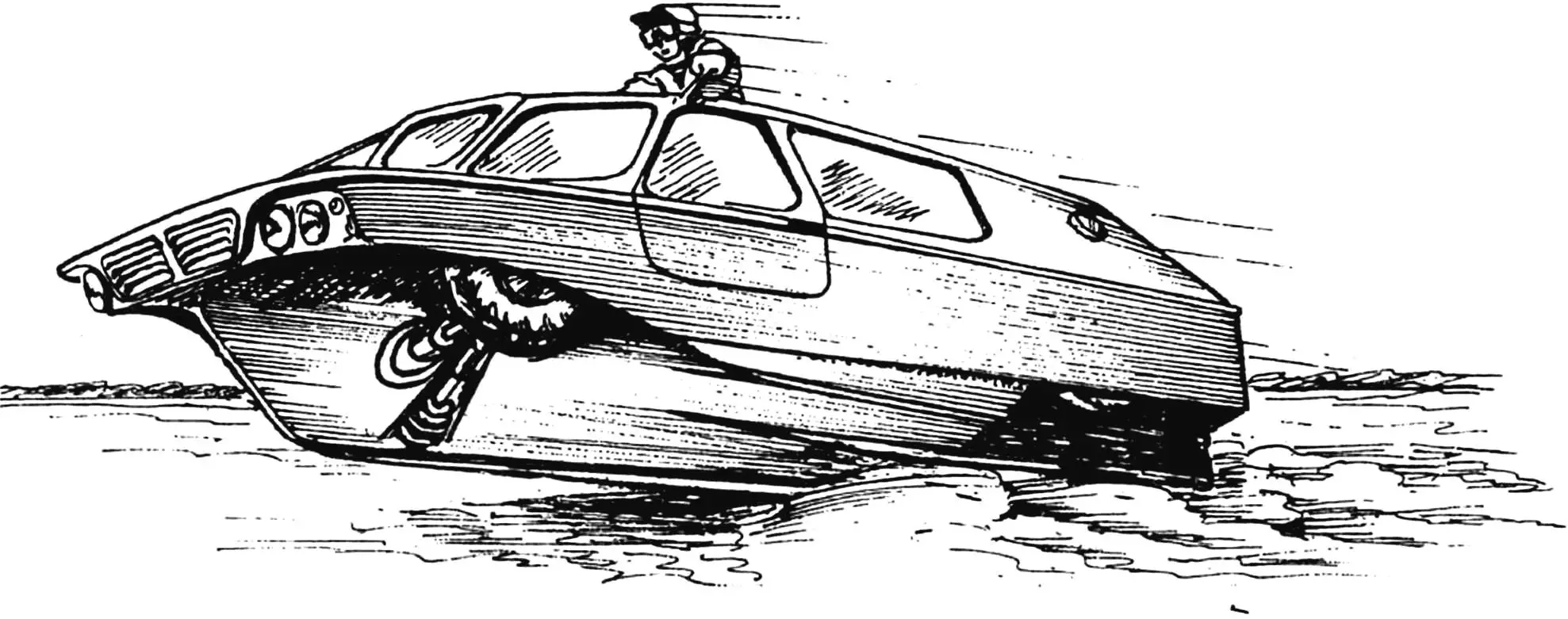

Musician D.T. KUDRYACHKOV is known among amateur constructors as the author of the unique amphibious car «Triton» — the only vehicle of its kind registered simultaneously with two state inspections: automotive (traffic police) and small vessels (GIMS). Our regular readers may recall the publication «Gliding… car» («Modelist-Konstruktor» No. 5, 1996), which contained a fairly complete description of the «Triton» design. In it the author shared his approach to solving complex technical problems that allowed him to create a vehicle equal in operational qualities both on land and on water.

The effectiveness of D.T. Kudryachkov’s work is hard to question. Proof of this is the present publication, in which the amateur constructor offers interested readers a description of his new amphibian. Externally it resembles its predecessor. Nevertheless «Triton-2» is truly a new machine: it has a modern front-wheel-drive layout, simpler and hence more reliable power drives, hydraulics in the control system, and so on.

As for the motives that prompted the former musician, now a pensioner, to take on this rather troublesome undertaking by today’s standards, he does not hide them: «I can’t just sit in retirement! Seriously though, I was driven by the desire to build a machine with higher operational capabilities. To test it. It and myself.»

Exactly that: to test oneself! Will there be followers?

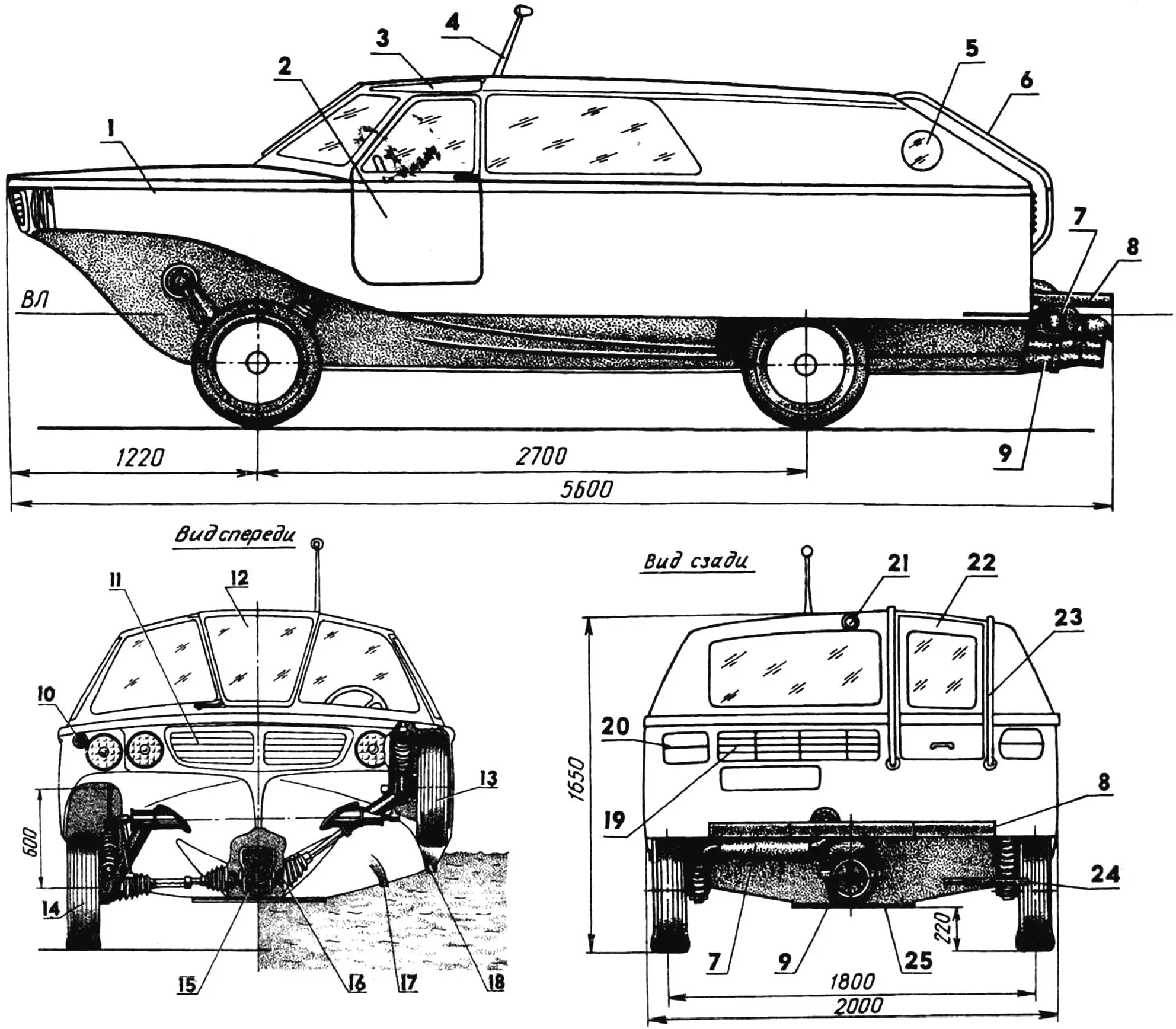

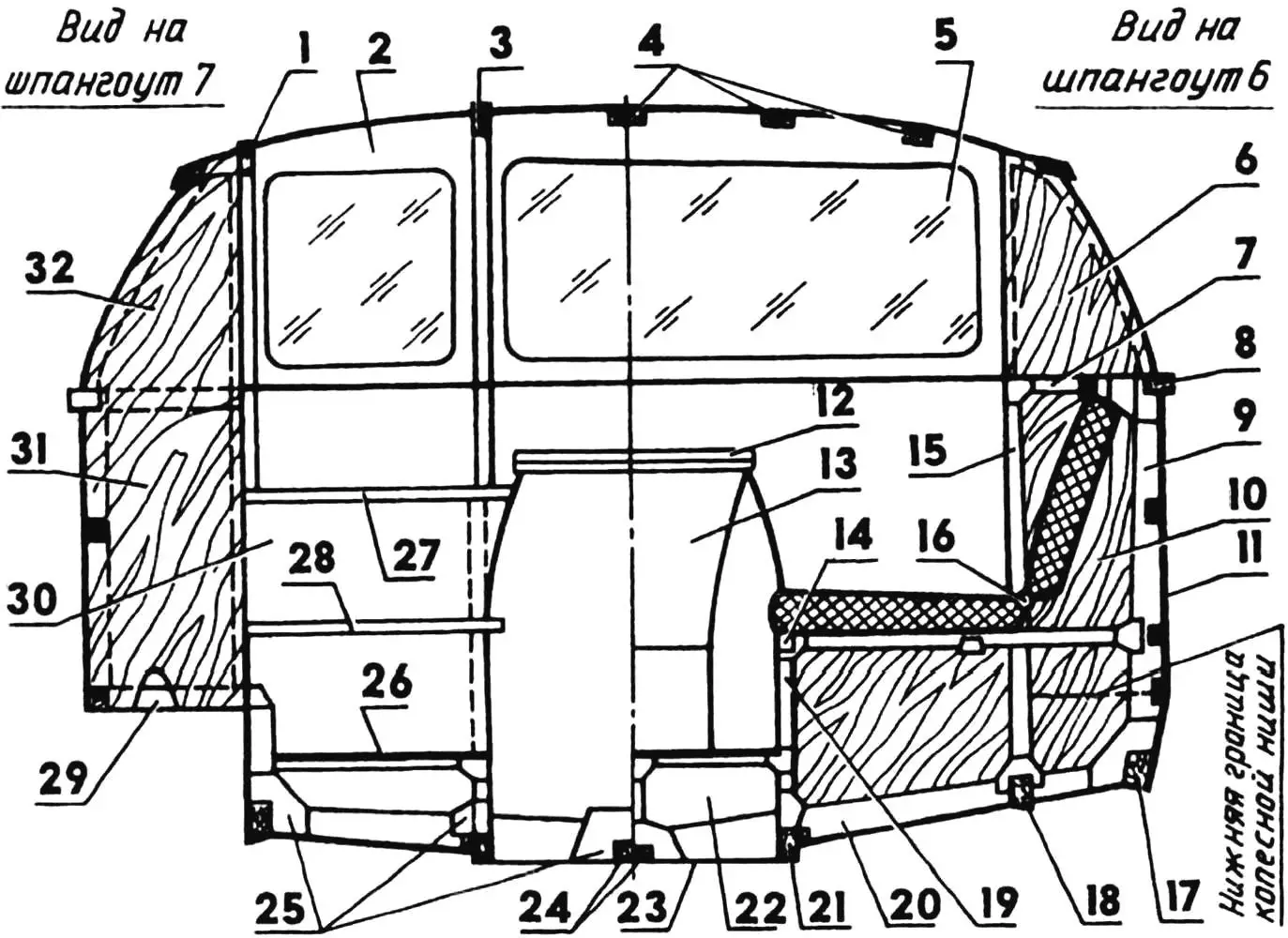

1 — hull, 2 — side door, 3 — hatch cover, 4 — masthead light mast, 5 — porthole, 6,23 — handrails, 7 — muffler, 8 — waterjet guard — upper step of ladder, 9 — waterjet, 10 — running light, 11 — intake duct grille, 12 — front door, 13 — front wheel in «afloat» position, 14 — front wheel in working position, 15 — gearbox with differential, 16 — telescopic half-shaft to gearbox final drive joint, 17 — longitudinal step, 18 — spray rail, 19 — outlet duct grille, 20 — rear light, 21 — stern light, 22 — lower rear door panel, 24 — lower ladder step (folding), 25 — hydrofoil.

Although «Triton-2» differs substantially in many ways from its predecessor — the «Triton» already known to readers — it has fully inherited all its merits and operational qualities. This is only natural, since the same design principles and practically the whole arsenal of technical means that work reliably on the «Triton» have been used. The same type and construction of wheel suspension, the same steering drive layout, the same quick-release couplings that allow turning the amphibian into a «pure» boat in minutes if desired, and much else. So to avoid repetition I suggest that those interested refer to the above publication «Gliding… car», where drawings and a detailed description of the components and mechanisms common to both «Tritons» are given. A preliminary look at that material would be useful, as it contains the body of information of which this article is a development.

So what is new in «Triton-2»? Externally the amphibian is no longer so extravagant. Its wheel track is reduced (which relieved some of the torsional stresses on the hull), there are no fenders, the wheels with suspensions fit within the hull outline, and a driver’s door has been cut in the port side (used only on land).

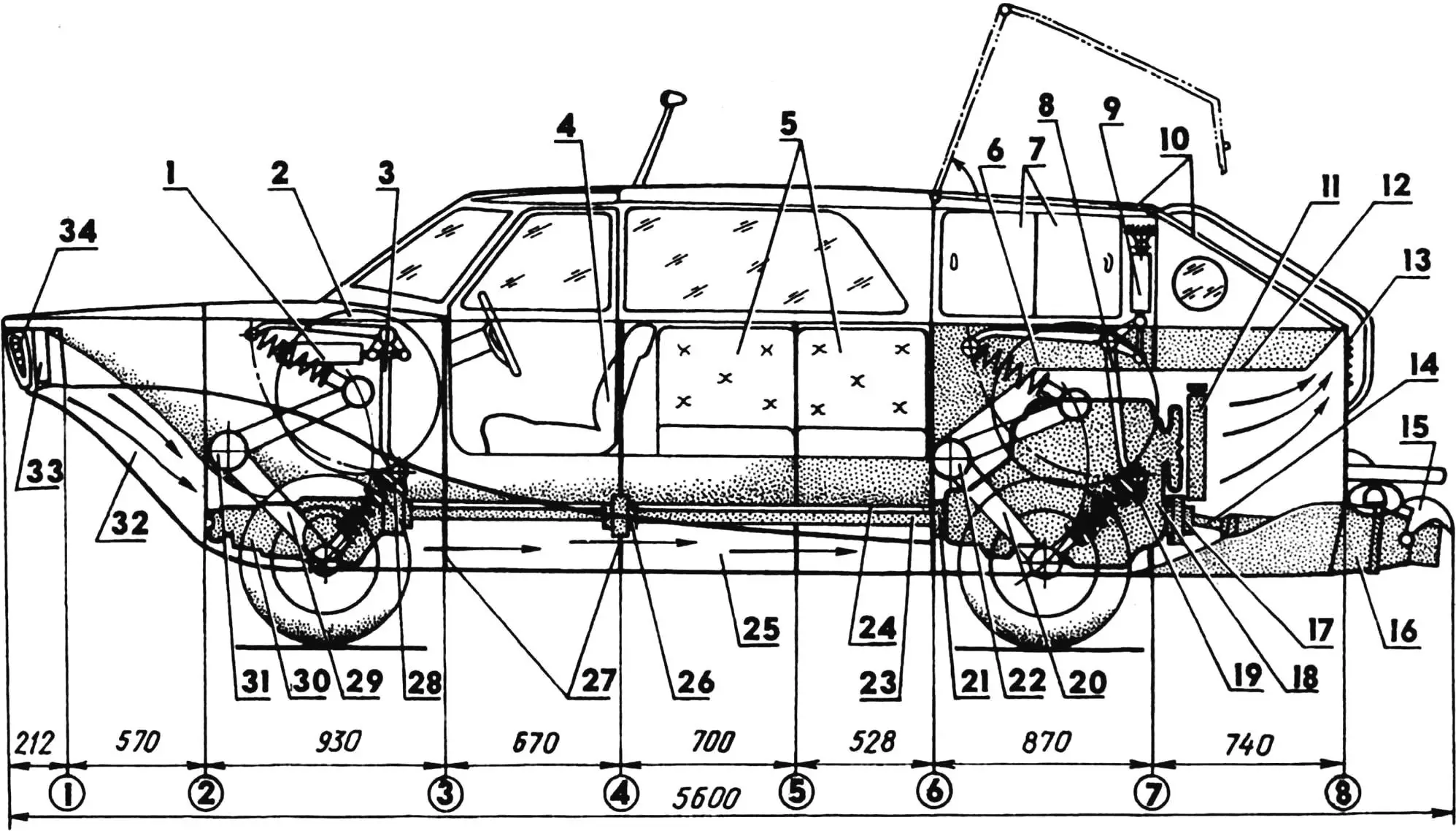

However, bringing the machine’s appearance closer to established automotive standards was paid for by a more complex load-bearing hull structure. The wheel well bulkheads and the driver’s door broke the longitudinal stiffeners of the sides, so two additional longerons had to be added to the structure — parallel to the sides at 300 mm, equal to the well depth. The rear wheel suspensions are mounted on these longerons (on the «Triton» this load was taken by the sides). Otherwise the hull structure is similar to the prototype — its basis is frames and longerons made of oak and pine timber of various sections, plus skin, bulkheads and knees cut from aircraft plywood.

1 — hull, 2 — bottom, 3 — recess in skin for telescopic half-shaft, 4, 8 — front and rear wheel wells (suspensions not shown), 5 — spray rail, 6 — hydrofoil, 7 — longitudinal step, 9 — waterjet intake grille, 10 — waterjet housing, 11 — waterjet guard.

The lower part of the hull, as on the old amphibian, is a continuous sectioned box platform of increased stiffness — a «load-bearing bottom». All its bays are isolated from each other, as the frames are closed (except for the lower branch of the duct) by plywood bulkheads equal in height to the bottom longerons.

The side (driver’s) door has a space frame and an automotive seal of elastic rubber. It is located in the wide bay between frames 3 and 4. The door opening does not affect the load-bearing bottom structure, since its lower edge is 100 mm above the waterline.

There was another problem connected with the rear wheel wells. By intruding into the traditionally inviolable «boat» zone of the bottom, they reduce and distort its planing surface. By all existing rules in boatbuilding this must not be done without risk to the amphibian’s hydrodynamic quality. And yet if one takes into account the results of experiments carried out in the US Navy Taylor Model Basin by the well-known American specialist in high-speed craft hydrodynamics E.R. Clement (journal «Boats and Yachts» No. 66, p.22), the rear wheel wells turn out not to be so harmful. Clement established that a planing hull should have a taper toward the stern of 30…35% of maximum beam at the chine. It is logical to assume that the stern portions of the «Triton-2» bottom allotted to the wheel wells effectively serve the same purpose — reducing the bottom planing area toward the stern.

To bring practical results closer to theory (according to Clement the stern taper should be smooth, while on «Triton-2» it is stepped) the bottom is supplemented with a wide hydrofoil, two short longitudinal steps and side spray rails.

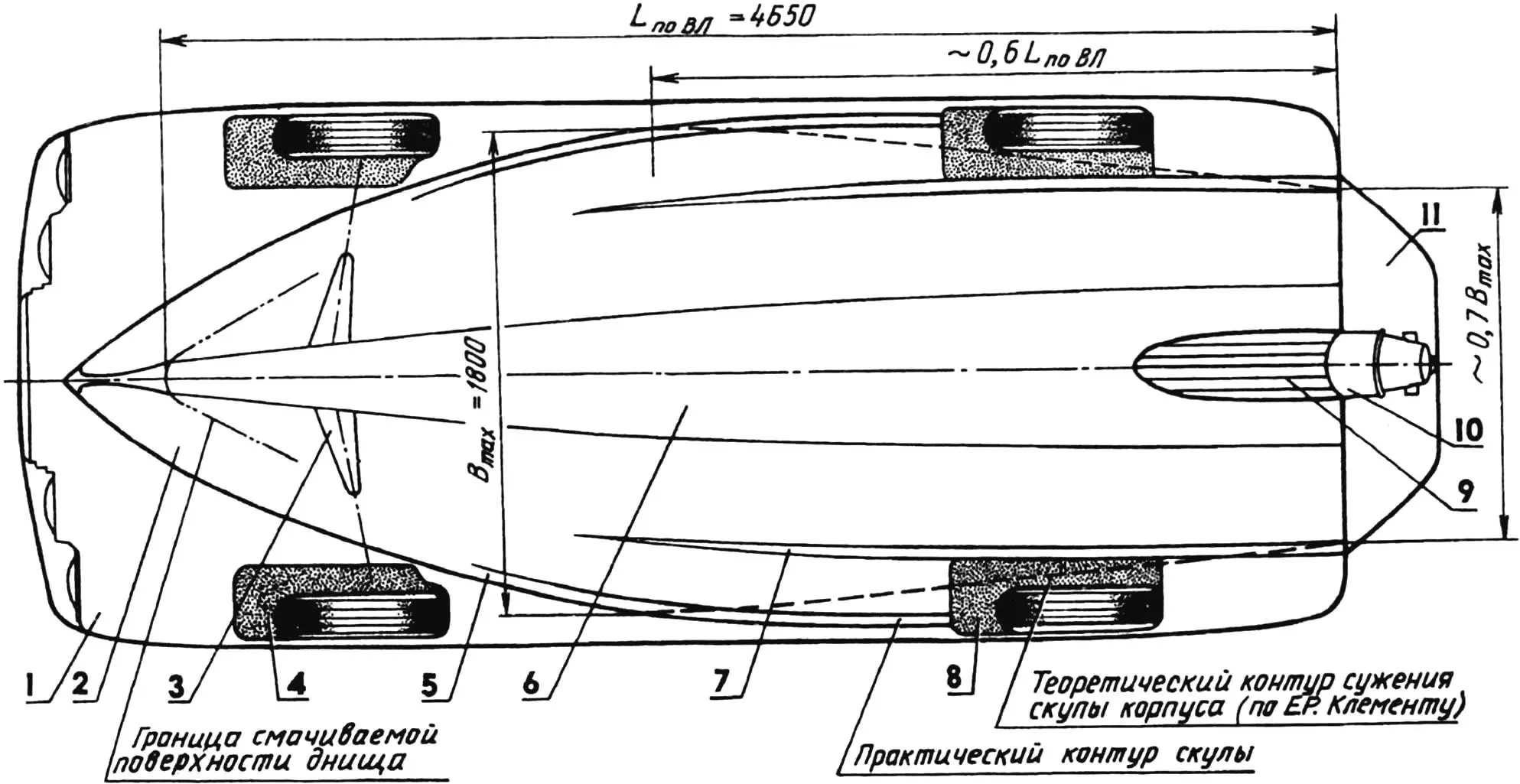

1, 9 — wheel suspension hydraulic cylinders, 2, 6 — wheels in «afloat» position, 3, 8 — yokes, 4 — driver’s seat, 5 — passenger seats, 7 — cabinet doors, 10 — rear door panels, 11 — engine liquid cooling radiator standard, 12 — sound-absorbing hood, 13, 34 — outlet and intake duct grilles, 14 — waterjet rotor shaft, 15 — waterjet reversing mechanism, 16 — waterjet housing, 17 — waterjet cam clutch, 18 — engine, 19, 28 — upper plates with wheel suspension dampers, 20, 29 — wheel suspension arms, 21 — propshaft cam clutch, 22, 31 — wheel suspension arm pivots, 23 — propshaft, 24 — sole (cabin floor), 25, 32 — duct lower and forward branches, 26 — propshaft intermediate bearing, 27 — hull structural frames, 30 — gearbox with differential, 33 — engine liquid cooling radiator additional.

The layout of the new amphibian’s powerplant and transmission is unusual: the engine (from GAZ-31029) is in the stern, and the gearbox with differential is in the bow. They are connected by a long, well-balanced propshaft with an intermediate bearing and a disconnecting device — a cam clutch. On the other side the engine is coupled via another disconnecting device (a similar cam clutch) to the waterjet rotor. Both clutches have welded housings filled with transmission oil. Their control is at the driver’s station.

This layout required special attention to removing excess heat from the powerplant. The two-circuit liquid and air cooling system on «Triton-2» is augmented by an additional low-height radiator at the very start of the duct (ahead of frame 1) that runs to the engine through the full length of the hull under the trunk and sole. The radiator and cabin heater are connected by a three-way valve to the engine supply hose, so either the radiator alone or the heater and radiator in series can be used. Behind the latter, on rubber seals, a spray shield is fitted, operable from the driver’s seat: in rain and on water in fresh weather it can be closed. In that case the radiator is cooled by natural spray.

1, 3 — door opening longerons (batten 40×20), 2 — lower rear door panel, 4 — ceiling stringers (batten 20×15), 5 — rear window, 6 — cabinet front bulkhead (aircraft plywood s3), 7 — half-beam (batten 30×20), 8 — gunwale (batten 40×30), 9 — timbers (frame vertical leg, batten 50×20), 10 — front wheel well bulkhead (aircraft plywood s4), 11 — skin (aircraft plywood s4), 12 — folding table panels, 13 — engine sound-absorbing hood (plywood, foam, leatherette), 14 — bottom longeron upper shelf (batten 20×20), 15 — additional longeron post (batten 40×20), 16 — passenger seat folding mechanism pivot, 17 — chine stringer (batten 30×30), 18 — bottom stringer (batten 30×25), 19 — bottom longeron post (batten 20×20), 20 — floor (frame lower leg, batten 70×20), 21 — bottom longeron lower shelf (batten 35×35), 22 — duct lower branch, 23 — hydrofoil (aircraft plywood s6), 24 — false keel (batten 60×30), 25 — knees (aircraft plywood s4), 26 — sole (aircraft plywood s6), 27 — door opening sill (batten 40×20), 28 — internal ladder step, 29 — half-floor (batten 30×20), 30 — transom, 31 — rear wheel well bulkhead (aircraft plywood s4), 32 — cabinet rear bulkhead (aircraft plywood s3).

The most important feature of «Triton-2», however, is the absence of «intermediaries» in its transmission — no reduction gear or chains in the wheel drives. The advantage is clear: fewer non-standard parts and assemblies, lower noise, simpler maintenance, and finally lower project cost.

Let us turn to the individual assemblies.

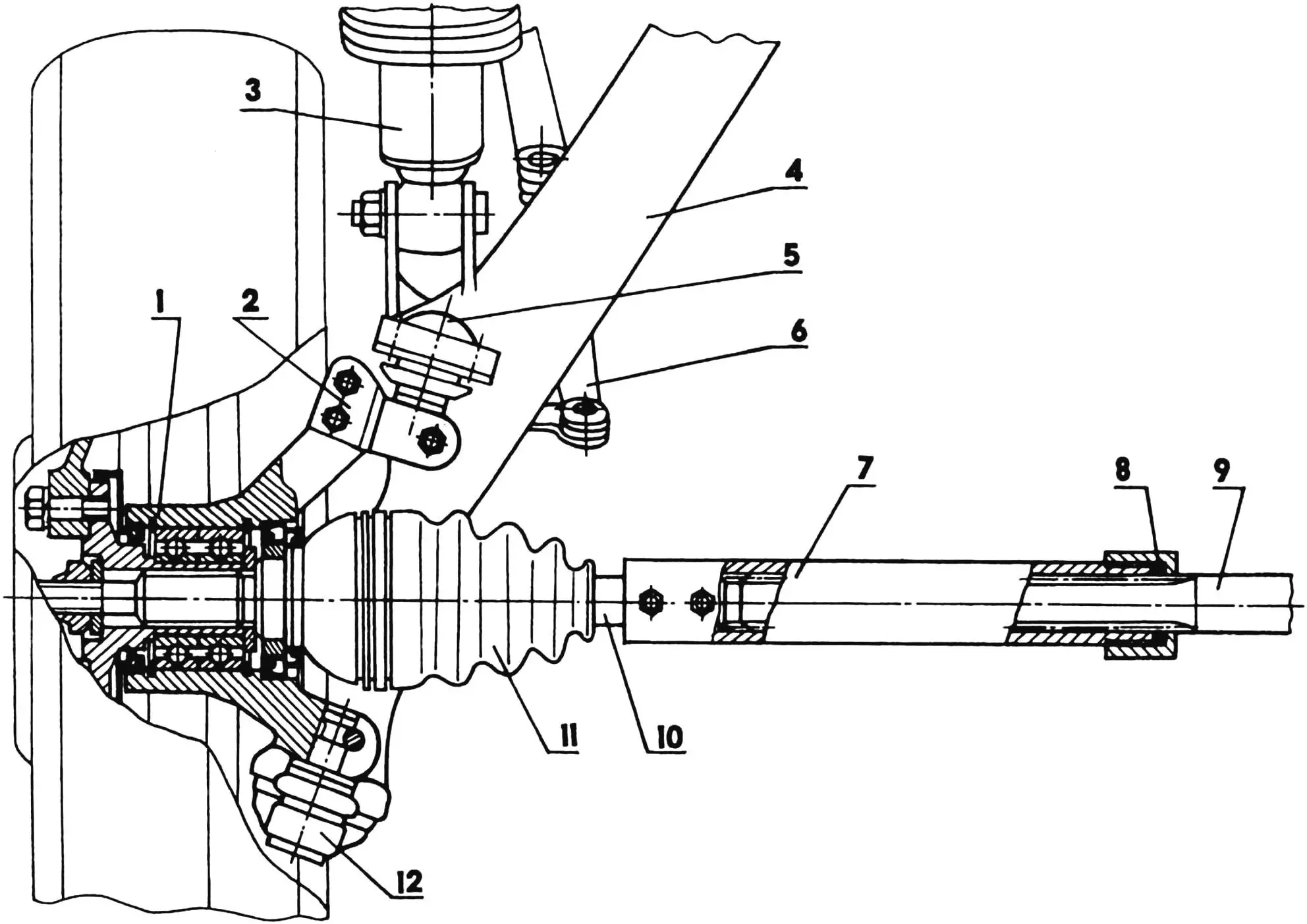

1 — steering knuckle, 2 — upper ball joint pin bracket, 3 — damper, 4 — suspension arm, 5, 12 — upper and lower ball joints, 6 — steering drive bellcrank, 7 — telescopic half-shaft splined tube, 8 — packed seal, 9 — telescopic half-shaft splined shaft, 10 — shortened standard half-shaft, 11 — CV joint boot.

The wheel suspensions have an important place in the new amphibian’s design. They are now raised from the water or lowered not by a cable winch but by double-acting hydraulic cylinders with indicator lights on the instrument panel. The mechanical part of the drive has been changed accordingly. The upper spring and damper plate is pivoted to the hydraulic drive yoke and, placed by it in the working position (in the support socket on the hull), needs no locking — the suspension kinematics are such that under load the wheels cannot move on their own to the «afloat» position.

The multifunctional nature of the front suspensions requires strict coordination of all their elements. In particular, the shape of the lower ends of the arms carrying the ball joints was carefully worked out on a mock-up so that the third function of the amphibian’s front drive — free wheel lift to 600 mm — could be performed without binding. The wheels are from VAZ-2108 together with constant-velocity joints (CVJs). They are linked to the ZAZ-968 differential by home-made telescopic half-shafts with sliding splines (travel up to 200 mm). This ability to extend allows the half-shafts to stay connected to the wheels when raising from the water. The suspension operation is also ensured by the special kinematics of the steering drive, taken entirely from the «Triton».

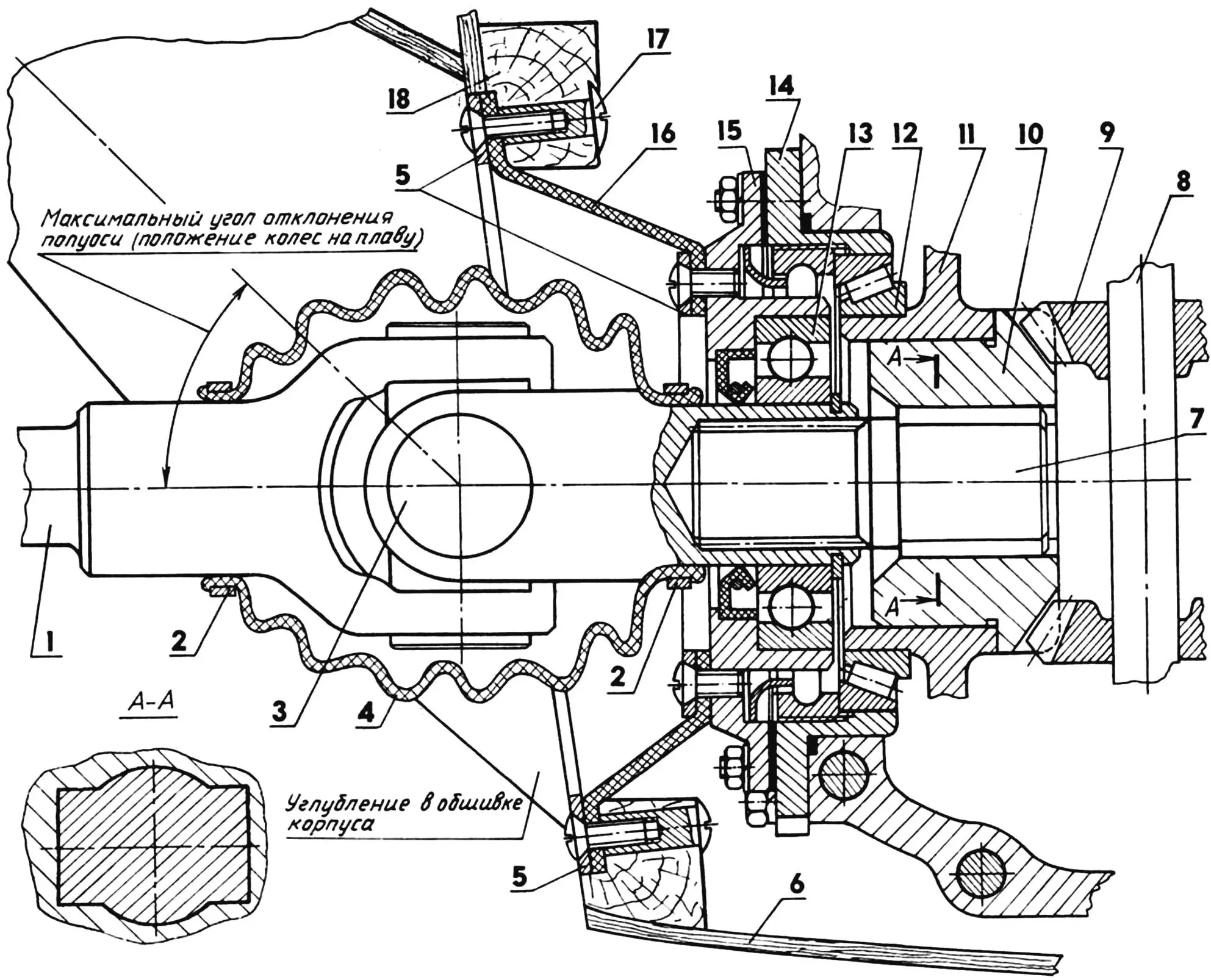

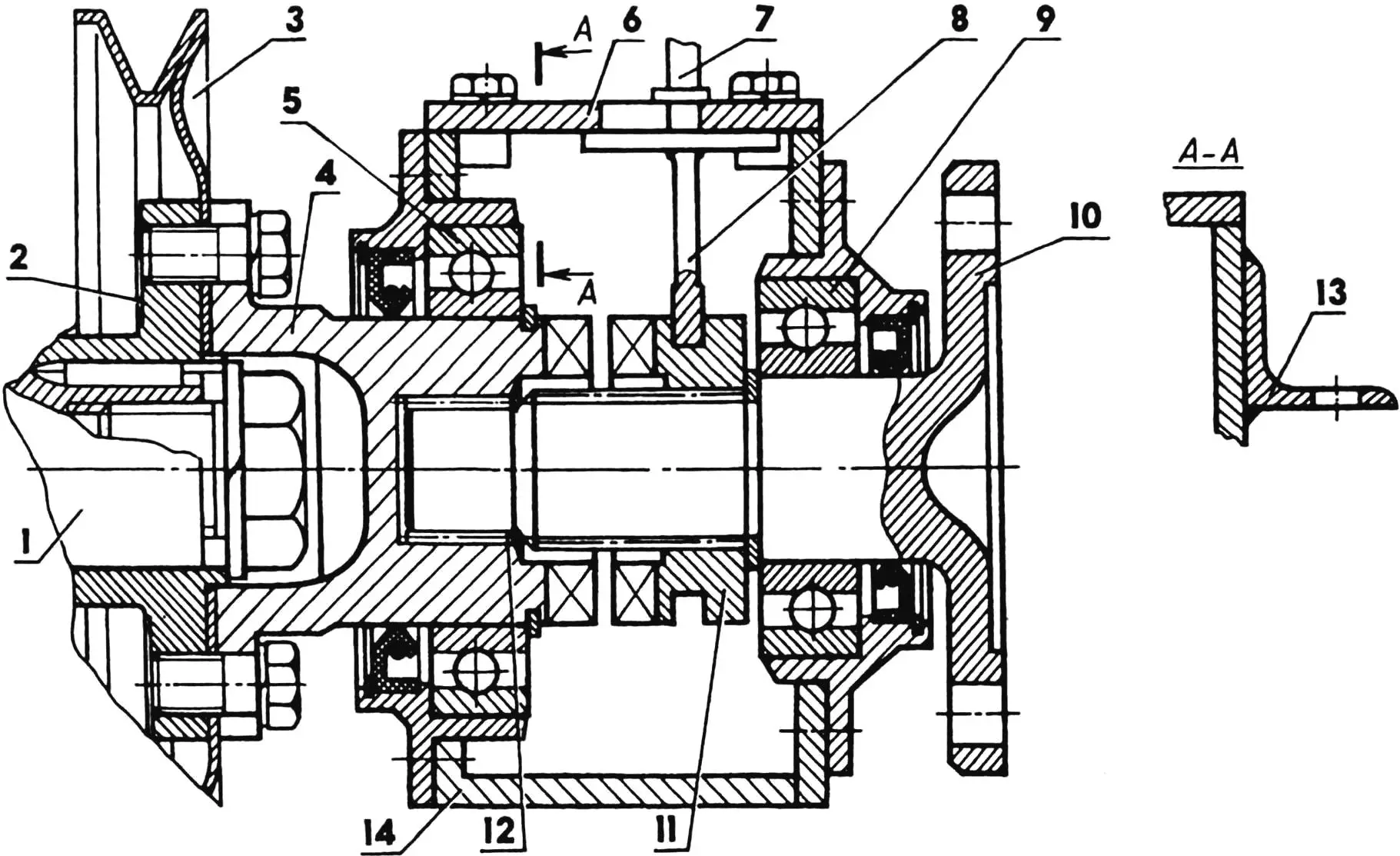

1 — half-shaft, 2 — clamps, 3 — universal joint cross, 4 — rubber boot, 5 — thrust washers, 6 — hydrofoil, 7 — combined shaft, 8 — pinion pin, 9 — pinion, 10 — half-shaft driven gear, 11 — differential housing, 12 — differential bearing 2007913, 13 — half-shaft bearing 206, 14, 15 — bearing housings, 16 — rubber cover, 17 — threaded sleeve, 18 — hull longeron.

On the differential side cardan joints are fitted with a break angle of up to 44° — with the wheels in the «afloat» position. The working angle of the joints is 2…4°. (I am currently working on fitting CVJs from the «eight» here too. I think they will be more reliable than cardans.)

I would draw attention to another very important feature of the front drive specifically for amphibians (with or without hull wells, displacement or planing): when the wheels are raised, both the suspension arms and the extending half-shafts take on practically the same V-shape characteristic of the bow boat portion of the hull, and the small recesses in the skin for the lower parts of the half-shafts do not impair the amphibian’s performance, since when planing the forward part of the hull literally flies over the water.

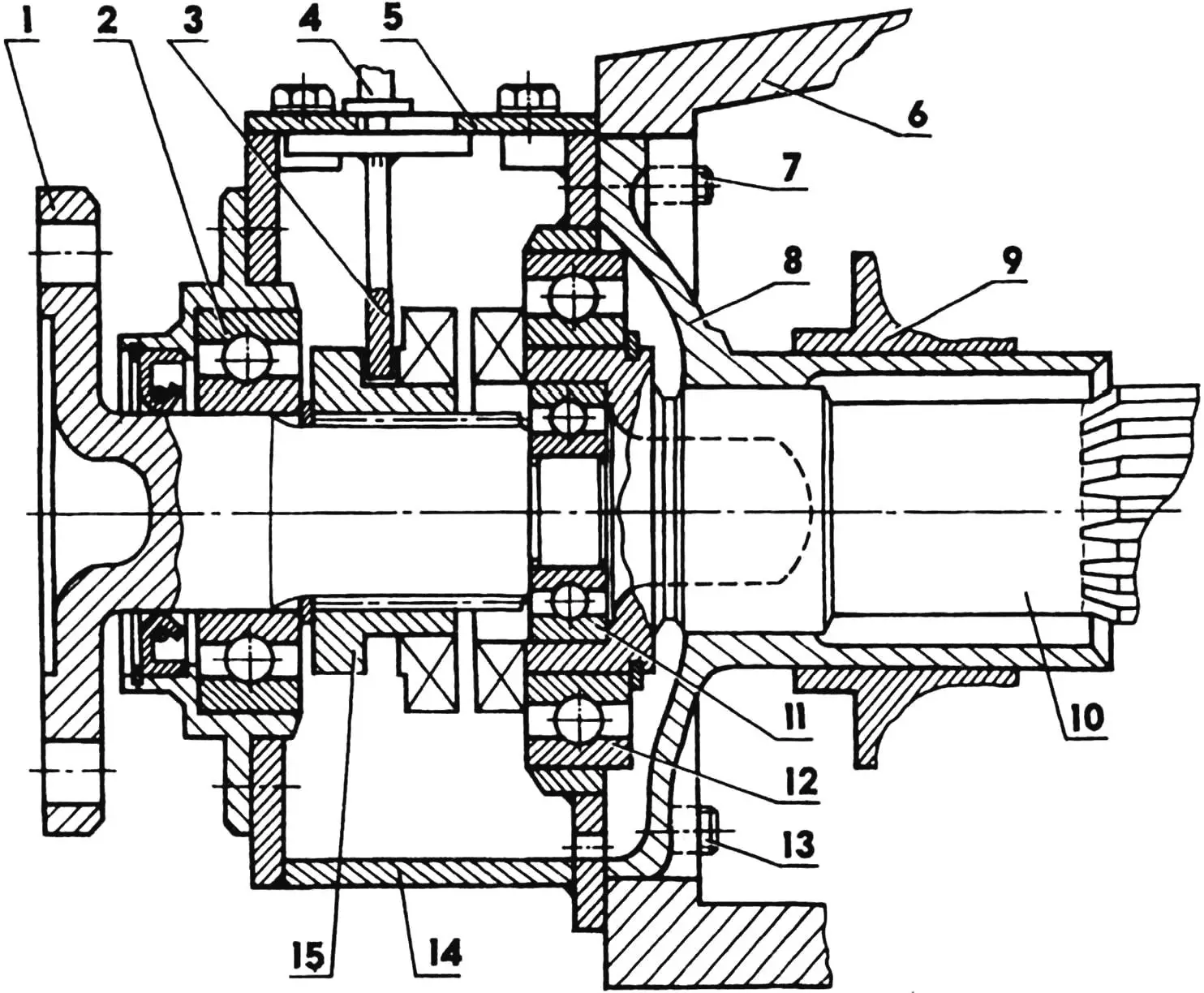

The propshaft disconnecting mechanism is a home-made cam clutch (only one part in it is standard — the front cover of the GAZ-31029 gearbox). It is attached to the engine clutch bellhousing face in the same way as the gearbox — with four studs.

1 — splined shaft, 2 — bearing 206, 3 — fork, 4 — driver, 5 — clutch housing cover, 6 — engine clutch bellhousing, 7, 13 — standard bellhousing studs (4 pcs) for clutch housing, 8 — engine gearbox front cover, 9 — clutch release, 10 — gearbox primary shaft with driving half-clutch, 11 — bearing 203, 12 — bearing 110, 14 — clutch housing, 15 — driven half-clutch.

The waterjet disconnecting mechanism partly repeats the cam clutch design. It is connected to the front end of the crankshaft via the generator and water pump drive flange. Three more bolts — M10×1 thread — were added to the three standard flange bolts. The starter ring is replaced by a bolt with a plain head.

The clutch housing has two angle brackets by which it is cantilever-mounted to the engine cylinder block through a special adapter made to fit (using cam cover bolts and sump studs).

To compensate for engine movement relative to the transmission, cardan joints with sliding splined connections are used in the gearbox and waterjet shaft lines, and to reduce noise and cushion shock loads — flexible rubber-metal couplings.

1 — engine crankshaft tail, 2 — crankshaft hub flange, 3 — water pump and generator drive pulley, 4 — driving half-clutch, 5 — bearing 110, 6 — clutch housing cover, 7 — driver, 8 — fork, 9 — bearing 206, 10 — splined shaft, 11 — driven half-clutch, 12 — needle bearing, 13 — right bracket (25×25×3 angle) for clutch to engine, 14 — clutch housing.

Both disconnecting mechanisms are operated remotely by cable from the driver’s seat.

The brake systems are the same as on the prototype: service — hydraulic, two-circuit, with dry hydraulic line connectors, acting diagonally on all wheels; parking — cable — on the rear wheels only.

From the above it is clear that the front-wheel-drive layout implemented on «Triton-2» fits into the hull quite naturally. It may be considered the most rational, if not the only possible one, since it allows getting rid of many intermediate units in the amphibian transmission in general, and in a planing one in the first place.

It is thought that the ideas embodied in «Triton-2» will help amateur constructors in building planing amphibians.

Purpose of «Triton-2»

The amphibian can be used as a weekend or long-distance touring vehicle on combined water-and-land routes. With appropriate outfitting it will find use in rescue services, coast guard, and expeditions.

Technical data

Curb weight, kg … 1100

Gross weight (displacement), kg … 1450

Engine power, hp … 100

Waterjet:

single-stage, rotor diameter/pitch, mm … 219/230

Highway speed, km/h … up to 120

Planing speed, km/h … up to 50

«Modelist-Konstruktor» No. 7’97, D. KUDRYACHKOV