All wheelchairs domestic production have a primitive manual transmission.

For issue electric wheelchairs under a license known to the West by “Myra” preparing stavrovskiy plant of automotive and tractor equipment. But… its mass is 120 kg, and the cost — almost like “Zaporozhets”. This stroller is deprived of the opportunity to develop and to move it in case of failure of the actuator due to its own muscles cannot.

All this made us to undertake the creation of Autonomous drive for a standard wheelchair. During the development process it becomes a small and light unit set-top box, dubbed “Letran”. This solution allows first of all to convert commercially available wheelchairs in electrified without the design improvements that make them easier to transport, carry and storage, no increase of size, has the ability to use manual drive.

Our self-contained unit also can be used for electric light vehicles.

Overall dimensions of the drive: length 403 mm, width 290 mm, height — 440 mm; weight 32 kg; electric motor power — 220 W; battery capacity — 55 A. C. voltage motor power supply — 12 V. the Maximum speed of the chair with the “Alerana” is 7 km/h Time of continuous motion to charge the battery depending on load — 3…5 hours.

Schematic view of the wheelchair with electric drive “Letran” shown in our drawings. The block console is located under the seat between the rear wheels; the frame of the wheelchair it is attached pivotally by means of a lever. The coupling consists of a fixed on the frame of the seat of the two brackets which screws-lambs fixed axis freely rotating in the hub of the lever. Retaining bolt prevents movement of the bushing along the axis. Disconnect block-console disabled person can independently, without rising from the chair. To do this, just Unscrew the thumbscrews and disconnect the electrical connector.

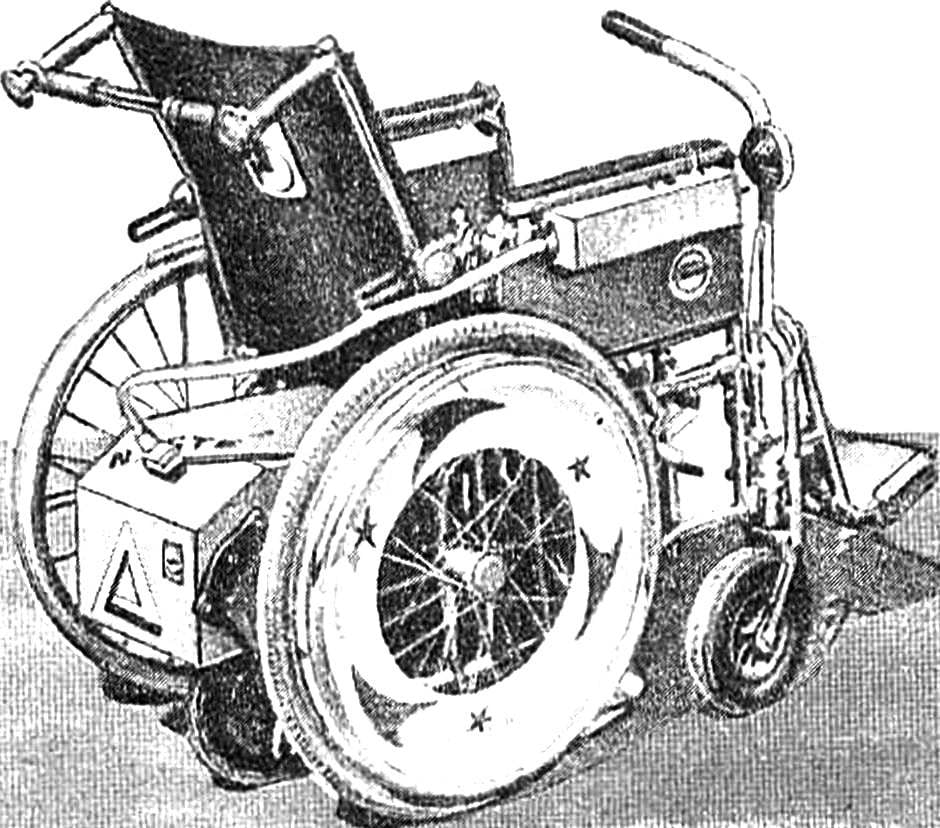

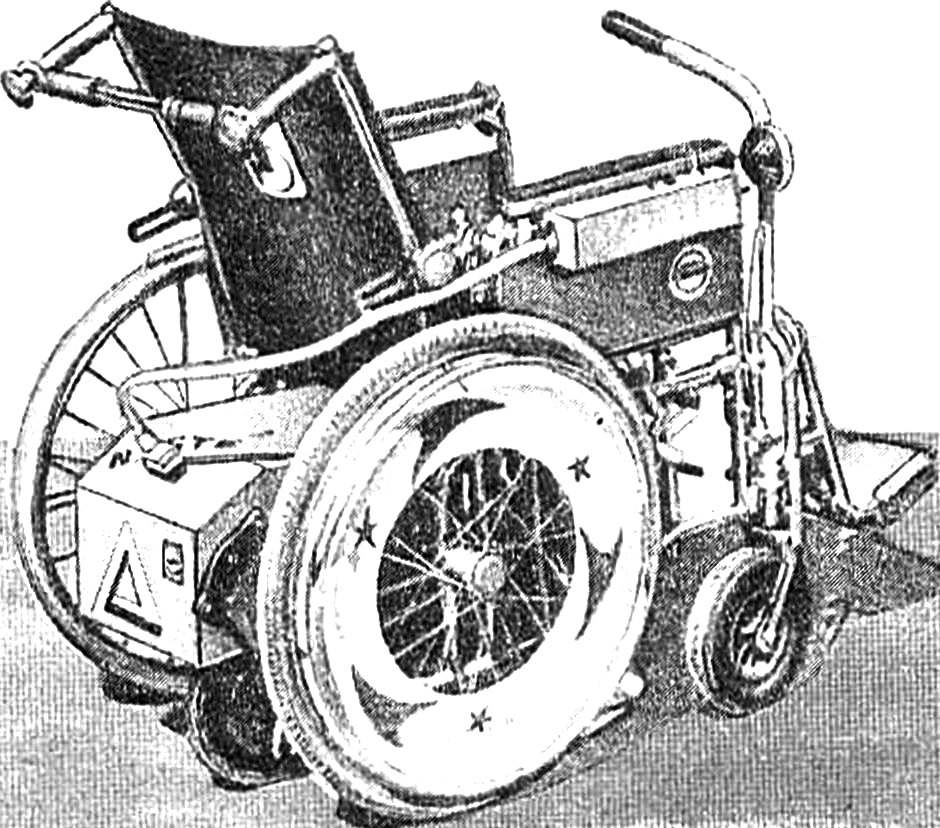

General view of a wheelchair with self-contained electric:

1 — wheelchair 2 — Autonomous motor unit-prefix “Eletron”, 3 — bracket axis, 4 — axis, 5 — lever, 6 — nut, 7 — screw-clamp, 8 in — sleeve.

Stand-alone unit with electric drive:

1 — frame, 2 — battery, 3 — reducer, 4 — electric motors 5 — chain, 6 — wheel, 7 — casing, 8 — electronic control, 9 — control panel 10 — plug 11 — steering arm, 12 stud.

Thanks to the hinge and symmetrical load distribution with respect to the axis of the drive wheel unit does not load the frame of the chair and substantially does not change its technical characteristics. Driving wheel loaded unit weight, can develop traction sufficient to ensure that when the passenger mass of about 80 kg climbing slope about 20°. Need to mention that our wheelchair allows you to confidently move only on roads with improved asphalt or concrete surface. This is due to the small diameter of the front wheels (220 mm); is the same wheel used in the unit of the electric drive.

The scheme of installation of electric motors:

1 — shaft (steel 45), 2 — coupling half (D16T), 3 — the right coupling half (D16T), 4 — left coupling half (D16T), 5 — elastic element (rubber), 6, 8 — right and left engines, 7 is the driven gear.

Unit “Letran” shown on our drawings. Structurally, it consists of a rigid welded frame which includes a battery, gearbox and the engines. The reducer through chain transmission connected to the wheel hub; the unit is completely enclosed. The motor control is carried out using a controller.

For block fabrication equipment was used, commercially available industry: automotive starter battery type 6СТ55, two DC motor МЭ272 (used in the last models the “Muscovites” and “Lada” for the fan drive cooling system) with a capacity of 110 watts each and a two-speed gearbox engine type In-50 (moped).

Carter, standard motor-50 is truncated in such a way to remove the mechanism kick-starter. The place is closed with a lid. The crankshaft is also removed. Instead installed the shaft coupling and its both ends are connected with the motors.

Refinement of engine In-50:

1 — plane trim Carter’s 2 — axis mounting holes, 3 — a crankcase-50, 4 — axis crankshaft 5 — axis sprocket, 6 — axis struts of the engine mount, 7 — gear shift lever, 8 — flanges.

To secure the engines, you must prepare the place for the studs. On the crankcase right and left (in a place) located plate alloy D16T with a thickness of 3-4 mm. length of the select pins so that the two coupling halves had a slight axial play.

Alteration of the gear shift mechanism is as follows. The standard switching mechanism is pivotally connected a lever arm. Speed — first, neutral and second switches by turning the handle. In a convenient location to the frame is welded to a plate with three grooves in which the lever is fixed at a predetermined transmission. Of course, you can use a cable shift linkage.

Reducer it is advisable to fix on the frame is not hard, and using rubber gaskets-absorbers. It is very important to adjust the alignment of both engines, and all gears and bearings are lubricated with grease. The unit will operate with minimum noise.

In the transmission chain used regular sprocket moped (Z=15) and the driven sprocket of a Bicycle “Eaglet” (Z=41). With this gear ratio sprockets electrified wheelchair can develop in second gear the speed of 7 km/h, and on the first of up to 3.5 km/h the moped chain Tension should be carefully adjusted.

The steering is made in the form of a lever which can be connected either with the right or left front pivoting wheel of the wheelchair. For this you need to remove the axle with bearings front wheel and loosen the nut with its axis. In place of nuts wrapped the threaded end of the steering lever and the plate, marked in the figure by the letter “G”, combined with the feather fork, and then after they drilled the bolt hole M6.

Steering “Alerana”:

1 — steering arm 2 — spacer, 3 — tube, 4 — arm, 5 — puck.

Circuit of the inverter control of motors.

Electrical schematic of the control panel.

The figure shows also the electrical diagrams of controller and control panel. Transistors 818 and KT 7КТ152-63-3 must be placed on the radiators. The contacts of the relay R should be designed for switching current up to 10A. Variable resistors 2.2 kω device is adjusted so to narrow down to the desired limit the angle of rotation of the resistor in the control handle. After the output transistor of the regulator will be fully open, further turning the knob will actuate a relay, allowing direct connection of motors to the battery.

The purpose of the switch “S1” on the remote — reversing motors reversing. Switch “S2” includes the controller unit. Socket “S3” connect charger and external consumers voltage of 12V: radio, heating pads, car type, water heater and food, etc.

Given our description of the unit of the electric drive is designed for homebrew who already have experience of independent work and some Amateur skills. It is obvious that in our design it is possible to improve a lot and even more so to use some of the other components and parts.

Versatility “Alerana” is that it can also be used to drive bicycles and pedal cars, children’s electric cars, trucks in-plant transport trolleys used in hospitals and sales rooms, with a capacity of 100…150 kg. of Course, depending on the desired speed of the vehicle will have to choose the appropriate value of the gear ratio of a chain drive, and in some cases to install on the unit driving wheel of larger diameter, for example, “the sulker” with a diameter of 340 mm from the children’s bike. Should probably mention our experiments on additional equipment wheelchairs and recumbent with solar panels. Note that this significantly increased the autonomy of the “Letrina”, and recumbent turn into santamobile.

Scheme of the solar bike.

Scheme cancellous.

Children’s pedal car with electric motor and solar panel.

Cargo trolley with power drive.

Recommend to read ADDING MACHINE FOR “KIDS” Now, not only in family but also in kindergartens of children of five, six, and even earlier beginning to see the first difficulties addition and subtraction within the initial two or... VELOVIC WITH POCKETS Two-wheeled transport — an indispensable tool: the products whether to go to a distant shop or a neighbouring market, potatoes from the garden to bring — but few if any economic goods in... Scroll back to top

All wheelchairs domestic production have a primitive manual transmission.

All wheelchairs domestic production have a primitive manual transmission.