Little micro-car “Buddy” machine… for kids. It was created in a laboratory experimental simulation and design Club for young technicians Novosibirsk Akademgorodok. Despite its small size, it all like a real car: engine, transmission, driveshaft, closed rear axle with a differential and other components.

Little micro-car “Buddy” machine… for kids. It was created in a laboratory experimental simulation and design Club for young technicians Novosibirsk Akademgorodok. Despite its small size, it all like a real car: engine, transmission, driveshaft, closed rear axle with a differential and other components.

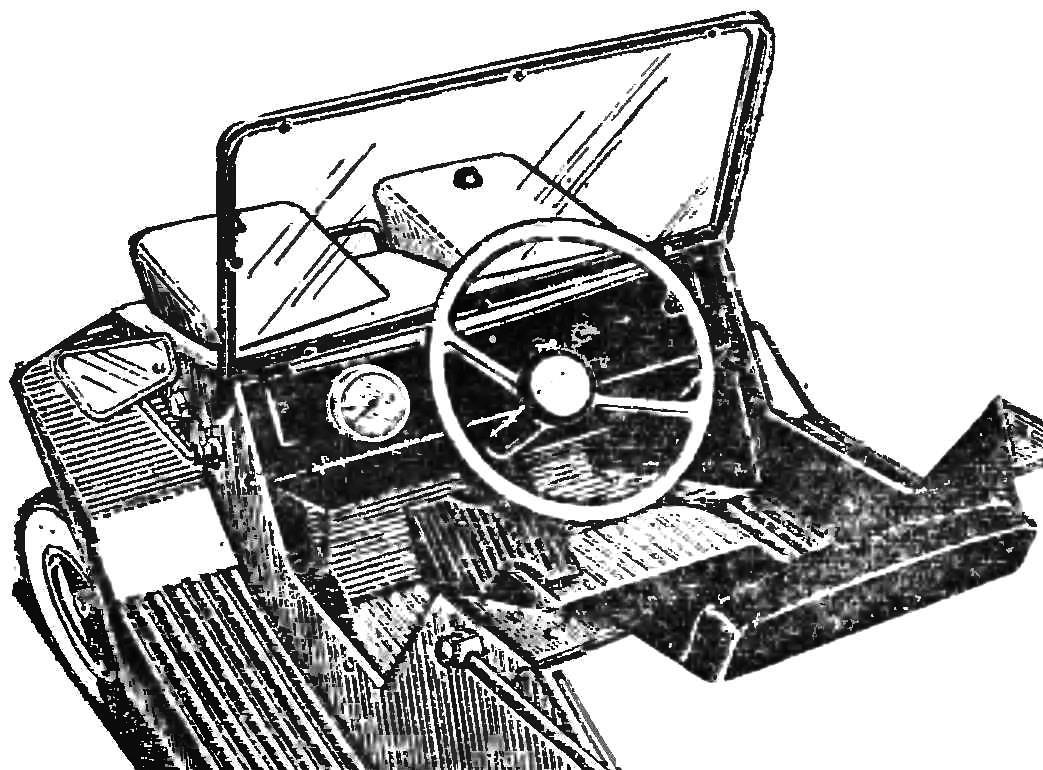

Open body is very compact and is intended only for yourselves, to protect the young driver from rotating parts and spray when driving on wet roads. In the back there is a soft driver’s seat, control levers, instrument panel and steering wheel (Fig. 1). All this is mounted on the chassis of the machine and is not connected with the body.

Unfastened the two locks installed on the dashboard, the body can be raised and free access to the engine.

To remove the body Unscrew the two bolts at the rear, which are the axes of the hinge body. The car body is made of cold rolled steel sheet thickness 0,7 mm. the car Shape is strict and straightforward. Such a solution allows to lighten the work in the manufacture of machines and does not require special equipment.

Fig. 1. The driver’s seat.

On the slant of the hood in the “radiator” grilles installed two lights of a motor scooter Ø 95 mm, and the rear direction — indicator lamps and stop lamps. Two direction indicators are on the sides of the front end.

The machine is fitted with fenders — mudguards with steps, covered with a rubber Mat. Windscreen if needed, you can lay on the hood body and secure with lock retainers.

The body is painted white nitroglyptal enamel, the wings of the car — bright red, with the silhouette of the body these two colors combines and gives the car a smart look.

The rear of the car is made in the form of open space, it is trimmed with a chrome cover molding and polished duralumin guard rail.

Instrument panel painted black, it has a speedometer, warning lights, three switch: turn on ignition, turn on headlights, the inclusion of turn signals. An additional toggle switch under the dashboard serves as a transition from DC to AC when charging the engine.

On the flap there are two lock body mounting and the button sound Electrosignal (see Fig. 1).

On the chassis and inside the body mounted harness electrical terminating connector to six contacts. With this connector chassis wiring connects to the electrical system of the body. Connector is installed inside the instrument panel.

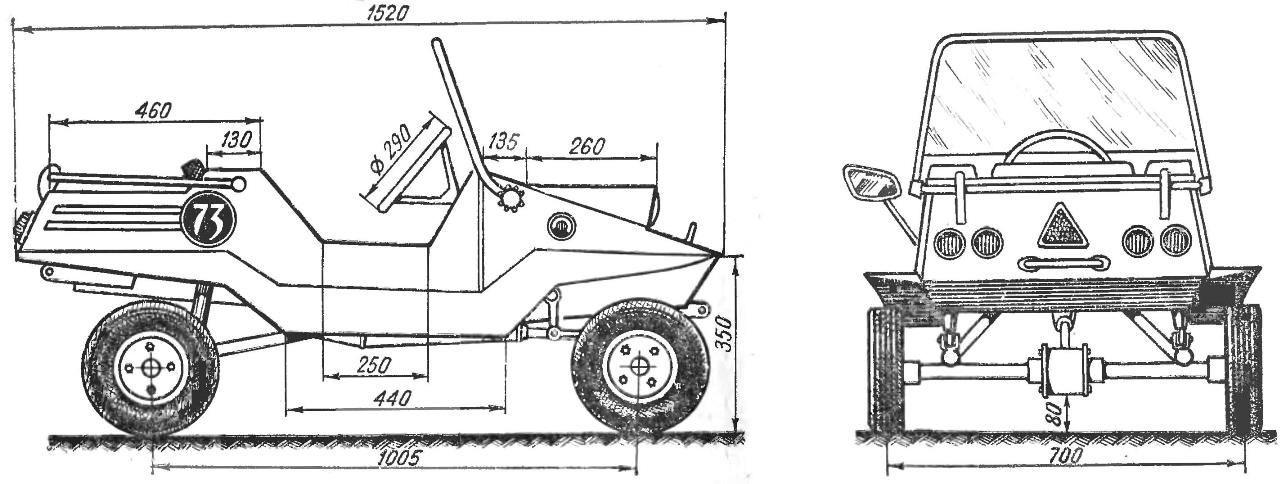

To the chassis of the car “my Friend” applies steel tube frame consisting of two longitudinal members and five cross members. The total length of 1240 mm. frame, the Frame has a trapezoid shape, extended at the rear. Dimensions of cross: rear — 580 mm, front 370 mm. the Frame is welded from pipe Ø 20 mm.

In the front part of the frame includes a bracket engine with three eyelets. The engine is mounted across the frame with screws. On the upper ends of the bracket welded to the two fingers to install shock absorbers front suspension.

For the third cross rail to the upper part of the frame is welded a U-shaped bracket of the instrument panel, he also serves as the front support of the body.

The fifth cross rail to the top of the side members with the right and left sides are welded two brackets with brackets in which the ends there are holes for bolts suspension components of the rear axle.

To the bottom of the fourth cross member is welded four lugs for mounting of the pendulum rear suspension (Fig. 2).

Fig. 2. Side view and rear.

In the corner, to the left, on the back of the frame is welded box to install the battery pack.

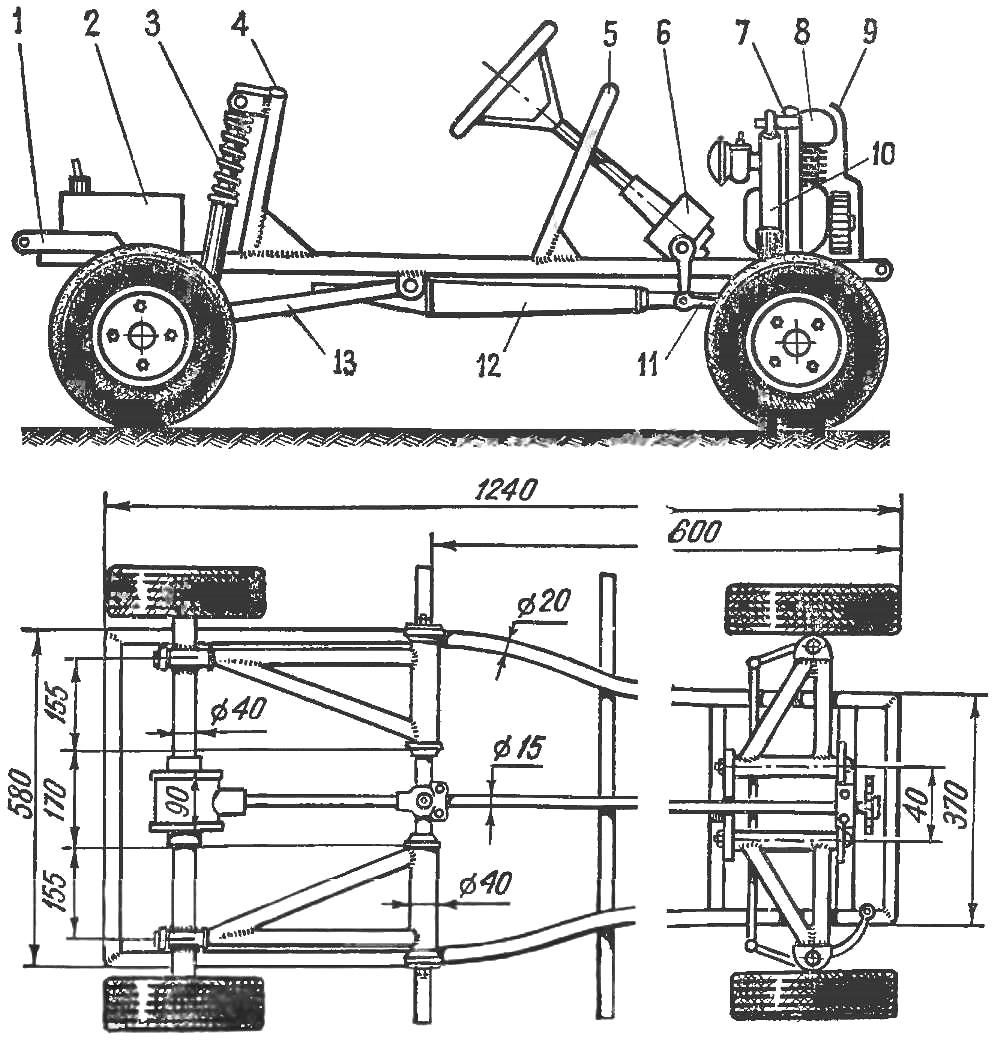

The front axle consists of two lateral horns in the form of rectangular triangles, welded steel tubes 0 20 mm. In the vertex of the angle is welded axle steering knuckle front axles. Near the axle brackets are welded with holes for the mounting bolts of the front shock absorbers. In the pipe, which is the leg opposite the vertex of the angle, the trunnion pressed two bronze bushings, in which are held bolts of the rocking plates to the frame (Fig. 3).

Fig. 3. The look of the car from the side and from above with removed body type:

1 — bracket hinge mounting of the body; 2 — tank; 3 — suspension; 4 — a suspension bracket; 5 — P arc-shaped fixing body; 6 — the steering mechanism; 7 — bracket front suspension; 8 — engine; 9 — coolant fan shroud; 10 — spring suspension; 11 — longitudinal steering rod (conventionally shown on the right); 12 — the muffler of noise of issuance; 13 — pendulum rear suspension.

The steering mechanism. In the rocking axle set steering knuckle front axles. On the axis of the worn hub, which rotate on ball bearings closed type. They fixed the Ganka and zaspirtovanny. The hub has four studs that secure the wheel disc.

On the left steering knuckle is welded to the lever rod, which is connected with a plow steering mechanism, and vengeful gear ratio 1 : 3. Both the steering knuckle by ball joints and are connected with the transverse rod. Thanks to these tie rods wheels have synchronous rotation.

Rear axle has a collecting sump, consisting of a welded steel ring welded to it with a socket bearing shank. In bearings mounted on the shank of the propeller shaft. Two sides to the ring with five bolt flanges pressed with sleeves for the axles. In each sleeve with the socket-recess molded into the ball bearings. The sleeves rotate on bearings steel axle with splines on the ends. The inner ends of the axle shafts enter the slotted bushing differential rear axle, outer, leaving the sleeves in the wheel hubs, fixed with nut and sprintout.

Rear axle is suspended on two independently swinging pendulum. The front part of the pendulum is fixed in the lugs of the frame similar to the mounting of the rocking of the front axle. The back has the fingers that are part of the bushing that is welded to the top sleeve of the rear axle housing. The fingers are fixed with nuts and splinted and bushings installed free to on rough road the rear axle would have the angular displacement and the transverse plane.

Pendulums made of pipe Ø 20 mm. Rear axle attached to the frame via a spring-loaded shocks with eyelets on the rear ends of the pendulum (see Fig. 3, 4.)

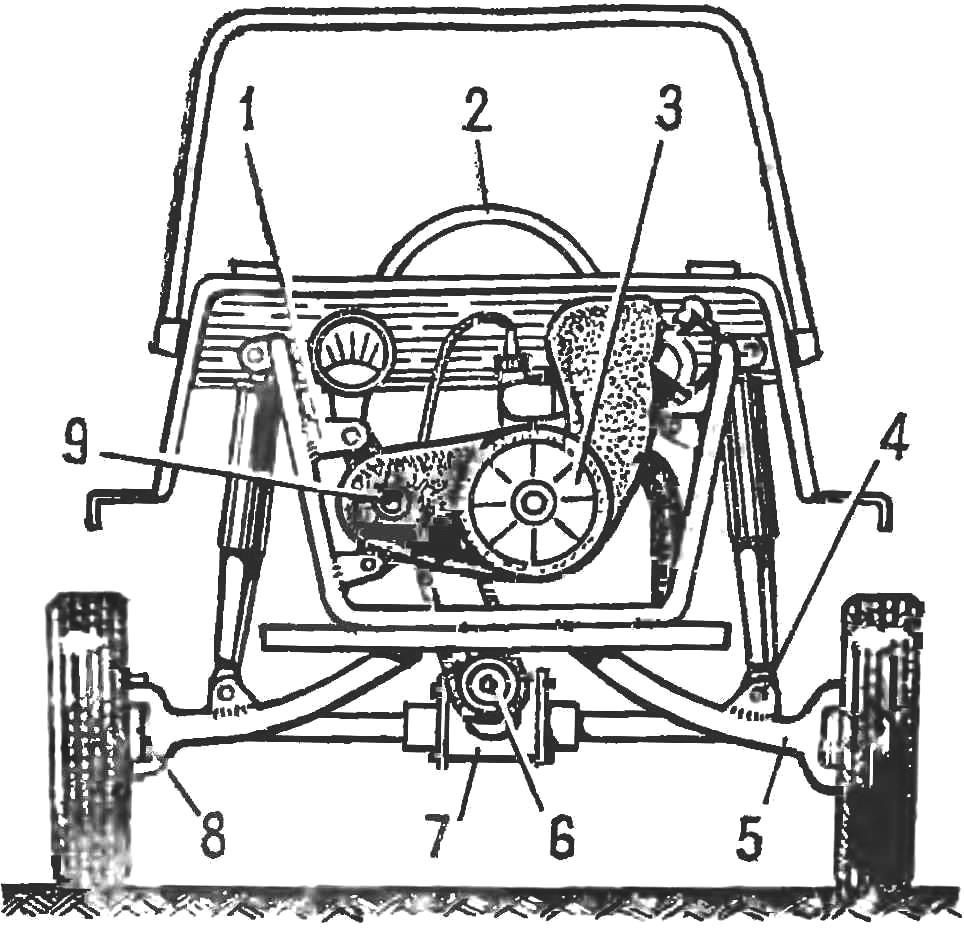

Engine. On the car “Friend” installed a two-stroke engine, sh-50 with a displacement of 49.8 cm3. For better cooling on the crank shaft is worn the impeller, which rotates and drives the flow of cold air on the cooling fins of the cylinder and the head Cover of a casing removed, the lower part of the ledge cut below the chain from the sprocket of the engine were not ago, as the moped down to the star of the propeller shaft (see Fig. 4).

Fig. 4. Front view with removed body type:

1 — bracket with lugs; 2 — steering wheel; 3 — fan; 4 — bar suspension mounts; 5 — rocking chair front suspension; 6 — asterisk propeller shaft; 7 — Carter differential-bowl; 8 — rotary axle, 9 — ratchet hand crank.

The propeller shaft is made of 45 steel, Ø 15 mm, total length with hinge equal to 1000 mm. On the front end there is mounted a sprocket PA 21 teeth, which is fixed on the dowel and tightened the nut. For asterisk is an indoor suspension bearing bracket, which prevernal two bolts to the front crossmember. The second bearing is installed on the bracket from the third crossmember. At the rear end of the shaft is mounted on the splines of the universal joint. Its one side is connected with the shaft shank of the rear axle welding.

The overall layout of chassis and its main dimensions can be seen in figure 3.

Management. On the car “Buddy” like on other cars, there are a number of levers mentioned earlier. We will focus on the specifics of managing “Friend”.

Usually the car is driven in the following manner: with the engine running press the clutch pedal, include the transfer, smoothly releasing the clutch pedal at the same time adding to the momentum. Our car is different. The young driver there is no need to do such complex manipulation, and we need only simultaneously and smoothly, press both pedals — the clutch and gas. To stop, we need both pedals to let go. The brake pedal on the Hog there. It confuses the young driver. So on the right side of the cockpit mounted lever hand brake, which is always handy. Brake pad is pressed directly to the rubber wheel at the top.

In the power supply system includes: fuel tank (PVC container), mounted on a metal bracket welded to the frame; a fuel line connecting the fuel pump with the carburetor, and the carburetor. The fuel pump from the boat motor “Moscow”, the diaphragm runs from the pressure fluctuations in the crankcase of the engine.

Electrical equipment for Hog — sectiontwo, combined DC and AC. For better winding turns on the switch connecting the battery with the ignition system.

When the engine began to run, the battery is disconnected, and the ignition system is the same toggle switch is switched to from maggino. From her on-the-go work lighting and signal lamps. With the engine off, parked, you can connect the battery.

TECHNICAL DATA OF THE CAR

Dimensions, mm: length — 1520mm, width — 780, height — 800 (with a lowered windscreen — 540); base — 1005 gauge — 700, wheel diameter — 290. Machine weight — 47 kg. Engine — sh-50 with a displacement of 49.8 cm3, the transmission on the ass of the wheels combined with the prop shaft. Speed: limiter — 5-8 km/h without the limiter — 40 km/h. Electrical equipment — sectiontwo, combined. AC and DC current. The body is all-metal, outdoor single.

M. LARKIN