With the best examples of technical creativity S. P. KOROVIN, designer from the city of Kumertau (Bashkortostan), readers of our magazine are already familiar. In the “photo stitch” (see “modelist-Konstruktor” No. 1 2000) was presented his most famous design: the plane “Visit”, children’s car, seven-seater “Orbit-1500” and the water motorcycle (jet ski). Later readers appreciated another Stanislav Petrovich development company “askor” (“modelist-Konstruktor” No. 4-5’02). Now available “Marlin” is an improved version of the watercraft, published in “Panorama”. “Marlene” is superior to its predecessor in terms of maneuverability, comfort and design.

With the best examples of technical creativity S. P. KOROVIN, designer from the city of Kumertau (Bashkortostan), readers of our magazine are already familiar. In the “photo stitch” (see “modelist-Konstruktor” No. 1 2000) was presented his most famous design: the plane “Visit”, children’s car, seven-seater “Orbit-1500” and the water motorcycle (jet ski). Later readers appreciated another Stanislav Petrovich development company “askor” (“modelist-Konstruktor” No. 4-5’02). Now available “Marlin” is an improved version of the watercraft, published in “Panorama”. “Marlene” is superior to its predecessor in terms of maneuverability, comfort and design.

In Bashkortostan a lot of rivers and lakes, on the shores a great place to spend the weekend. Often a lovely summer morning Korovina was getting into his “Orbit-1500” and went to the nearest pond. It is one thing to rest only on the shore, the other still on the water. Stanislav had a motor boat, but for transportation it required a rather bulky trailer. So never took the boat with me…

Once Stanislav, looking through technical literature, he suddenly realized, as he finally solve the problem of water recreation. In one of the technical journals he saw the figure, three projection of a jet ski with dimensions. And a short explanatory text. Stanislav remembers only that the jet ski was called “Marlin”. It then left your apparatus. Although its power circuit and fabrication technology was developed independently. He himself had experienced the new design.

The design and construction of the watercraft gone several winter and spring months. Summer Stanislav hung on a transom Board of a boat motor Breeze (eight horsepower) and pulled the “Marlin”… in the city pond. With a single rider jet ski and there is even glissirovat! But to travel together in motor output “Breeze” is not enough.

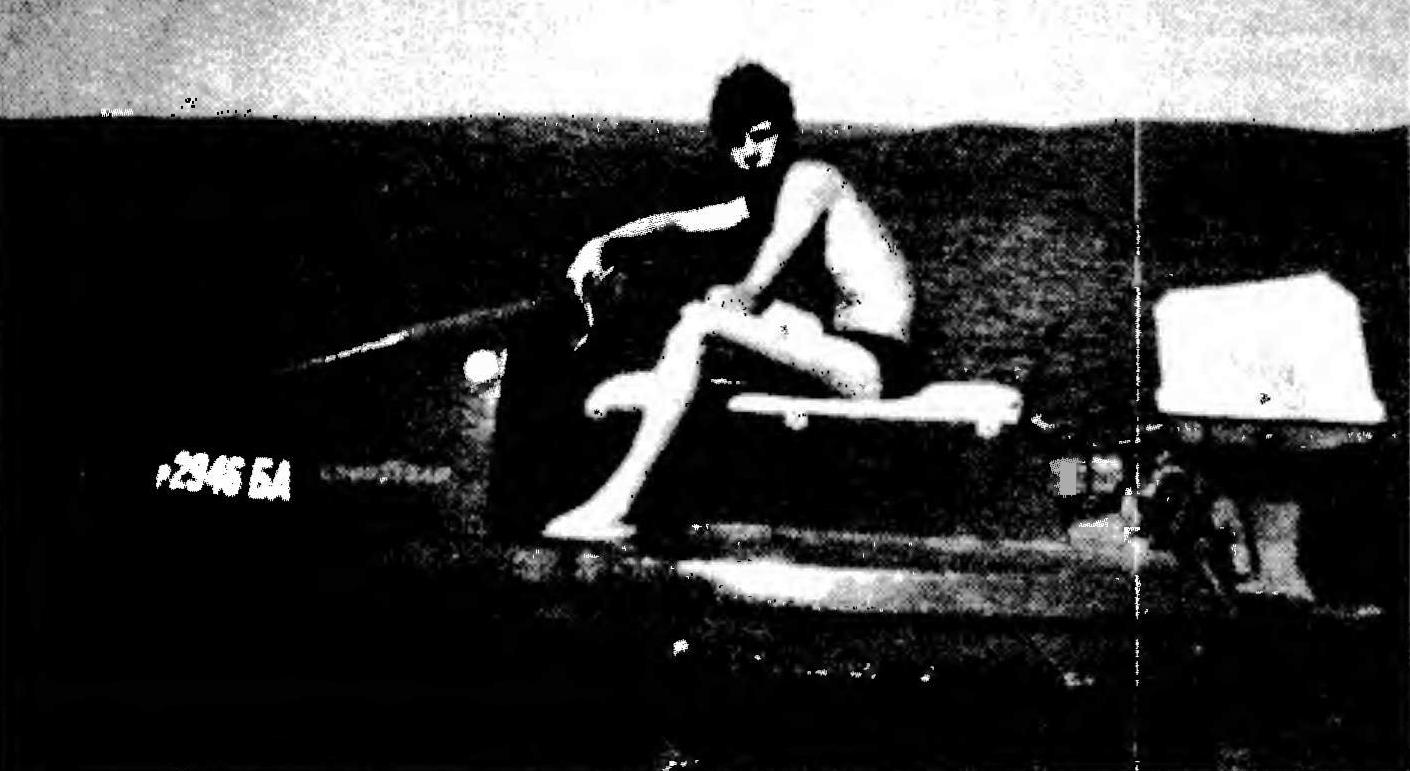

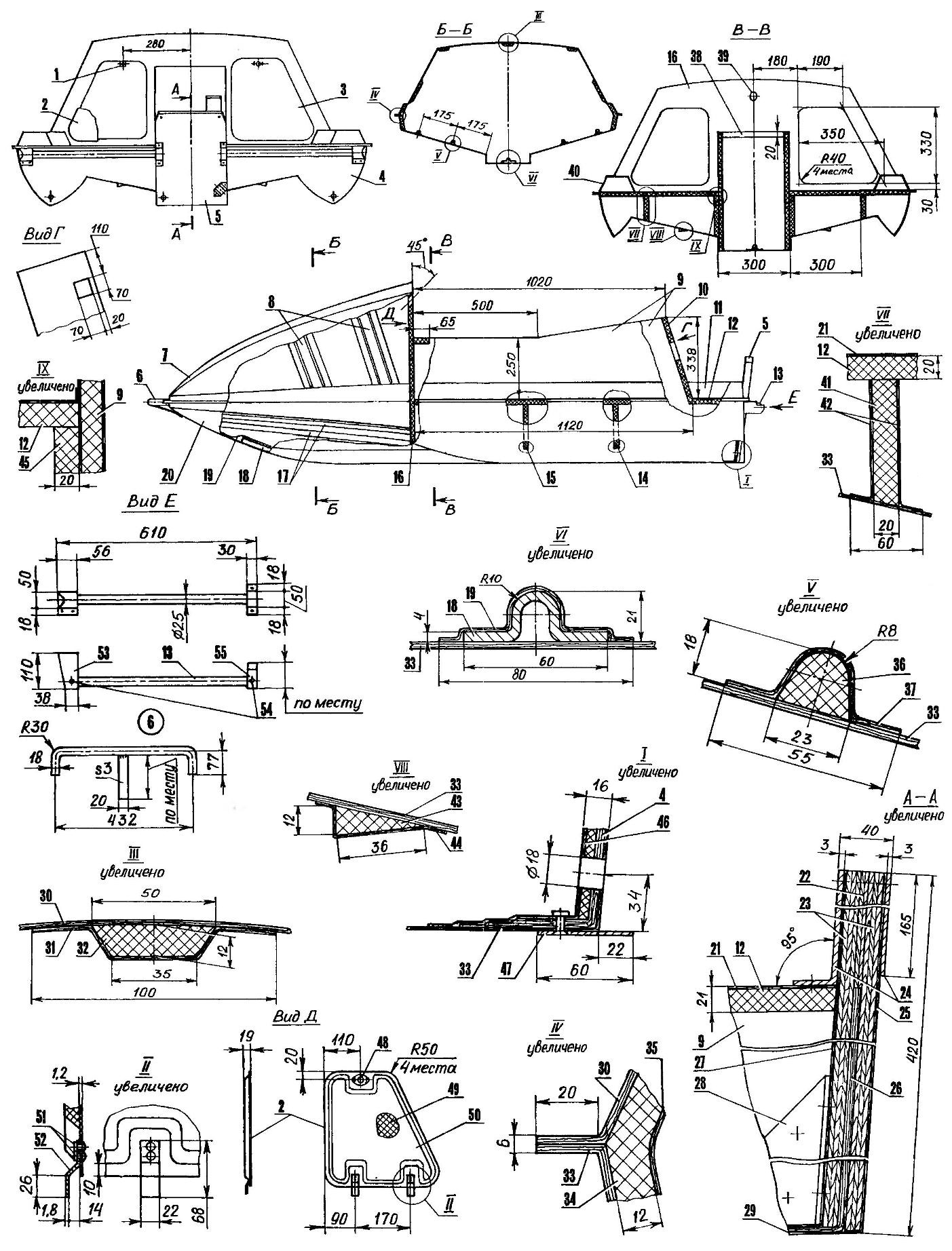

Watercraft “Marlie” engine (conventionally not shown):

1,9 — holes for draining water from the housing; a 2.7 — longitudinal planing steps; 3,8 — transom handrails; 4 — bracket remote receiver water pressure (speed sensor); 5 — transom Board; 6 — hole for draining the water from the aft Luggage compartment; 10 — the left nose hatch of the trunk; 11,19 — removable manhole covers; 12 — fairing the nose of a trunk; 13 — double seat; 14 — left hand steering wheel; 15 — button start starter switch “stop”; 16 — a speedometer; 17,24 — halves decorative casing the helm; 18 — right arm wheel drive control throttle of the carb (lever throttle); 20 — thrust of the rotation of the engine; 21 — bow grab handle with a support; 22 — the steering shaft; 23 — fairing vehicles; 25 — the seat is in the raised position; 26 — loop swivel seat mounting; 27 — locking raised seat; 28 — the aft wall of the trunk; 29 — tie-rod; 30 — the bottom of the watercraft

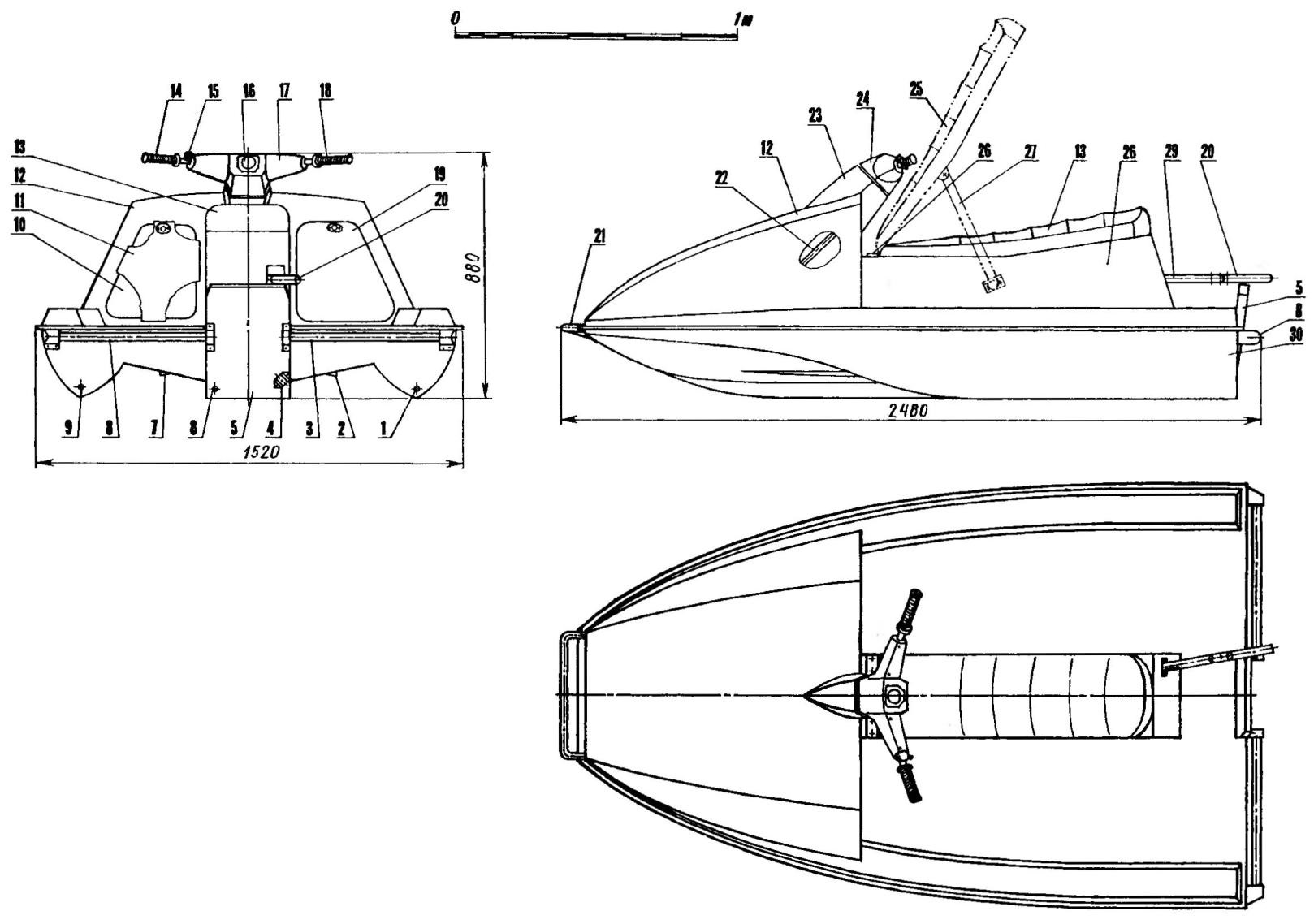

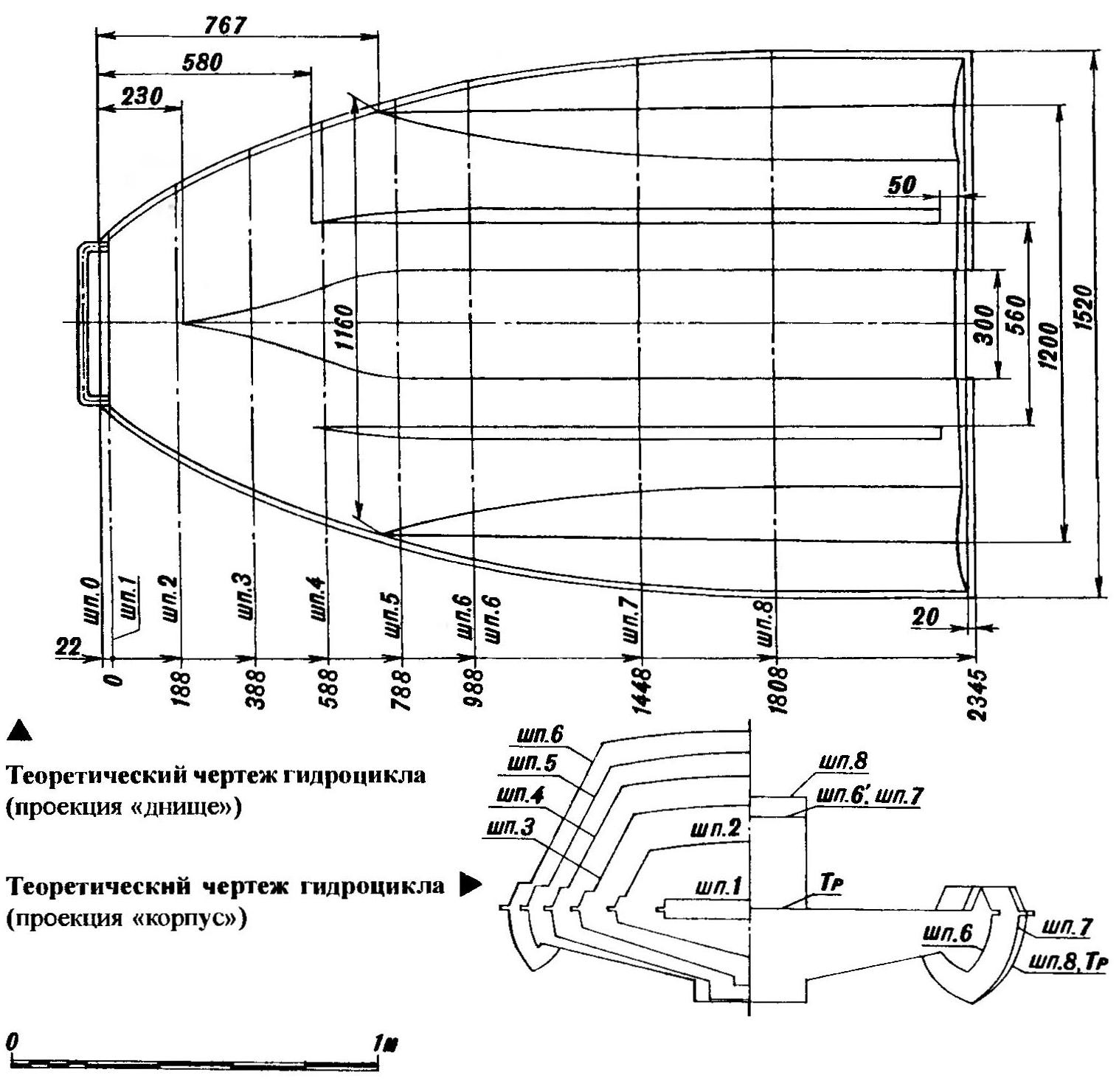

The hull of the watercraft:

1 — locking loop of the left nose hatch of the trunk; a 2.3 — manhole covers nose trunk; 4 — transom (foam); 5 — brincava Board; 6 — bow handrail with backup (titanium, tube 18x 1; sheet s3); 7 — fairing nose trunk; 8 — right slant lining; 9 — the lateral wall of the aft Luggage compartment; 10 — the end wall with a hole for steering rod; 11,40 — the bulwarks (4 layer glass); 12 — deck (foam); 13 — left transom handrail (D16T, pipe 25×2); 14 — frame №8; 15 — frame № 7; 16 — frame № 6; 17 — the bottom stringers; 18 — keel beams (D16T); 19 — “peel” of the keel beam (2 layer glass); 20 — the bottom is; 21 — cover of the deck (2 layer glass); 22 — core transom Board (plywood s5); 23 — outer layers of transom Board (plywood of 12 s); 24 — pads transom Board (D16T, sheet s3); 25,27 — taping the transom Board (4 layer fiberglass); 26 — transom (gluing fiberglass s5); 28 — the right scarf (D16T, sheet s3); 29 — keel part of the bottom (4 layers of fiberglass); 30 — shell fairing nose trunk (4 layers of fiberglass); 31 — “peel” the top of the stringer (2 layer glass); 32 — upper stringer (foam); 33 — the shell of the bottom (4 layers of fiberglass); 34 — left side stringer (foam); 35 — “peel” side of the stringer (2 layer glass); 36 — bilge stringer (foam); 37 — “peel” the bottom of the stringer (2 layer glass); 38 — bracket for seat mounting (oak, bar 65×20); 39— the hole for the steering shaft; 41 — left bulkhead (foam): 42 — taping the bulkheads (one layer of glass); 43 — the longitudinal planing steps (foam); 44—”peel” of redan (2 layer glass); 45 — left deck support (foam); 46 — taping transom (4 layers of fiberglass); 47 — hole to drain the water from the housing; 48 — bonnet lock; 49 padding (foam); 50 — sheathing (2 layers of fiberglass T-10); 51 — 03 rivet; 52 — hook (D16T. the profile s1,8); 53,55 — mounting brackets handrail (titanium, sheet s3); 54 — rivet (steel, pipe 8×1)

Was later tested another engine— a combination of “Vortex” and “Hello”. The fact that the club ALS “Rotor”, which worked, Stanislav, “tops” boat “Greetings-22” were used to make Deltamatic engines. And all the corners were littered with retired “Nizami”. There, in the corner, rested and not vending Beltelecom “Vortex-30Э” with electronic contactless ignition.

Without thinking, Stanislav has made of duralumin, a transitional plate, expanding on her “Whirlwind” so that he could be connected with the column of “Hello” and fit under his hood.

The first tests “Marlin” with the new engine showed that this is what you need! At speeds 50 km/h jet ski confident out to gliding, easily towed water skier.

To transport your machine, the designer has built a nimble truck-trailer with padded rubber cradles. Two wife Olga took up the bow, and Stanislav for the transom handrails — they raised the “Marlin” and was hoisted on to the trailer. Then put in a car trunk boat motor and drove from the garage home and kids so the whole family to head out of town to the pond. And often for quite long. For example, Korovina repeatedly stopped on the banks Nugushskoe reservoir, located 80 miles from Kumertau.

“Marlin” very good on the water. Turn it is possible only with great effort. Therefore, in contrast to similar imported machines from his deck you can catch fish (the benefit is there to house them!), without fear of waves from a passing ship, standing upright and an adult to get into not only the transom, but even from the side. “Marlene” when it lurches, but not overturned.

And management? It is so simple and easy that Olga previously never to touch the steering wheel of a car or motorcycle, has mastered his first attempt!

In addition, Korovinskoe the device is quite inexpensive to operate, because the fuel it is a readily available gasoline a-76, while foreign watercraft requires expensive AI-95 and the same expensive imported oil.

HOUSING DESIGN

The hull of the watercraft consists of a plurality of isolated compartments: fore and aft racks, and twelve (six on Board) side of the sealed volume formed by the frames, longitudinal walls, deck and bottom. Furthermore, additional buoyancy apparatus give another side, because they also represent, though small, sealed cavity.

Structural materials from which made the “Marlene” is the glass fiber reinforced plastic (multi-layered composition of glass, mainly for the brands T-25, and epoxy resins) and foam (for the most part brand PS-200). In the manufacture of separate knots and details of used jet ski made of anodized aluminum, stainless steel, plywood, wood and leather.

The Cabinet is executed in parts. Separately for plywood Boobs were shaped (usually of four layers of fiberglass on epoxy glue) the nose fairing of the trunk, the bottom and sides. Fairing the inside is reinforced with three top stringers and four slant plates, and the bottom four stringers (from the inside) and two longitudinal planing steps (outside). All of these represent a strengthening strip of foam of different sections, covered with strips of fiberglass. In the bottom still glued powerful keel beams — thick-walled aluminum profile to the front end of which bolt is attached to the heel — the steering shaft bearing.

After docking the nose fairing and the bottom line of their connection inside was also reinforced by two side stringers — wide strips of foam and the same wide strips of fiberglass on epoxy glue. Outside (front) fairing and the bottom is additionally bonded bow handrail of titanium pipe 18×1 mm.

First physically real frame № 6 (frames No. 1 to 5 of the conditional) is entirely cut out of the foam sheet with a thickness of 20 mm, covered on both sides with fiberglass and inserted into the intended opening, where it separates the nasal the trunk from the rest of the enclosure volume. Frame not deaf: in the middle of it drilled a slanted hole for the steering shaft, and the sides cut with two rear hatch with removable lids. (The latter fitted with quick-release bonnet locks opened by the tip of a screwdriver or even the edge of the coin.) Frames No. 7 and 8 on the composition of such sixth: the foam and layer fiberglass with the “epoxy” on the sides.

The power circuit housing four complementary longitudinal element covered on both sides of the foam thickness 20 mm: two bulkheads that extend from bulkhead No. 6 to the transom and is hidden under the deck and two walls, protruding above the deck and forming the volume aft of the trunk. They are connected by a rear end wall with a square hole for passage of the tie rod, and on top of them lies a folding double seat from foam and leatherette. Seat fortochnymi two loops pivotally connected to the bracket (oak beams glued between walls of the frame № 6) and in the tilted — up position is kept simple locking of duralumin parts.

Transom received by end extensions of the bottom inside layers of fiberglass cloth with epoxy resin to a thickness of 5 mm. Next, also from the inside, the transom is reinforced with a layer of foam thickness of 5 mm (except the Central zone, which fits transom Board) and finally four layers of fiberglass.

Exterior of the case oclean the contour of the transom with a strip of stainless steel that protrudes from the hull below the maximum of 22 mm. This step is necessary to ensure that jets of water on the plane were not glued to the transom and did not create additional bottom flow resistance. The transom drilled holes to drain the leaked water in the compartments. The holes are closed with tight stoppers.

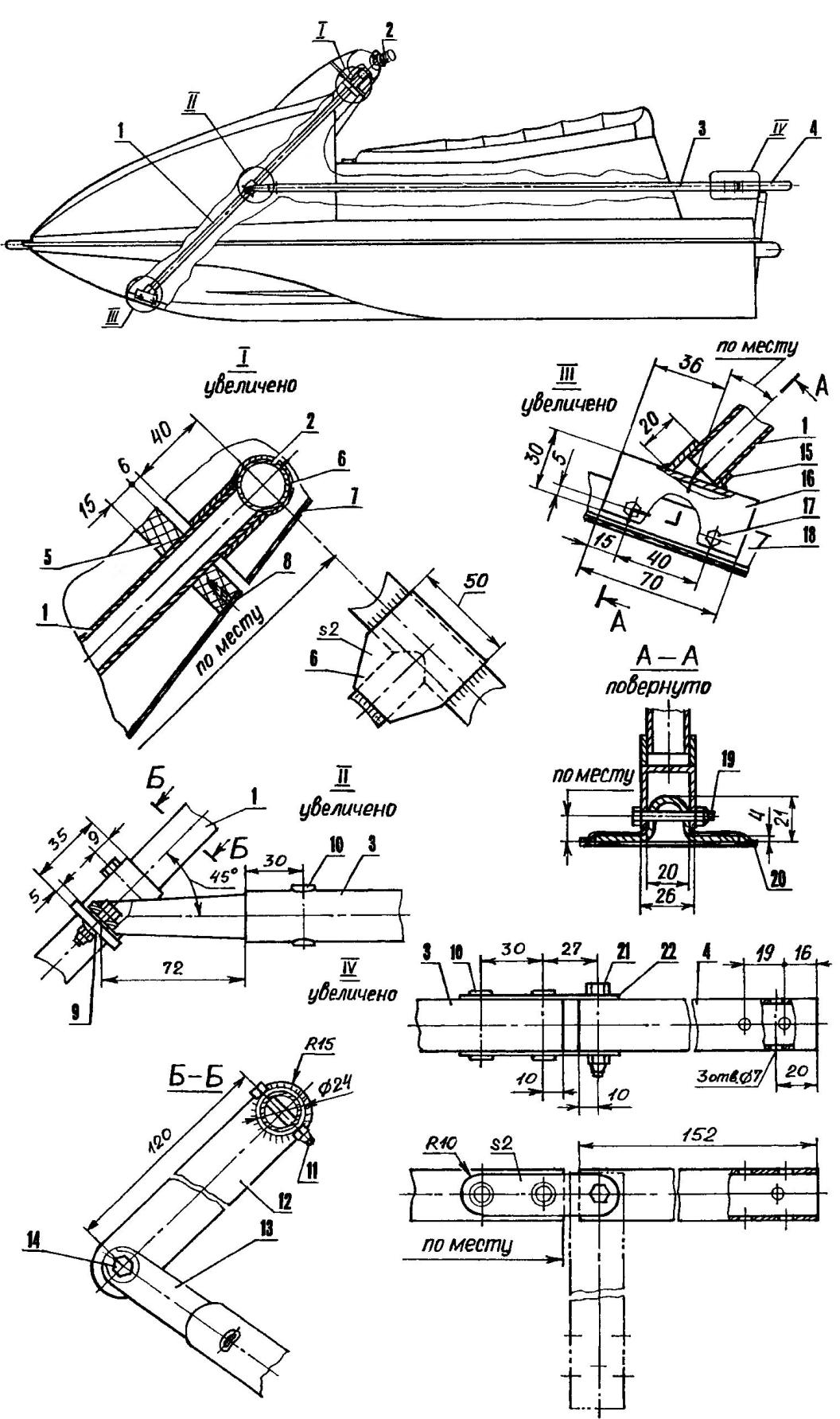

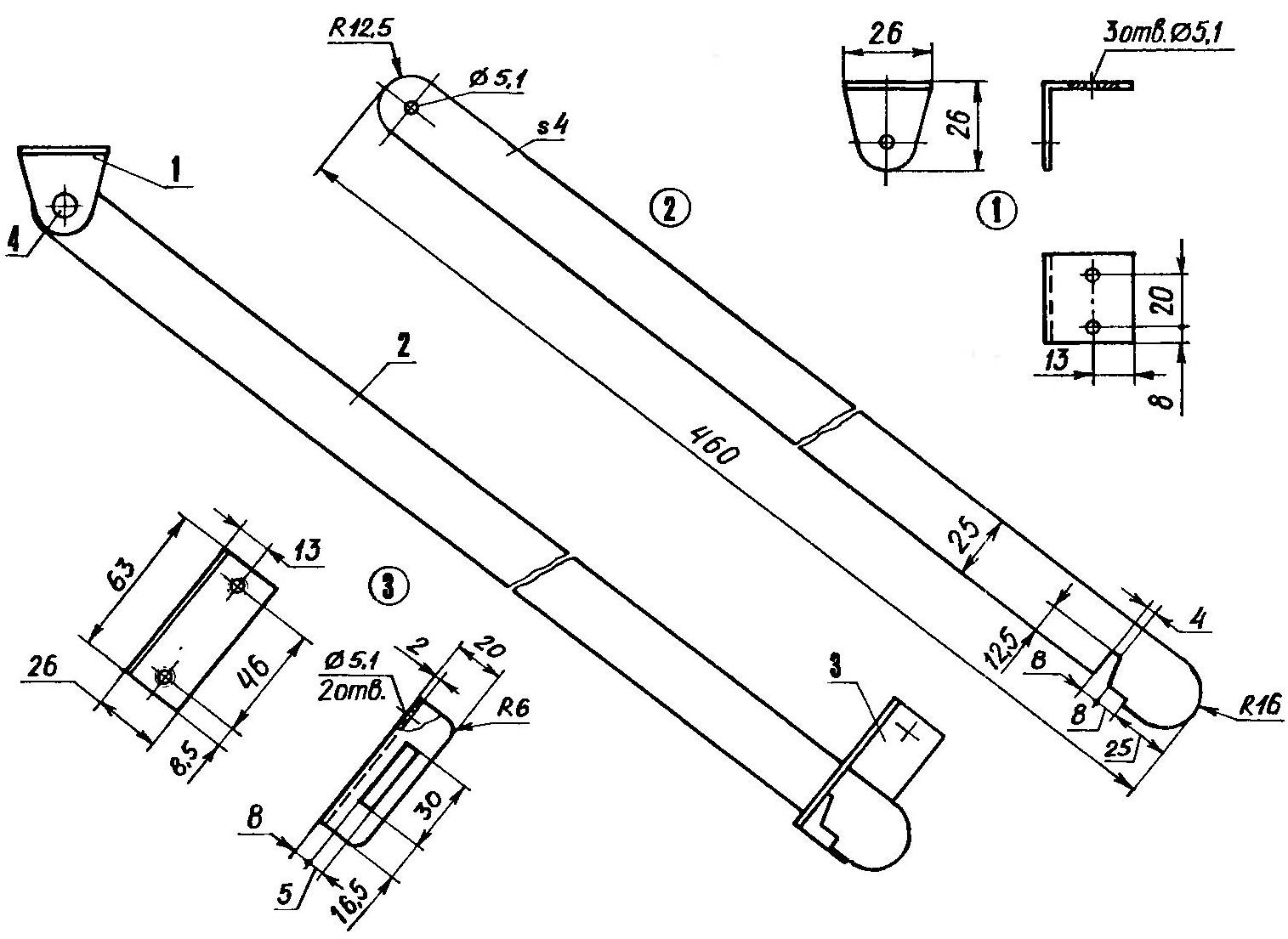

Steering:

1 — steering shaft (steel, pipe 20×1,5); 2 — wheel (steel, pipe 25×2); 3 — tie rod (D16T, pipe 25×2); 4 — the lever of rotation of the engine (D16T, pipe 25×2); 5 — bearing-bearing (polyurethane); 6 — plate (steel, sheet s2); 7 — a decorative casing (fiberglass); 8 — screw-3×10 tapping screw (8 PCs. contour); 9 — ball bearing SHS-6; 10 — tubular rivets (steel pipe 6×0,5, 3). 11,14,17,19 bolts with self-locking nuts M5; 12 — a Pitman arm (steel, pipe 24×2, folio 55); 13 — tip (steel); 15 — Jack (steel pipe 26×3); 16 — foot (steel); 18 — keel beams (D16T); 20 Kil (bottom, GRP); 21 — a bolt with self-locking nut M6; 22 — earring (steel, sheet s2, 2 PCs.)

The lock raised seat:

1 — loop (D16T, area 26x26x2); 2— the lever (D16T, sheet s4); 3 — focus (D16T, area 26x20x2); 4 — rivet Ø5 (AMC)

In the Central area of the transom wearing the epoxy transom Board on which hung the outboard motor. The Board consists of three layers of plywood of different thickness. After installing it on the transom on both sides were covered with glass cloth (four layers) and reinforced with two aluminum pads under the clamp motor mounting. This whole package for brake linings pulled along the contour six M5 bolts, and a shelf front plate is still attached by three screws to the deck.

Since the main force from the engine to the hull of the watercraft transmitted through the transom Board and the aft wall of the trunk, the junction Board and walls in the depth of the boot are reinforced with two triangular gussets of duralumin sheet thickness of 3 mm. Rear flange width of 20 mm each gusset plate fastened to the Board with the four screws on epoxy glue, and a triangular plane to the wall by four through-bolts M5.

To the outside of the transom and the transom Board is attached with M5 bolts handrails of the dural tube, the brackets which are riveted from sheet titanium. In addition, handrails are used when towing a water skier. The umbilical cord (nylon cord with a diameter of 5 mm and a length of 30 m) is attached a carabiner to the external brackets of the handrail.

The deck of the watercraft is also made from a sheet of foam of thickness 20 mm, covered on top with fiberglass. The deck relies on frames No. 7 and 8, the longitudinal bulkheads and the ends of the walls of the aft compartment in addition, on the supports from the foam bars section 20×20 mm, attached with epoxy glue to the walls aft of the trunk. The contour of the deck is glued to the frame No. 6, the joint between bottom and sides of the transom.

And again. In the left bottom corner of the transom Board has a hole to drain accumulated in the feed trunk water, closed tight with a cork, and in the lower right corner of the attached mounting bracket remote receiver pressure flow of water (speed sensor). Speedometer receiver connected by a thin rubber hose, laid on the aft wall of the trunk and dumped into a hole in the end cap of the trunk at the level of the deck. In the same harness with this hose also routed the cables from the battery and the cable throttle actuator control throttle of the carburettor on the steering wheel.

From the same end caps mounted outside (through another hole) and fuel hose with embedded in a “pear” of the transfer pump.

STEERING

All the controls of the jet are concentrated on the steering wheel, located on the cut fairing nose trunk. Steering shaft — steel pipe of diameter 20 mm rotates in two bearings: the nest of a U-shaped heel screwed to kilimo bar, and polyurethane washer, integrated in a decorative casing of the steering wheel. To the upper end of the shaft welded crossbar handlebar of steel pipe with a diameter of 25 mm, the “horns” which put on the motor arm (speedometer and controls here too motorcycle).

On the wheel of the first “Marlin” was not a decorative fiberglass shell. But in the new version and I must say, has greatly enriched the design of the watercraft. At least now he looks finished.

About the middle of its length, the steering shaft has a steel bipod, pivotally connected with a rather long dural traction. As the hinge is used is pressed into the end of the Pitman arm ball bearing SHS-6, commonly called a “fish eye”. It permits travel in a wide range of angles, which is very important in the management system of the watercraft, the control action pull is transmitted to the massive engine, forcing him to turn and change its position on the transom Board.

The front end of the tie rod end equipped with a nozzle for connection with the ball bearing, and the rear is connected with the rocker, mounted on the outboard motor.

Start combination of motors “Whirlwind — Hello” with a push button starter. Upon failure of the battery used by the starter cord.

Everything you need during a trip is aboard the “Marlin”. Side the property is distributed on the trunk: outboard fuel tank capacity 20 l, tow tether, fishing tackle and other Luggage — in the nose; battery, tool kit, folding paddles and personal belongings in the rear.

It’s not the latest upgrade to “Marlin”. To master shallow backwaters, inaccessible even motor boats, Stanislav intend to equip your watercraft a water-jet engine, good layout of the apparatus allows for such revision. Structurally, his water cannon on the quarter is already done. So, next summer Korovin will need to look no longer on Nugushskoe reservoir…

The main characteristics of the watercraft “Marlin”

Length, mm…………………………………2480

Width, mm……………………………… 1520

Height, mm………………………………….880

Weight without motor, kg…………………50

Maximum speed, km/h ……….55

Maximum load, kg………….150

Engine power, HP………………30

Fuel capacity, l……………………………20

A. TIMCHENKO