We offer homemade household heat stabilizer can be used in incubators, dryers, fruit, mini-greenhouses etc. From existing analogues it is original schematic construction, maintaining the temperature with an accuracy of ±0.1 °C, tolerance with fluctuations in the AC 160 to 240 V, and can operate from a DC source with voltage up to 310 V. the Power regulated heater element can reach 750 watts.

We offer homemade household heat stabilizer can be used in incubators, dryers, fruit, mini-greenhouses etc. From existing analogues it is original schematic construction, maintaining the temperature with an accuracy of ±0.1 °C, tolerance with fluctuations in the AC 160 to 240 V, and can operate from a DC source with voltage up to 310 V. the Power regulated heater element can reach 750 watts.

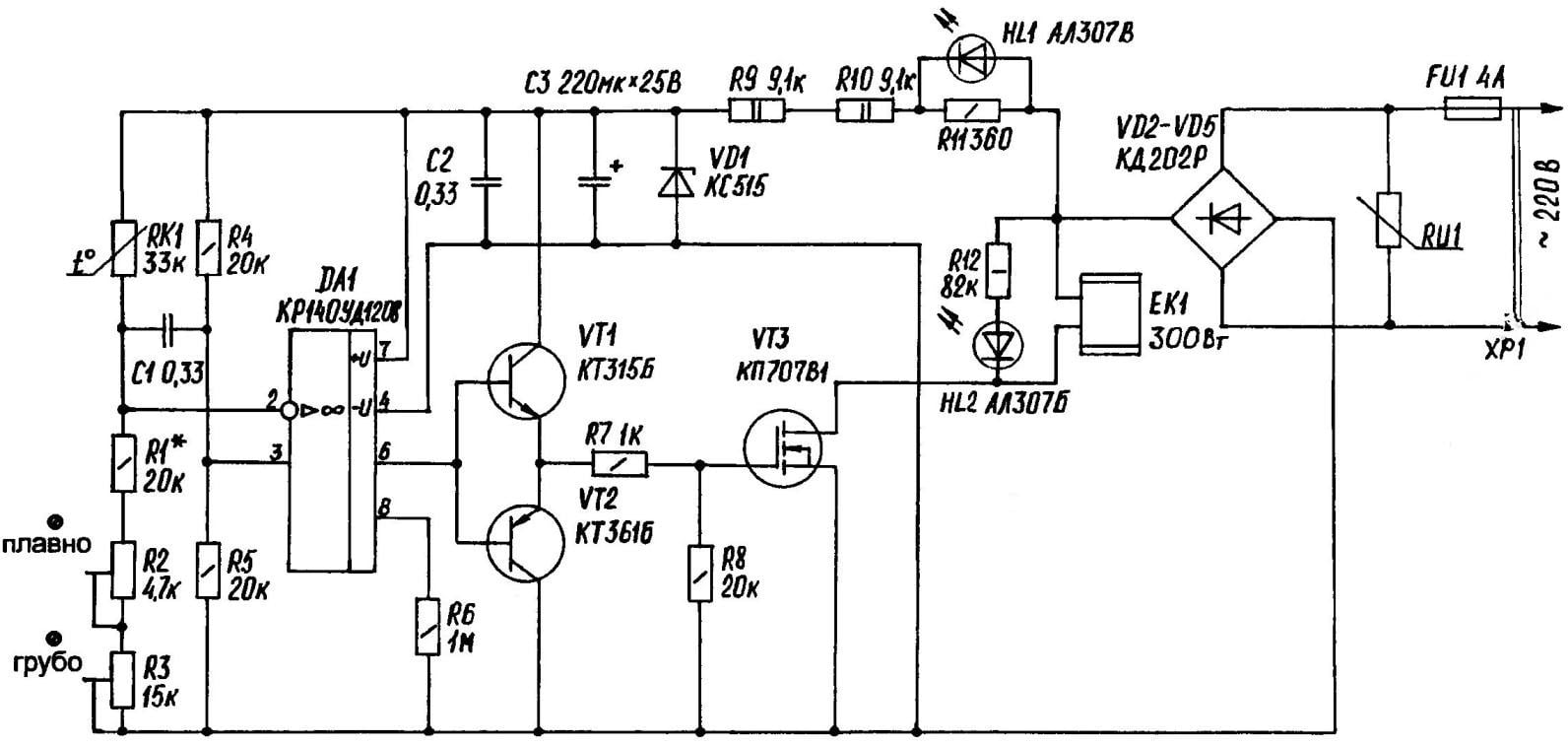

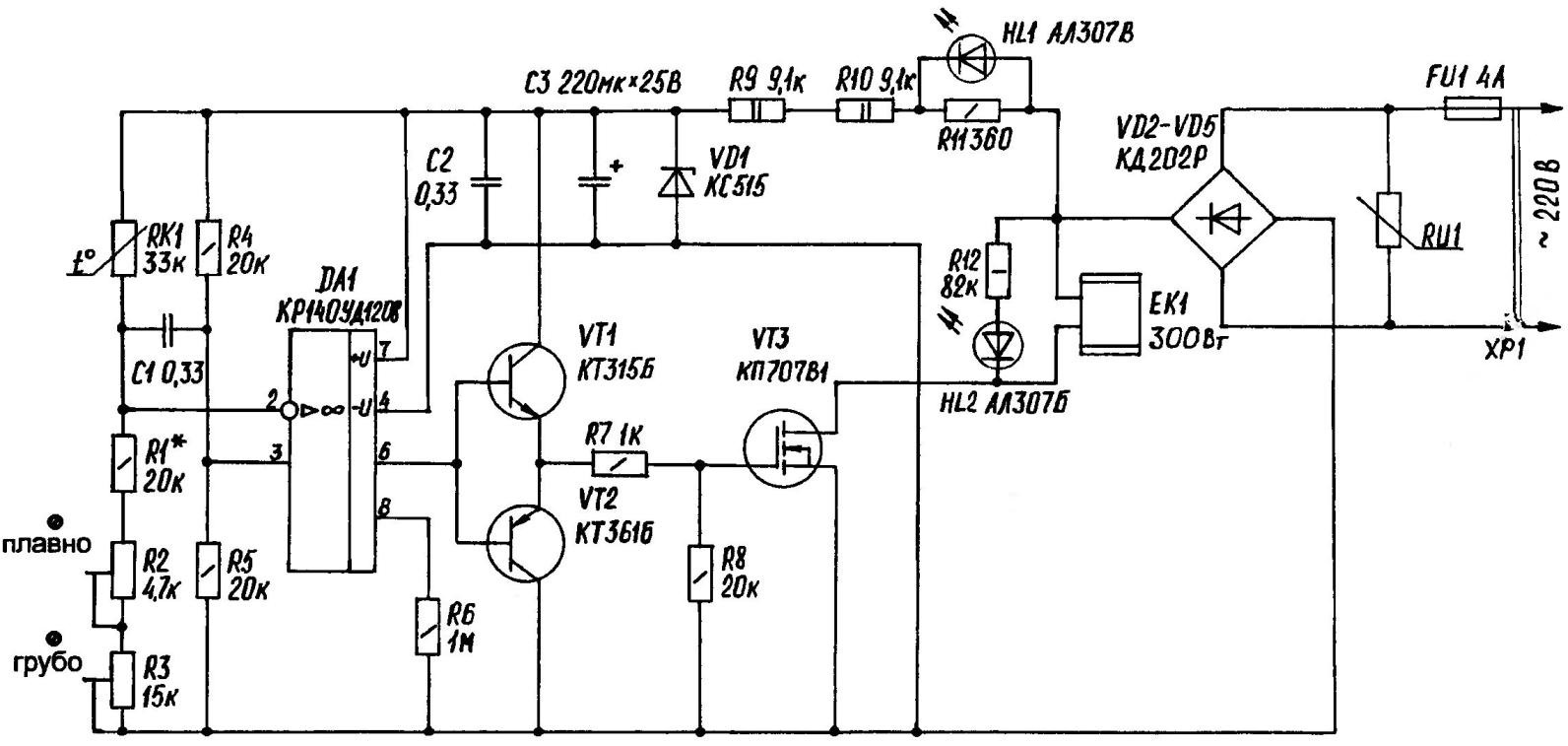

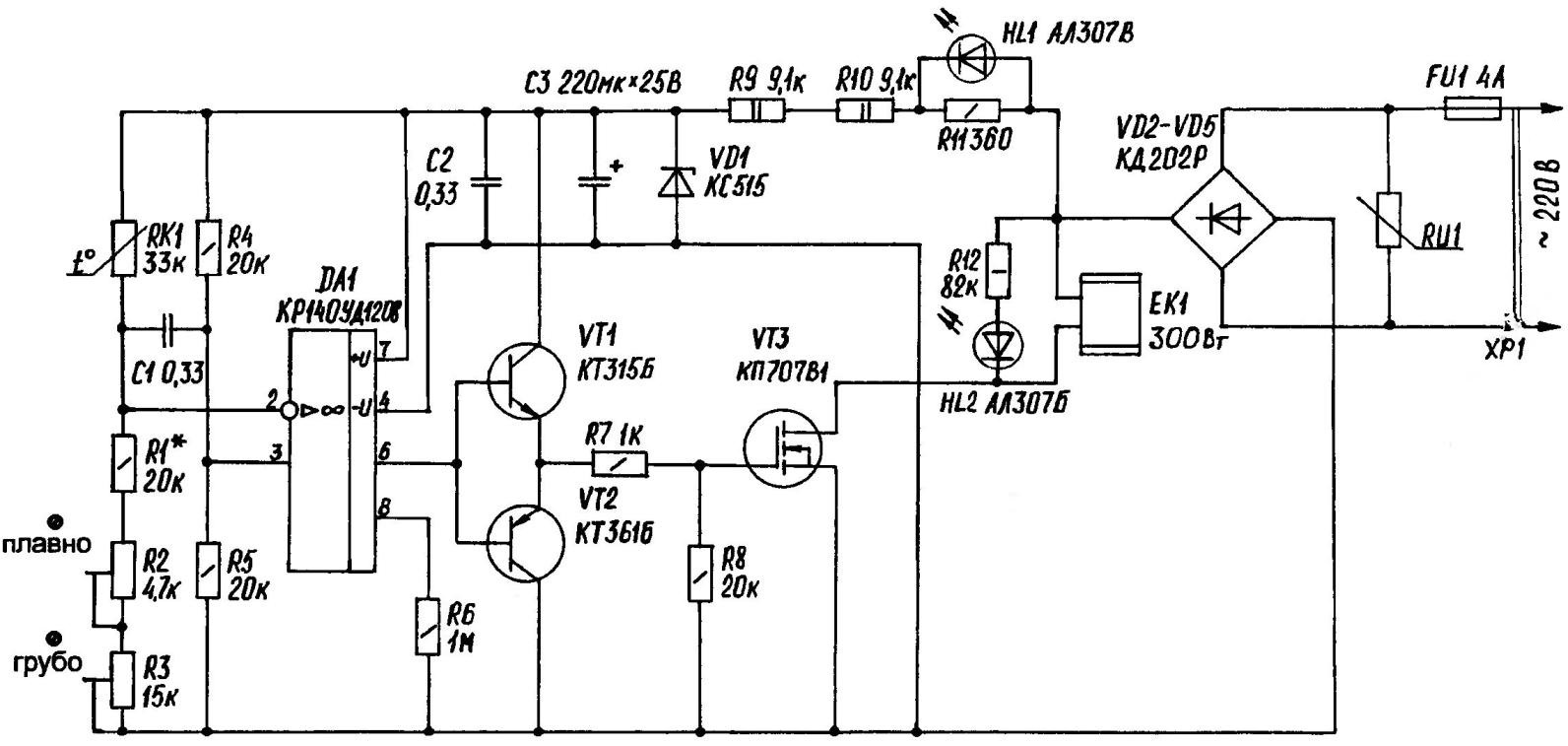

While the temperature inside of the controlled object is higher than that set by resistor R2 smooth and ROUGH resistor R3, the output of the comparator, is made on operational amplifier (op-amp) КР140УД1208, is the low voltage (log. 0). Is below the opening threshold of the power MOS transistor VT3. It is closed and the current through the heating element EK1 is not leaking.

When as a result of lowering the temperature of the controlled object, the resistance of the thermistor RK1 is increased, the comparator switches to the opposite state. The voltage at the output of op amp is repeated by the transistor VT1 and becomes sufficient to open the field effect transistor.

In the work by this algorithm are most obvious advantages of the power MOS transistor before the thyristor or triac. Used here КП707В1 practically does not create interference, it is not necessary to arrange the scheme to enable the passing of mains voltage through zero. All the time while the gate voltage is above threshold (10 or more almost fully open transistor), it is in a conducting state.

The presence of a current amplifier in a bipolar VT1 and VT2 due to the fact that the power MOS transistors have an input capacitance of several thousand pF. While it is not charged, КП707В1 will be in active mode (when the resistance changes from very large to a minimum, while a large amount of heat). However, OU can not long-term to ensure that current and operate at a significant capacitive load. So there is a need to use current amplifier to quickly charge and discharge the input capacitance of the power MOS transistor.

The comparator works here without positive feedback provides hysteresis. In this case it is quite acceptable. Power used by the heating element sufficient to heat inertia, the temperature a few degrees, exceeded the threshold and the comparator reliably switched to the opposite state.

HL2 led is the power indicator of the power MOS transistor VT3. The presence of dvuhpolnyh damping resistors R9 and R10 is caused by the possibility to feed heat stabilizer (in the absence of a household outlet) from a car battery using a standard voltage Converter 12/220 V. take into account that almost all converters operate at a frequency from units to tens of kHz. Therefore, it is unacceptable to use a couple of them the quenching capacitor, capacitance of which is inversely proportional to the frequency of the current, and hence very different for a network of 50 Hz and “transformative kilohertz”.

Circuit diagram homemade heat stabilizer

A compulsory element of the scheme, according to the author, should be a fuse FU1 and varistor RU1. Especially when used heat stabilizer in rural areas, where the mains voltage generally low relative to the nominal, but there are his throws, which can lead to equipment failure. The presence of the varistor will allow sacrificing a thermal fuse to protect it from non-standard modes of the heat stabilizer. The indicator also included the state scheme (and hence the integrity of the fuse) is the led HL1.

A large part of the heat stabilizer is placed on the Board size 80x80x1,5 mm of one-sided foil fiberglass. The installation is made by soldering, but can be a method of cheating. Power MOS transistor for better cooling installed on a typical finned heatsink dimensions 75x30x15 mm.

The entire circuit is placed in the housing of the industrial controller RT-3. As the thermistor used open-frame WT1 TR-1 with a low thermal inertia; it is installed on the Board of fiberglass dimensions 10x3x0. 5 mm and covered with a thin layer of epoxy resin. Only when applying such a temperature-sensitive semiconductor device can be achieved maintain the temperature with accuracy of at least ±0.1 °C, although for most household tasks are quite reasonable two series-connected posinkovic 15-kilimnik thermistor STZ-or 19 MMT it is well known (KMT).

The heat stabilizer also used fixed resistors MLT-0,25 and adjusting cylindrical SPO-0,5 (SPZ-19a). Capacitors type K73-17, with the exception of the 220-microfarad K50-35 (HITANO, WESTON).

The role of semiconductor triodes VT1 and VT2 are equally good any silicon of the corresponding structure. As the MOS transistor VT3 can be used as domestic КП707 B1 (КП809) and imported IRF840 (2SK1117,2SK1118) and similar analogues. Instead VD1 КС515 indicated on the circuit diagram, is acceptable any Zener, designed to Ist from 13 to 18 V. In fact, there is no restriction in the choice of LEDs and their induced color. Diode rectifier bridge КД202Р can be replaced by КД24Б (КД248). The only part in the scheme, which has failed to find domestic analogue, this 310-watt varistor, designed for a maximum operating voltage AC 275-300 V.

In establishing and adjusting heat stabilizer need to be very careful: the circuit has a galvanic connection with home network and is at a high potential relative to the grounded devices. The thermistor should be placed in a perforated protective casing that prevents accidental touching of the heat-sensitive element and at the same time allowing air to freely move next to him.

Trial operation of the heat stabilizer in conjunction with a mini-incubator “Kvochka” is extremely unreliable mechanical steel equivalent, filled with air, with the heaters of the four series-connected lamps shestidesyatiletiya showed that a homemade device is able to maintain temperature at the required level established by the resistors R2 and R3, with an accuracy not lower than ±0.1 °C. And it is a very good performance, especially considering that the optimum for poultry terms-incubation at a temperature in the range of 37.7 to 38.3 per °C.

O. BELOUSOV, Cherkassy, Ukraine