How much mystery was associated with this unusual machine! Journalists called it nothing more than a “nameless car.” And this is understandable – the designers were in no hurry to reveal their plans, talk about their searches, successful discoveries until a real fundamental solution crystallized. On the streets or roads you can often see cars without a factory mark and unusual shapes. On the bumper or windshield there are inscriptions: “test”, “test”. Recently, among the “unnamed” cars one could find a car that broke tradition. She has a name – “Maxie”. Behind are hundreds of kilometers of roads, tests at the NAMI test site. And finally, representatives of the press saw the small attractive “trailer”. The car is parked next to the Volga. It stands so close to it that the driver would not be able to get out of the back if the car were ordinary. But Maxi is unusual. The door was moved back, and the tester easily exited the cabin. We can’t help but compare the Maxi with the Zaporozhets model 965 standing next to it. The dimensions are almost the same, but the passenger compartment is much larger.

Before continuing the story about this car, it is worth recalling the main problem troubling the automotive world – the problem of the so-called “city car”. Every year there are more and more cars. Millions of five- and six-seat “family” cars clutter the streets and roads. This is what drives automakers’ desire to create more efficient designs for small cars.

It is well known that there are only two real ways to create such machines. The designer can choose a car layout with a front engine and front-wheel drive or give preference to a car with a rear engine and rear-wheel drive. Front-wheel drive cars are somewhat more complex; they are more demanding in terms of maintenance and quality of lubricants. But they are convenient, allow for the creation of various modifications and are therefore very common in Europe. Supporters of rear-engine cars are attracted by more efficient use of power, ease of design and maintenance.

The designers of the All-Union Scientific Research Institute of Technical Aesthetics chose the second option. The name “Maxi” (as opposed to the popular English car “Mini”, created by designer Isigonis) symbolizes the desire of the project authors to achieve maximum use of body space, a streamlined shape and greater convenience with small dimensions and weight of the car. The greatest effect could be achieved by combining a rear-engine layout with a carriage one. “Maxi” continues the traditions of its predecessors – the “Chita”, “Belka” cars, the new VNIITE taxi and foreign cars “Sigma-Pininfarina”, “Selena” from the Italian company GIA, etc.

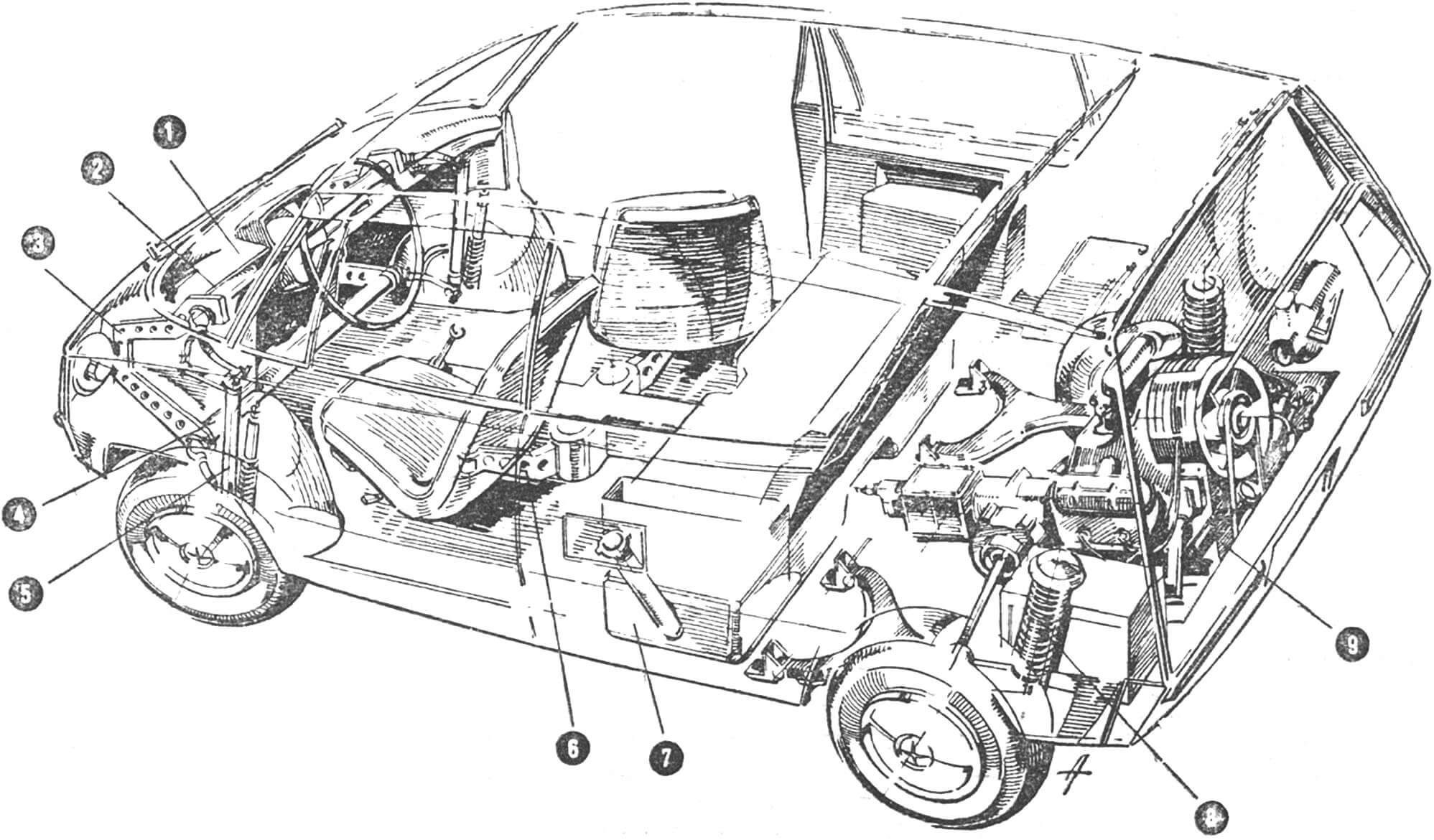

1 — instrument panel; 2 — upper torsion bar; 3 — power profile; 4 — lower torsion bar; 5 — rotary strut of the front suspension arm; 6 — rotary crank; 7 — gas tank; 8 — rear suspension; 9 – engine.

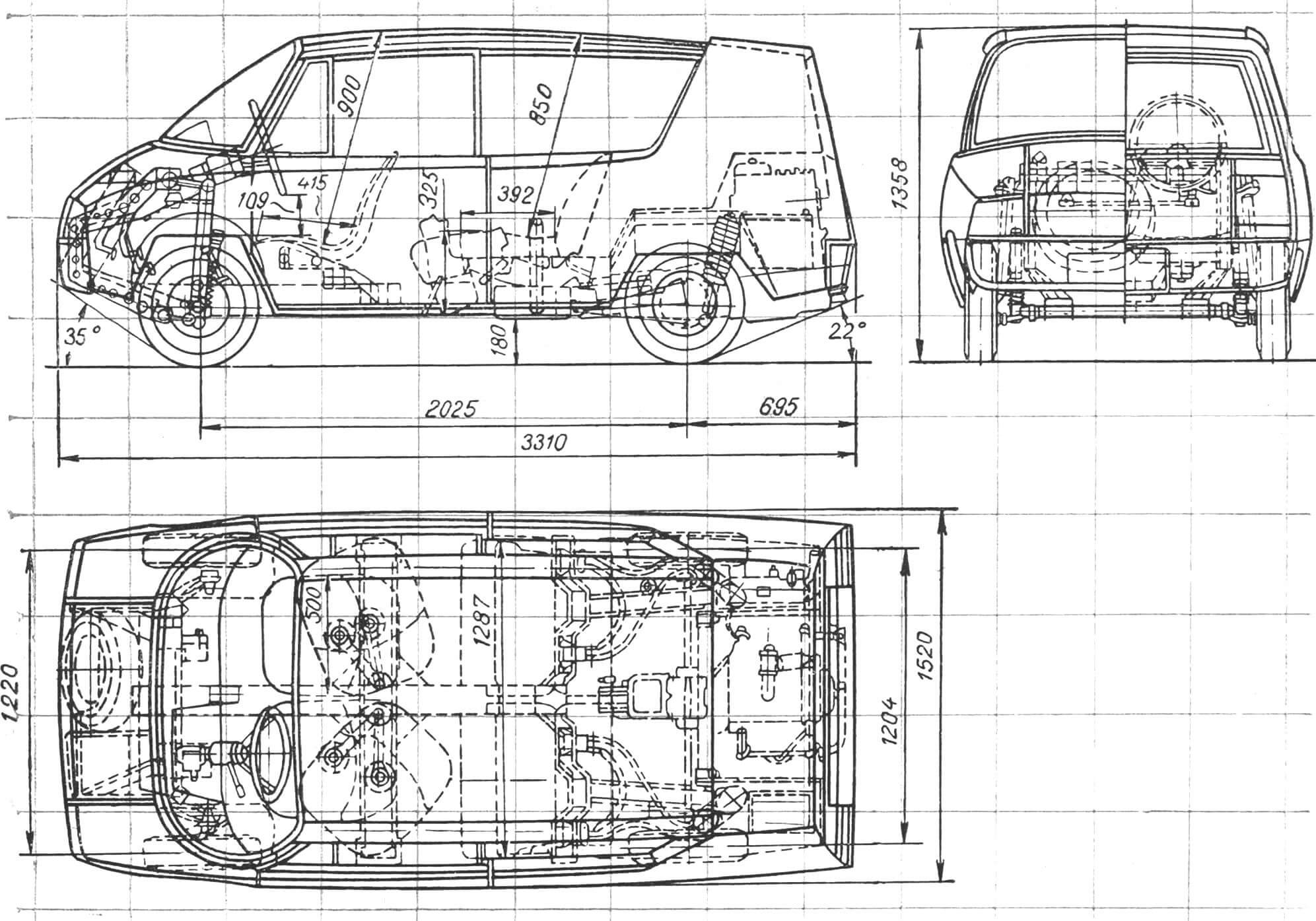

The Maxi prototype was created to test and demonstrate new principles and is not intended for mass production. Nevertheless, it allows you to clarify the following technical characteristics of the car: number of seats – 4; dimensions – 3330X1510X1320 mm; base – 2023 mm; dry weight – 600÷650 kg; engine power – 30 l. With.; speed – up to 120 km/h; fuel consumption – about 6.5 liters per 100 km; turning radius – 4÷4.5 m.

How did the designers manage to achieve such indicators? Here’s what one of the authors of the project, design artist VLADIMIR IVANOVICH ARAMOV, said about the new car:

— The absence of a protruding hood and a conventional trunk determines some fundamental features of the layout . The front seats are moved forward. This resulted in a gain in useful body volume compared to the Zaporozhets model 965. The small trunk in front, however, disappeared. In return, it was possible to obtain sufficient space, allowing, if necessary, to transport up to 0.6 m3 of luggage. This is achieved by moving the rear seat forward and lengthening the roof.

One of the main design features is the installation of the front seats on rotary cranks. The convenience of getting into and out of the car by the driver or his neighbor is determined by the presence of this crank, which makes it possible to rotate the seat around its axis towards the door opening.

Freedom of entry and exit for passengers sitting in the rear seat is ensured by the appropriate size of the doors. Such doors, swinging open on their hinges, would take up a lot of space and create a danger for others. Therefore, they are made movable. Their lower parts slide on outboard roller bearings.

The seats have a lightweight “anatomical” shape. The rear ones can be folded out individually or together to form additional areas for luggage. If the front seats are rotated, sleeping places can be equipped.

The rear window hinges upward for easy access to the trunk and engine. The power unit and rear suspension are taken unchanged from Zaporozhets. The front suspension of the Zaporozhets with two torsion bars located one above the other would create an obstacle for the legs and pedals. Therefore, the upper torsion bar had to be positioned higher, connecting it to the lower torsion bar with power profiles that go around the inner body panel; the ends of the suspension arms are connected by rotating struts, which are acted upon by the rods of the steering linkage, which is also moved upward.

The Maxi car uses wheels with a tire size of 5.20-10″ (like the BMK Mini car).

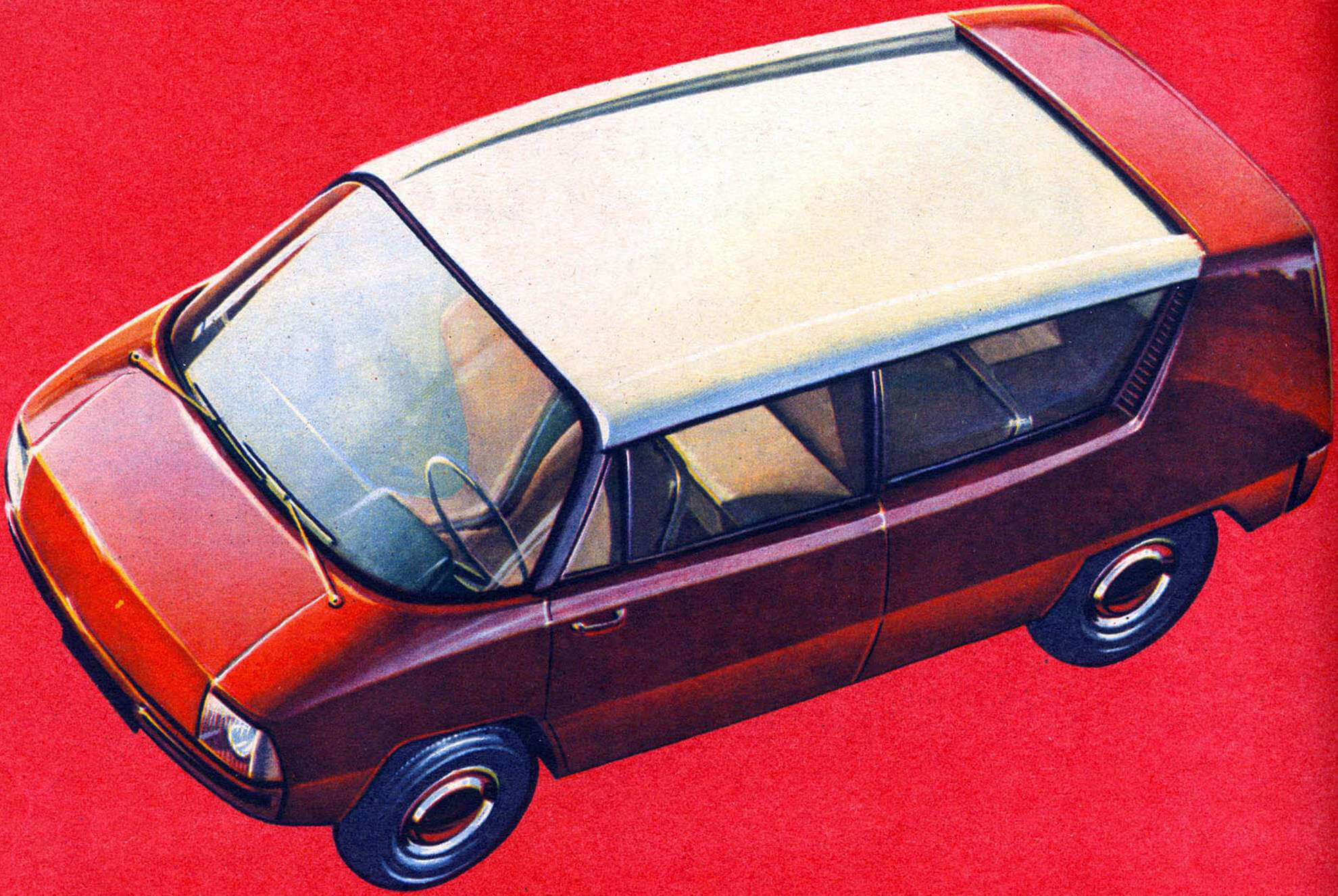

The Maxi body shape is characterized by a strongly sloping and rounded front part and a steeply cut rear part. According to modern concepts of aerodynamics, this shape is close to optimal in terms of streamlining and stability.

The most characteristic element of the Maxi’s architectural composition is the wide rear pillars in the form of aircraft fins, connected by a bridge protruding slightly above the roof. This bridge is not only an element of the composition. Possessing increased strength (it has double walls), it can protect the body from destruction when tipping over. Air intake openings are located along the leading edge of the bridge and pillars. The side ones supply air to the engine, the top one transfers air from the roof to the rear window, thereby protecting it from dirt.

The designers continue their search. Time will tell what the production model will be like. We are attracted to “Maxi” primarily because its design can be useful to designers of home-made cars. Such a machine can be made even more capacious and convenient by using a lower engine than the MeMZ-965 /Zaporozhets/. The best results can be achieved by taking the boxer engine of the M-62, M-72 or K-750 motorcycles as a basis and working to reduce its height. You can also create an assembly of two engines such as IZH-56, IZH-Yu or Java-350, similar to how it was done on the homemade Magna-1 car, demonstrated in 1967 at VDNKh. Of course, in both cases, the forced cooling system will require careful modification. By using such a unit, you can get a low, flat floor in the luggage compartment. You will also have to carefully consider noise and heat insulation between the engine and the passenger compartment. Improvements to the front suspension will make the front compartment even more spacious.

“Maxi” is a combination of the maximum useful volume of the body and great amenities with a small size and weight of the car. The car takes up very little parking space thanks to the sliding doors.

The layout and shape of the Maxi body can be recommended to modellers. The carriage layout and spacious passenger compartment with the small dimensions of the model will allow easy placement of radio control equipment. You can also make a copy model of the “Maxi” with a compression or glow engine.

V. MASIK