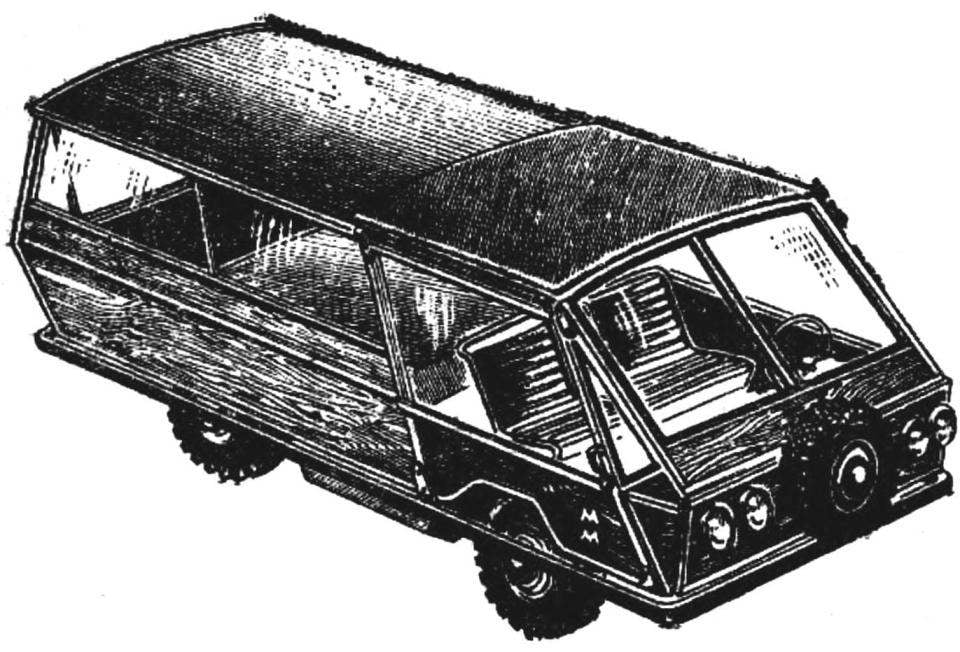

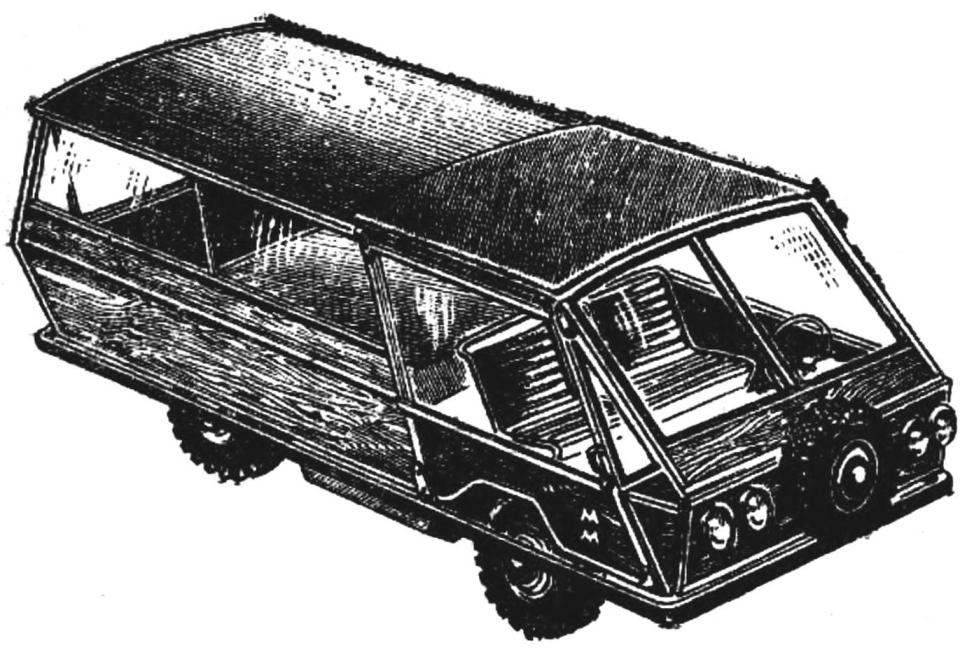

Description of the micro-car, only “Viking”, built by engineer S. P. Zack (“M-K” № 1, 1975), still attracts lovers autocostruzione. The stream of letters continues. Readers interested in the operating experience of “Minimax”, the possibility of its modification under the new requirements of traffic police. They asked to talk also about the individual elements of a design peculiar to the wagon layout, on the further development of this scheme. The most often repeated questions are answered by the Builder of the machine.

Will start with the most troubling. Almost every third reader asks to borrow the drawings, solemnly promising to return them after the construction of the car. And it never occurred to him that to make a set of the technical documentation for the machine — it is a whole design team that in Amateur art is usually limited to sketches, often understandable only to the author, and those in the manufacturing process are sometimes unnecessary, since a lot has to bring. I think the information that is enclosed in the article is sufficient to reproduce the original, as made quite a few of my followers.

Now, what evolution has undergone a “minimax”. In its original form it was operated for five years. Practice has shown that the power of the engine “planet 3” is not enough. Had to boost it (mainly due to the carb) to 20-22 BHP, but fuel consumption increased. There was also insufficient durability of the chain transmission. To protect it from road debris difficult, and approaches her uncomfortable. Mainly for this reason, “planet 3” was replaced by the powertrain (engine plus transmission) car ZAZ-968 (30 HP).

If it had to be redone and the rear suspension. As it now looks is shown in figure 1. The basis of the power scheme is cross-notched beam, which in combination with two longitudinal members creates a rigid space frame.

Fig. 1. The suspension scheme of the power unit and rear wheels:

1 — front node mounting the power unit, 2 — a bracket of fastening of the lever arm, 3 — arm suspension wheel, 4 — longitudinal beam, 5 — spring, 6 — absorber, 7 — sidewall, 8 — cross, 9 — rear node mounting the power unit, 10 — power unit, 11 — frame, 12 — Board.

Comparing the two vehicles, it should be noted that the second, which I call “minimax-2”, was much peamiste and economical: the consumption of gasoline And-76 on the highway on long trips was 8.5 l / 100 km in that time, forced Planeta-3 under the same conditions, burned for about 10 L. However, a kind word recall excellent reliability and unequaled with four stroke engines, convenience winter operation of Planet — warming it is practically not required.

Rear suspension С3А used in the “Minimax”, worked perfectly to replace its suspension with spring loaded “Lada” had only because of the incompatibility with the power unit “Zaporozhets”. But the new design behaves quite satisfactorily. The main check (and the whole machine in General) was the repeated journey through the rocky roads of the Caucasus. Had the mountain river Ford to overcome. Separate sections of the road impassable for passenger cars, were only ATVs and… “Viking-2”. Positively manifested short base and good ground clearance — ground clearance.

The disadvantage encountered after the upgrade, it should be noted overload rubber rear wheels: in “Viking-2” the durability of the tire size of 5.00—10 to 10-12 thousand km (in the “Minimax” she was about 20 thousand km). Had for the rear wheels to make the wheels 32 mm wider than nominal. It gave some effect.

I want to warn his followers: the use of tyres of 5.00—10 from motorized restricts the total weight of the machine. And move to the next tire size (from “Zaporozhets”, “Zhiguli” or “Moskvich”) entails some of the alteration that turns a completely different machine.

Improved and front suspension (Fig. 2). Put torsion bars from ZAZ-965, due to which it has been possible to relieve the spring part and recover regular rubber travel stops (previously, they had to cut).

Fig. 2. Front suspension:

1 — torsion ZAZ-905, 2 — upper support unit, 3 — auxiliary spring 4, the lower support pin.

In the “Minimax-2” is used (with inessential modifications) all the elements hydrocarbonous system “Zaporozhets”. In the actuator, hand brake weak spot is usually the cables, their terminations, sheath and seal. At the same time, the good word recall reliable brakes С3А, where instead of ropes — leverage-pumping units and rods. So after a long search managed to create a similar system (Fig. 3). There are no stretchable items, it does not need protection from dirt and is easily adjustable.

The weak point was the rear window and plexiglass. The aerodynamics of the body shape of the car will lead to pollution of the stern. In the “Minimax” organic glass from dirt quickly grew turbid. Had to go to the tempered windshield from С3Д. It would be possible if desired to put the aerodynamic deflector or wiper with washing.

“Minimax” was the detachable front part of the roof. It seemed tempting to ride with the top down. However, over the years of operation of the roof was shot only a few times — in the heat left without protection from the sun is not wanted. Yes, and the front Windows provided adequate ventilation. So in the “Minimax-2” roof is now fixed and glazed right door is the same as left — sliding.

The body of “Minimax” was covered with sheet vinyl plastic with a picture “under the tree” and is contoured aluminum profiles. The vinyl liner over time had warped, and the car lost elegance. When upgrading it was replaced the Micarta with the same pattern.

When you play a “Minimax” reduces the glass area. It turned out not always successfully. Simple shapes of car body require openwork top, and cut this area carefully.

Fig. 3. Drive handbrake:

1 — brake handle, 2 front levelling traverse 3 — intermediate rod 4 — seal 5 — rear pull, 6 — rear levelling traverse 7 — cross section of the transmission.

Experience of followers gives reason to also warn against underestimating the complexity of the construction of the car wagon. Not everyone knows that the suspension of conventional machines with standard layout fits poorly in the wagon layout. This is especially true of linking the front suspension and steering with driver and front passenger. Although the new requirements allow GAI to increase the height of improvised machines up to 1650 mm, but raising the center of gravity is unsafe, every inch needs to be on the bill.

It is also necessary to recognize that the combination of air-cooled engine with a body formed of flat panels, ensures low noise level in the cabin. Those who beckon the benefits of the car scheme, just need to decide whether they are ready to sacrifice them for the sake of acoustic comfort.

Overall layout and design features of “Minimax-2” meet requirements of the tourist machine. On long journeys in it quite comfortably in the front seat are two: the driver and passenger. With this sleeping place is laid out, and the entire load is located in the middle part of the body on the floor.

P. ZACH, enigneer designer, winner of NTTM

Recommend to read SYRINGE PACKAGE Today, some liquid or pasty products are sold in soft pack with plastic tip. After using this content pack will be useful for home handyman. For example, it can be filled with a filler... “WATER BUG” – THE FISHERMAN’S BOAT Some fishing without a boat? Especially on large bodies of water. Want to make an original, near-silent boat? To business, then. Look at the picture. Interesting boat, built on the... Scroll back to top

Description of the micro-car, only “Viking”, built by engineer S. P. Zack (“M-K” № 1, 1975), still attracts lovers autocostruzione. The stream of letters continues. Readers interested in the operating experience of “Minimax”, the possibility of its modification under the new requirements of traffic police. They asked to talk also about the individual elements of a design peculiar to the wagon layout, on the further development of this scheme. The most often repeated questions are answered by the Builder of the machine.

Description of the micro-car, only “Viking”, built by engineer S. P. Zack (“M-K” № 1, 1975), still attracts lovers autocostruzione. The stream of letters continues. Readers interested in the operating experience of “Minimax”, the possibility of its modification under the new requirements of traffic police. They asked to talk also about the individual elements of a design peculiar to the wagon layout, on the further development of this scheme. The most often repeated questions are answered by the Builder of the machine.