The starting point of any design and experimental work, whether a solid CB or technical circle, a laboratory for students — identifying the problem, the technical problem. Based on experience WITH an CUT, try to identify the conditions that determine the success of children’s technical creative work.

The starting point of any design and experimental work, whether a solid CB or technical circle, a laboratory for students — identifying the problem, the technical problem. Based on experience WITH an CUT, try to identify the conditions that determine the success of children’s technical creative work.

So finding the problem. Hardly rights the Executive in charge of the case himself, is only “determined”, convinces her to take the decision of their students. We have Cute decided to do this with the active participation of students. Our experience shows that it is very useful if the topic of the search guys will help community consultants-experts of the enterprises, KB or NII, which is lively, interesting to talk about the current problems of selected industries. Sometimes we use even rough copies for innovators and inventors, manufactured at the enterprises.

However, it is not necessary to go to extremes: the future of design must not only be socially useful (this, of course, very important), but also attractive to young technicians. Will the guys scheduled to work on the design, some technological difficulties may occur in the course of creating the model — all this head should also include in the first selection stage technical specifications. Here it is necessary to recall that the proper development of the creative process in children is possible only when a sufficient level of knowledge in the chosen area of technology. And the most interesting tasks, usually contain elements of a number of branches of engineering. That’s why the head can not be avoided on the lessons of the theoretical course, a sort of ABC’s of applied engineering knowledge. In our opinion, this is a partial solution to the problem of Polytechnical training.

An example of a comprehensive approach to the selection of the topic of creativity can serve our mechanical “mole”. The idea arose when we observed the laying of cable through underground pipes from well to well. What ingenious ways did not use the workers to push hard steel wire winding pipe even Tried to run into the pipe cat tied to a thin cord, hoping the cord then stretch the cable… And it was not.

Thus was born in Cute technical mission under the code name “Mole” — a device for movement inside the pipe and simultaneous pulling of the cord or wire. The obvious necessity of the mechanism plus its unconventional, novelty for the participants of the circle (in fact, the construction of “moles” exist) has led to intense creative work in the laboratory.

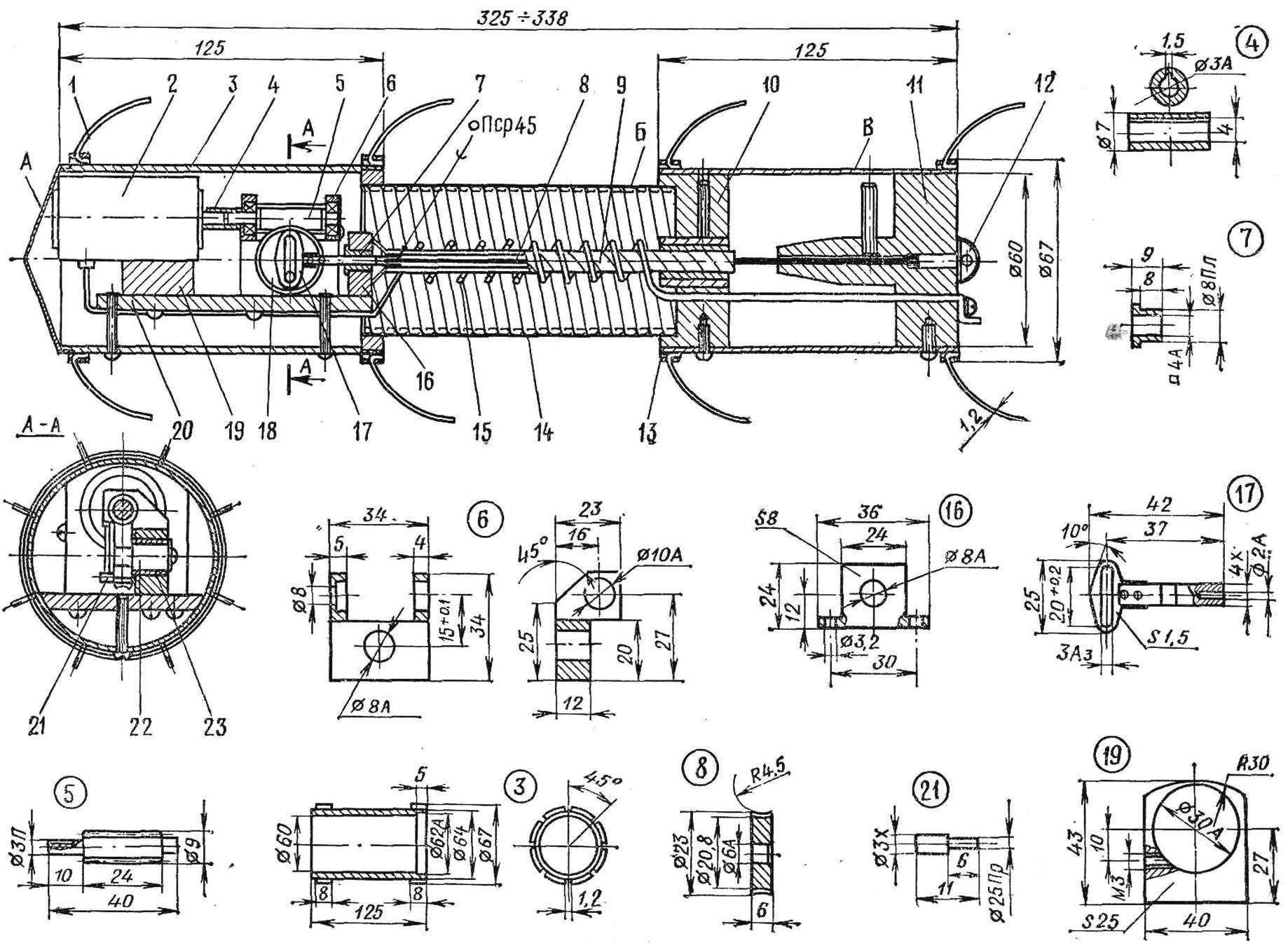

Longitudinal section of the mole:

(And front hard case with spring-like “legs”, B, a flexible connector, In rear hard case with spring-like “legs”): 1 — “the foot” of wire OVS Ø 1,2—1,5 mm, 2 — motor, 3 — body, 4 — coupler. 5 — worm 6 — front bearing 7 — shaft sleeve (bronze), 8, flexible roller 9, a flexible sheath, 10 front panel 11 rear panel 12 — eyelet for a cord (wire), 13 — mounting “foot”, 14 — outer sheath flexible connecting link 15 — spring 16 — shaft 17 — yoke 18 — worm wheel, 19 — pole motor, 20 — fee — based, 21 — finger 22 — roller worm wheel 23 the hub.

At first glance, it seemed a simple idea, but one problem was clinging to the other. Here and design the transformation of the motion from the electric motor, the method of movement, the possibility of overcoming the bends on the pipeline route, return the device to the surface failure mechanisms, finally the desire to achieve simplicity and cheapness of construction.

The adopted technical solution was formulated, of course, not immediately. Together with the head of the children learned the device with the telescopic case, foldable “legs”, roller mover, etc. the Final decision was prompted by the structure of the body… common earthworm. Had to play through the mechanism of the similarity of the body movements of the worm by converting the rotational motion of the motor shaft into the translational motion of the rigid links of the mechanism.

The proposed design does not claim to absolute originality and perfection, but the original, it is the students and gives ample room for further improvements. If such a device is to provide, for example, measuring or control devices, you can turn it into a “controlling mole” for routine inspections of the internal surface of large pipes, And if we provide him with a television camera?.. Many manufacturing alternatives and the use of the mechanism available to students in technical circles.

Design of the mole consists of two separate buildings, linked by a flexible, recruited from piano wire, a movable element which is located within the elastic shell. The reciprocating movement of the flexible element from the rocker mechanism causes relative movement of the housings. Resting spring “legs” in the wall of the pipe, both the housing alternately tightened and repel, mimicking the crawling motion of a worm.

The rotation of the motor via a spring-loaded soft coupling, which facilitates the centering of the shafts is transmitted to the worm gear, which is converted into reciprocating motion of the yoke with your finger on the worm wheel.

Rear housing is closed by a lid which is attached to the power cord and pulls the cord or cable. The yoke is connected with a flexible element through the rod by soldering; this ensures a stable and centered position of the yoke. The entire actuator is mounted on a base fixed in one of the buildings. The engine model is the motor constant current (from the PDM) with a speed of 1800 min, a power output of 9 watts. The driven worm gear pair having a gear ratio 1:44, is connected with the yoke, which with the help of elastic steel wires Ø 0.5— 0.6 mm, connected to the rear part of the model.

The immediate propulsion of the model are steel flexible pieces of wire Ø 1,2—1,5 mm (“foot”). The size of the limb depends on the nature of the surface on which the moving model. The speed of the mole — 0.03 m/s. It can be changed by reducing or increasing the gear ratio of the worm gear and increase speed scenes. The design and purpose of the rest of the details can be seen from the drawing, made members of the group.

Mechanical “mole” attracts specialists for movement along the curved piping through flexible movable connection between buildings. It should be noted that the “mole” well – “crawling” and on a flat surface, overcoming on the way various obstacles. Therefore, the “mole” may be of interest to managers of technical circles as a great creative design work.

V. SHOLOKHOV, Director Kuta Novosibirsk Akademgorodok,

A. LEONENKO, head of the laboratory of experimental mechanics