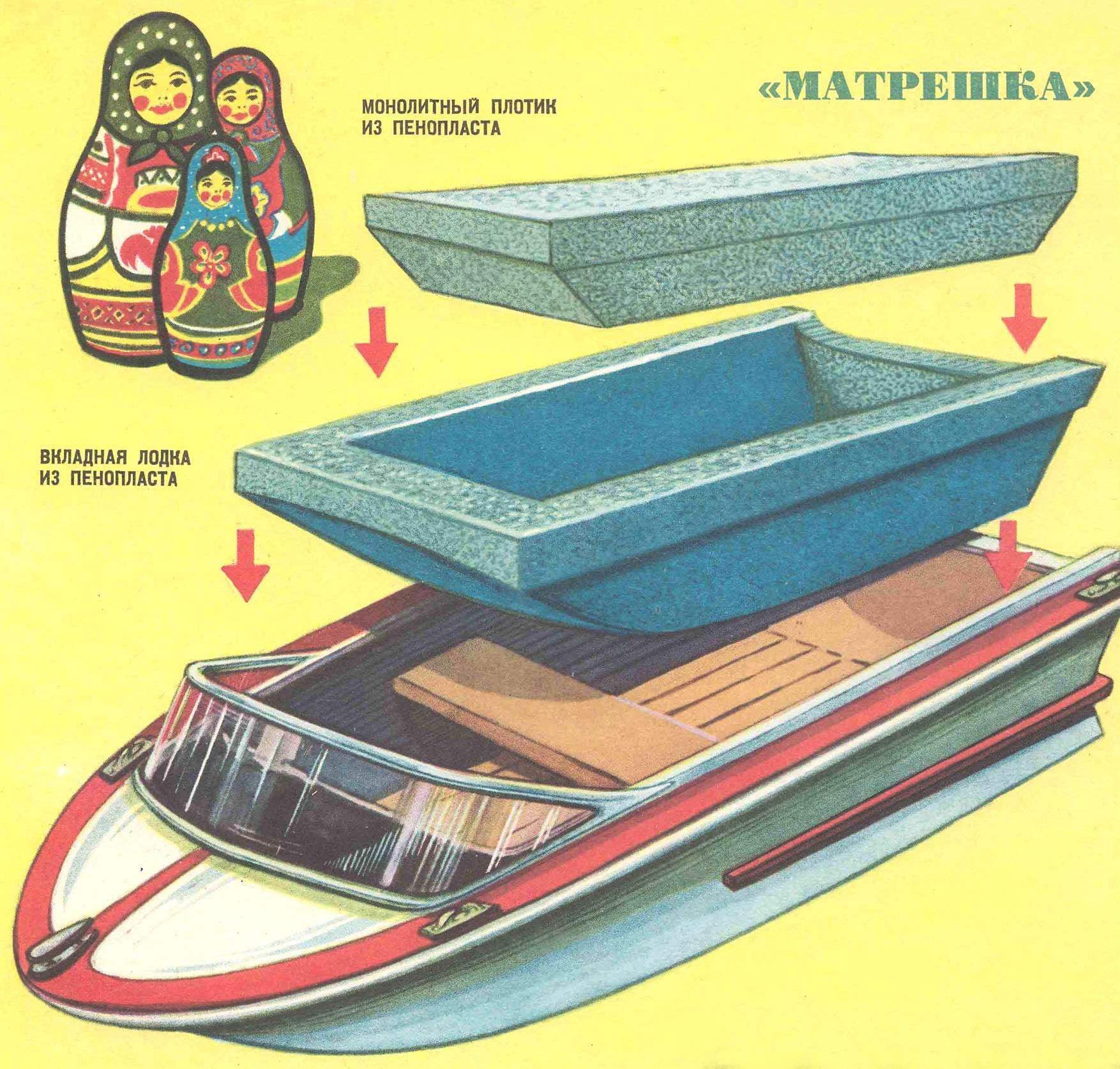

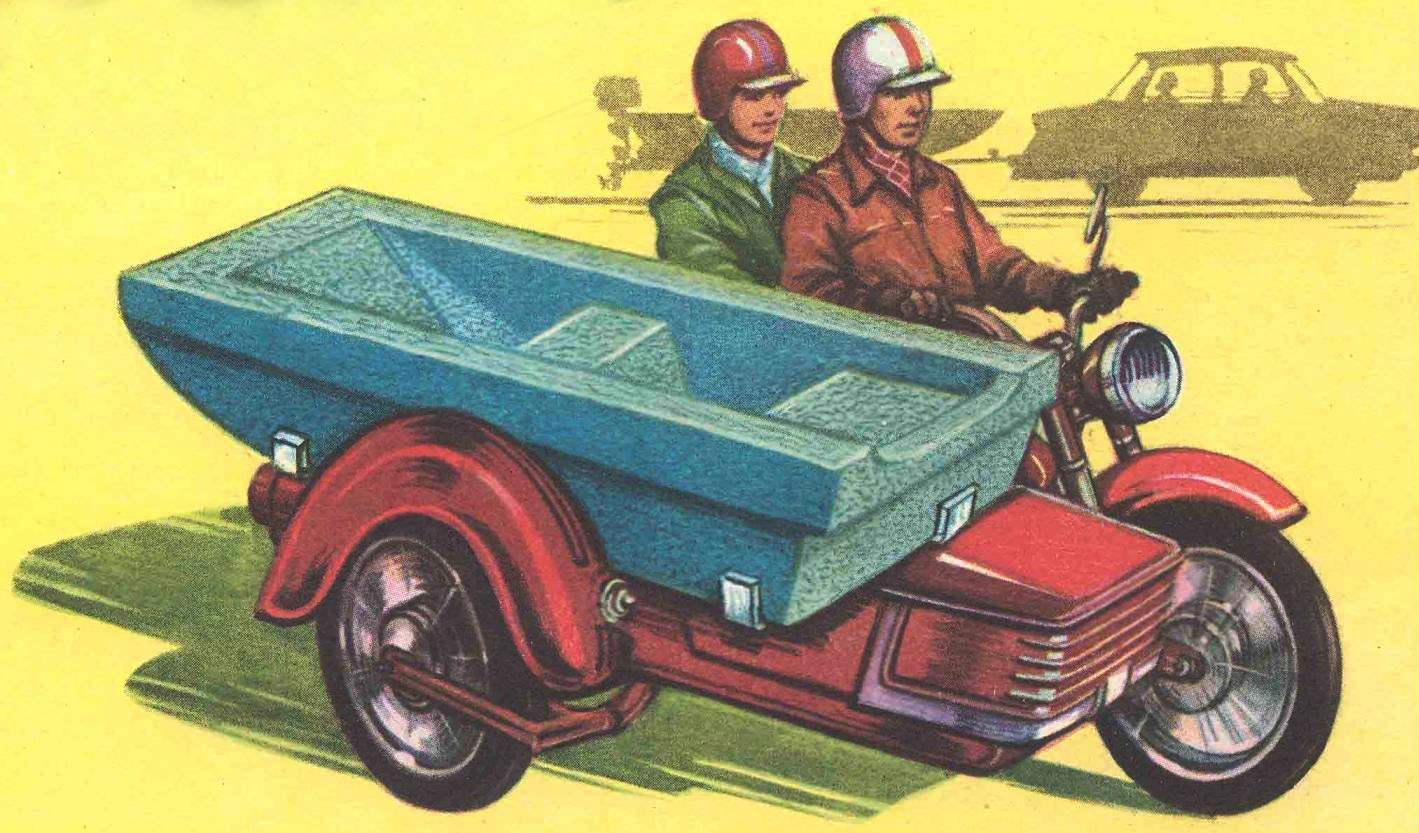

The name we gave zernoproduktovy Motorboats, which is one of the young employees of our design Bureau, Igor Kosachev, has offered to invest inside of the boat “Progress” with the big company. His proposal, he explained this “Progress” can not serve everyone; after all someone want to go fishing, someone to water-ski…

The name we gave zernoproduktovy Motorboats, which is one of the young employees of our design Bureau, Igor Kosachev, has offered to invest inside of the boat “Progress” with the big company. His proposal, he explained this “Progress” can not serve everyone; after all someone want to go fishing, someone to water-ski…

We immediately set to work. Did the layout of the liner, which is the minimum clearance was in the cockpit of “Progress”, and immediately saw that the inside of this liner, you can put another small boat or raft from foam, which is very convenient to start the skiers. It turned out, really, “Matryoshka”.

First out on the water showed that our idea was a success. On subsequent trips we have put on a “Doll” the motor “salute”, and she became self-propelled.

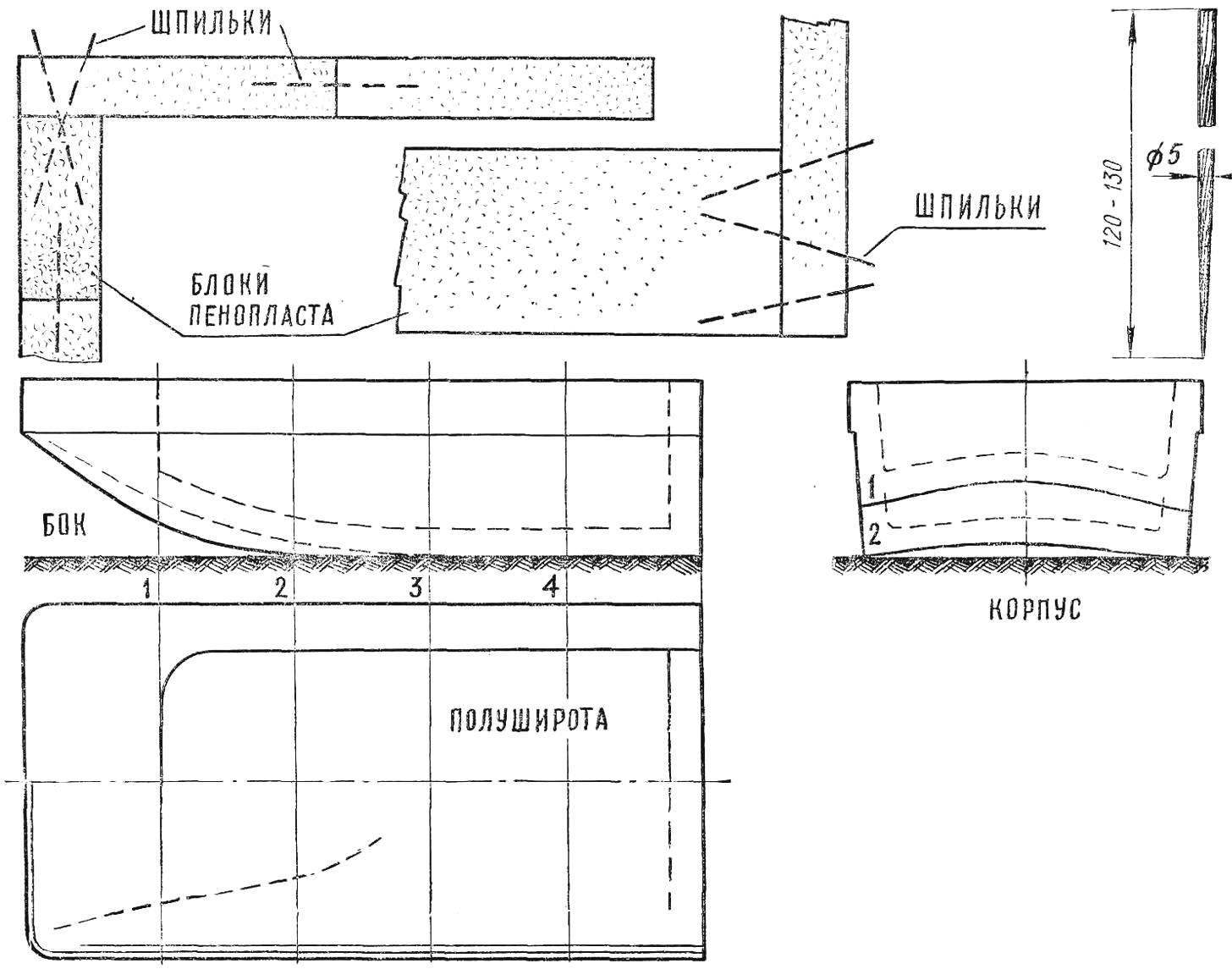

Been tested and other options: for example, transportation of “Russian Dolls” is not in the cockpit of the boat, and krasivom the trunk of the car (Fig. 2). It turned out to be very convenient in cases when the boat was not needed or it is but some reason it was impossible to take with you. Drove even on a motorcycle, tied over the stroller.

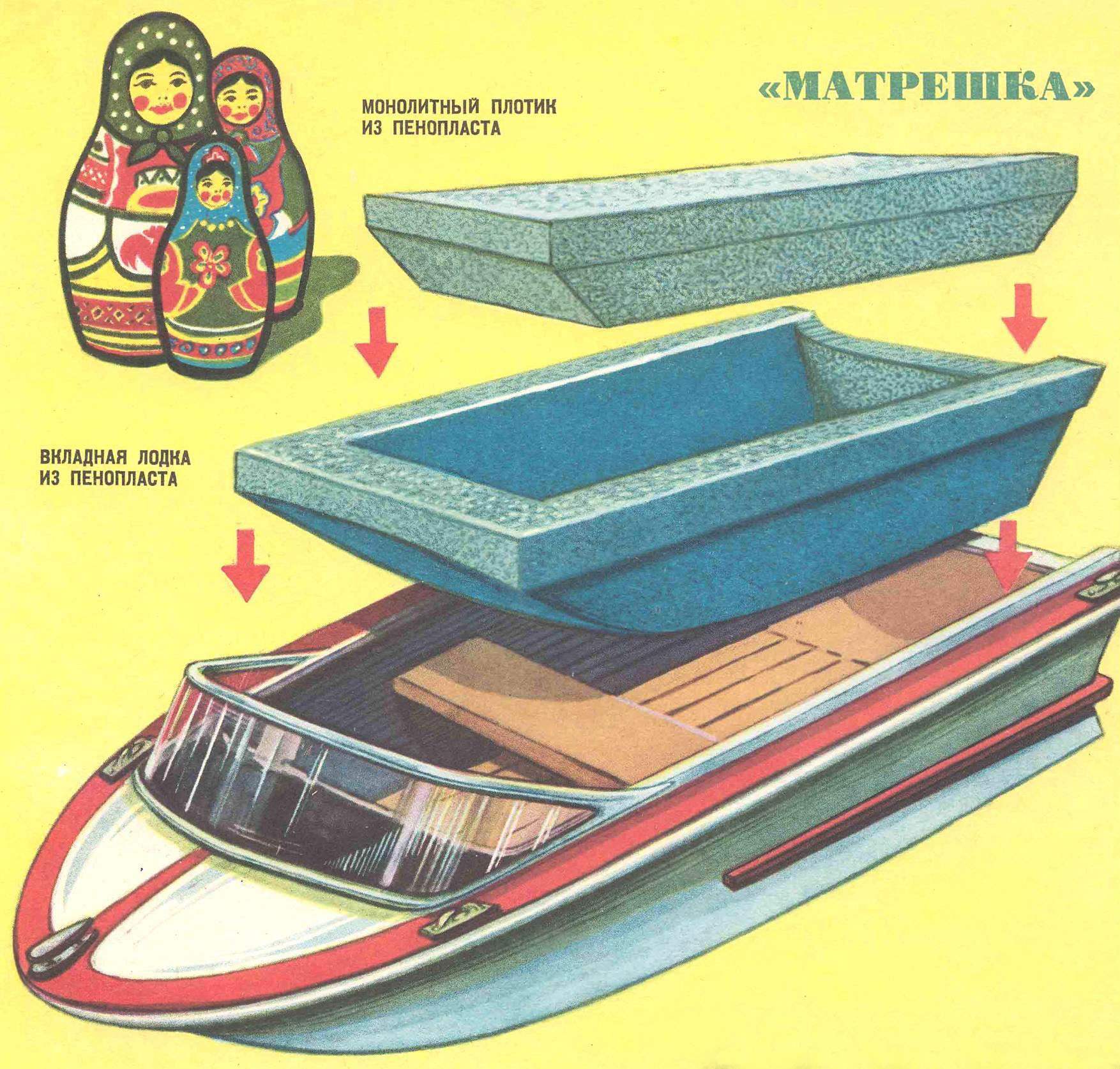

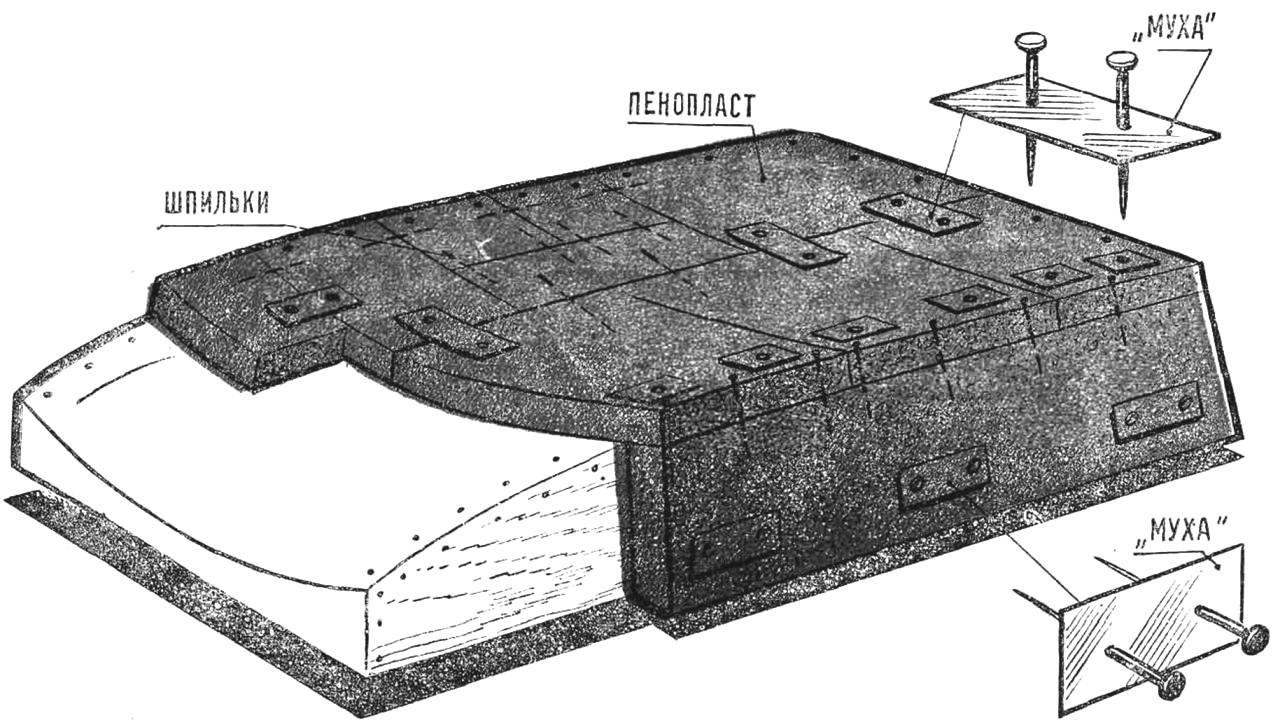

For the construction of the “Dolls” the best use sheet Styrofoam brand PVC-1 or PS-1 with a thickness of 30 to 50 mm from the pre-made templates cut needed for construction details. It is not possible to buy sheets of large size to fully carve out the side or transom, they can be assembled from scraps. Very light and at the same time strong enough “Dolls” out of Styrofoam packing crates, which are now packaged in various precision instruments, typewriters, etc. the Individual pieces are glued together with epoxy glue, with the strengthening of the seam, as shown in figure 1, the wooden studs. These are manufactured from hard wood species — oak, ash or bamboo, for example, from a broken ski poles. Stud smeared with epoxy glue, its stab in the foam (or hammer light hammer blows). This gives you the opportunity to adjust and press to one another in separate panels (or pieces) of foam, and after polymerization of the adhesive studs play the role of the power frame, much increasing the strength of the product. When selecting an adhesive should be preferred epoxy resin ED-6 because it’s thicker than ED-5, less glue will go into the pores of the foam. It saves resin, reduces weight and enhances durability of the product. If epoxy to get will fail, the bonding can be performed thick the casein is of good quality. Carpenter’s glue is not suitable for this.

Fig. 1. Connection technology of the foam using wood studs and theoretical drawing “Doll”.

Fig. 2. “Matryoshka” on krasivom the trunk of the car.

The finished boat should be covered with fiberglass PA epoxy resin. The number of layers of glass depends on what kind of foam was used for dense is only one layer inside and two outside layers (cloth-brand of ASTT (b), commonly called “canvas”). More porous foam will require two layers of cloth inside and three outside. For finishing and painting of the boat to prepare strips of wood and synthetic paint.

The technology of Assembly of the housing. The cockpit of the boat “Progress” (as well as most other serial motor boats) is of a rectangular shape. Therefore, to obtain the maximum displacement independent “doll” in its contours and shape in plan to approach the type of “sea sled” or trimaran. We chose “sea horse”, because their shape is easier, and the ride quality, they are not inferior to the trimaran of the same size (Fig. 1). The case of the “Dolls” were in the cockpit of “Progress” with the lowest gaps along the length and width, you need to first make a prototype out of cardboard or cheap plywood and, only having worked with him possible options for styling “Doll” to begin its manufacture. The case went into the cockpit to stand up on the seat (banks). It is quite clear that seat backs must be removed or folded. All adjustment must be done “in place”. Having finished it, you can start gluing the hull. It must exactly match the layout.

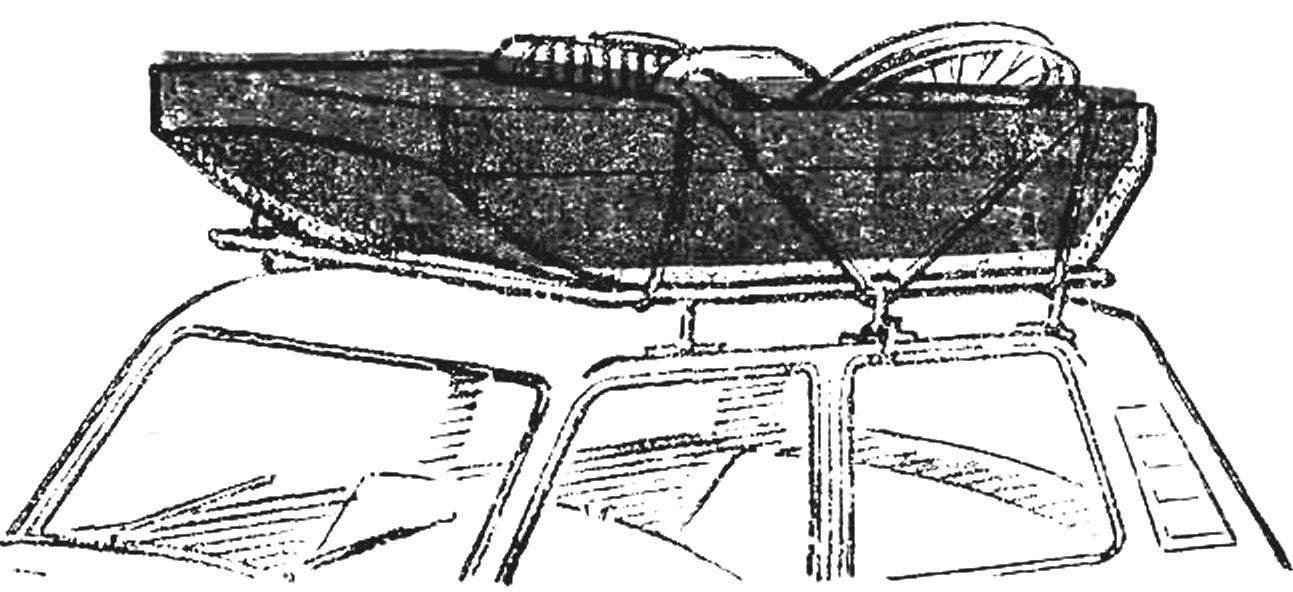

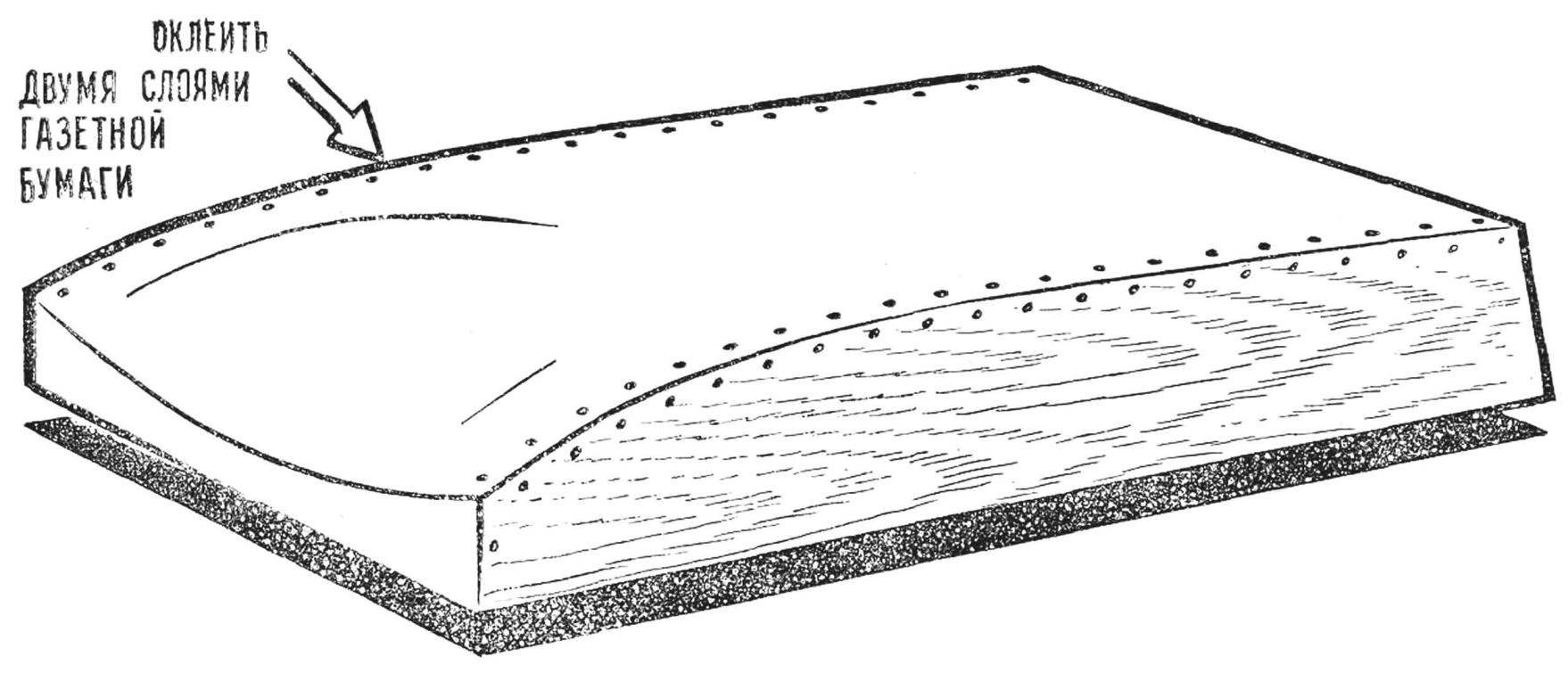

To glue the body is best on the model of “the fool”, made from low-value boards or plywood in accordance with figure 3. All linear dimensions of this model should be smaller than the layout on double thickness of foam panels. If these drawings are not suited to the existing boat, you need to redraw all the frames and transom. This draws the grid corresponding to the scale increase or decrease, and it is sequentially transferred to all lines in the drawing. Ready the dummy (Fig. 3) trimmed and glued two layers of newsprint on an ordinary starch paste. When the paste dries, the dummy two times to spread the wax with mastic for floor.

Fig. 3. The dummy for bonding hull “Matryoshka”.

Fig. 4. Technology of gluing the hull to “fool”.

You can start gluing. It is conducted in such sequence. First, on the dummy is overlaid with fiberglass, cut the patterns, and evenly spread the glue. Then stacked pieces of foam, pre-customized one to another (Fig. 4). So they are not shifted, they are temporarily attached to the “dummy” long wire nails with “flies”, which at the end of the work out. As mentioned above, the pieces of foam are sewn together by wooden pins. Sheathing the dummy completely, it is necessary to give the glue a good cure. For this you need 30-50 hours when the air temperature in the room not less than 20°. Then, using a large knife, Struga and Shoe rasp the outer surface of “Matryoshka” is smoothed, then shpaklyuetsya and cover with fiberglass. Pasting multiple layers is carried out without interruption, i.e. by overlaying the next layer of fabric on the still wet previous. While using end of a brush should be tightly preformulated fabric, making sure that it is not air bubbles not impregnated with glue. The last layer of fabric, it is advisable to glue with the addition to the resin a small amount of dry paint (pigment) in the desired color. If you want to get the white surface is added oxide of zinc or oxide of titanium; if the green — brilliant green or oxide of chromium.

Removing the finished case with “fool”, it is sanded and glued into place fender, collar, poligars and Slane in accordance with the drawings. “Matryoshka” is ready to sail!

G. MALINOWSKI