Now, as strengthening the material-technical base of agriculture, in all growth, the challenge to improve its efficiency, to improve all quality indicators. This requires… care about how to allocate state funds and material resources were given highest return to better utilization of internal reserves of the collective farms and state farms. And they, these reserves are.

Now, as strengthening the material-technical base of agriculture, in all growth, the challenge to improve its efficiency, to improve all quality indicators. This requires… care about how to allocate state funds and material resources were given highest return to better utilization of internal reserves of the collective farms and state farms. And they, these reserves are. Leonid BREZHNEV

LIFT ON THE SLOPE. Many legends lives in the people of disobedience mountains. But, perhaps even more — about people winning rugged peaks, and especially those that managed to transform the slopes, making them fertile, turning them into orchards and vineyards.

However, today the work on such sloping fields located on steep ridges and terraces are the most time consuming. Difficult mechanization not only tillage, but also delivery of fertilizer up or down filmed transporting a crop. Limited application capabilities of existing machines in the conditions of mountain agriculture keep increasing yields and productivity. This reduces economic efficiency and profitability of the economy.

This explains why among the problems developed in many institutions, including the all-Union research Institute of tea and subtropical crops (VNIIGIS), one of the most important — the creation of machines and mechanisms, able to work in the mountains. Some of them have already commented on the pages of our magazine (“Tractor-climber”, No. 4, 1975).

Fig. 1. Mobile rope installation

Institute Unicist suggested that the original mobile road — air. This removable rope installation PKU-1 (Fig. 1). The Assembly is characterized by simplicity of design, reliability and great versatility. With its help it is possible to transport air through the gorges and ravines overgrown with mineral and organic fertilizers, knapsack sprayers and other agricultural implements, containers and harvest. This cable car to the tea or citrus plantations increases productivity by 12 times. Its versatility allows you to use the unit in different sectors of the economy.

The Foundation and power base of PKU-1 is a self-propelled chassis T-16. On it are mounted the main nodes of the setup: a frame, a drive mechanism, the drums for traction and carrier ropes, the mast (front) and a mountain stops that hold the chassis in place while you work. The kit Assembly includes ropes, hung them on the truck and hook it to the bunker.

A rectangular frame welded structure is used for fastening of all units and mechanisms of the installation. Their interaction is shown in the kinematic diagram (Fig. 2). The drive mechanism using the swivel is connected with the power shaft of the tractor. Torque with its stars gall chains is transmitted to the sprockets of the two shafts, which rotate on large and small drums. Great intended for carrying a cable and has at one end a ratchet mechanism, and the other Cam coupler. When you press on the foot pedal ratchet is switched on and the drum rotates freely, “pitting” suspension cable for pulling through it and attaching to the post on the site. For tensioning of the cable arm includes a Cam clutch, and the drum begins to rotate, winding the cable back. After switching a dog coupling cable remains in a tense position due to the ratchet is pressed by a spring to the drum. From dangerous prenotazione rope Ø 12 mm safety clutch protects spring And adjustment nut.

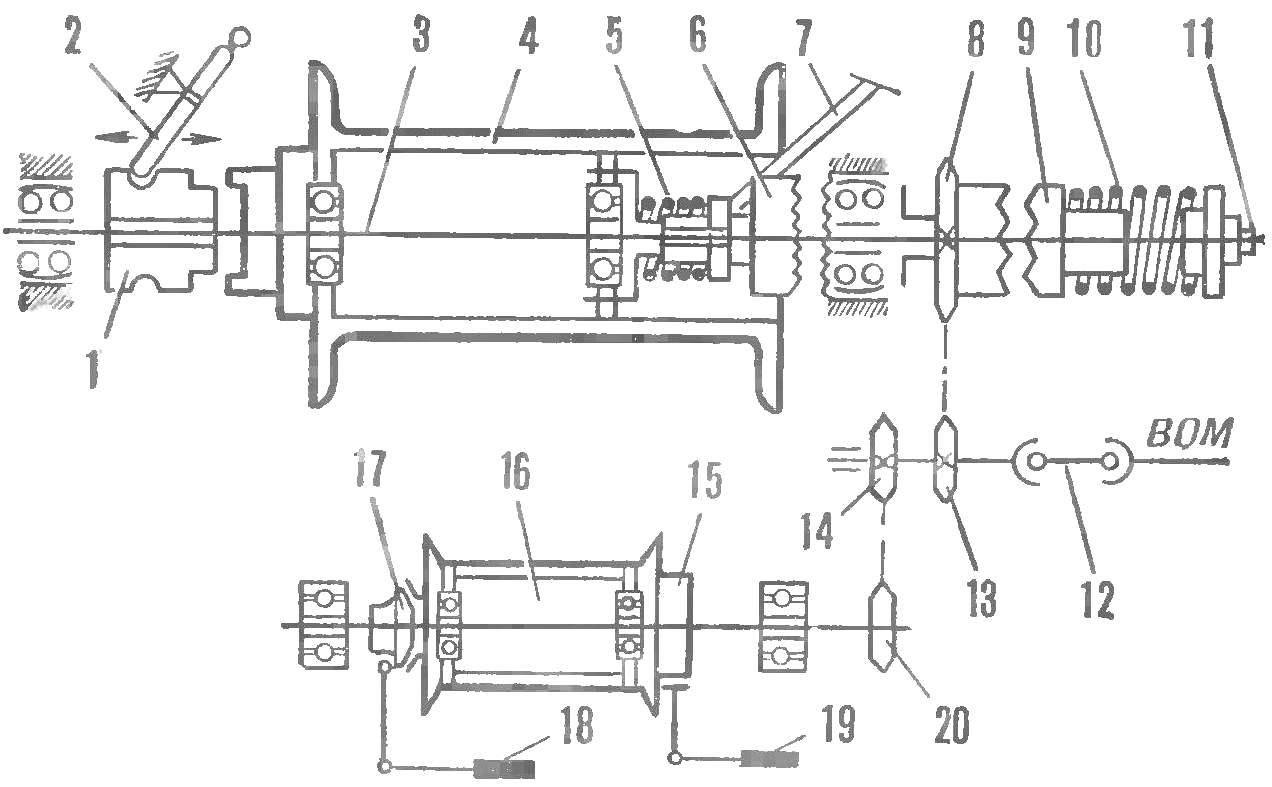

Fig. 2. The kinematic diagram of the setup:

1 — jaw coupler, 2 — lever clutches, 3 — shaft, 4 — drum suspension cable, 5 — spring, ratchet, 6 — ratchet, 7 — pedal ratchet, 8, 13, 14, 20 — stars, 9 — safety clutch 10 — spring, 11 — adjusting nut, 12 — swivel, 15 — pulley for brakes, 16 — drum traction cable 17 — coupling 18 — handle clutch, 19—, the brake handle.

Snare drum serves for winding the traction cable has one side of the clutch, and the pulley for the brake. Traction cable Ø 3-4 mm mesh to the pre-hung rolling cart with a tank or suspension for baskets. And cable car ready.

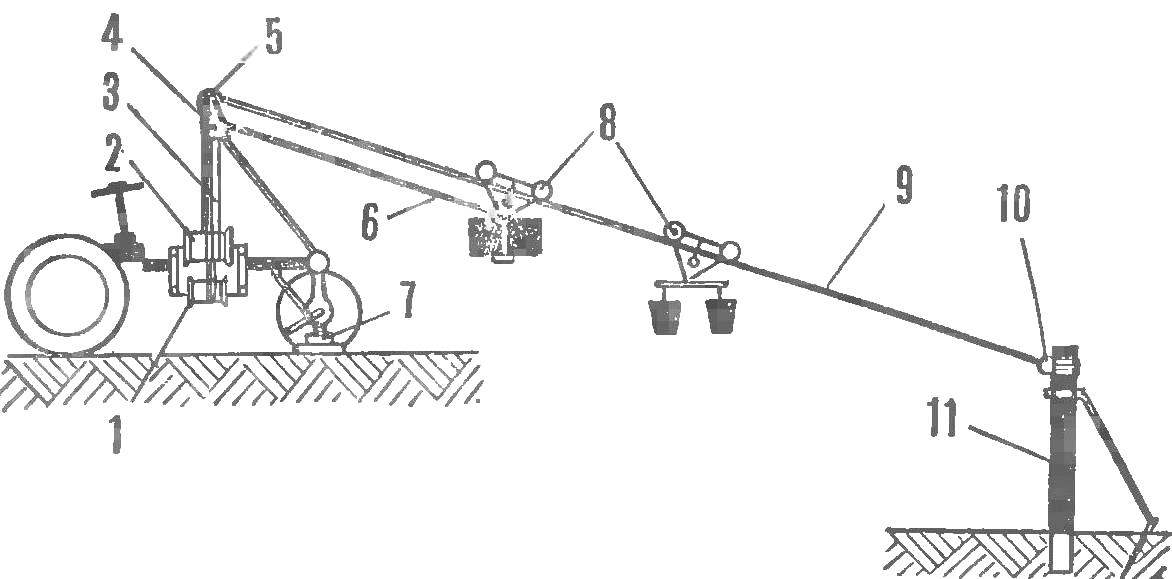

If the chassis installation is located at the top of the slope (Fig. 3) then after filling the hopper load to the tractor enough to let the arm of the brake pulley and the load under the action of its own weight will move down on the trolley down the cable. It can be unloaded anywhere on the slope, and automatically. On folding the bottom of the tank put a simple lock with a lever, and the place of unloading — pole. The lever, hitting the pole that opens the lock, the bottom is folded up and the cargo spills out. In this Way it is convenient to unload bulk materials: peat, manure, mineral fertilizers.

Fig. 3. Scheme of the installation down the slope:

1 — cable pulling drum, 2 — drum suspension cable, the 3 — strut, 4, 5 — roller, 6 — pull cable, 7 — mountain stops, 8 roller truck with two types of suspension load, 9 — wire carrier, 10 — hook mount to a pole, 11 — pole.

After auto discharge is enabled the brake and then clutch traction drum: the rope amatures back, and the tank pulled back to the place of loading and the cycle is repeated. For unloading at the site, located above or below, it is enough to move the pole.

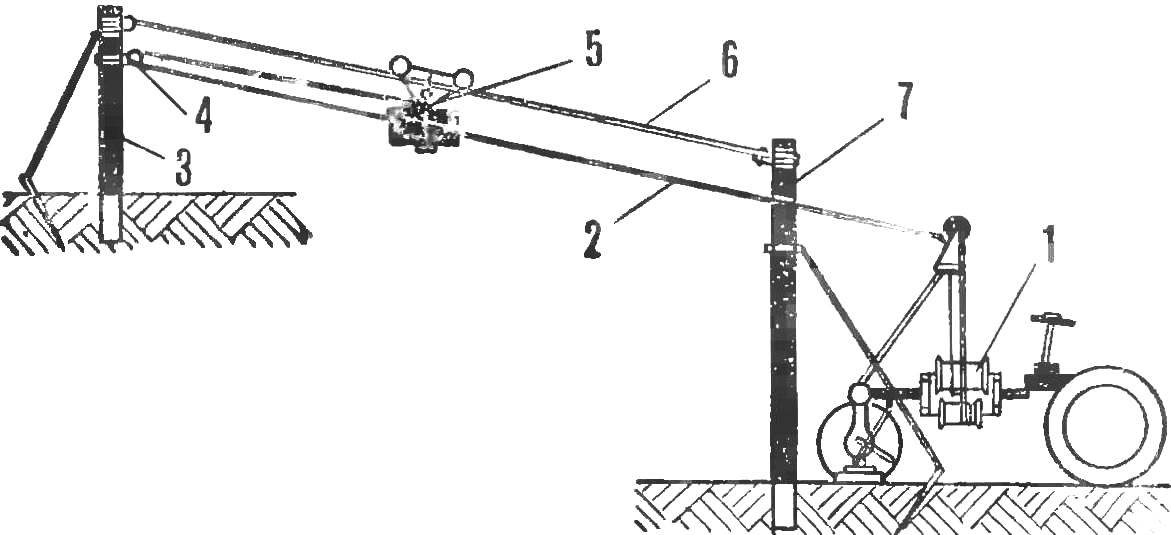

This scheme is convenient for transportation for a short distance and decided to work. Where air route is needed very often and where its length exceeds 150 m, each time to stretch the suspension cable is difficult, and the time it takes a lot. Here more convenient another scheme, shown in figure 4. The top and bottom of the slope dig in two pillars between which is secured a suspension cable. When this option is used only the traction device is installed, the cable which is supplied from located at the bottom of the chassis to the upper pole and through the reverse roller to the cart.

Fig. 4. The scheme of work is up and down constantly stretched the line:

1 — installation of PKU-1, 2 — pull rope, 3 — top pole 4 — reverse roller, 5 — roller cart weight, 6 — carrying rope 7 — bottom of post.

Mobile rope installation with a constantly strained lines is well established, for example, in the farm “Giancursi” in Adjara. Here, due to the complexity of the relief refused construction of roads on mountain plantations, replacing them with air, which transporterowych pesticides, fertilizers, harvest. The high efficiency shown by the installation in citrus farms: where it has been implemented, the cost of transportation of fertilizers decreased by more than five times. On installation, dismantling and relocation to another job takes only about 30-40 min For the service of three people, including the tractor. For an hour they can “carry” more than 2 tons of fertilizer or about 2 tons of blankets.

PROTECTION MICROSULA.

As corrosion eats away the metal surface, water erosion washes away fertile topsoil, particularly on sloping lands. Here is the most harmless rain is able to isbrandt ground paths from merged streams. Like microsemi, cascading them down and take away processed loose surface layer of soil. Therefore, applying on the slopes of the tools of cultivation is carried out erosion control operations, such as intermittent borsdane, linkowanie. But the available machines give good results only on the steep slopes up to 6°.

On more steeply sloped fields, a large effect is the so-called meleanie. However, along with it is necessary to perform cultivation, to fertilize, to form a cofferdam and seal the edge gaps between the rows of perennial plants — the problem is collectively impossible for existing guns.

To solve it successfully allows a simple design device, developed at the Kishinev Polytechnic Institute. It can perform the whole complex of the listed works and any of them individually or in combination.

The device is manufactured on the basis of universal vineyard machine PRVN-2.5 A and can be used in the unit with the tractor T-54B or others having a hydraulic system.

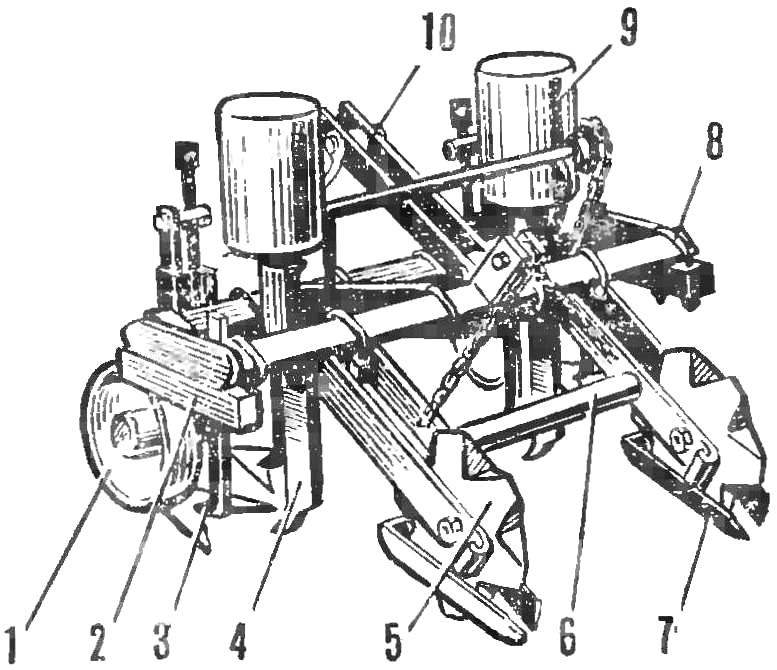

Assembly (Fig. 5) consists of a frame, supporting wheels, suspension and equipment for fertilizing, and replacement of the working bodies. These include longitudinal bars attached to the frame at various options, the flat-cutting legs with racks, xelerate, disks that are sealed and permissionusematerial, compucredit and removable cargo.

Fig. 5. Device for complex processing of sloping land:

1 — bottom rollers, 2 — frame, 3 — paws-plows with stands, 4 — xelerate, 5 — discs-seals 6 — removable cargo, 7 — compucredit, 8 longitudinal beams, 9 — tools for fertilizer, 10 — suspension.

When conducting cultivation and selevinia soil on the frame are fixed symmetrically to the six longitudinal bars. With the brackets installed stand with four legs and two knives-scelerata.

Saleres made in the form of stick knife with pentagonal cross section and a cutting angle of 35 — 42°. The front part of the sock has the form of a parabola with the continuation in a straight line, back — hollow and serves as a conduit for the supply of mineral fertilizers.

When carrying out a full complex of works on the ends of the bars are also wheels-seals. Each of them consists of two disks welded together from harrow BDST-2.5 or DB and 2.2. On the uneven bars, the disk is mounted on two rods with spacer. On their lower ends pivotally mounted to comeonline used to collect the soil lumps and the filling of the cracks.

The device operates as follows. Tractor, including the hydraulic system, lowers unit on wheels and a longitudinal leg and a knife-delires deepened into the ground. Paw cuts the weeds and cultivates the soil, and the knife forms a gap with a depth of 30-40 cm, and its thicker portion pushes her through the tightening wall. At the same time in the gap made fertilizers. For the knife is the drive that seals the edges of the gap and expands on it. The following comeonline raked and placed in the gap clods.

The advantage and effectiveness of the device with these working bodies is that the formation of erosion cracks and jumpers is made simultaneously with the cultivation of the soil and fertilizer in a single pass unit.

Such hinged working bodies were mounted on machines PRVN-2.5 A was used for experimental treatment of the land slopes to the farm “Said” and other farms in Moldova. According to local experts, in these areas water erosion was not observed.