This year we have in the Altai region, snow in autumn, almost a couple of weeks, has dropped quite a lot. Apparently winter is snow, so throw it not to shovel. Okay, that last year gathered a small but reliable snowthrower with the engine from an old chainsaw. In the spring time only experience: he has established himself, in General, good, although not without flaws. Based on the experience of use, summer had made some changes, and now present it to the readers of “Modeller-designer”.

This year we have in the Altai region, snow in autumn, almost a couple of weeks, has dropped quite a lot. Apparently winter is snow, so throw it not to shovel. Okay, that last year gathered a small but reliable snowthrower with the engine from an old chainsaw. In the spring time only experience: he has established himself, in General, good, although not without flaws. Based on the experience of use, summer had made some changes, and now present it to the readers of “Modeller-designer”.

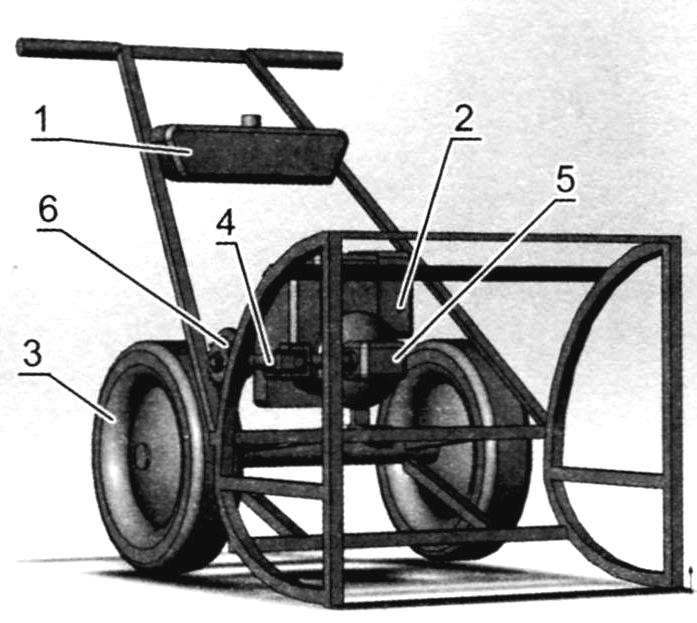

The power unit – from the old chainsaw “Ural-2M”. This motor was used because it is lightweight and sufficiently powerful (5 HP), also has a reduction gear 1:2 and the inertial coupling. This coupling is triggered when the rotor hits any foreign object, and it takes out the transmission without a break. And so the same motor can be easily removed and applied for its intended purpose (or a lawn mower, scythe, cultivator, etc., say in the summer when the snowthrower is not used). Mounting the power unit on the frame allow the use of the engine and of the chainsaw “Friendship”, only the power of this motor is slightly smaller, which is undesirable. These engines can be purchased inexpensively today. I also tried to use the low, turned parts, non-deficient materials and spare parts. As a result, the snowthrower was very inexpensive and simple to manufacture.

Motor it was decided to locate along the longitudinal axis because the center of gravity shifted to the left or right would result in misalignment of the exciting of the bucket in a horizontal plane. And then, to the left or right would remain nedochischennye trail from under the bucket. And this placement eliminates torque steer in one direction or another. Although this placement led to the use of additional drivetrain parts, but the snow thrower in this form, looks more natural. That in itself is also important!

The tank used the standard, chainsaw “Ural-2M” in volume of 1,6 l, and is attached by two bolts to the steering support, at which there were two lashing eyes. Throttle stick (throttle control) used from a motorcycle “Ural”.

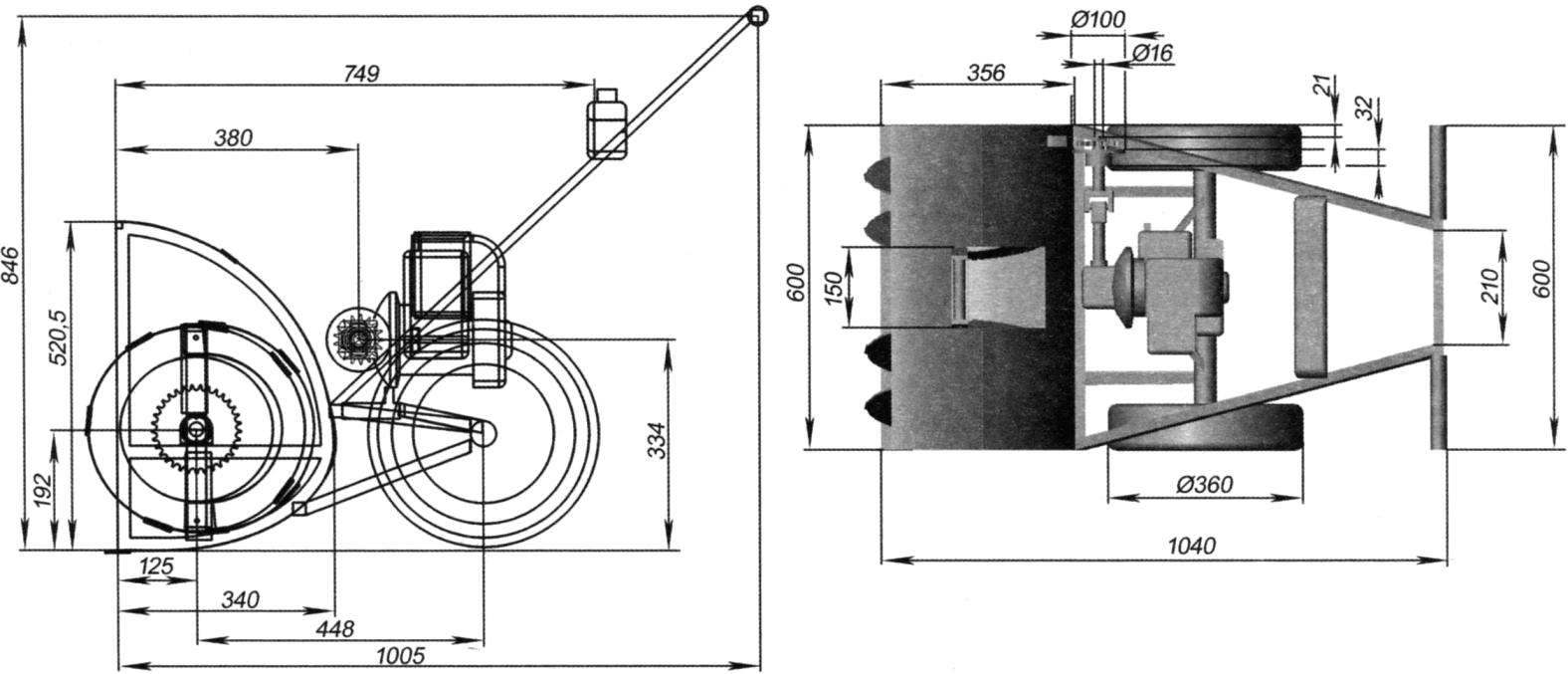

The principal dimensions of the snow thrower

The frame of the snowthrower is actually not, or it can be called a combined – couple of levers with the steering cross bar, welded to the frame of the bucket.

Almost all the frame is welded from square tubes 20x20x1,7 mm except for the top of the bucket. There used pipe of square section size 10х10х1,7 mm. Bucket “covered with” galvanized sheet 0.5 mm-thick sheet which is riveted to the frame by aluminum rivets with a diameter of 5 mm In frame construction made of metal plate 600x40x4 mm, it podvarennoe at the bottom of the bucket. And it, in turn, riveted plastic strip size 600x60x5 mm. this is Done for better sliding of the bucket on the surface (mostly pavement slab).

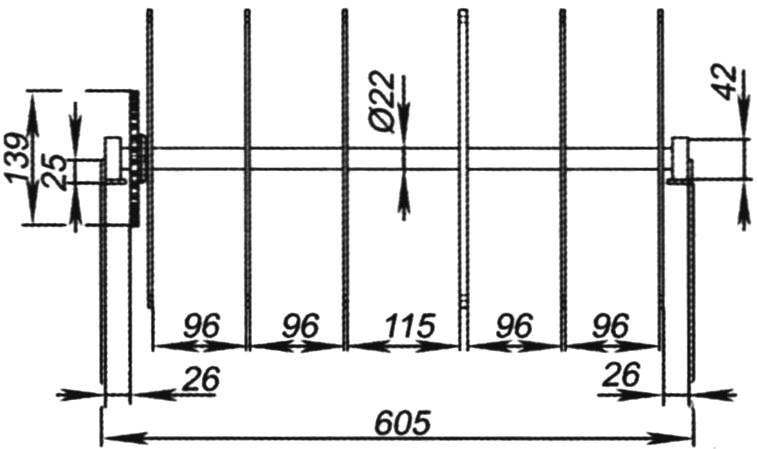

The working body consists of a shaft on which are placed two oppositely directed augers and the rotor. The shaft is made of plumbing pipe diameter 22×2 mm and a length of 568 mm. At the ends of the tubes are inserted and welded on steel end caps axle pivot bearings. Screw-rotor mounted on two bearings in the housings. Bearings sizes 40x16x16 mm – closed type ball. The housing is cylindrical and machined from steel and welded to their segment of the metal area 25х25х4 mm, which are bolted to the frame of the bucket with two bolts М8х40 mm nuts.

On the shaft of the screw and rotor are installed in the same way and is sprocket driven, it is bolted with four bolts М6х30 mm nuts to the flange that is welded to the shaft. This sprocket has 33 teeth under the chain gear with a pitch of 12.7. The circuit is used from a motorcycle “Ant”. Pay attention to the fact that the chain transmission is installed inside the body of the bucket with a purpose: first, to hide the moving chain with the sprocket, and secondly, when the dimensions of the snow thrower, the bucket will have a big width of snow, thirdly, less dead spots in the bucket (from which it is impossible to capture snow, or limiting it). To the shaft is welded twelve steel band-wings for fixing the screw blades and rotor.

Rotor-screw with stripes-wings without blades

Snow thrower chassis (frame with engine and wheels):

1 – tank; 2 – engine; 3 – wheel; 4 – propeller shaft; 5 – bearing unit; 6 – sprocket (z=17)

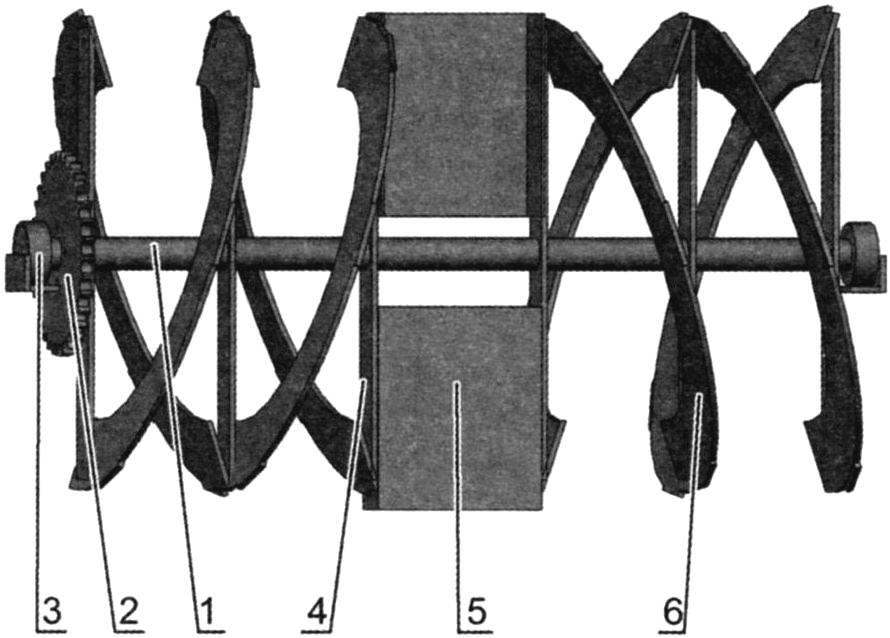

Rotor-screw Assembly:

1 – shaft (pipe 1/2″); 2 – the driven sprocket of the rotor shaft-auger (z=33); 3 – bearing housing (2); 4 – wing rotor (a metal plate 30×4); 5 – blade rotor (2pcs); 6 – lobe screw (8 PCs); 7 – wing auger blades (4 PCs); 8 – seat angle (2 PCs.)

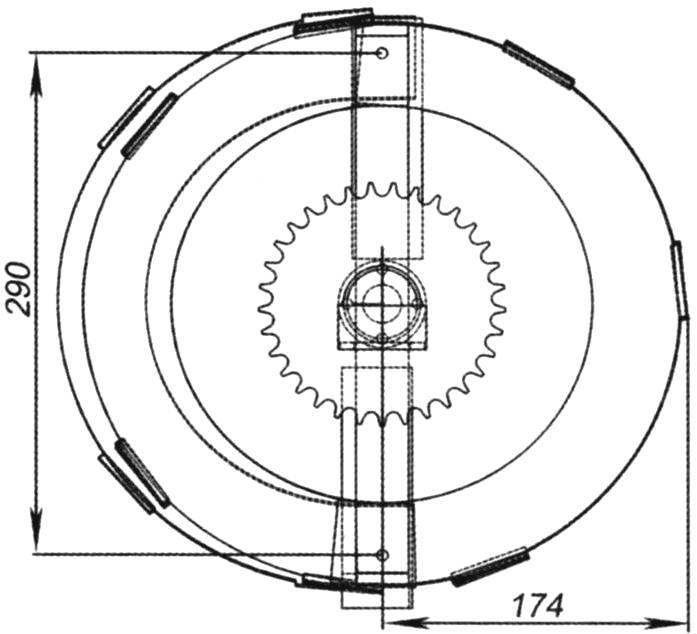

Rotor-screw: main dimensions

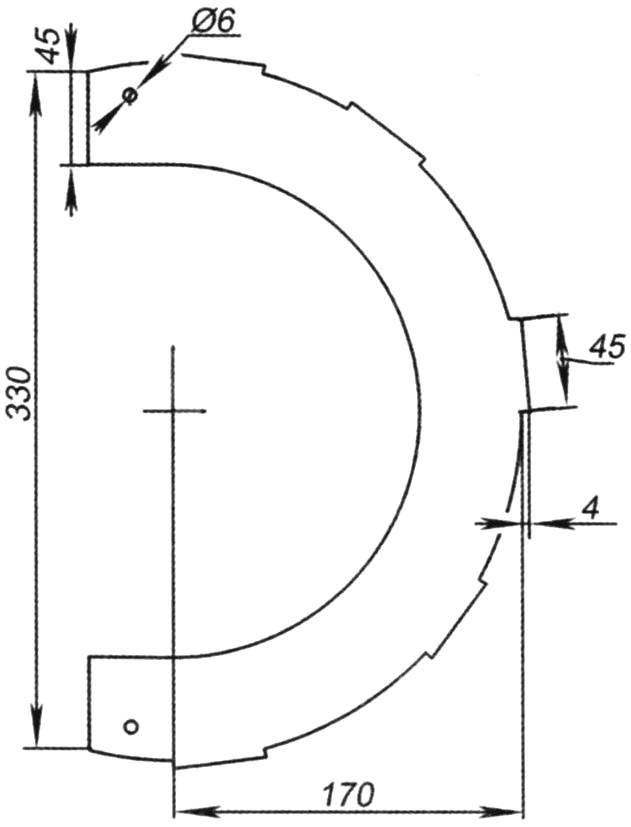

The blade of the screw

Auger blades are made of duralumin sheet thickness of 4 mm. They are composite. Each piece (in the shape of a horseshoe is to save material) is cut out with a jigsaw. This design of the blades facilitates their attachment, and replacement in case of breakage. The blades cut teeth for cutting dense snow. “Horseshoe” attached to the wings of the screw bolts with M6 thread and nuts. The exposed portion of the twisted bolts cut and podlipny, in order to not cling, and does not spin. Duralumin sheet is used specifically to facilitate rotating rotor design-auger. Operation demonstrated – dural 4 mm sheet provides sufficient strength.

The rotor blades (two pieces) made of stainless steel sheet 2 mm thick. I used it not on purpose, but because it was not at hand ordinary steel sheet of the desired thickness, and duralumin sheet over. The rotor blades are mounted, if possible, the same distance from the shaft to eliminate the runout during rotation. You need to manually balance the rotor by placing it on the bearings. But if the wings and rotor blades-auger will be set to the same size and identical, then balance do not have. But the check is still needed.

Drive chain has the ability to tighten or loosen, setting closer to or further from the drive sprocket shaft screw-rotor frame.

In place of the drive sprocket reducer motor chainsaw mounted driveline. It connects the gearbox with the lead 17-bevel sprocket chain transmission (pitch 12,7 mm). Sprocket mounted on the end of the second knee of the propeller shaft. Himself, the driveshaft is supported by two sealed ball bearing sizes 40x16x17 mm, installed in the buildings. Housing machined from steel, and podvarennoe to the corners of size 40x40x4 mm and length of 120 mm, which are attached to the frame by means of two threaded bolts with nuts М10х40 mm.

Wheel sizes 3,25×8 inch with the built-in disk-hub bearings, used Chinese cars. Wheels are installed on the tubular shaft, made of water pipes with a diameter of 26 mm and a length of 550 mm. At the ends of the tube are welded two studs of an external diameter of 20 mm, on which are mounted the wheels and fixed them with two bolts М10х30 mm. these wheels I have already put this winter (the first was a smaller diameter). These wheels are more comfortable to work with, as they have a large diameter and width and not so much fail in the snow. However, the quality of the rubber leaves something to be desired.

The drive wheels do not yet began, and I think that’s right. As the snow thrower is lightweight and the traction is low. At work, if you come across a dense area Packed with snow, you need big pulling power. But it will not create even with good tires, and to put steel lugs will ruin the paving. But there is a solution: with the increased resistance to movement necessary to stretch one foot in the axis of the wheels and push the snow thrower. This way I clear with no problems and meter height (depth) of the snow.

On the first bucket stood as the sleeve that directs the snow to the side, but I refused as wet and sticky snow it clogged. And the sleeve contributed to the creation of snowdrifts, and this led to the arrest of snow. And when you work from snow flying in your face, the sleeve does not save. Small snow dust the wind blows in the corresponding direction. Sleeveless snow from the rotor, rotating at high speed, thrown high up and forward and sprayed. As the air is constantly moving, even when it seems that there is no wind, dust, snow gently falls around. But if the wind blows, it generally takes far. On a small, idling engine speed, the snow sprayed and it is more dense, crashes and falls ahead. It is necessary to work in any “corridor”.

Result: either the right or the left dumps no snow (snow depth of about 600 mm)

In General, the snow turned to small dimensions; light – weight was only 35 kg; economical – consumes little fuel, one liter of gasoline is enough to clear a fairly large area, and most importantly quite productive and easy to use.

Total consumption of basic materials:

Square tube 20x20x1 mm – 7.8 m square Tube 10x10x1. 5 mm to 0.6 m. the Pipe diameter of 22×1,7 mm – 0.6 m; pipe diameter 26×1,7 mm -0,55 m strip Steel section 40×4 mm – 1.2 m; section 30×4 mm – 1.8 m Pallista standard sizes of galvanized tin. Petrol motor, two wheels and something else on the little things.

And of the identified shortcomings: it is portable and manual starter, which is inconvenient to carry.

D. ELEPHANTS, Altai Krai