For transportation of large cargo by land over distances of hundreds and thousands of miles of not-yet-invented method than the railway. It accounts for in the country about two thirds of total turnover. In the ninth five-year plan to build new roads, increased capacity and capacity podvesnoy composition.

For transportation of large cargo by land over distances of hundreds and thousands of miles of not-yet-invented method than the railway. It accounts for in the country about two thirds of total turnover. In the ninth five-year plan to build new roads, increased capacity and capacity podvesnoy composition.

Specific applications in marine, river, automobile, air transport.

And for liquid and gaseous products best form of “transportation” — the pipeline. Pumping oil and petroleum products through pipes will increase over the five-year period more than doubled, and the transportation of gas will increase by approximately 1.5 times. Our country ranks first in the world in the development of large-diameter pipes.

But let’s say you need to transport sand, gravel, crushed stone and other building materials from the quarries where they were mined, or ports for short distances on concrete plants, for example. How to be, to build a railway? Unprofitable. To use a truck? But since loads of bulk and mass, you need huge trucks with load capacity of 150 tons and more. For these giants also need a special — and very expensive — road. And if you need to remove construction materials or ore from deep open pits — pits? The air is sometimes filled with so much exhaust, that required a special installation for ventilation.

Another option, also requiring new solutions — the export of ore mined in the mountains, especially in winter, in snow drifts and debris. The ore sometimes is delayed in the mines, until you have a chance to take her. All this applies to the North of our country: it is difficult to operate the transport are designed, in General, to work in quite different conditions.

A serious problem of modern big cities become garbage, household waste by waste recycling companies. Hundreds of thousands of cars on these busy traffic, but traffic artery of the city is already overloaded!

“Lilo-1” is the current setting for the transportation of construction materials in shulaveri, Georgia. In these tubes on the overpass moving containers.

In all these and many other cases, the solution can be… pipe. Such transport is described in fantastic literature; in different countries done a lot of projects moving loads on the pipes.

…Moving belt conveyors, slide gate valves bins: gravel and crushed stone backfilled directly in pipes running part on land, part on the overpass. Coarse gravel is transported by pipes? Yes, there is a trend in technology — to move the bulk or small goods through pipelines in liquid or gas flow. But it did not develop because excessive wear of the pipeline itself, and the power consumption is greater, the greater the distance.

Well, if you try in another way: in the pipe to move not just the cargo, and containers on wheels, a kind of trolley? In the Soviet Union has built the world’s first installation of a pipeline for container transport. It is designed for transporting materials from the quarry to the concrete products plant near the village of Shulaveri, Georgian SSR. Through the pipeline in diameter of 1020 mm at a distance of more than two kilometers delivered more than 640 thousand tons of building materials per year.

This system was designed jointly by the special design Bureau “Transnefteproduct” and Institute “Rosgiproles”. But this was preceded by a long research work. In SLE “Transnefteproduct”, ‘ve done the calculations, constructed the model of pnevmotsisty of glass tubes with a diameter of 40 mm and a length of 25 m. On it and had all the features of the future trails. And when the original data were obtained, collected the second model, or rather the stand also from glass pipes, but with a diameter of 100 mm and a length of 250 m. designers Developed the pipeline for container transport called “Transprogress”.

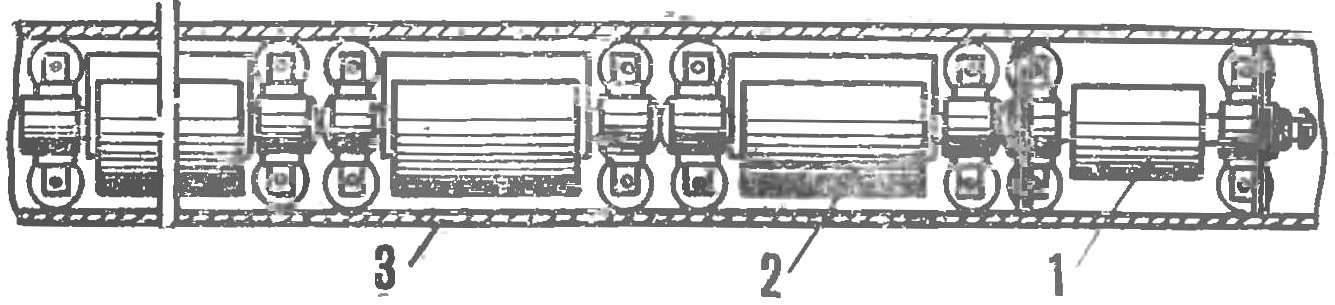

In General terms, the system “Transprogress” corresponds exactly to the idea expressed above: in the pipeline are moving containers on wheels — trolley. They can be single or combined into compositions.

When the containers are formed in the train, they are joined by the so-called pneumology is a special trolley equipped with a sealing cuffs, tight to the pipe wall. The corrugated sheetthus plays the role of a special piston. A small differential pressure is only 0.1 ATM. — is enough to propel the composition from the containers on wheels weighing up to 25 tons And the drop when lifting with a slope of 6° — about ATM.

Built near Tbilisi is the system of pneumatic transport, the composition of the containers weighs 25 tons. It consists of six wagons and two pneumatov located at the end of it. Pneumopathy equipped with special seals that completely cover the cross section of the pipeline and provide the necessary traction.

Fig. 1. Scheme pneumophila:

1 — pneumovac cuffs; 2 — trolley-container; 3 — the pipeline.

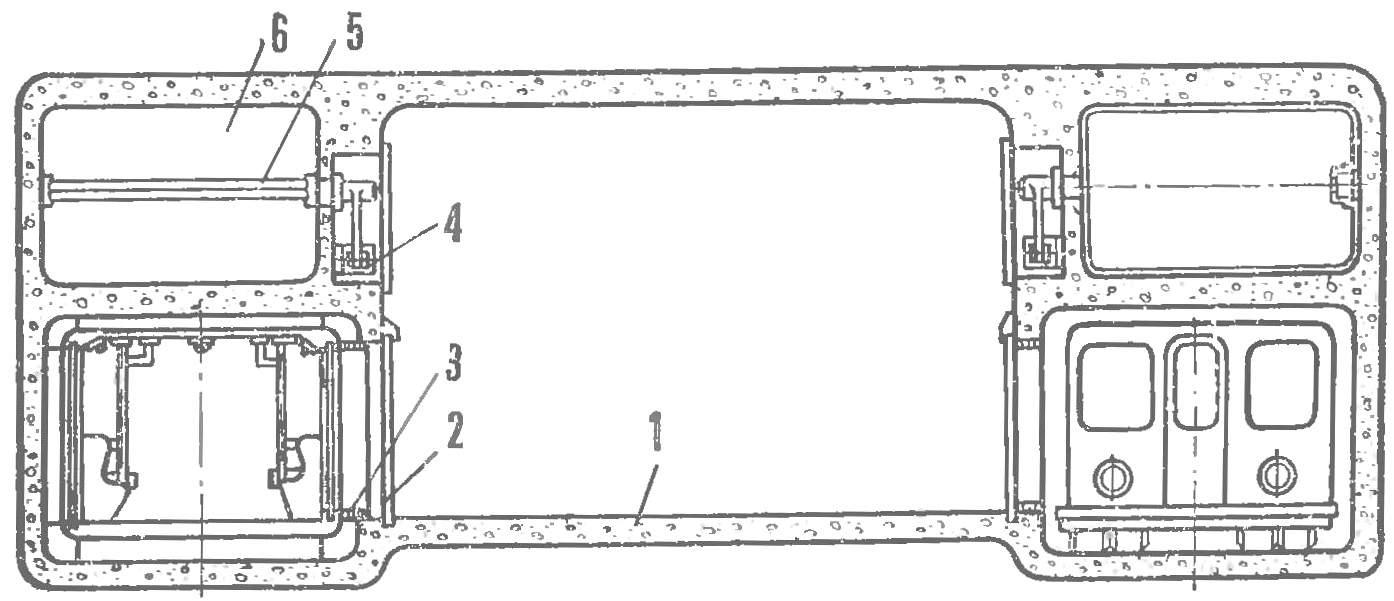

The differential pressure created by the blowers. The speed of trains up to 45 km/h Loading and unloading station, turnouts, and sluice gates prevent the pressure reduction, the braking device, accurately stopping of heavy containers in the specified location are the main parts of the system “Transprogress”. All operations of loading and unloading containers, managing their movement is automatic, controlled by a dispatcher from a Central console.

Pneumatic transport can be one, two or multi tubes depending on the intensity of the work. The water mains to be laid underground, on the ground, on racks. A system of smaller diameter is suitable, for example, for intra-plant shipments. it can be hung along the walls and under the ceilings of industrial buildings, which eliminates the aisles in the shops.

Operation “Transprogress” is not dependent on the weather; the system is particularly effective for use in the mountains, in the swamps, where other transportation is either very expensive or even inapplicable.

The route of the mobile pneumatic conveying — they can be quickly dismantled, easily transported to another place and reassemble. It is very convenient for large construction projects, where it is necessary to apply sand, gravel, cement n other similar building materials.

Pipes can be of a variety of materials — metal, plastic, concrete.

Wheel containers-trolleys is coated with a layer of rubber or a similar elastic material, for example polyurethane. Therefore the pipe wear and running gear of the rolling stock is very small. “A “engine” — air flow — generally invulnerable! So, very high operational reliability and durability — up to several tens of years of trouble-free operation — property, in our time is extremely important. And another thing, not less essential: no noise. It makes “Transprogress” is exceptionally good for large cities. You can transport a variety of goods and even passengers. And the urban air will be cleaner: pneumatic road because they do not emit harmful exhaust.

As a consequence, speakers and other favourable features of the new mode of transport. All the floating cargo is securely isolated from the external environment: they are hidden in containers and even in the pipe. So it is easy to observe when transporting the technological conditions, hygienic.

People for maintenance “Transprogress” requires very little Productivity here is higher than in road transport, 10-15 times.

That is, in the most General terms, the work of Soviet scientists, designers, engineers and workers on the creation of a new transport system. It was decided at the modern technical level is needed, and models and computers. And of course, not without inventions. Approximately 50 fundamentally new schemes, units, mechanisms issued copyright certificates. Many of them are proprietary and are patented in USA, Japan, Germany, England, France, Italy, Canada, Sweden. In a word, “Transprogress” is a major success of Soviet inventive thinking, design savvy, working skills.

What’s next? The line of pneumatic transport near Tbilisi works reliably and well demonstrated. So, success must be nurtured and enhanced, creating a new installation. And such projects already exist. For Volgograd, designed the railway, where two pipes will be transported 3 million tons of sand per year. The length of track 11 km, pipeline diameter — 1,220 mm. the Calculation shows that the transport of one tonne of sand at a distance of one kilometre pipeline in containers is cheaper than a car, more than three times. Thus, the investment will pay off in less than three years.

Fig. 2. The landing station on the line of pneumatic transport of a passenger:

1 — platform, 2 — door platform, coinciding with the train door; 3 — retractable seal vestibule. 4 — the damper actuator auxiliary pipeline; 5 — the valve of the auxiliary pipe in the drawing in open position; 6 — auxiliary piping (bypass). It goes parallel to the main pipeline at intermediate stations. With the damper the air, pushing the car is transferred to the bypass. Then the train stops to experience the air pressure and stops. The flap is closed — bypass closed, the air again presses the wagons, a train moving.

The same system — for transportation of sand and gravel designed and built where there is already operating experience of similar structures under Tbilisi. But now the length will be 50 km away from a career in shulaveri to concrete products plant on the outskirts of the city. 50 km — this is not an experiment and not a prototype, and the current industrial setting!

In the middle of last year, the Japanese newspaper “Mainichi” wrote that Soviet technology pipeline for container transport is the best solution in the “war” with household waste. Article on this topic appeared because the Japanese company group “Sumitomo” purchased a license to the Soviet system “Transprogress” with a view to use it primarily to transport debris, waste and loose materials.

It’s hard to imagine the complexity and difficulty of this problem. Elimination of waste is a complex task of environmental protection, sanitation, hygiene, Economics, and technology. Fundamentally there is no solution so far. Many countries use a vacuum system for collecting waste directly from the garbage of homes, hospitals, canteens, schools and kindergartens. But this system, developed in Sweden, is not universal. Radius of action it is limited to two or three kilometers, and then — waste treatment enterprises have to carry waste cars. But the challenge is to completely eliminate the contact with debris and quite to free the streets from garbage trucks. In social terms, the challenge is to dramatically reduce the number of workers employed in the unattractive business of collecting and removing debris, turning them into operators, dispatchers, specialists in the repair and maintenance of mechanized transport systems.

Here is the range of tasks and allows the most (today) completeness to solve the system “Transprogress”. Already completed feasibility study for container pneumatic transport of household rubbish in Moscow. The effectiveness of the new method significantly outperforms all known methods. And in Leningrad system “Transprogress” for these purposes is already being implemented. 500 thousand m3 of waste will be transported in containers through the pipeline in diameter of 1220 m at a distance of 11 km.

There are all prerequisites in order to introduce a new system for transporting grain, creating an extensive system of pipelines with the field currents to the Elevator. How this must break free of cars! And how dramatically will decrease grain losses, now very sensitive.

And transportation a new way of building materials: sand, gravel, crushed stone, limestone, cement needs in the construction of large structures: dams, industrial buildings provide savings of tens of millions of rubles, now spent on vehicles. Particularly important “Transprogress” may acquire for the development of the newly discovered Siberian oil and gas fields. In the swamps, where each meter is given a normal car and even with the tractor work, where you have to almost use the helicopters to carry the most common building materials, containers running but the pipes will be an invaluable vehicle.

And calculations confirm this.

But coal, which is transported in open gondola cars? And feeding in large livestock farms? The pneumatic transport will provide the necessary hygiene, complete security.

Many can even list the ways of application of system “Transprogress” in various sectors of the economy. But perhaps the most effective is the use of se principles for the organization of urban passenger services. And such a project is already there — to Moscow. It was developed by SKB “Transnefteproduct”, together with the Chief architectural and planning administration of the capital.

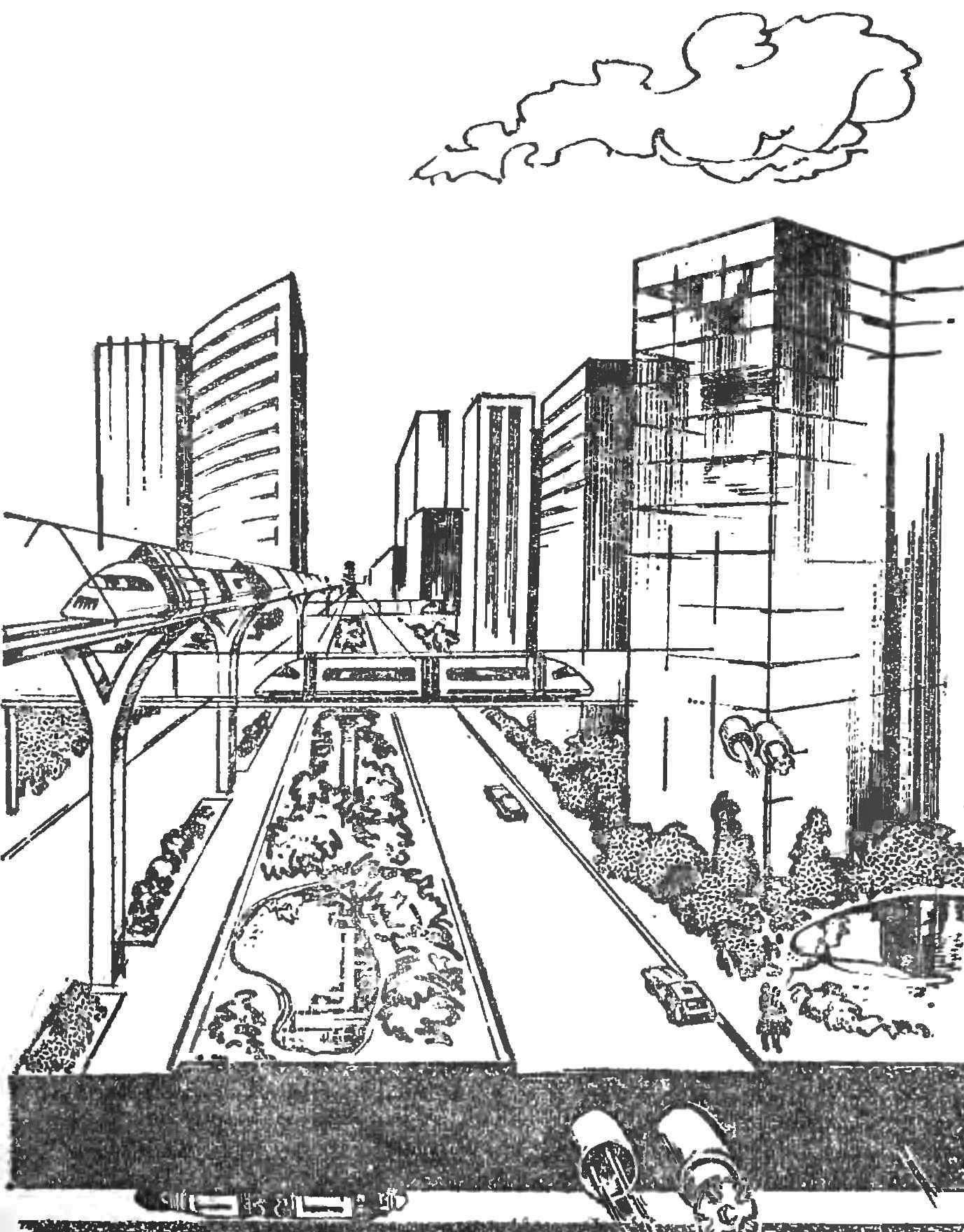

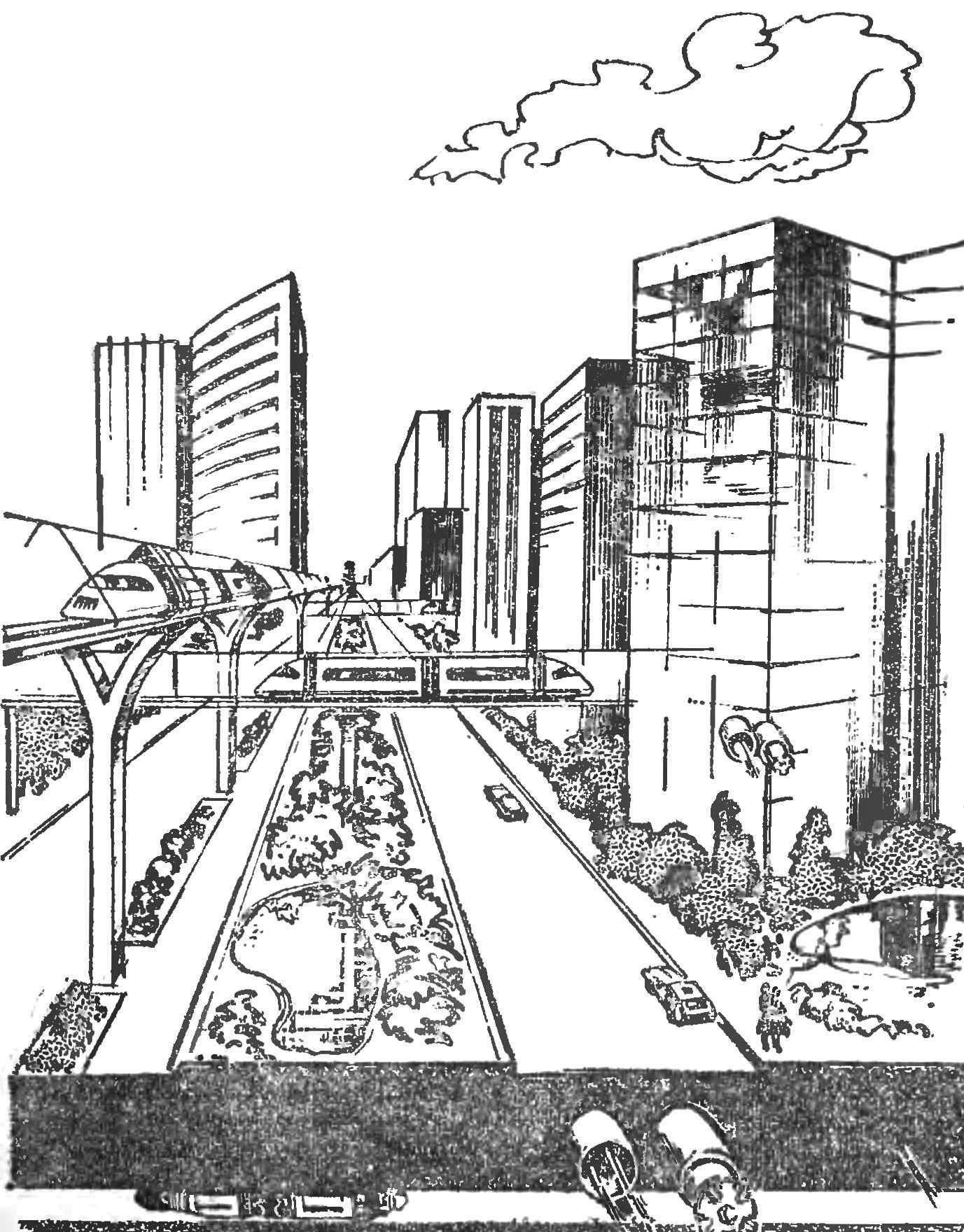

A new form of transport chosen because it is much cheaper than the subway and just as silent, save the environment, does not emit toxic substances. As a “starter” phase of the world’s first passenger pneumatic conveying selected district of Moscow city of Zelenograd. Because it clearly expressed for the residential and industrial zones and direction of passenger flows. The route goes from the train station sequentially through the production areas and residential areas.

The six kilometre track will consist of two tunnels with a cross section of 3X2 m. the Material of the tunnels — reinforced concrete section length of 1.8 m. the Track goes and just on the surface, and on the overpass, and with depth in the soil. It will have 4 stations.

Fig. 3. It will look like the passenger system of pneumatic transport in a large modern city.

The train will consist of several to ten cars, each of which holds 125 passengers. He will be able to reach the speed of 90 km/h.

The body of each car is sealed, all-metal bearing, it has four doors, two in the end walls. In the front and rear cars of the cockpit for the driver with the control devices. On the end walls is equipped with a special seal.

Pneumatic transport capacity is second only to rail and metro. In Moscow it can complement the latter, carrying the message with airports, leisure zones. And in the cities that have a stable flow of passengers, a pneumatic transport can serve as a primary means of communication.

R. YAROV, engineer