If you manage to build such a mini-sailboat, you will immediately become the owner of a whole “fleet”! In fact: the boat of the proposed design, called “Hummingbird” by the author for its diminutiveness, as a result of a very simple conversion can become a dinghy, a windsurfer, and a rowing boat. Moreover, it will be useful not only for relaxation, but will also serve as an excellent training device for beginning athletes.

A sailboard for beginners must be, above all, stable! This is how we reasoned when developing new, wider hulls for surfers of the Tornado-Aquata class. In addition, meter-wide boards were practically not inferior in speed and maneuverability to sports sailboats. This gave us the idea to create a universal hull capable of performing the functions of a training or pleasure windsurfer, as well as becoming the basis of a miniature dinghy.

All this determined the success of using the sailboat, called “Hummingbird,” as a trainer for a novice surfer and even a yachtsman. After all, the so-called “sense of the wind”, to which an athlete gets used to when sailing on a board, will turn out to be very valuable when mastering other types of sailing ships.

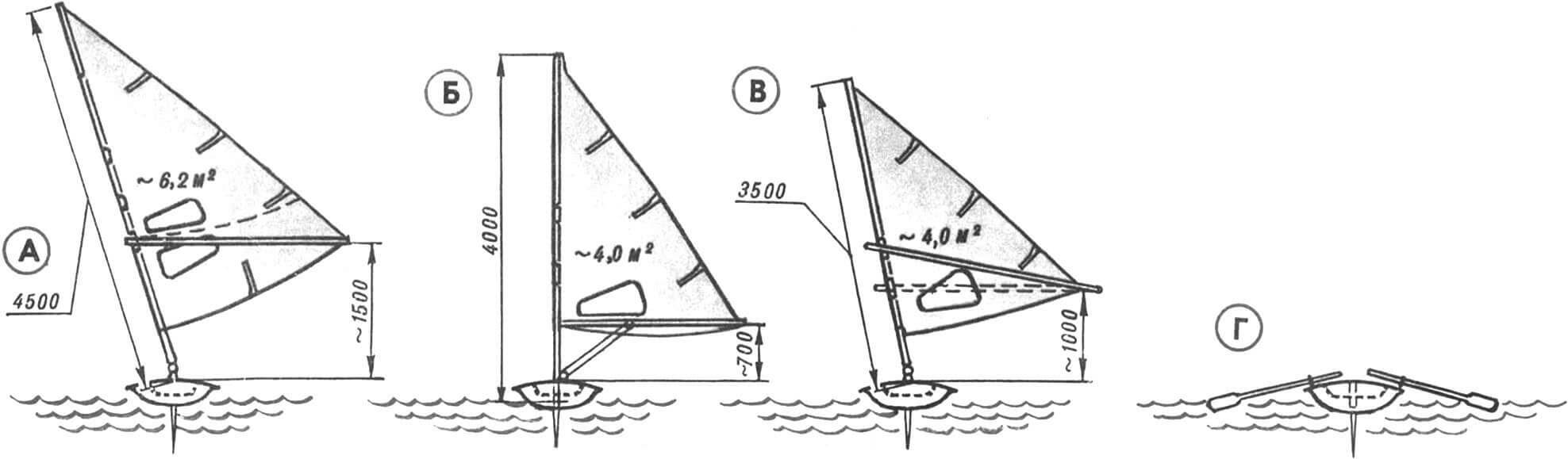

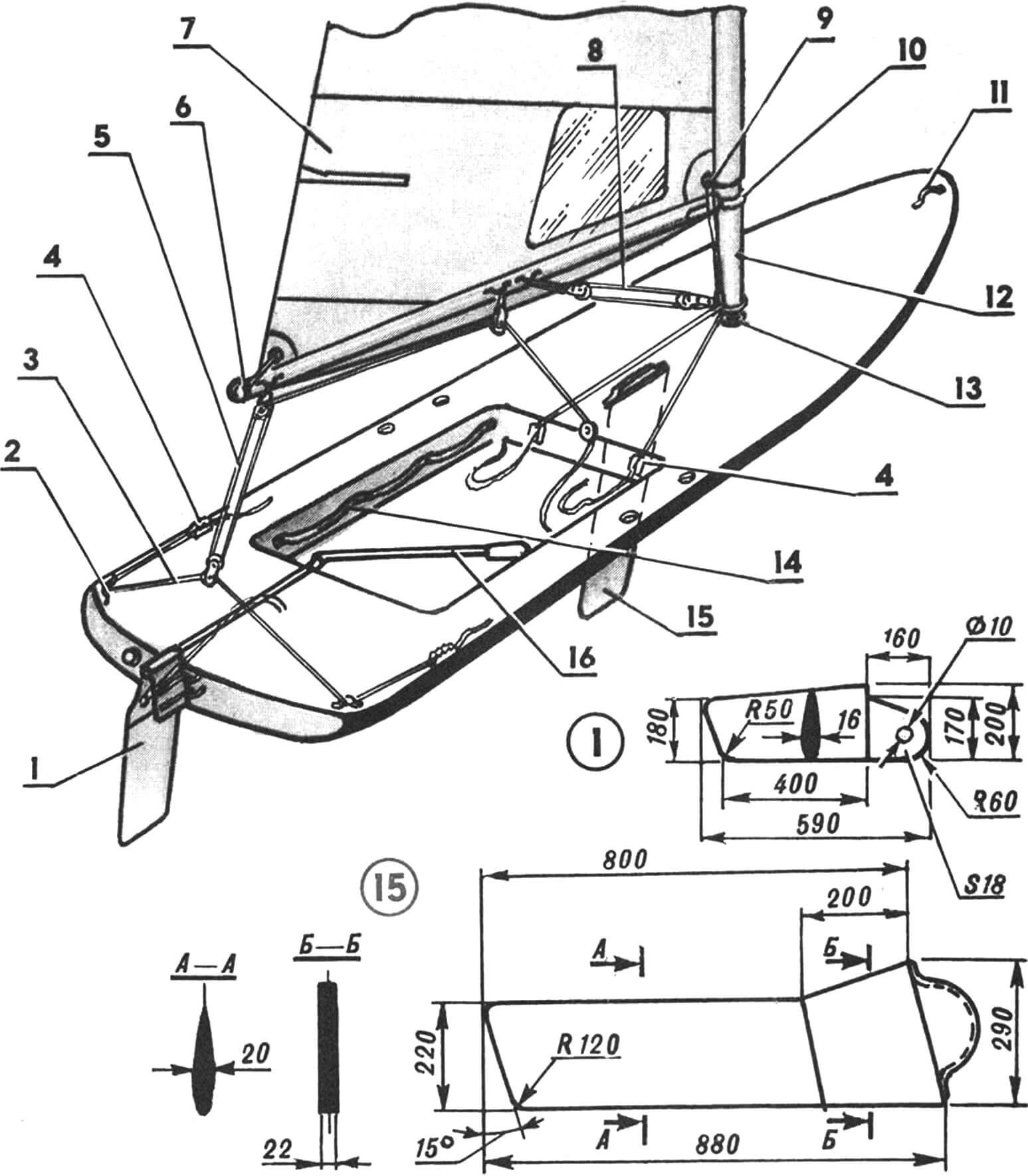

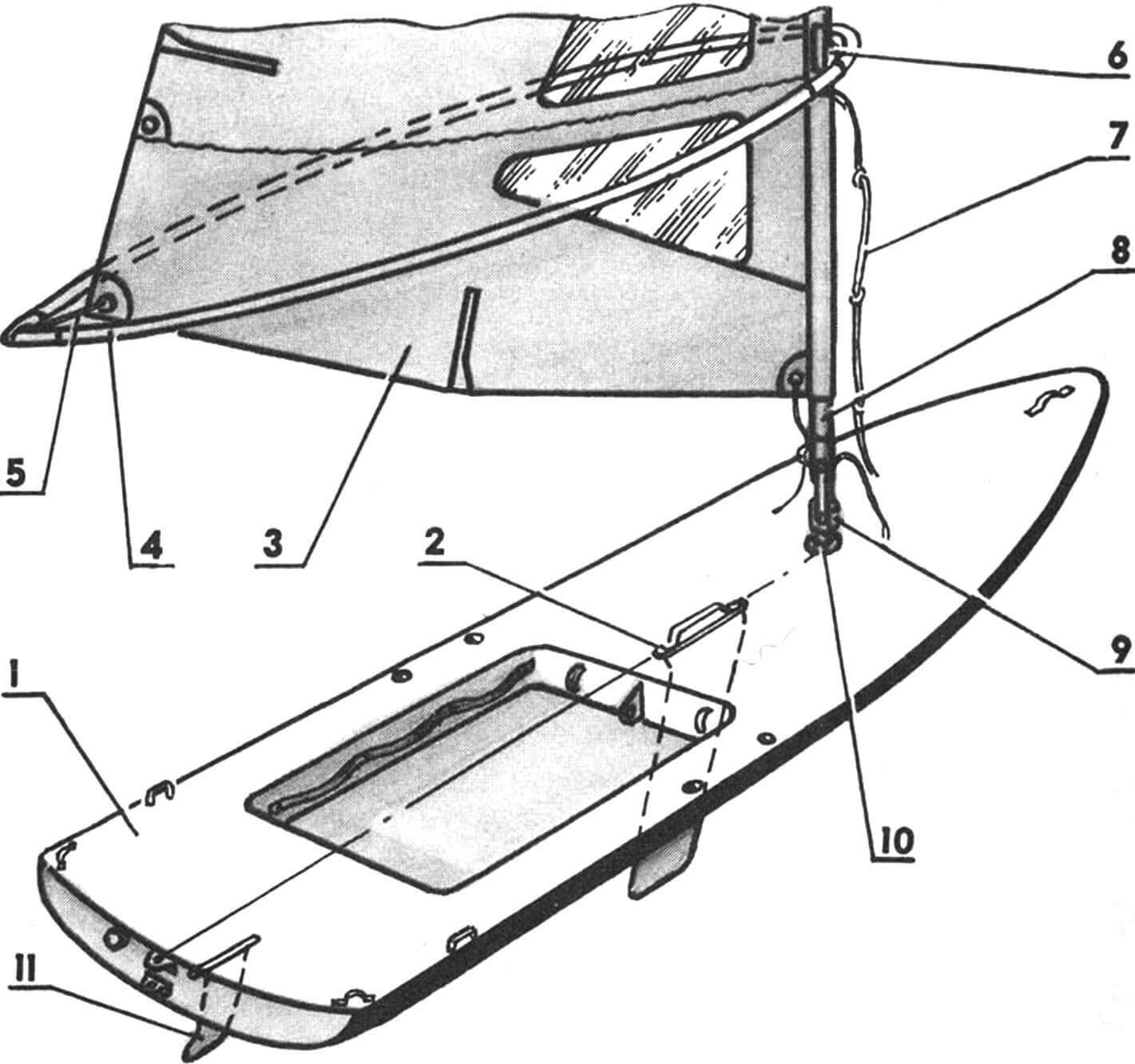

Options for assembling a universal watercraft are shown in the figure. This is a regular sailing board, a windsurfer with a reduced sail area (“storm” version), a mini-dinghy, and a rowing boat. All modifications are based on the same body.

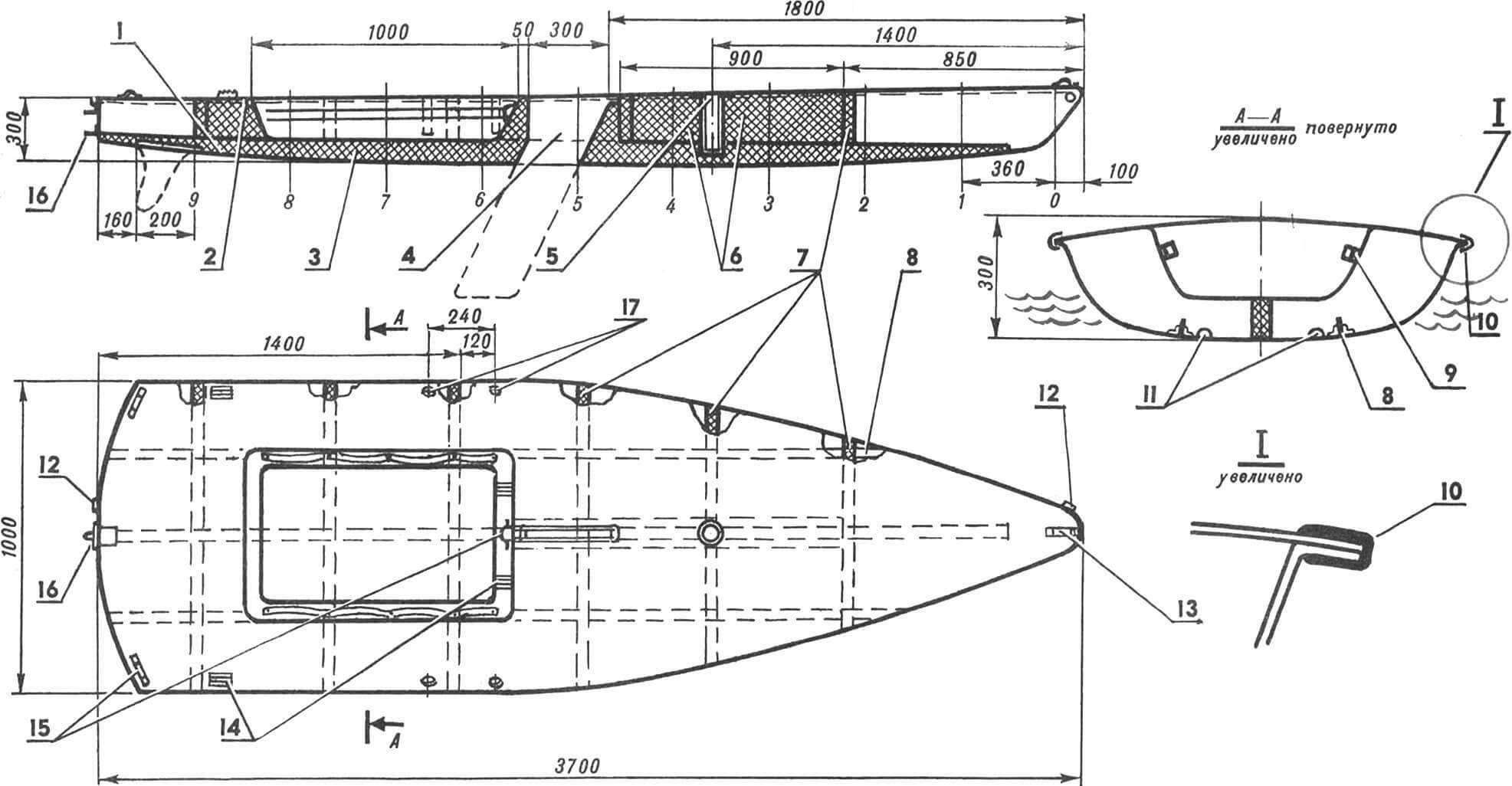

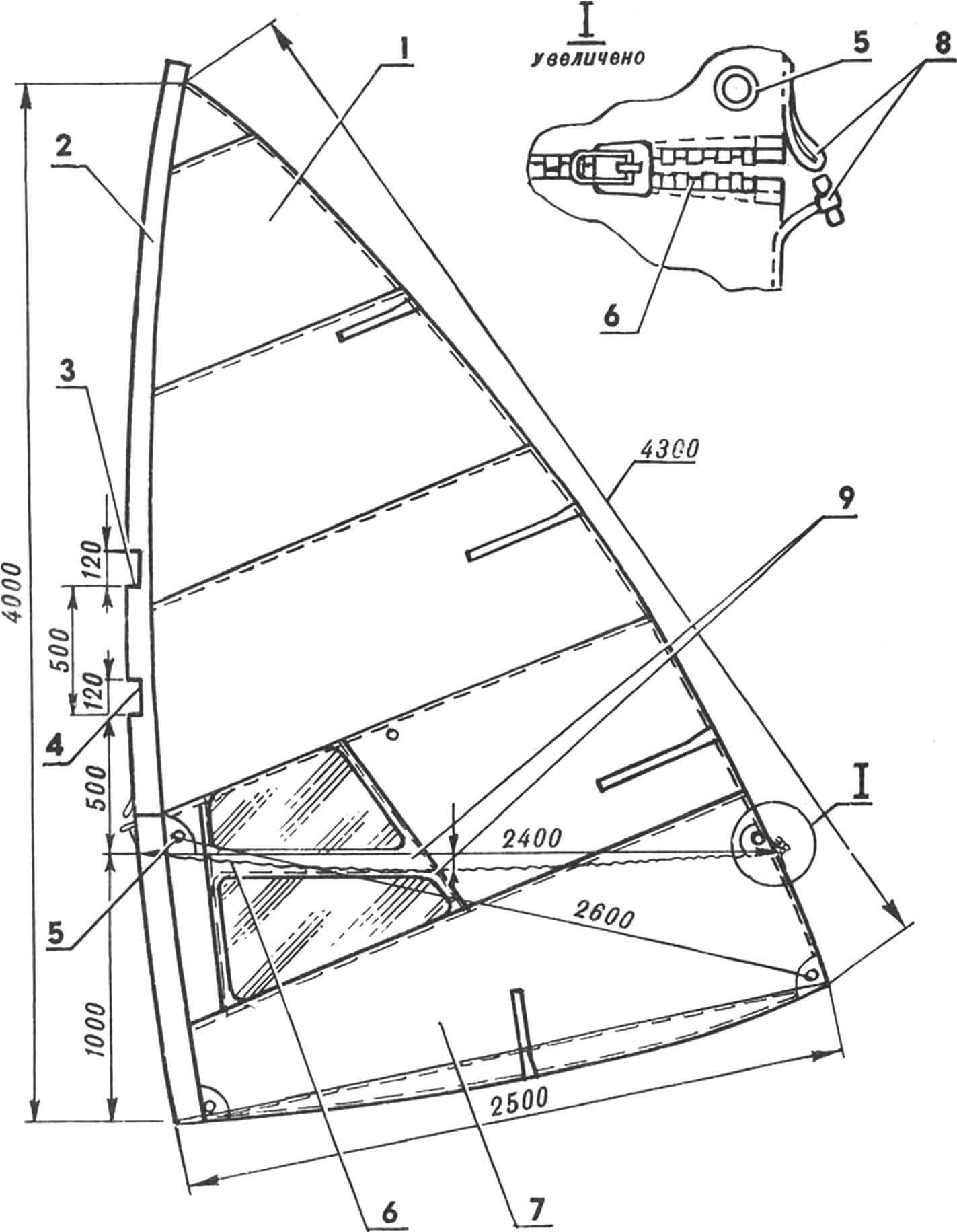

The Hummingbird hull, which is wider and has a greater load capacity compared to a conventional sailing board, has a small cockpit and is equipped with a universal step glass, suitable for installing both a windsurfer’s hinge and a removable mini-dinghy mast. The hull consists of three main parts: the bottom, deck and centerboard well; Each of them is molded in individual tooling.

A – a windsurfer with a normal sail area (6.2 m2 ), B – a mini dinghy, C – a windsurfer with a reduced sail area ( 4m2 , the dotted line shows the low position of the boom in the “children’s” version), D – a rowing boat.

For gluing the body, it is recommended to use the following materials: satin weave fiberglass (about 30 linear meters), cold-curing epoxy resin grade ED-5, ED-20 or polyester resin type PN-1, PN-3 with appropriate additives, plasticizer and hardener (about 20 kg), as well as polystyrene foam PS4, PVC or similar. The main strength and rigidity is provided by the shape of the hull, and additional strength is provided by the foam keel, frames and stringers, glued to the skin with the same binder that is used when molding the hull parts. The seam between the deck and the bottom is glued with two additional layers of fiberglass.

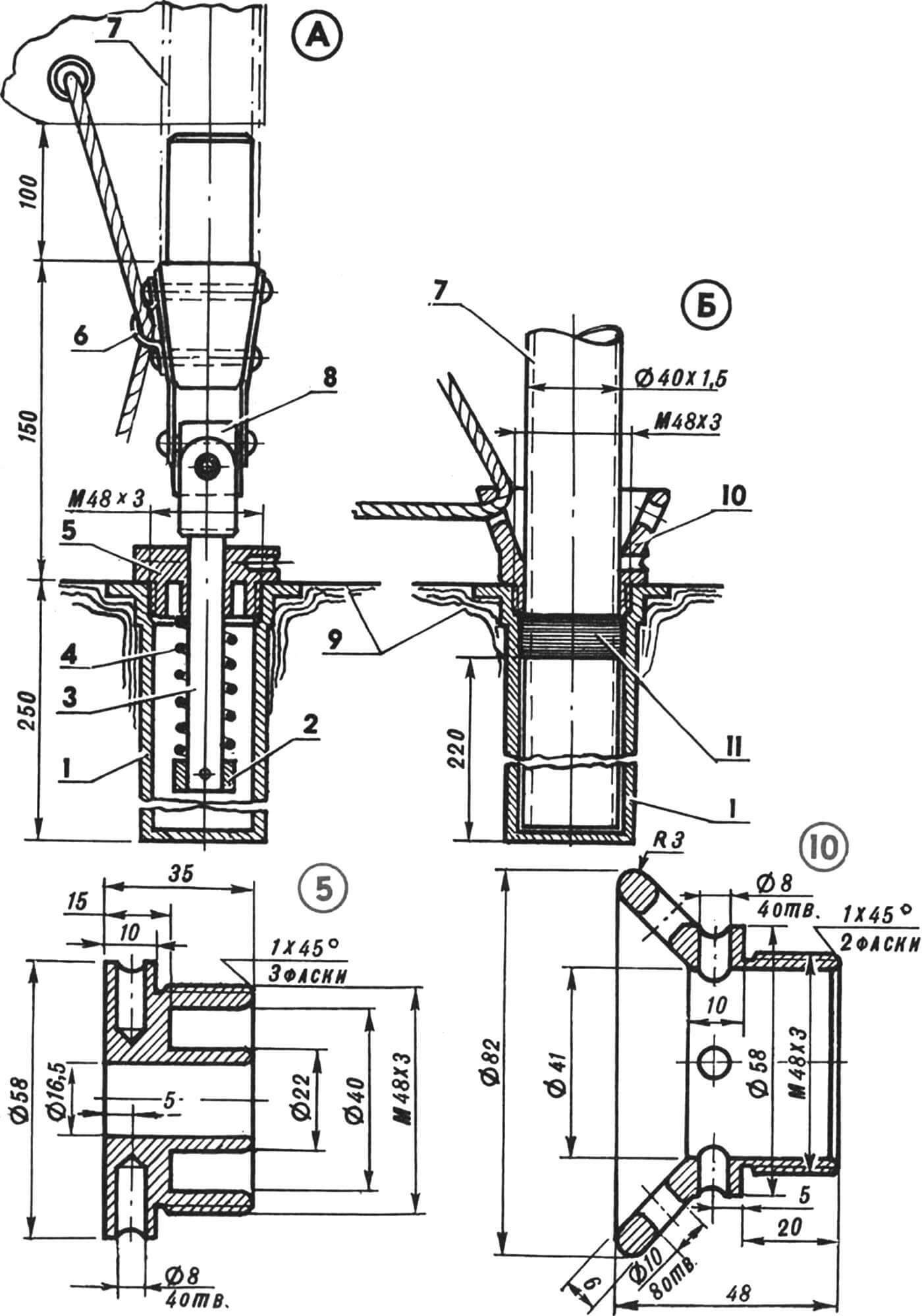

1 – bottom of the hull (fiberglass 2.5…2.8 mm thick), 2 – deck with cockpit (fiberglass 2.8…3 mm thick), 3 – keel (foam plastic 25…30 mm thick), 4 – centerboard well, 5 – steps, 6 – reinforcement blocks for steps and centerboard well (foam), 7 – frames (foam 30 mm thick), 8 – bottom stringer (foam covered with two layers of fiberglass), 9 – straps for heeling a sailboat in the mini dinghy version, 10 – fiberglass tape reinforcing the seam at the junction of the deck and the bottom, 11 – scuppers in the frames (except for frame No. 4), 12 – drain plugs, 13 – mooring bracket, 14 – cable stoppers, 15 – brackets for guiding the sheets, 16 – steering loop , 17 — sockets for removable oarlocks (duralumin tubes Ø 22X 1.5 mm).

Unsinkability is ensured by complete sealing. To increase the tightness of the fit to the shell, it is advisable to cover the frames around the perimeter with foam rubber tape and impregnate it with a binder. (This especially applies to its fourth frame, which divides the hull into two sealed compartments. All other frames have scupper holes at the bottom for draining water.) A significant volume of foam molded in the hull ensures emergency buoyancy even with completely flooded compartments.

There are drain holes in the bow and stern of the sailboard hull that are closed with screw caps. In addition to their main purpose, they also serve for ventilation of internal compartments.

It is hardly advisable to dwell on the technology of manufacturing a ship’s hull from fiberglass, since this has already been described many times in “M-K”, the magazine “Boats and Yachts” (No. 6 for 1978, No. 1 for 1980, No. 2 for 1985, No. 1 for 1987), and other publications.

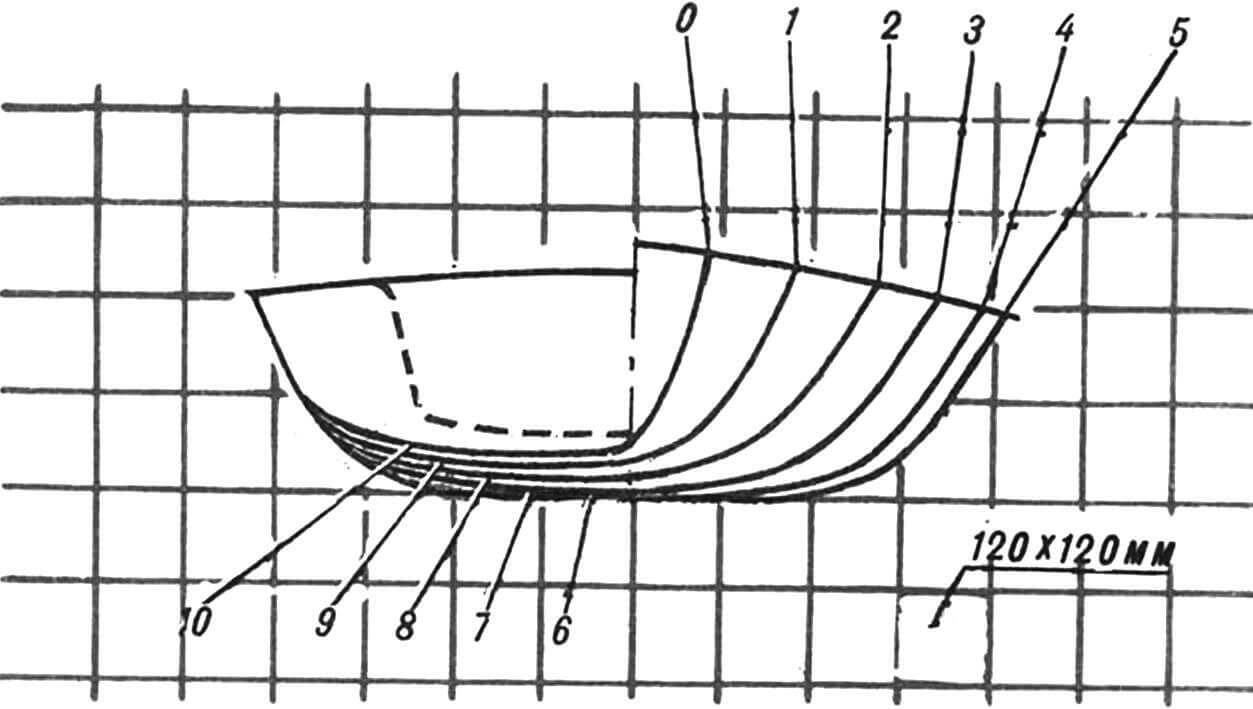

You can use a factory sail, mass-produced by the More production association. It needs to be modified, since the dinghy version, as well as for “storm” and “children’s” windsurfers, requires a sail with an area of approximately 4 m2 instead of the standard 6.2 m2 .

1 — upper part of the sail (area 4 m2 ), 2 — mast pocket, 3, 4 — windows for attaching the boom-wishbone in the “storm” and “children’s” versions of the windsurfer assembly, 5 — additional boots with eyelets, 6 — fastener “zipper”, 7 — lower part of the sail (area 2.2 m2), 8 — power fastenings of the ends of the “zipper”, 9 — fabric inserts for filing the “zipper” in the cut window of the sail.

The easiest way to alter a sail that does not have windows. It is cut into two parts along a line perpendicular to the luff, and then turning into a smooth curve with a deflection of about 150 mm. If a sail window falls on the cut line, the transparent film is reinforced by sewing additional overlays made of durable fabric. A plastic “zipper” is then sewn onto both sides of the sail, the same type used for sleeping bags. If the zipper turns out to be longer than the cut line, then its free end is tied to the luff of the sail with a cord. To prevent the connected parts of the sail from “spreading,” special fasteners are used to relieve the force loads from the ends of the “zipper.”

1 — rudder, 2 — bracket for guiding the sheet, 3 — boom-sheet shoulder strap, 4 — cable stopper, 5 — boom-sheet, 6 — boom (duralumin pipe Ø 30Х1.5 mm), 7 — sail, 8 — boom guy , 9 — Cunningham guy, 10 — attachment point for the boom to the mast, 11 — mooring bracket, 12 — mast (duralumin pipe Ø 40Х1.5 mm), 13 — mast mounting nut, 14 — foot strap, 15 — centerboard, 16 — extension tiller.

In the clew and tack corners of the upper part of the cut sail, boots with grommets are sewn, and in the luff (mast pocket) additional windows are cut that serve to attach the boom-wishbone to the mast: the top one is for the “storm” version, the bottom one is for the “children’s” version execution.

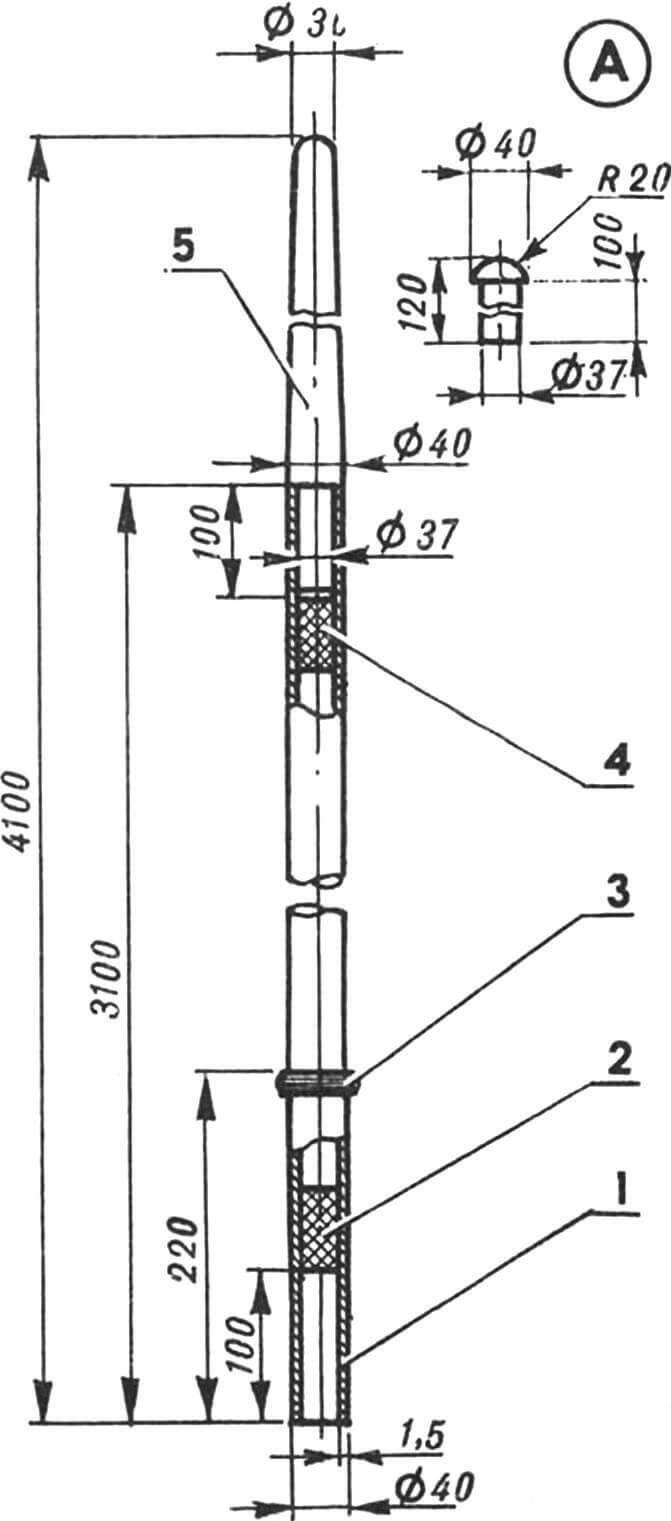

The mast is collapsible, universal, used for all modifications of the sailboat. Its main element is a duralumin pipe Ø 40X1.5 mm with foam plugs glued with epoxy resin. At the bottom of the mast, a thickening (retaining ring) is provided with a special nut for fastening it in the step glass. The easiest way to make it is by winding thick nylon threads impregnated with epoxy resin.

1 — hull deck, 2 — centerboard, 3 — sail, 4 — boom-wishbone (duralumin pipe Ø 30X1.5 mm), 5 — sail clew guy, 6 — boom-to-mast attachment point, 7 — start-sheet, 8 — mast, 9 — universal joint, 10 — hinge fastening nut, 11 — fin.

A replaceable top is inserted into the upper part of the mast – long (for a regular windsurfer) or short (for the “storm” and “children’s” versions of the sailing board and mini-dinghy).

The mast is attached to the steps embedded in the body with two nuts. The first is constantly on a hinge, the second, removable, serves to rigidly fix the mast and is put on top of the latter when converting the vessel into a mini-dinghy. On the “skirt” of the second nut there are holes for guiding the sheets – the boom guy and the Cunningham guy.

1 — mast pipe (D16AT), 2,4 — plugs (foam plastic), 3 — retaining ring (nylon thread with epoxy binder), 5 — dinghy mast top (beech); A – windsurfer’s mast top.

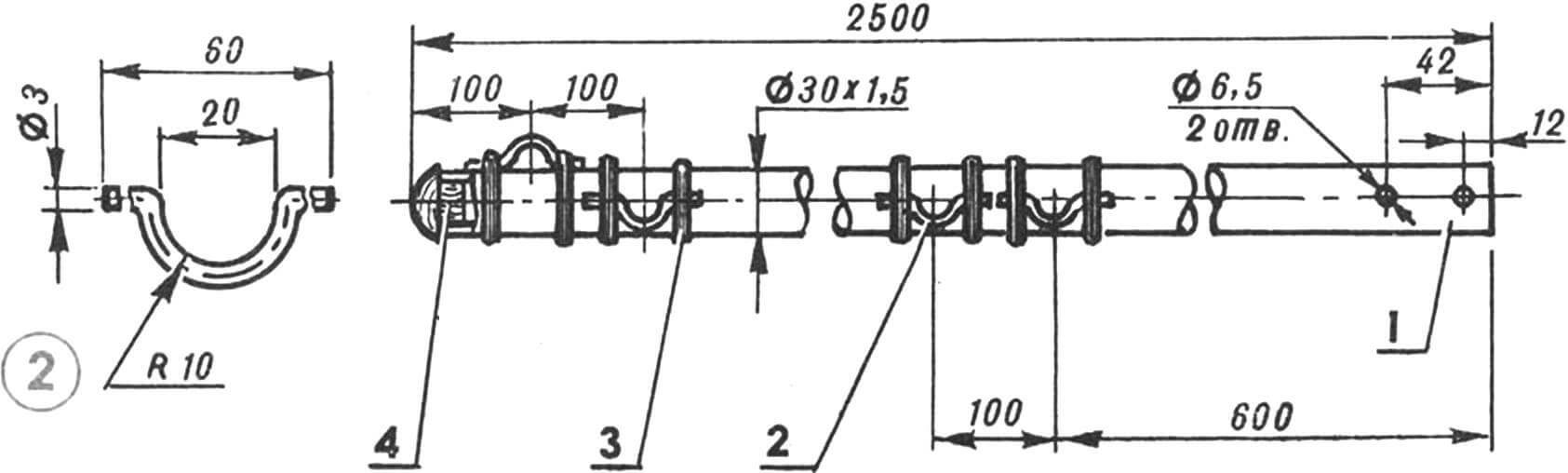

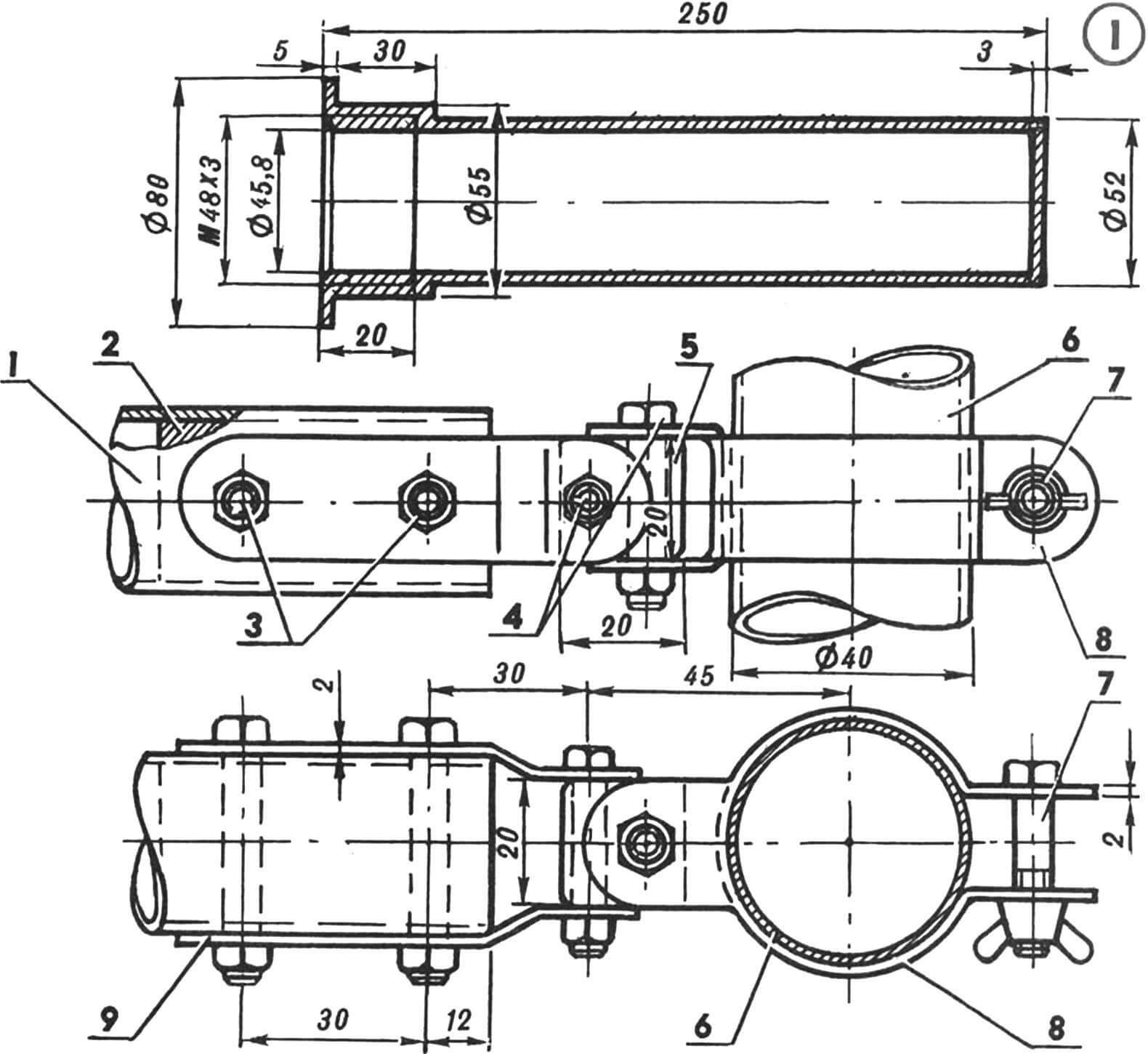

The kit of the Hummingbird sailing board includes two booms: a regular windsurfer’s boom-wishbone and a special tubular one, with an attachment point to the mast, designed for a dinghy.

The centerboard is sword-shaped, made of thick plywood, used in all operating modes of the vessel.

1 — boom pipe (D16AT), 2 — block fastening bracket, 3 — bracket fastening (nylon thread with epoxy binder), 4 — nock (beech).

The steering wheel is of a “yacht” type and is hung on the transom only when converting a surfer into a dinghy.

1 — mast steps, 2 — spring support bushing (brass, bronze), 3 — spurs, 4 — spring, 5 — universal joint nut (D16AT), 6 — bracket, 7 — mast, 8 — universal joint holder (brass) , 9 — layers of fiberglass, 10 — nut for rigid fastening of the mast, 11 — retaining ring of the mast.

A capsized sailboat can easily be placed on an even keel by one person, and due to its shallow depth, the cockpit turns out to be almost dry when straightened. To tilt the mini-dinghy, it is advisable to place leg straps on each side of the cockpit.

The last option for assembling the Hummingbird vessel is a rowing boat. Therefore, when gluing the hull, it is advisable to provide a couple of special sockets for the oarlocks.

1 – boom, 2 – insert (beech), 3 – bolts M6X 45, 4 – bolts M6X35, 5 – cracker (brass), 6 – mast, 7 – wing nut M6, 8 – clamp (steel sheet 2 mm thick) , 9 — overlay (steel sheet 2 mm thick).

In conclusion, it should be noted that readers of the magazine who are seriously interested in a universal sailboat will find it useful to familiarize themselves with the publications of “M-K” (No. 3, 6, 8, 9 and 12 for 1980, No. 7 for 1981, No. 7 for 1982 g.), as well as the following books: Katkov P. P. Technology of plastic shipbuilding and ship repair. L., “Shipbuilding”, 1968; X. du Plessis. Small-tonnage vessels made of fiberglass. L., “Shipbuilding”, 1979; Hayden G. On a board under sail. M., “FiS”, 1982; Zolotov Yu. V., Shershakov N. V. Windsurfing for everyone. M., “FiS”, 1984; Kislov A. A., Ilyin O. A. Windsurfing – the first steps. M., “FiS”, 1985.

BASIC TECHNICAL DATA OF THE “HUMMINGBRI” SAILING BOARD

Maximum length, m 3.7

Maximum width, m 1.0

Freeboard height at the bow, m 0.22

Minimum freeboard height, m 0.16

Hull draft, m 0.1

Hull draft with centerboard, m 0.68

Weight with weapons, kg:

sail 2.0

centerboard, fin, rudder blade, steering gear 2.5

boom-wishbone, dinghy boom 4.5

mast assembly 2.5

oars (set), oarlocks 3.5

body 20.0

Total: 45.0

Windage area, m 2 :

sailboard 6.2

mini dinghy, sailing board for children and beginners, “storm” version 4.0

Windage height above waterline, m:

sailboard 4.5

mini dinghy 4.0

“storm” version of the windsurfer 3.5

Centerboard area, m 2 0.13

Dinghy rudder area, m 2 0.08

N. VASILIEV