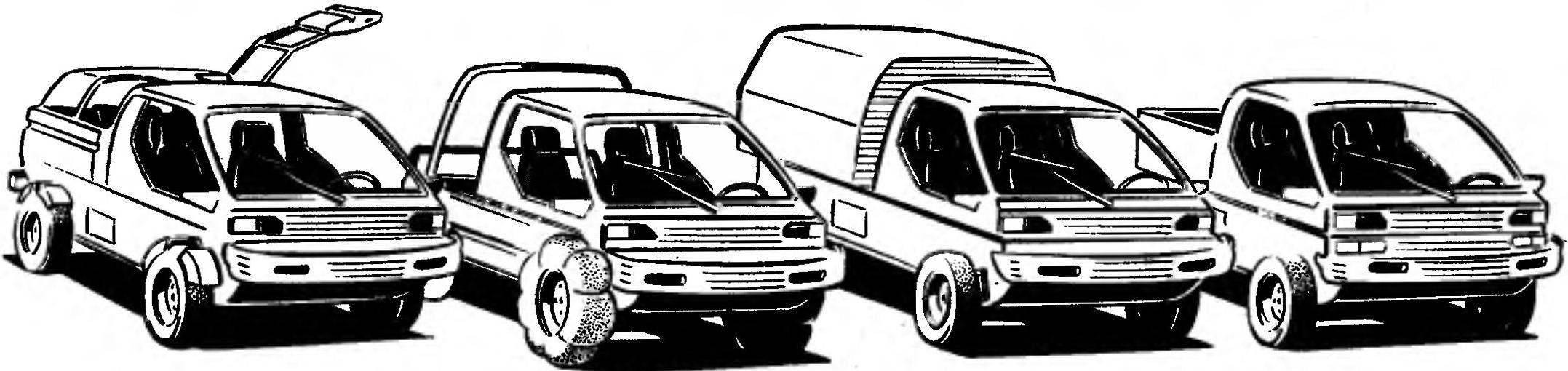

The car body is represented by three modules: carrier, front and rear.

Bearing module — base of the whole structure and by analogy with the microprocessor technology is a “motherboard” for all units. It is the power components, suspension, engine and auxiliary systems, which essentially turns it into a separate transport unit is a cargo platform.

Two other elements play a more decorative role, giving the car a form or convenience when placing the cargo.

Suspension handed out. It’s not against the rules of safety, although it imposes some specifics in operation. On the other hand, the lack of wheel arches niches allows you to “clean” the shape of the body and used tires of any diameter.

Fig. 2. The layout of electric vehicle:

1 — absorber, 2 — shield,

3 — carrying module, 4 — module power unit (MSU), 5 — a cargo module, 6. security, 7 — module, 8 — motor, 9 — wishbone front suspension.

Fig. 3. Body shell:

1 — mount the front suspension (St.Z 3.5 mm), 2 — edge (PT.S, pipe 60x30x3 mm), 3 — mount rear suspension, 4 — node sample of the cargo module, 5 — roller, 6 — protective plate, 7 — area of the reference front end module (Art.S, gon 32x32x3 mm), 8 — guides for cargo module (Art.45, 36x27x2,0 mm), 9 — load-bearing (St.S, pipe 60x30x3 mm), 10 — lateral bracing (Art.S, pipe 14×1,5 mm), 11 — rear cross beam (St.S, pipe 40x28x2 mm), 12 —frameworks for removable modules (titanium pipe 14×1,5 and 22×2,5 mm, sheet thickness 4 mm).

Fig. 4. The front suspension arms:

A — upper arm (Art.Z, 50x25x3 mm) — lower arm (PT.Z, 50x25x3 mm).

Fig. 5. Arm rear suspension.

Fig. 6. Diagram of a modular power plant:

1 — starter generator STG-21,2 — electromagnetic coupler, 3 — DVS (488 CC) “Whirlwind-30”, 4 — pump, 5 — fuel tank, 6 — filter, 7 — control unit 8 — batteries (two 100 Ah), 9 — thyristor control unit, 10 — power STG-3.

Fig. 7. Fiber optic system:

1 — reflector lamp 2 — halogen lamp 3 — lamp, 4 — hub, 5 — diaphragm, 6 — fiber harness, 7 — reflector headlights, 8 — auxiliary reflector.

Fig. 8. Dashboard:

1 — headlamp switch 2 — turn signal switch, 3 — liquid crystal display (120×64 mm), 4 — switch window washer solvent, 5 — buttons auxiliary lights, heater glass & alarm, 6 — arm control heating-ventilation 7 — radiotek, 8 — electronic clock, 9 — glovebox, 10 — louver ventilation system, 11 — Board fiber-optic system.

The front of the car reminds the panel of the trunk “eight”. Here are the front Windows from the same model, which according to the requirements we have moved (although only 18 cm, but this is enough for ventilation or exchange of views with the inspector; however, for fans of “podlokanj” drive the glass can be moved at all). The whole structure weighing in at 48 kg is attached to a quick-release lock and can be removed by one person for 5-6 seconds. From equipment modupe are the control sensors, main lighting system, electric and gas springs. Access to the interior of the car by the lifting or shifting of the module relative to the supporting frame.

Cargo module — quick-decorative design weighing only 38 kg. it is Located on the N-shaped guides of the bearing module. Made of composite materials. Glass of organics. Of equipment is equipped with only the auxiliary svetonakopitelnye. Access to the interior is the shift module backward relative to the front.

Front and cargo modules are a frame made of titanium tubes with a diameter of 14-22 mm (which can be replaced by steel) covered with aluminum (1.5 mm) sheet. Irregularities and voids filled with foam. The outer and inner surfaces are covered with 5 layers Stekloplastik.

The bearing module is a spatial structure consisting of steel pipes of rectangular section (40x29x2,5 mm). Joints of the elements of the frame reinforced steel gussets from a sheet thickness of 2.5 mm. At the front of the frame welded plugs under the front suspension. Bottom design protects 1.5 mm piste stainless steel. Top power design limits removable security arc, and from the sides of H — shaped rails, which are attached to the decorative body modules. The spatial gaps are filled with foam, and the exterior floor covered with 2 mm plastic.

Front and rear suspension are nothing out of this. They are classic, pendulum-type, trailing arms (a detailed description can be found in issues of the journal for the 1982-1985).

Steering — automotive type.

Depending on the road conditions, the machine is equipped with wheels of different diameter (you can even put the tires of large diameter when using the car in the snow), but usually applied enhanced in the rim of the tire of the sidecar FDD.

The power plant, like any other electric car, consists of two main parts — the drive and energy source.

The production of progressive-drive — motor — wheel — is problematic in a controlled environment. Was easier to choose appropriate drive from decommissioned equipment at the nearest airport. Used primarily starter generator STG-3 or similar; they need 4 or, at least, 2 (for zadneprov-tion option). The transfer of torque from the engine to the wheel through the gimbal, but you can chain by analogy with the actuator used in motorcycles.

Now the most important point — the power supply. There are several solutions to this problem:

a) to buy more sets of batteries and is guaranteed to drive 60 miles a day,

b) to wait until better times, when there will be the promised superaccumulation,

C) to produce fairly complex “engine-generator”.

We chose the third option and not a mistake.

Part of a modular propulsion system we have included: ice (488 CC) “Whirlwind-30” with electronic control mode of operation, the generator (modified STG-21), battery pack (2 batteries 100 A/h) multi-thyristor control unit (MT-200) and other auxiliary systems.

Experience showed that instead of the voracious engine “Whirlwind” is better to use a small diesel, but the generator needs to purchase only aircraft, such as CPT-21, CPT-18 or similar : they are equipped with a freewheel, and you won’t have many problems at startup. The weight of such a complex can reach 100 kg (us — 92 kg) output power 10-20 kW, which is sufficient for this class of car.

The kit of electronic equipment includes a fiber optic system, elements of which can be made independently. It refers to a system of passive control of lighting devices — turn signals, headlights and high beam, brake and other systems. This system operates very simple — you only need one end of the fiber to expose to the lamp (e.g., turn-nick) and the other display on the instrument panel. As optical fibers are fine threads of fiber from the popular lamp. The necessary length is achieved by successive gluing epoxy compound end of the ends of the optical fibers. To improve the perception of the panel can be set tapers (expander light beam) or to use small lenses.

A similar system covers the entire design of the car F2 “Ulan”. More interesting but also more complicated and presents an active fiber optic system. The principle of it is quite simple and lies in the interruption of the light flux from the source to the receiver. From the difference between the reference value and the actual determination of the required parameters (e.g., fuel level or speed of rotation of the wheel). As the control is used Microsystem based on КМ18ЮВМ88 processor (the analog of the 8088), which sequentially polls each device by a single sotocinal, bringing needed information on a liquid crystal matrix panel.

According to requirements it is forbidden to change settings of the lighting devices. On the other hand, in relation to auxiliary photoelectric — there are no restrictions. Therefore, it is possible to make upgrades additional lights for brake, turn signals. To obtain the necessary light output, you will need to connect in parallel multiple optical fibers (10 — 20). As a light source you must use the powerful halogen bulbs (нас30У400 W). By overlapping the luminous flux of the electronic shutters is achieved by the operation of required svetosistem.

To obtain a clean and durable coating when working with ugleplastika we applied an ultrasonic mixer. In addition, for better impregnation of the layer Steklov-letcani have used rollers for squeezing the linen from the washing machine. Finally, useful household ultraviolet spotlight: followed it at a distance of 1…1.5 meters from the object and left it powered on all the time cure the resin.

The foam you can use any brand, but it is better to buy DoCoMo-nently solution, which is used in the manufacture of refrigerators.

The Assembly frame or frame should be performed on the stocks (the blue table), at least on the floor. All welding — gas shielded (carbon dioxide, argon). The whole place needs to be clean and varnish or protective paint.

The car is very nice, quite light (curb weight — 550 kg) and speeds up to 90 km/h.

R. SINGATULIN, Saratov

Recommend to read KMD IN “EARTH” VARIANT There is an expression: "the Best is the enemy of good." It remains true, however not always. Any Modeler familiar with one of the standard domestic compression motors — KMD-2,5.... DINING FOLDING In a small room dining table standard sizes — already a hindrance. Much easier if in the off position, its surface could reduce to, say, fold to the size of the narrow tables occupying...