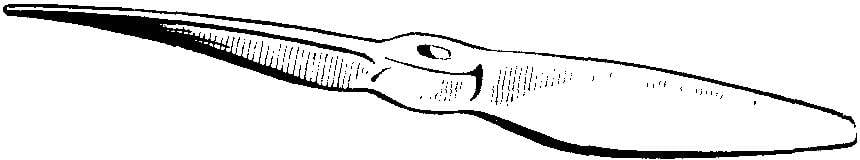

Model propellers for internal combustion engines are usually made from solid wood: beech, ash, birch, hornbeam. However, work on the air screws is very labor intensive and requires a certain skill. Two identical screw is almost impossible to do, which is why there is instability of the flight.

Recently, the propellers are made of composite materials by stamping. As used composites glass and carbon fiber combined with epoxy resin. The advantage of these screws is obvious. Fiberglass has a higher strength and flexibility than timber. This gives you the opportunity to make the blade thinner, which improves the aerodynamic efficiency of the propeller. In addition, the stamping method gives consistent results when replicating the screws.

To make a mold, you first need to decide which screw is required for your model. For example, Tierney engine KMD will fit the propeller 200 x 100 (symbol for diameter and pitch of the screw) to Cordoba flight with the same engine 220х100, and for “bouzouki” — 180—190х100. Not to make several molds, it is better to lay a universal propeller 220х100 to then necessary only to cut cast screws diameter. Reference screw used in forming the matrix, cut from fiberglass with a thickness of 10 mm.

Half of the hull mold (depth of samples – 11 mm; hole Ø 8 mm drilling together in the collection).

Half of the hull mold vyfrezerovkami of steel, cast iron or aluminum. In any case, these parts must be very rigid, as in the process of forming them tightening the screws with considerable force. Half carefully adjust to each other that between them there is no gap. At the ends of the workpieces drilled the holes for the M8 bolts. Pulling parts of the case, drill the holes for the dummy axis of the screw, and then the channels for die casting. Cavity is performed by milling.

The mold Assembly.

The sequence of operations for filling the mold.

Reference air screw back pressed against the sheet of Plexiglas with a thickness of 4-5 mm by using a dummy axis. The free space between the blades and the glass is filled with clay. So it turns out the punch front of the propeller. The finished part shape on the working surface is covered with a separating layer of mastic or a soap emulsion. Superimposed on top half of the hull mold, and through holes filled with the “mixture” composed of epoxy resin with filler (aluminum powder).

After curing of the resin glass is removed, the propeller is removed, at the same time carefully clean off all the clay. Then, lubricated with a separating layer and screw, and a ready part of the matrix, the bolts pull the two halves. Free volumes poured a new portion of the “mixture”. Waiting for the resin curing, the parts dismantled and control the quality of the shaping surfaces. The mold is ready.

For forming the air propeller cut glass yarns required length (1.5 screw diameter), anneal them in the oven or on the tile or washed in gasoline and acetone to remove the wax. Strands gather in the “flagella” and impregnate them with epoxy. Place these “blanks” in the matrix, tightening its bolts. The excess resin needs to be extruded in the grooves. The number of glass yarns and resin is determined by practices. If fiber is small, the screw will be too brittle and might break when running or in flight. Extracted the handle screws on edges and balance. We must not forget that during all work with resins, you must protect your hands with rubber gloves or special trains, closing the pores on the skin. Preferably the use of a fume hood.

CHARLES S., group leader, Alma-ATA region syut

Recommend to read WHEEL PLUS SAIL Many can make a shift to summer camp? Because it ends so quickly! And no matter how much enthusiasm in the students-smart, funny, summer time beckons them to postpone for a time the... THE EJECTOR ON A COPY Using copy booster of the spaceship "Soyuz" in the class of models K-2 has, along with the advantages and disadvantages. In the manufacture of models, it is difficult to meet the launch...