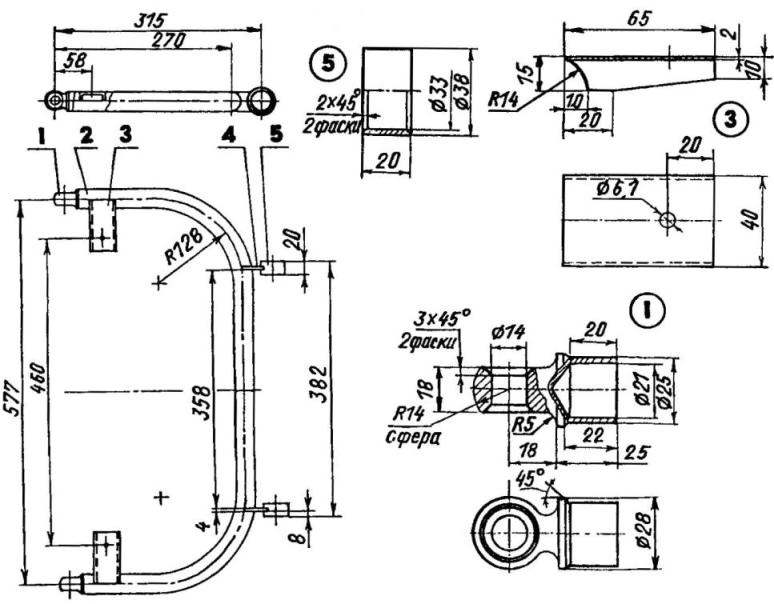

Plugs embossed two nylon bushings. From the pipe, in which there were these bushes, a sawed-off length of 100 mm (for the body of the damper) and it welded two steel washers with a diameter of 46 mm (rests for the springs and bump of microporous rubber) and pipe carrier.

From napadovska stock piece cut a length of 225 mm. on one side it is welded to the carabiner hitch and the emphasis of the bump, and the other side is threaded M22x1, so you can adjust the spring stiffness of the damper. (The spring is selected from the kit for engine valves “Lada”.)

The whole adjustment of the damper have been reduced to achieve the free movement of the rod in nylon bushings. This had to make it scan at 22 mm and remove burrs.

Blank carabiner clip cut from sheet steel and the tip of its hook is bent down (this is clearly seen in the picture of the assembled rifle) just enough to pressed up latch freely passed into the hook back and loop the tow fit of the recumbent.

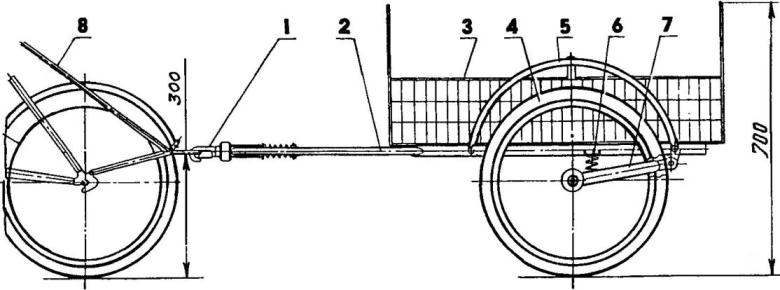

Macnc suspension:

1 — tip (steel 45, 2); 2 — beam of the pendulum (tube 28х 1,5); 3 — supporting base (steel, sheet B2, 2); 4 — console (steel, sheet s4. 2); 5 — holder rubber (tube 38×3, 2 PCs.)

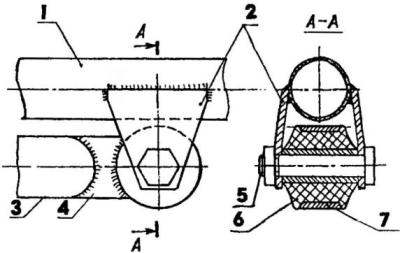

The left attachment point of the pendulum pendants:

1 — the frame of the trailer; 2 — ears of suspension of the pendulum; 3 — beam pendulum; 4 — console; 5 — M10 bolt; 6 — the rubber (VAZ-2108); 7 — yoke rubber

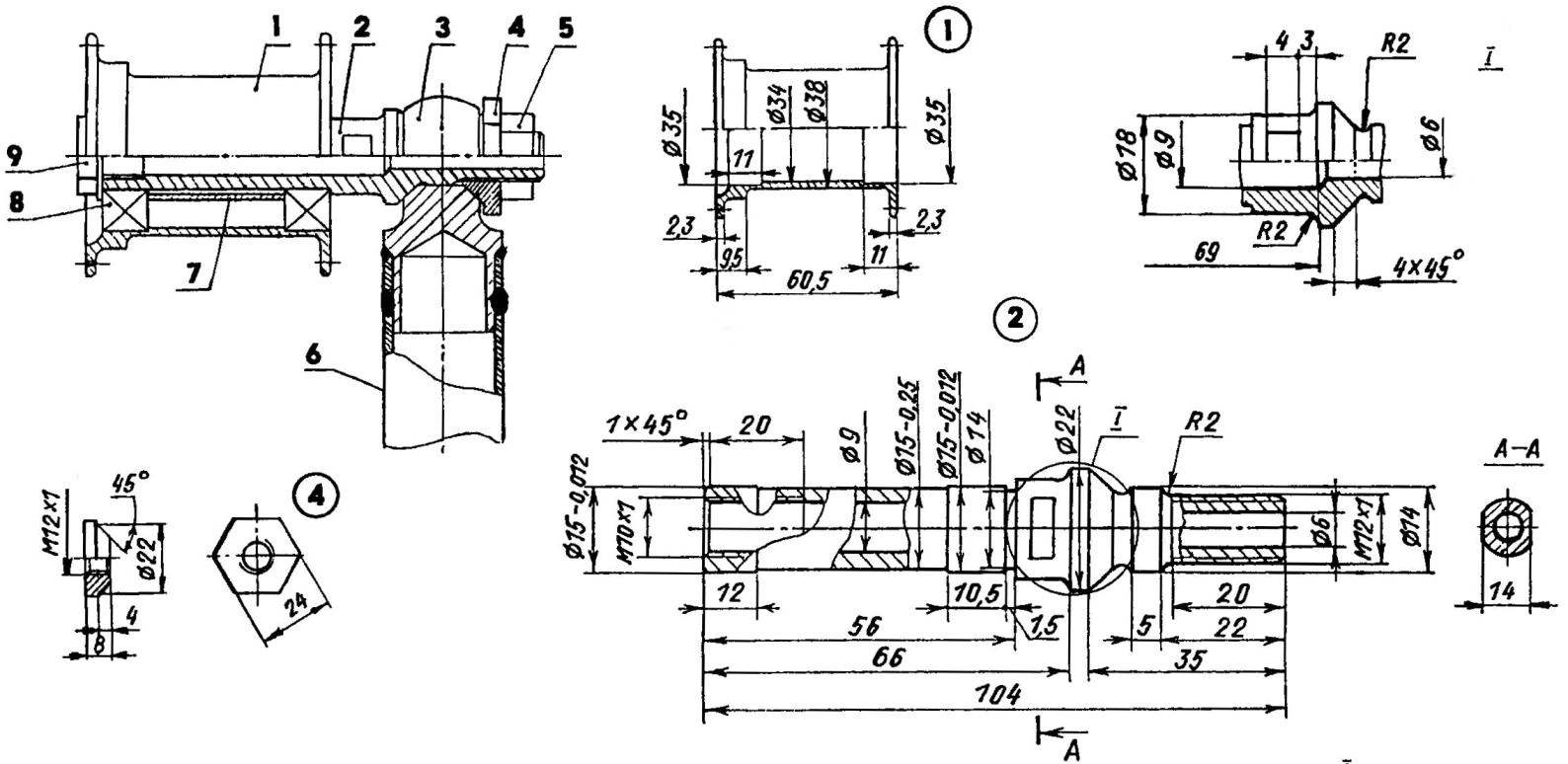

Easy-site wheel:

1—bushing; 2—shaft (or 45 steel 40X, HRC 35…40); 3—tip of the pendulum suspension; 4 — cone nut; 5 — a lock nut M12x1; 6— pendulum suspension; 7 — spacer sleeve; 8 — bearing 60202 (2); 9 — screw M10x1

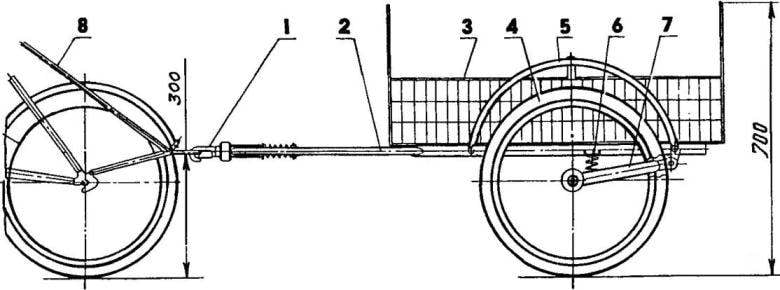

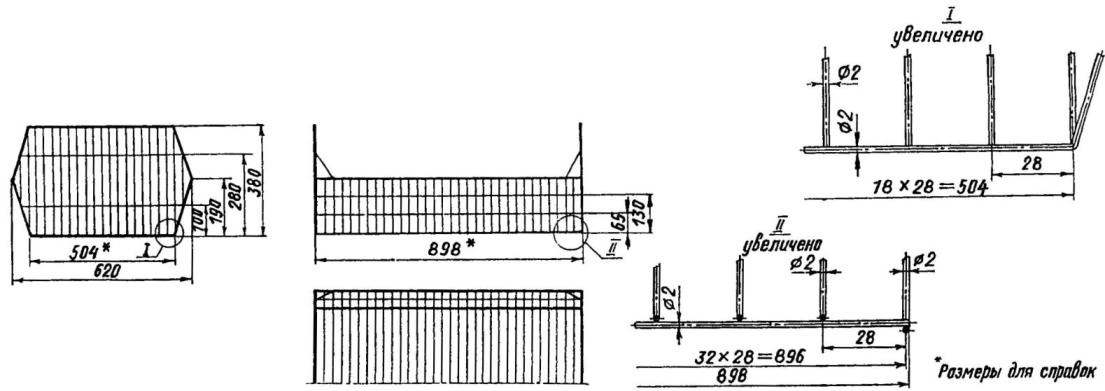

Truck body trailer

I must say that in the movement of loaded trailer (we have he often had to carry at one time more than 100 kg) creates a fair extra load on the frame of the towing (and it was and pedal cars, and bicycles, and mopeds). Therefore, we use the same towing device. It is welded from pipes with a diameter of 12 mm from the frame of an old Bicycle attached to the velomobile at the top of the suit its frame, to clamp the seat tube and the feathers of the frame at the rear wheel.

This joint just in design and works flawlessly. And that movement was not accompanied by a knock at the carbine, he before the trip wrapped with a rubber band width of about 10 mm, which chooses the gaps, but leaves freedom, so to speak, to maneuver. One end of it is fixed on the towing fixture and the other after the taping is fixed on the coupling device. Three or four turns of the tape eight is enough. And after a bit of exercise to connect the trailer to the velomobile thus manage over 30-40 seconds.

The finished frame along with a damper was painted composition that dries at room temperature, so the nylon bushing installed to their workplace immediately. If the paint will dry in a furnace, then installing the sleeves should wait — kapron afraid of high temperature. We have had so. that cooled after stoving sleeve simply spilling out.

Easily removable wheel assemblies with the cantilevered mount is actually designed us for velomobiles, but they fit perfectly to the trailer. As blanks for the hubs of the wheels were the bushing type, “torpedo” from a road bike. Before processing each billet was annealed by heating in a furnace to a cherry color (you can also hold it for one hour in the flame of a gas burner). Turning minimal and boiled down to the groove at the ends of the workpiece landing slots for bearing 60202. The mass of the part is significantly reduced by turning it to those dimensions that are marked on the figure.

The configuration of the axes for this sleeve is simple and the manufacture is not difficult; Turner average skill.

The mounting of the removable node is. First, the bearing with plenty of grease mark “joint”, is pressed into the housing until it stops, where it is fixed by the punching of the edges of the mounts in three places. Insert spacer and press second bearing. The length of the spacer is selected such that the outer ring of the second bearing is rested on the bottom of its landing nest, that is to fit the bearing was like floating. This gives the trailer a very easy move.

After proper Assembly so the bushing does not require any additional adjustment or maintenance during operation. A sign of a well adjusted wheel next: after a gentle push it should make about 120-140 revolutions and then stop.

Conical mount axis removable node in the tips of the pendulum is very reliable. Even screwed in by hand the flare nut choose all the gaps in the connection and is not unscrewed to any, even the most bumpy road. And to remove wheel for repairs or home storage requires the minimum of effort and time.

The design of the trailer it is possible to use 16-inch wheels, folding bikes. However, we are the rim, spokes and tires of the Bicycle “the Schoolboy” — them trailer rolls much easier, and the strength provided. However, to insert the spokes in the hub, where they have 36 holes and in the rim in which the holes 28 had “sweat”. But with the spokes from the front wheel “the Student”, using cover them in two crosses and conceding four holes symmetrically on each side of the bushing, the problem has been successfully addressed.

And finally, the truck body. It is made by a method of spot welding a set of items from stainless steel wire with a diameter of 2 mm. To the frame of the trailer body is secured by four clamps on the bolts.

Since the recumbent and the trailer is small in size and delicate, recumbent raised a red flag on a wire mast for greater visibility on the road. Serve the same purpose and reflective reflectors that are screwed to the rear of the trailer.

Technical data of the trailer

Length, mm 1470

Width, mm 750

Height, mm 700

Track mm 680

The course CenterStage

the device, mm 40

Suspension travel, mm 30

Weight, kg 11

Load capacity kg 70

Body volume, m3 0,19

A. KARPUK, G. T a m b o V

Recommend to read

TRAILER “COMPROMISE”

TRAILER “COMPROMISE”

As the vacation period approaches, many auto tourists (especially families) begin to think about where and how they will rest on the road: living in a campground or on wheels, equipping... CAP VS SAWDUST

CAP VS SAWDUST

When drilling holes in the ceiling sawdust get in your eyes, that interfere. To avoid this, put the drill bit on the cap of the cream or shampoo.

The trailer is made in the club “Tourism, and pedal cars”, which I ran for several years. Used in construction sites and technical solutions repeatedly tried and tested in our velomobiles. So the trailer turned out immediately — didn’t even have it, as they say, to bring — and completely met our expectations. To date built five of these trailers, and they all showed a high operational reliability.

The trailer is made in the club “Tourism, and pedal cars”, which I ran for several years. Used in construction sites and technical solutions repeatedly tried and tested in our velomobiles. So the trailer turned out immediately — didn’t even have it, as they say, to bring — and completely met our expectations. To date built five of these trailers, and they all showed a high operational reliability.