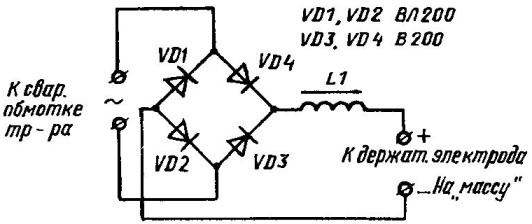

Of course, it is useful to equip the ENA and sufficiently powerful straightener that will enable you to perform high-quality welding on direct current. As practice shows, are the most acceptable technical solution, based on the so-called the bridge rectifier diodes are capable of giving to the load a direct current of not less than 100 A. for the purpose of cooling each of semiconductor valves it is desirable to provide a radiator having a heat transfer area of about 200 cm2.

Pretty good performance, for example, the rectifier bridge, composed of two groups of powerful bipolar diodes B200 and ВЛ200, the design of which (with the “anodic” or, conversely, the “cathode” heat removal and having a distinctive corps, respectively, green or crimson) makes it easy to combine them in a super compact unit with “plus-minus” and “minus-plus” contact-radiator groups, between which is installed a rubber gasket (see “modelist-Konstruktor” No. 5’97 and No. 9’02).

For reliable ignition of the arc is usually used a capacitor or inductor. However, the latter is preferable because its inherent high energiekosten and performance. The construction depends on the magnetic circuit. The most affordable for many is the “iron” of the burnt transformers. More precisely, packets of typical configurations from electrical steel.

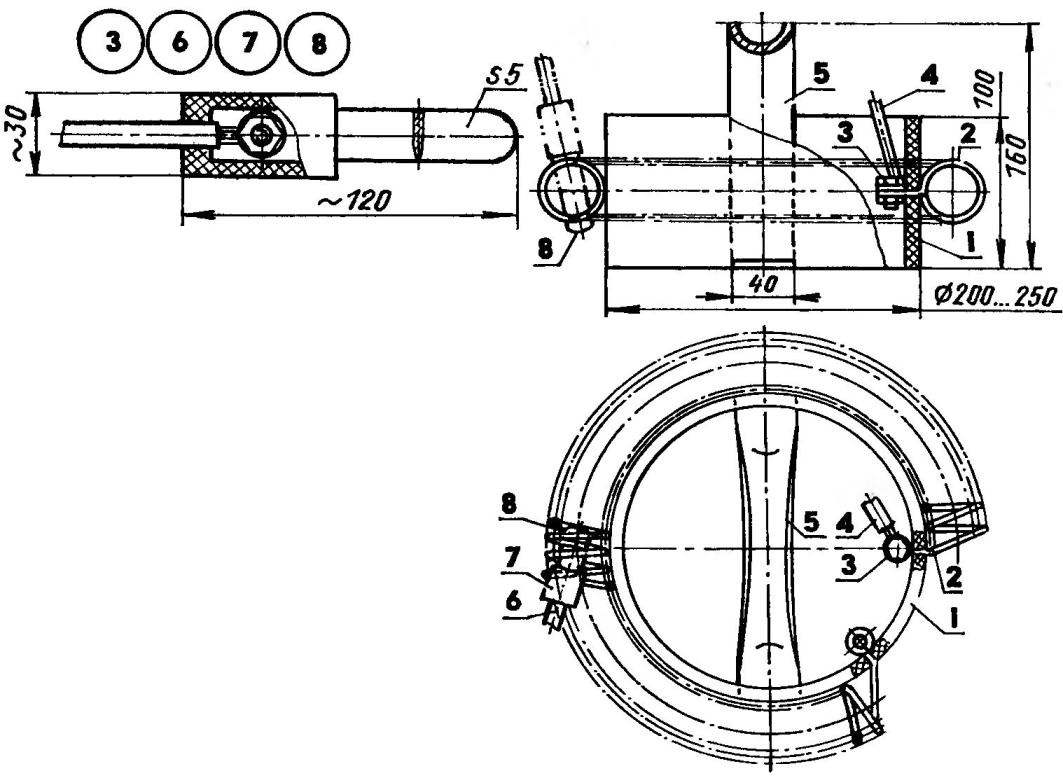

Ring rheostat:

1 — base-insulator (asbestos cement pipe); 2 — resistant coil (cylindrical coil spring from drills, chrome vanadium steel wire d3 — 4 wrapped d40, the ends are annealed and after installation at site bent bolt M8); 3 — terminal (M8 bolt with nut and two washers, 2 sets.); 4 — welding cable “limit switch”; 5 — carrying handle (steel strip 40×2); 6 — welding cable with two “limit switches”; 7 — swage-insulator (rubber hose 20×3, L50); 8 — blade contact (copper strip 25×5, L110)

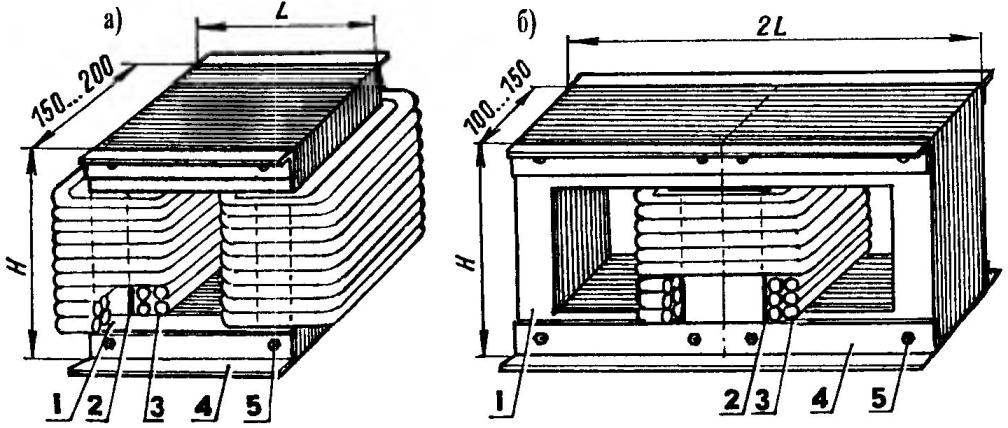

Scheme rectifier-grossartige unit, as well as options of the welding choke in the core magnetodiode (a) and on armor (b), sostavleniia of the two model cores core:

1 — magnetic (package, typed in the NC the most affordable plates of transformer steel); 2 — insulating gasket (2-3 layers salonsalon tape); 3 — winding (35 to 40 turns of cable with a total secheniem 25 mm2 copper wires or aluminum 35-40 mm2); 4 — clamping bracket (metal area of 15×15 or 25×25,4 pieces); 5 — coupling (stud with two nuts and washers, 4 or 8 set).

Good chokes work, in particular, when the magnetic core to them — rod core with a width of 30 mm and a thickness of 150-250 mm package (from the old power supply) or two coupled, adapted as a kind of armor with a package thickness of 100-150 mm. Winding contains from 35 to 40 turns of well insulated wire (conductive bus, cable) section 35-40 (aluminum) or 25 (copper) mm2. Advantage: you can use any electrode.

These chokes easily incorporated into the rectifier, or arranged in separate blocks. If you have to deal with welding many besides use the 4-mm electrodes, we can not do without forced air cooling. In this case, the fan is preferably set directly on the rectifier ESA.

In the last author’s version had to go to the installation of more powerful radiators from 500-amp diodes. The result is a homemade ESA, which according to its technical and operational parameters capable of being, that is, on equal footing with welding machines of industrial manufacture.

A. PEVNEV, Dimitrovgrad, Ulyanovsk region.

Recommend to read

THE USB CONNECTOR IN THE CAR

THE USB CONNECTOR IN THE CAR

It never hurts to have your own car, in addition to the cigarette lighter socket, and even first connector, adapted to USB or even mini USB. Such adapters are useful in many cases, for... SPINNING, SPINNING

SPINNING, SPINNING

Windmills vs birds and moles. We have cottages, and in villages was a big crop of cherries. But flocks of starlings raiding is not yet ripe fruit. People saved them as best they could:...

Almost a quarter of a century are a subscriber of the journal “modelist-Konstruktor”. About the same age are engaged in electric welding apparatus (ESA). Convinced that the most appropriate mass and power “svarochnik” – with a toroidal magnetic core (for example, from a burnt-out electric motor power 3-5 kW). Manufacturing technology of such devices has been maintained in the pages of “Modeller-designer” (see, in particular, publication in № 8’92, 11’92, 3’94, 9’94, 1 ’96, 3’96, 8’97, 11’99). From my own experience and practice of other handmade designers, I also believe it is appropriate to emphasize that the idle current from sturdy welding transformer designed for connection to a household 220-volt network should be of the order of 0.5-1 A. If a smaller value of this parameter decreases the power at most – heated magnetic core, and with it the whole of ESA.

Almost a quarter of a century are a subscriber of the journal “modelist-Konstruktor”. About the same age are engaged in electric welding apparatus (ESA). Convinced that the most appropriate mass and power “svarochnik” – with a toroidal magnetic core (for example, from a burnt-out electric motor power 3-5 kW). Manufacturing technology of such devices has been maintained in the pages of “Modeller-designer” (see, in particular, publication in № 8’92, 11’92, 3’94, 9’94, 1 ’96, 3’96, 8’97, 11’99). From my own experience and practice of other handmade designers, I also believe it is appropriate to emphasize that the idle current from sturdy welding transformer designed for connection to a household 220-volt network should be of the order of 0.5-1 A. If a smaller value of this parameter decreases the power at most – heated magnetic core, and with it the whole of ESA.