Reference ski is made in a similar way. In comparison with the great snowmobile “Idea-2” the design of it is simplified: no copper wear plates and cut under tooth-gear drive wheels. Simplification did not affect the performance and knot strength of the structure.

Track mover consists of front drive shaft with rubber gears, rear output shaft with rubber rollers, supporting skis, two supporting skis and the track.

Caterpillar Assembly consists of two strips of rubber conveyor belt cross-section mm 40×10, to which increments of 90 mm bolted cross birch Truckee. The fastener consists of М8х60 bolts, M8 nuts, guiding-clamping bonok widened and thick-walled duralumin washers. The connection of the ends of the tracks — back to back with the lining from the same conveyor belt and draw bolts through washers.

Guide ski:

1 — snake (plywood s10); 2 — sole (nylon, sheet s5); 3 — bearing (steel, sheet s5); 4 — eyelet (steel, sheet s5. 2); 5 — undercut (area 35×35, 2); 6 — quickdraw (tube Ø10); 7 — rivet (aluminum kit); 8 — washer (set)

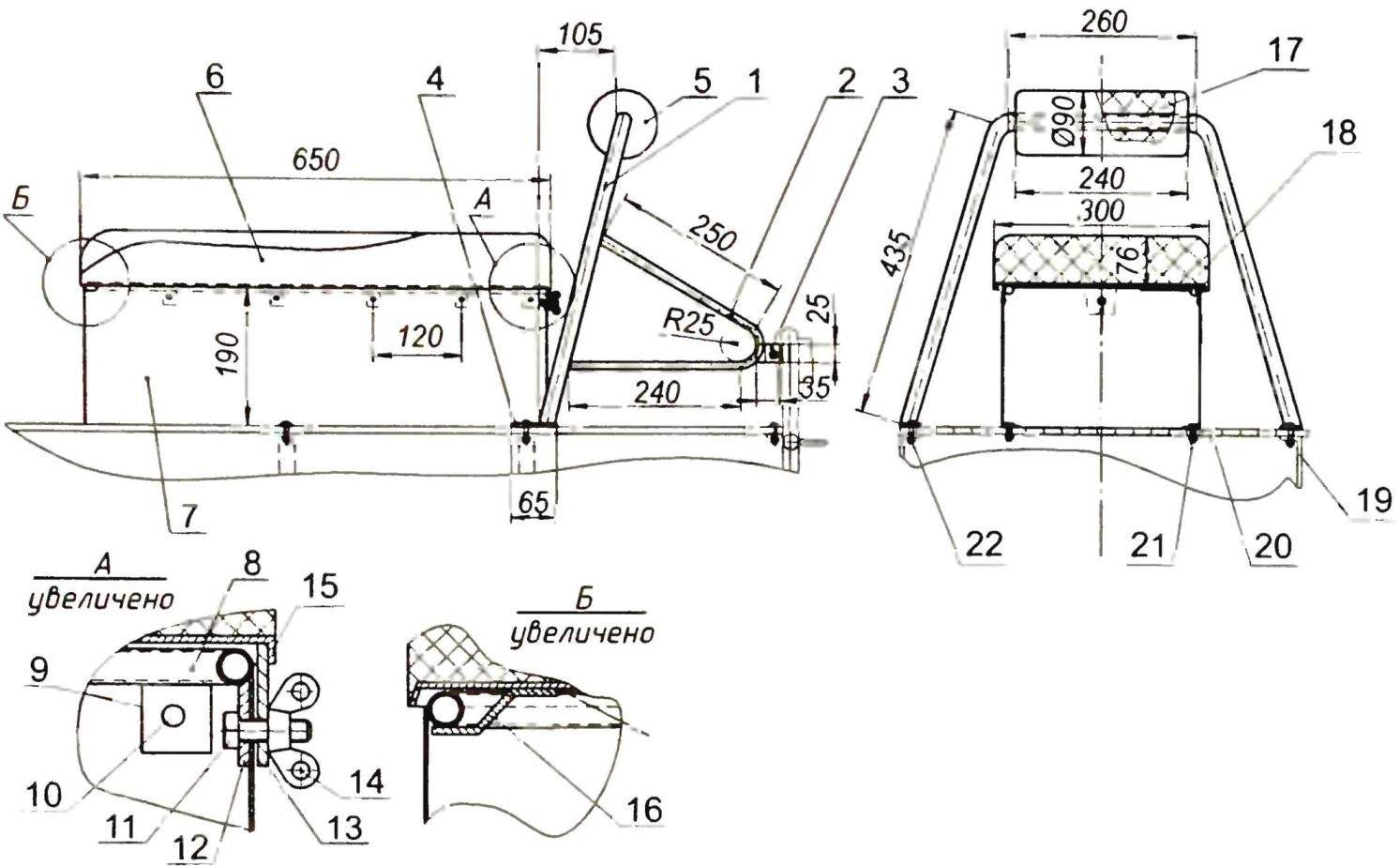

Ski reference:

1 —snake (plywood s10); 2 — sole (polyethylene, sheet s5); 3 —support bracket (steel, sheet s5, 4 PCs); 4 — bushing support bracket (steel pipe Ø21,3,4x); 5—strut support bracket (steel, sheet s5, 8); 6 — brace (steel, pipe Ø12, 2 PCs); 7 — rivet (aluminium, Ø3, set); 8 — washer (steel set)

Support ski:

1—snake (made of anodized aluminum, the sheet s10); 2 — bearing bracket (steel, sheet s5); 3 — bushing bracket (pipe Ø21); 4—rivet (aluminum, Ø5,2); 5—damping bushing (rubber pipe Ø16×5)

Steering:

1—duplici steering arm; 2 — steering shaft; 3 — time; 4 — knuckle (2); 5 — adjustable pull (2); 6—regulator-tip (2 PCs); 7 — welded nut (2 PCs); 8 — locknut (2); 9 — steering knuckle (2); 10—bearing knuckle (bronze, 2); 11 —compression spring (2 PCs ); 12 — Bush steering knuckle (tube Ø21,2); 13—support bracket of the steering shaft; 14 — the bracket fixing the steering shaft to the front portal frame: 15 — pin (2 PCs.), 16—beam frame (tube Ø33,5); 17 — bushing knuckle (tube Ø42,3, 2)

Add-on:

1 . seat back; 2 — brace arc; 3 — lug attachment of the strut to the frame (steel, the sheet s5, 2pcs); 4 — bearing shower (steel, sheet s5, 2 PCs ); 5 — cushion seat back (foam), 6 — trim seats (leatherette); 7 —tool kit (duralumin, sheet s2); 8 — frame instrumentalnoy box (tube Ø12), 9 — lug connection of the frame and the walls (steel, sheet s5, 10 PCs.); 10 — rivet (aluminium, Ø3, 10 PCs); 11 —bolt lock tool box (welded bolt M8); 12 — eyelet locking (steel, sheet s5); 13 – fork lock (steel, sheet s5); 14 — a lock of a lock (wing nut M8); 15 —seat base (steel, sheet s2); 16 – hook (steel, sheet s3); 17—gasket cushion seat (foam); 18 —gasket seat (foam); 19 -longitudinal frame; The 20 – floor (plywood s10); 21 —fastening the tool box to the floor (bolt M6 with extended washers, set); 22 – fastening the arc back to the frame (bolt M8 with lock washers)

Manufacturer bonok may chill the casting in the form of aluminum debris. Drilling holes in the bands and tracks were produced on templates.

Driving and driven shafts are welded with a preliminary check for a heartbeat and curvature. For normal operation, a special accuracy is not required. The curvature of the lugs of the shaft and the axis kompensiruet use self-aligning bearings.

Leading gears are cut with a sharp knife from a sheet of rubber (from the sidewall of the tire from the tractor K700 with water as lubricant). Accurate method of cutting is that first made a template of the star with holes for mounting. Then the shaft is slipped a rubber blank with a template, is attracted by regular bolts and cut.

On the frame, the spars in the first place, marked and drilled holes for mounting the bearing housing with the drive shaft. Then on the actual size of the track is determined by the place of attachment of the driven (idler) shaft and propisyvayutsya grooves to allow movement of the bearing bodies with the aim of track tension.

The lugs of the mounts of the supporting skis should be welded after installation on the frame of the driving and driven shaft and tension track: put flatter relative to the frame, and the guide bosses and weld.

Fixing the retaining lugs ski also welded in place with a slight decrease from the line of the upper branch of the caterpillar, to the floor of the caterpillar, it is desirable to attach two wooden longitudinal slats, which will protect the plywood from eating away the threaded part of bolts.

One of the important conditions of the build — parallelism of the supporting skis of the longitudinal corners of the frame spars and the required location of her sole below the outer diameter of the rollers of the driven shaft 15 — 20 mm.

The engine Assembly from the mounting face, the mounting brackets are exactly exhibited at the driven sprocket to the drive shaft of caterpillar tracks and cheeks prihvatyvayut welding. The final fusion of the cheeks is done already when removing the engine, the chain Tensioning is performed the tensioning roller.

Veneer consists of front fender-fairing, floor, and tool kit under the seat. Fairing and floor are made of birch plywood, and the box — sheet duralumin Mounting tabs are welded in place.

The seat is made on the basis of sheet steel glued to his pillow of foam covered with a durable waterproof leather. The seat to the frame tool box, mounted here by means of a hook and is fixed (locked) onto the fork with a bolt and wing nut.

A few recommendations to those who decide to build a snowmobile:

— well served and pine Truckee (failed tracks of nylon pipe);

— proportional increase of all sizes can build a snowmobile under a more powerful engine (from “IZH-the planet Jupiter”);

— for all skis, you can apply a 6-mm plywood in two layers;

— under the new laws of 1996 homemade equipment with an engine capacity over 50 CC must carry on the examination and to put on record in supervision;

— two people of average build “PAAs-125” still lucky(!);

— handy drag hook to the sled or sleds:

— removing steering skis may be carried in the “UAZ” and “Niva”;

— mechanics for beginners is better to install the imported engine of comparable power — this will be less of a hassle.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.

A bit of history. I’m 48 years old. Twenty years ago with his younger brother built a sled “Idea-2” — material about him was published in the “Modeller-designer” №11 for the year 1991. Later, when I was Director of Заводоуковскоq station of young technicians under my supervision in her circles were made around 20 such structures with different bike engines of Soviet manufacture. I must admit that the construction of the snowmobile largely contributed to assigning me to this position.

A bit of history. I’m 48 years old. Twenty years ago with his younger brother built a sled “Idea-2” — material about him was published in the “Modeller-designer” №11 for the year 1991. Later, when I was Director of Заводоуковскоq station of young technicians under my supervision in her circles were made around 20 such structures with different bike engines of Soviet manufacture. I must admit that the construction of the snowmobile largely contributed to assigning me to this position.