Has long been a regular reader and subscriber of the journal “modelist-Konstruktor”. I want to share one interesting result of technical creativity. Sometimes people ask for a drawing apparatus, a photo of which is posted in social networks is decided and for this reason also more to say about it.

Has long been a regular reader and subscriber of the journal “modelist-Konstruktor”. I want to share one interesting result of technical creativity. Sometimes people ask for a drawing apparatus, a photo of which is posted in social networks is decided and for this reason also more to say about it.

We live in the Altai, in its steppe part, where, as you know wide open spaces and snowy. And since winter lasts six months, then my son wanted to make a vehicle for driving on snow. It was assumed that the main requirements -small size and lightness, so it could without much difficulty be placed in the trunk of the car, and then get to explore the outdoors. I didn’t want to collect that is no problem today to buy at the store or say “hackneyed” homebrew circuits, and approach to the creation of the product creatively, bringing something of their own.

Because of the problem the technique of large sizes – wheel and propeller -did not fit. It was decided to make a tracked machine.

Looking at the movement of various light tracked vehicles in the snow, I came up with this idea – the wheel of the snowmobile especially-is not needed. In good snow crawler snowmobile is mainly controlled by the roll in one direction or another. And on the roads to move was not originally intended. So from the front of the ski refused (“extra” item to weld it’s never too late). Seat decided not to put to be able to move freely in the apparatus and thereby change the center of gravity for the various maneuvering on the go. It was assumed that the device was supposed to have a speed of 5-10 km/h and at low speeds in the snow brake is also an extra device.

With such resistance to movement of the machine should stop immediately. So the result came out, while throwing the engine speed camera almost immediately stops.

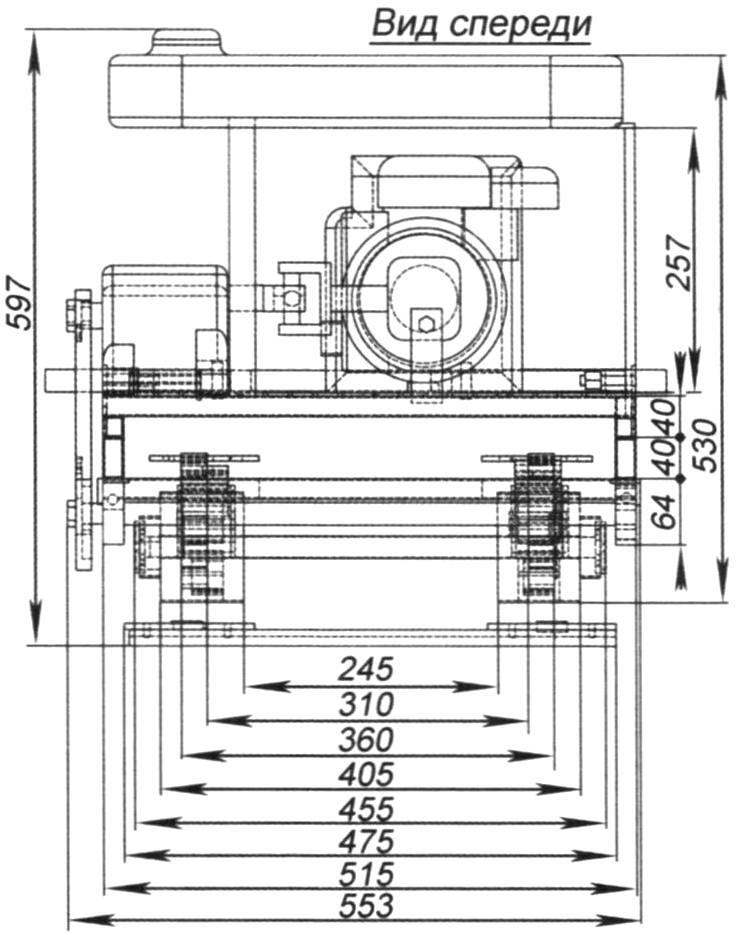

General view and principal dimensions caterpillar snowboard with a motor “Ferdinand”

From the scheme, “motsamai” refused, as the machine as a “locomotive”, I think, would have a low efficiency. And again, “superfluous” detail – trailer, which adds mass, increases drag and fuel consumption. And if you have a limited amount of car Luggage carrier trailer and put a particularly nowhere. Having estimated all of the intended capabilities and features of the device, it appeared that for the planned speed of 5-10 km/h and low mass of the device, you can use the lightweight engine is of small capacity – about 4-6 HP total weight with driver will create a low specific pressure on the area between 0,7 – 1 kg/m2 and the unit will not have to fall into the snow.

The result was that a “pilot” unit “snowboard on the inchworm motor” – for winter and summer. Why the “pilot”? As they say, there is no limits for perfection. Snowboarding my son and I rode the rest of the winter and snow of the spring.

Camera was good, it does not sink in the snow, readily passes the high snow, easy turns with a small roll, and on the solid surfaces set in the right direction by braking the left or right leg. I want to try snowboarding in the summer, ski guide! And if you install the steering bearing in the front position, it is possible to exploit it as a Transporter.

The figure shows the overall layout and principal dimensions of the apparatus.

A horizontal arrangement of the engine and transmission due to the need to provide a large area for support and maneuver of the driver. Frame suspension skis with rollers is shifted maximally in the back, as there is a large mass. With the same purpose, the center mounts of the springs has shifted to higher mass loadings, that is ago.

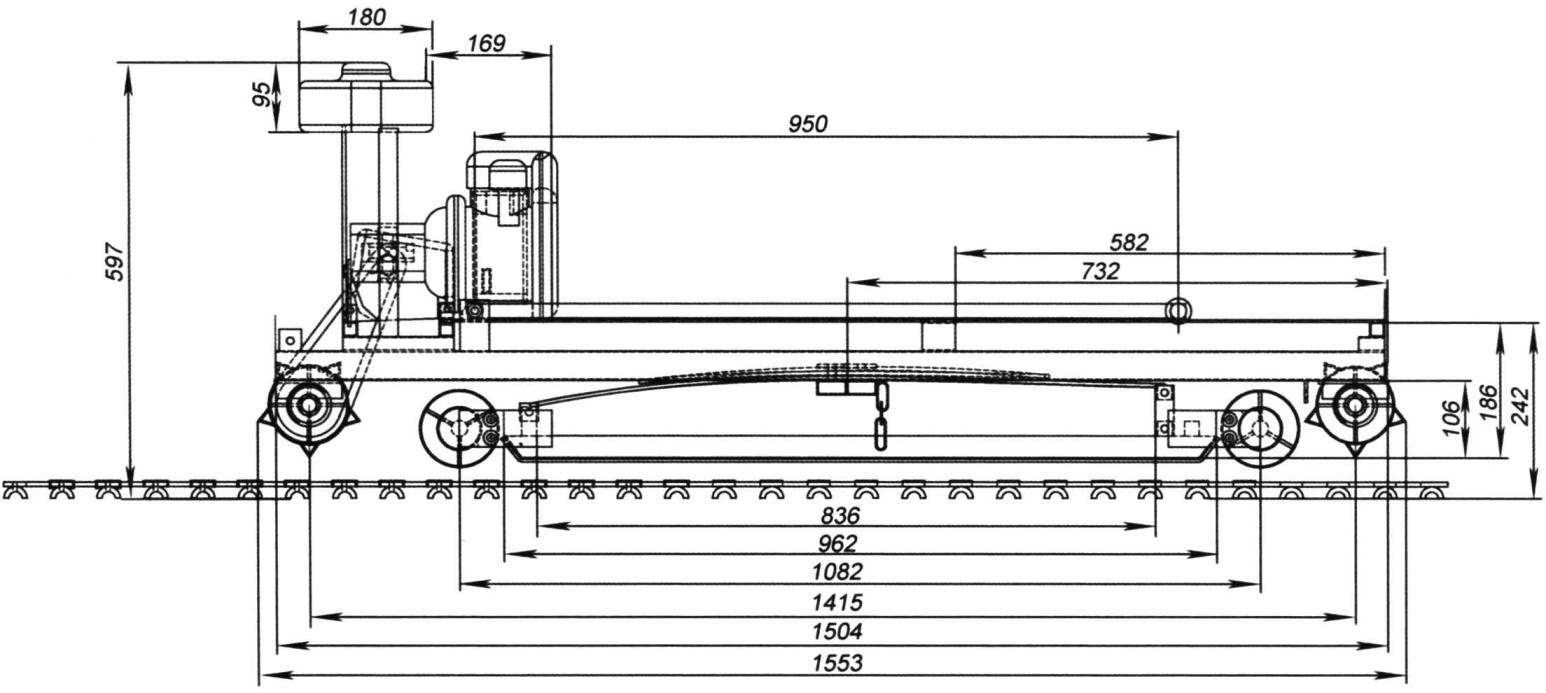

General view (caterpillar disbanded):

1 – frame; 2 – leaf caterpillar; 3 – Trak (half PPR pipes Ø32); 4 – clamp; 5 – motor; 6 – gearbox; 7 – fuel tank 8 – supporting steering arm; 9 – chain drive; 10 – supporting platform; 11 – driveline

a)

b)

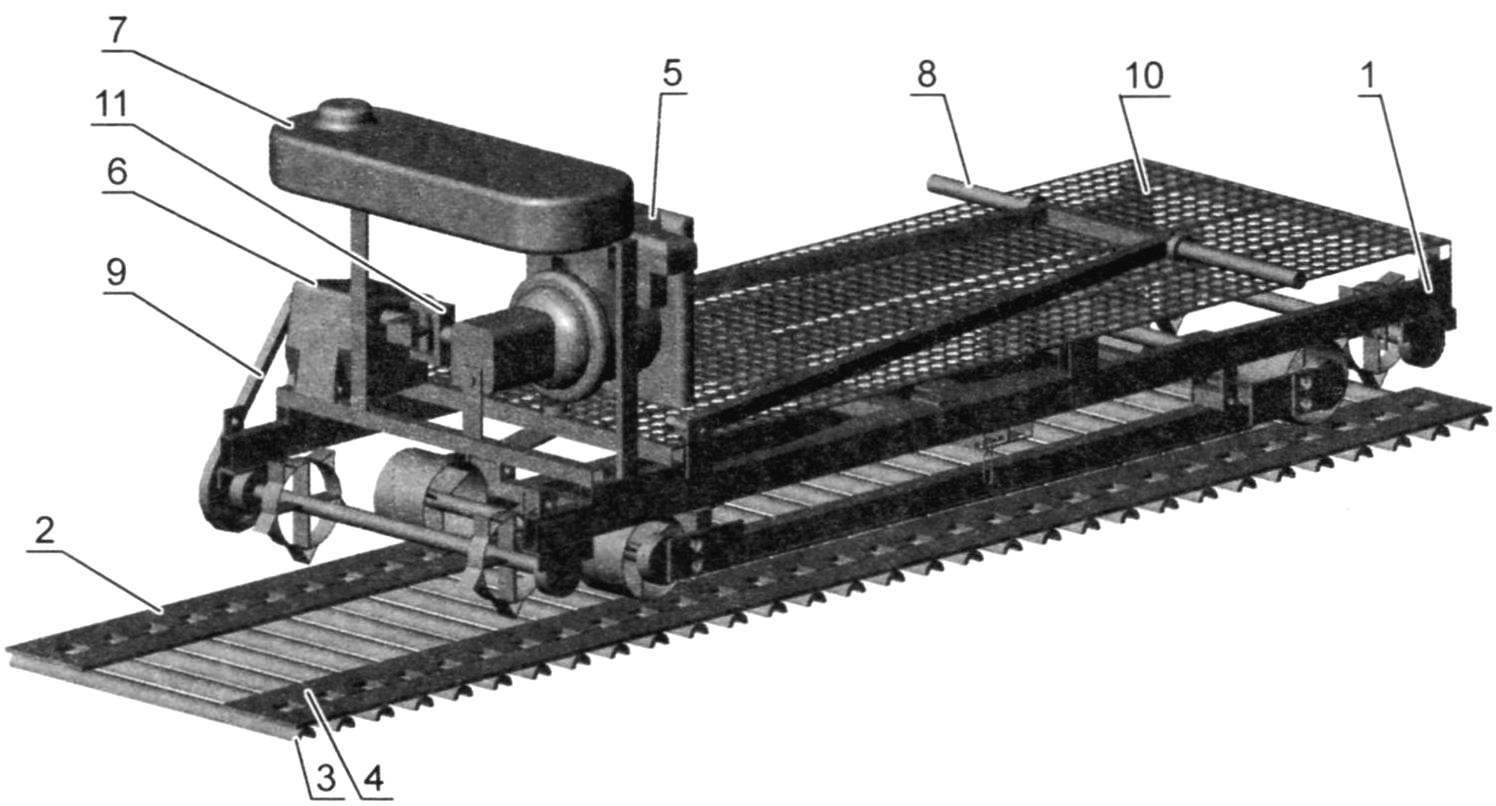

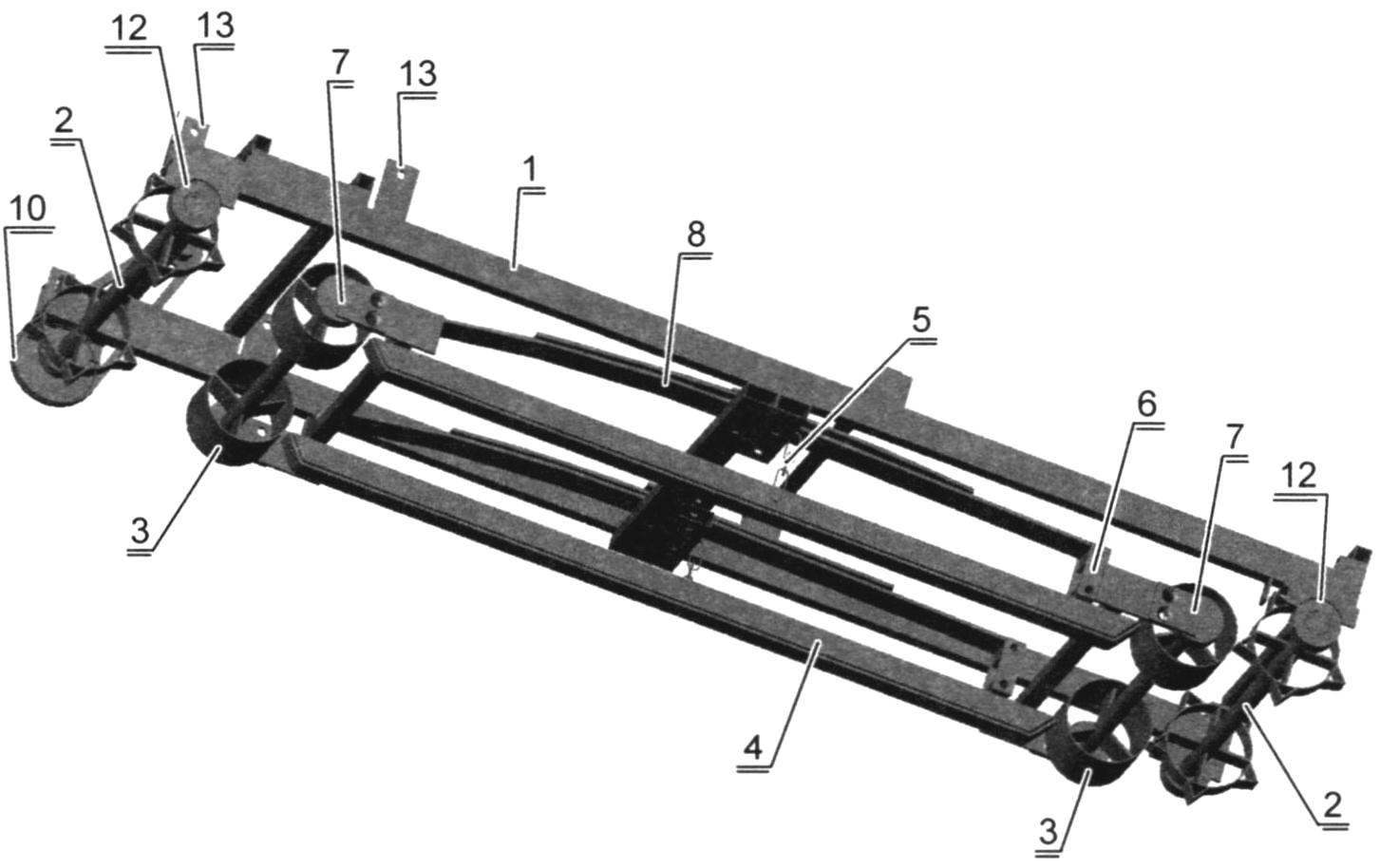

Frame with suspension (a – top view; b – bottom view):

1 – frame; 2 – master and slave shafts; 3 – block the rollers (front and rear), 4 – ski with plastic lining; 5 – limiting circuit; 6 – earring-spring; 7 – block bearing with housing; 8 – a pair of springs; 9 – pressure plate mounting springs with bolt holes; 10 – sprocket driven (scooter “Ant”); 11 – sprocket (from motor scooter “Ant”); 12 – bearing housing driving and driven shafts; 13 – front and rear “ears” securing the steering support

Arm-leg has only two pivot mounting points to allow height adjustment. It serves to hold the office of driver in traffic and the best of the machine control the torso. Optionally, of course, you can hard lock the steering support. But, in addition, on the frame there are two mounting pillars, front of the engine. It is made for use of the apparatus as the conveyor. In front of the ears attaching the steering support can be clipped the rope to transport the device as a sled.

Powerplant – the engine of the chainsaw “Ural-Electron”, without any alterations, just trimmed the excess metal from the reducer. Engine capacity – 112 cm3, power – 5 HP, rotational speed of a crankshaft of the engine at maximum power – 16 200±200 rpm engine Mount – subframe – used chainsaw “Friendship”. It is identical to the “Ural”, the only difference is the material: the chainsaw “Ural” mount of aluminum alloy, and the “Friendship” it is steel. Subframe welded to the frame.

The frame is made of pipe cross-section 20x40x1,5 mm 20x20x1,5 mm, all through the inner hole of the tubes is filled with foam. This is done to avoid the entry of snow or water inside the pipe.

For the manufacture of a reference platform used in metal band, “cutting” size 125×3 mm. of the Strip welded together in a single “Board” and welded to the frame at several points. The point of mounting Board raised from the frame to a height of 40 mm. Strip has the technological feature – on the one hand, it blunted the edge of the carved hole, and on the other a sharp edge. And as for clutch shoes driver a sharp edge is more suitable, then “Board” welded sharp edge up. I foresee the comments of the readers that the through holes in the platform will contribute to the snow with the tracks. The process of operation showed that “Board” is not clogged with snow, not only – fallen snow fell into the holes from vibration during movement.

Pendant consists of two skis, made of pipes of square section with dimensions of 30x30x1,5 mm, with plastic riveted plates of solid polyethylene black pipe with a wall thickness of 5 mm. To the ski via a base bearing mounted shaft with rollers. The shaft is made from a section of water pipe 15 inches, with welded in inserts-pins by a support bearing. The skating rink size 107x80x1,5 mm made of water tubes, is also expected to pull on his rubber, but this was not done. Any problems with the roller without rubber bondage has not yet occurred, as the ice rink is moving on the rubber leaf caterpillar from the conveyor belt. In the suspension used pair of springs from two sheets, each from the car “Moskvich-412”. The stiffness of the springs is adjusted so as to have a small deflection when boarding of the driver. Ski in suspension with a spring, has a limiter reverse, to reduce the shock load on the track. The tension of the caterpillar are two bolts with nuts М10х65, mounted in the rear part of the frame in a special support in front of buildings bearing the driven shaft of the caterpillar.

Driving and driven shafts of the tracks are identical, but with a slight difference of pins of one shaft for mounting the driven sprocket of the chain transmission. The very star under the caterpillar is made of water steel pipe sizes 107x25x1,5 mm, welded with five teeth of a steel strip 25×4 mm. dimensions of the Spokes of the sprocket are made of the same steel strip of size 25×4 mm. All cooked in a sealed single unit. With stars removed chamfer with edges from the leaf to the caterpillar, and the sharp edges are rounded to reduce wear of the canvas caterpillars.

All pivot bearings (eight pieces): closed-type, ball size 56x20x20 mm, the hull under them turned from steel and welded four metal corner size 25x25x4 mm and four-band dimensions mm. 50x80x4 on the metal Housing the area is screwed to the frame with two bolts М10х55 М10х35 mm and mm Housing with welded strip is screwed to the suspension bracket using the two screws М10х35 with countersunk head, in order to have less protrusions in the chassis and eliminate the gearing to suspension.

The drivetrain consists of reducer chainsaw with a gear ratio of 1:2. The gearbox connected to shaft drive with gearbox from a motorcycle “Voskhod-3M”. First gear has a ratio of about 1:3. Chain transmission from the box to the drive shaft of the caterpillar consists of a drive sprocket of 11 teeth and the driven sprocket of 28 teeth. Itself the chain and sprockets used scooter “Ant”. Gear ratio chain transmission is 1:2,55. Total, total transmission ratio 1:2:3:2,55=0,065. Of course, you can pick up a belt CVT dynamics, I think it would be better, but the weight will, I assume, heavier.

The inchworm is made of two strips of the conveyor belt sizes 125×5 mm from the machinery. In the tape, center cut rectangular holes the size 30×34 mm, the teeth of the drive sprocket. Between the cutouts fixed brackets, made from steel strip size 60x30x1,5 mm. Clamps are used for the best sliding rails and sprockets, as well as to reduce wear of the canvas caterpillars. Tapes are connected by tracks, which was dissolved in half PVC pipe with a diameter of 32 mm. Pipe trucks bolted to the conveyor belt by bolts 6×25 mm with washer.

The fuel tank fit in size and style from the moped “Riga-14” (for those who do not remember: he was installed over the rear wing of a moped and served additionally by the trunk).

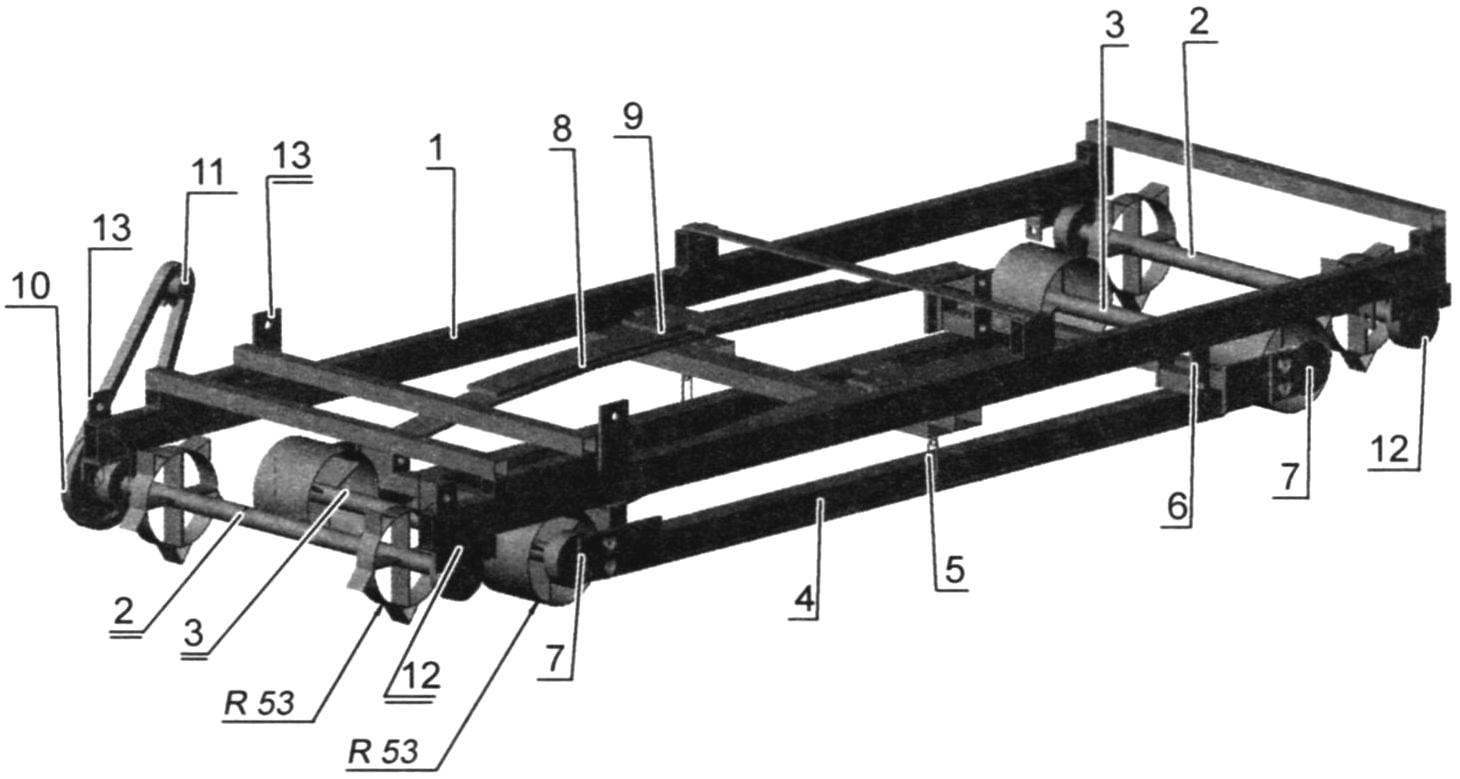

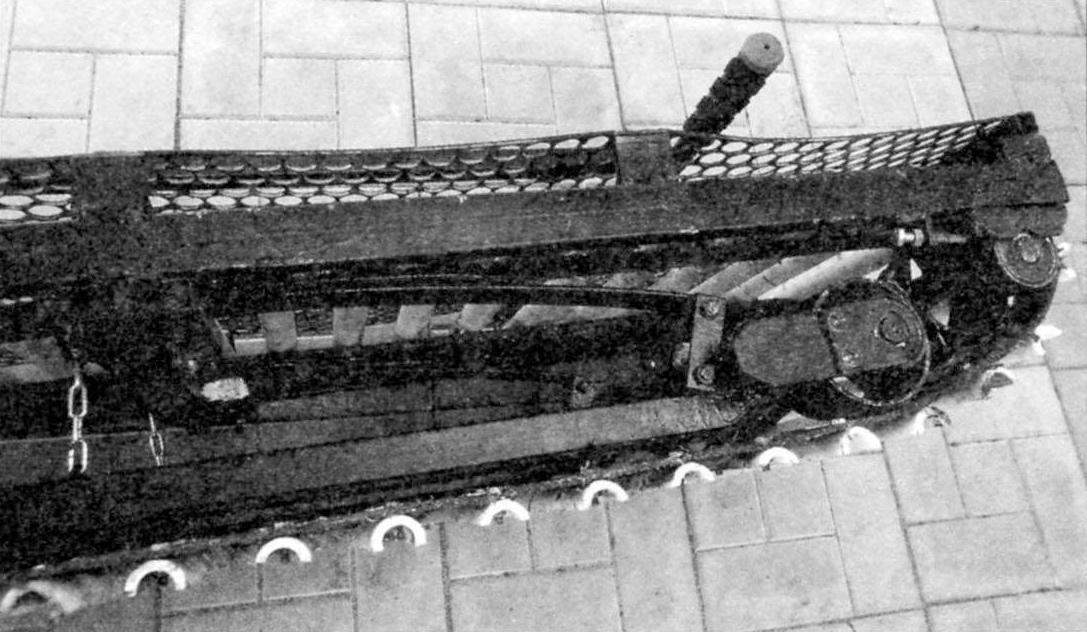

Drive snowboard

Tension node

Total dry weight “Ferdinand”, as I jokingly called for a kind of projection of the front part of the shaft with the caterpillar was 65 kg. With incomplete disassembly of the machine was able to weigh the separate main parts, namely: engine – 6 kg; gear-chainsaw – 2kg; caterpillar – 10.5 kg; slave and drive shaft from caterpillar in the amount of weigh 6 kg.

In the trunk of our car “Ferdinand” loaded by one person. With the rear seats folded the car’s arm-the support is omitted and a snowboard astern rolled into the trunk.

And in conclusion wishing to build a similar machine that I used handy, inexpensive materials. But you can install another engine with better characteristics, today they are selling a great many. Or improve an existing, basics, and inclinations to upgrade is to install another carb; the larger the silencer; to adapt a different starter, as the removable is not very convenient. Instead of a gearbox to supply the variator. You can use the aluminium and fibreglass, and can facilitate the design. The main thing is that, in General, the design works.

Prepare sleighs in summer, and good luck in creativity!

D. ELEPHANTS