Modelers often have certain difficulties in acquiring light and noiseless gears, wheels, propeller, and propeller and other parts for improvised structures. At the same time, these problems can be avoided if prudent, businesslike now use a throw away to landfill discarded, worn-out nylon products, old plastic items and other “synthetic stuff”.

Modelers often have certain difficulties in acquiring light and noiseless gears, wheels, propeller, and propeller and other parts for improvised structures. At the same time, these problems can be avoided if prudent, businesslike now use a throw away to landfill discarded, worn-out nylon products, old plastic items and other “synthetic stuff”.

Here will rescue its microlaena, turning industrial and domestic plastic waste into durable, elegant, attributable first to the category of scarce goods. The more that you can equip it to your desktop, as experience shows, every fan of tinkering with your own hands.

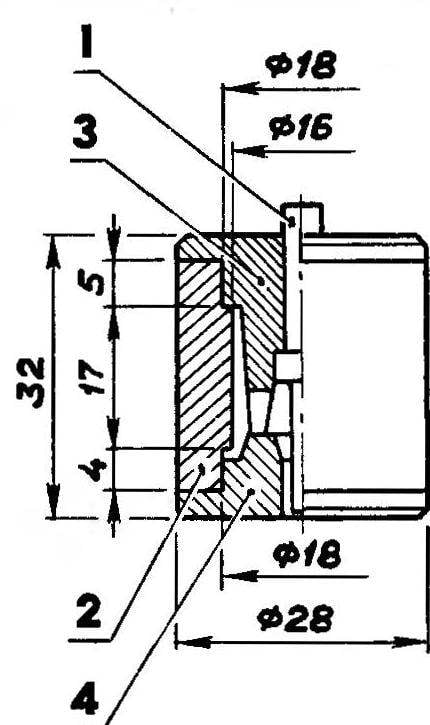

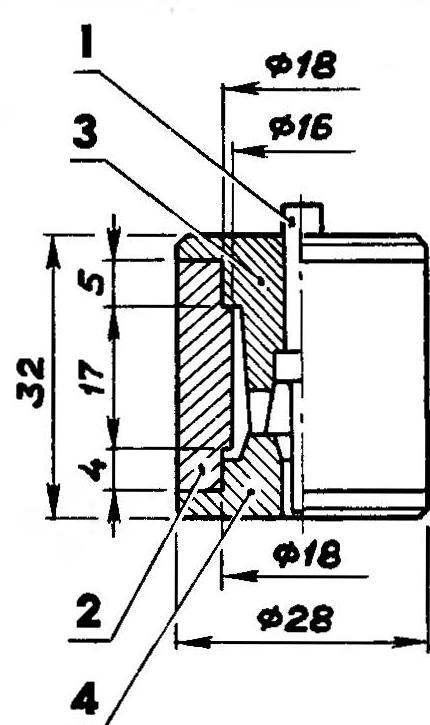

The first thing required for the development of home technology of moulding of plastic materials under pressure, is press. Could not be better suited here school press, commercially available. If they have not been found, use homemade. For example, a screw, an acceptable design option which can be found in binders “M-K” over the past years. The role of the melting device will perform the usual hot plate. Will be found at home and a suitable bath of water-cooler. With the raw material too, apparently, won’t be a problem. Well and the mold injection device is easy to fabricate enthusiasts on approved drawings (see figure). Dimensions, of course, can be taken by others. An important principle of the idea.