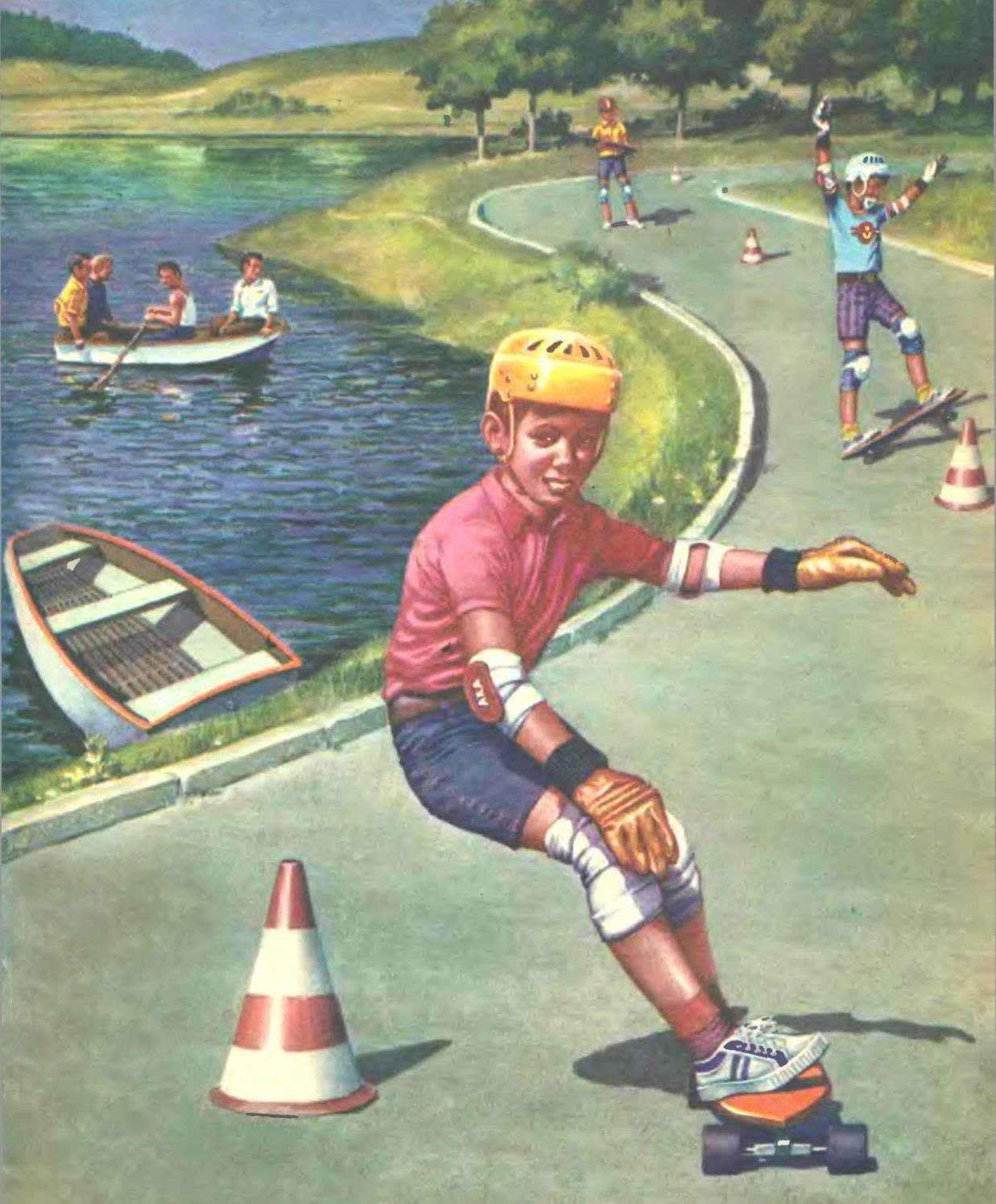

In recent years, increasingly popular among young people acquires a new exciting sport, something akin to the classic surf art of the slide with the crest of the wave on the Board. It is also used Board, however, somewhat smaller. At its bottom secured four rubber-coated roller. As you’ve probably guessed, the slide on this Board with ocean waves and asphalt, using the natural slope.

In recent years, increasingly popular among young people acquires a new exciting sport, something akin to the classic surf art of the slide with the crest of the wave on the Board. It is also used Board, however, somewhat smaller. At its bottom secured four rubber-coated roller. As you’ve probably guessed, the slide on this Board with ocean waves and asphalt, using the natural slope.

The appeal of “land surfing”, apparently, can be explained by the fact that to stay on Board while driving for the first time is hard enough, but mastering this skill, the rider gets real pleasure from the rapid movement on the lightest sports projectile, obedient to the slightest tilt of the case.

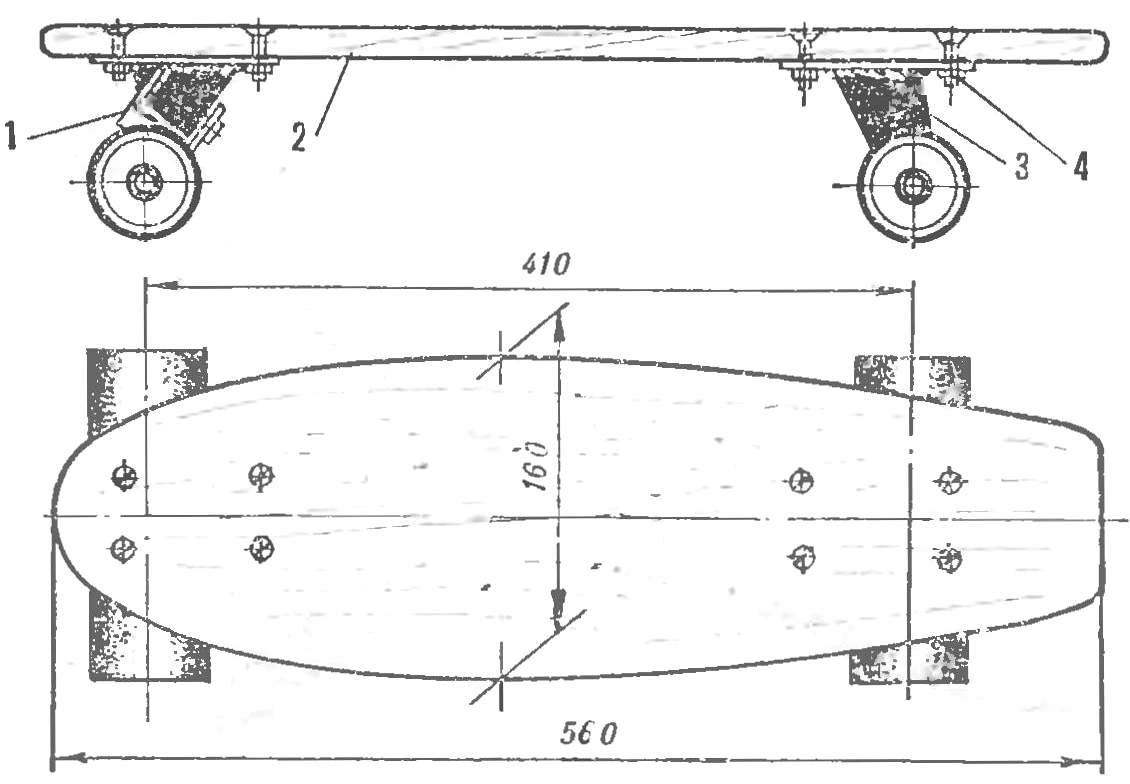

Design land surfer simple. Board sawed out of plywood with a thickness of 12-15 mm. the Edges are smoothed with a file and sandpaper, the surface is painted in any bright color.

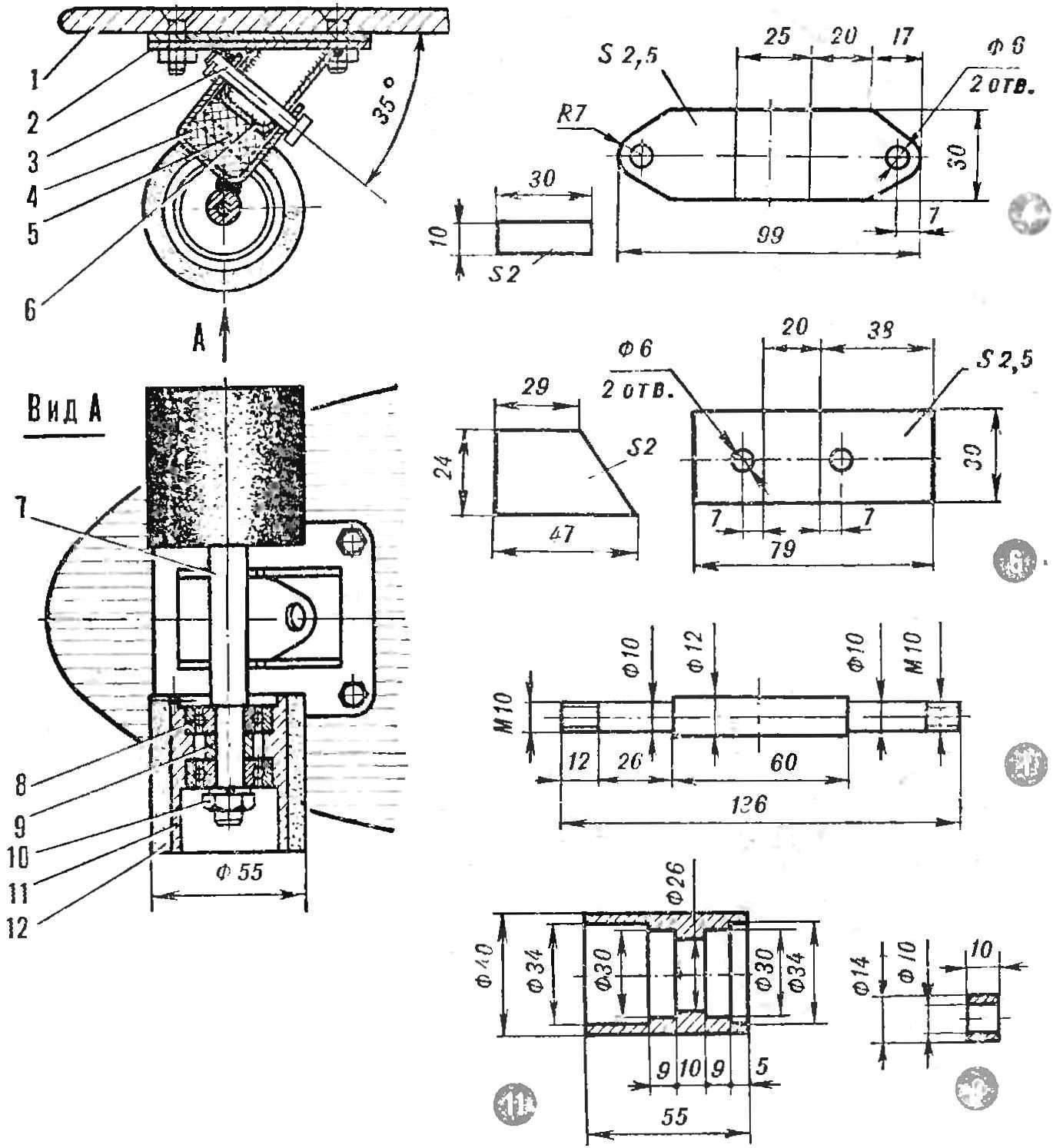

The most attention should be paid to work on suspension from the thoroughness of its production to a significant degree on how the security in the drive and ride quality and handling.

Each wheel consists of a hub turned on a lathe out of aluminum, two bearings and tires — a piece of rubber hose of suitable diameter. Before you carve the hub, pick up the bearings — their sizes will depend on the size of the groove. In the drawing, dimensioned bearing No. 200.

Fig. 1. General view of the asphalt surfer:

1 — front axle, 2 — Board, 3 — rear axle, 4 — M6 bolts with nuts.

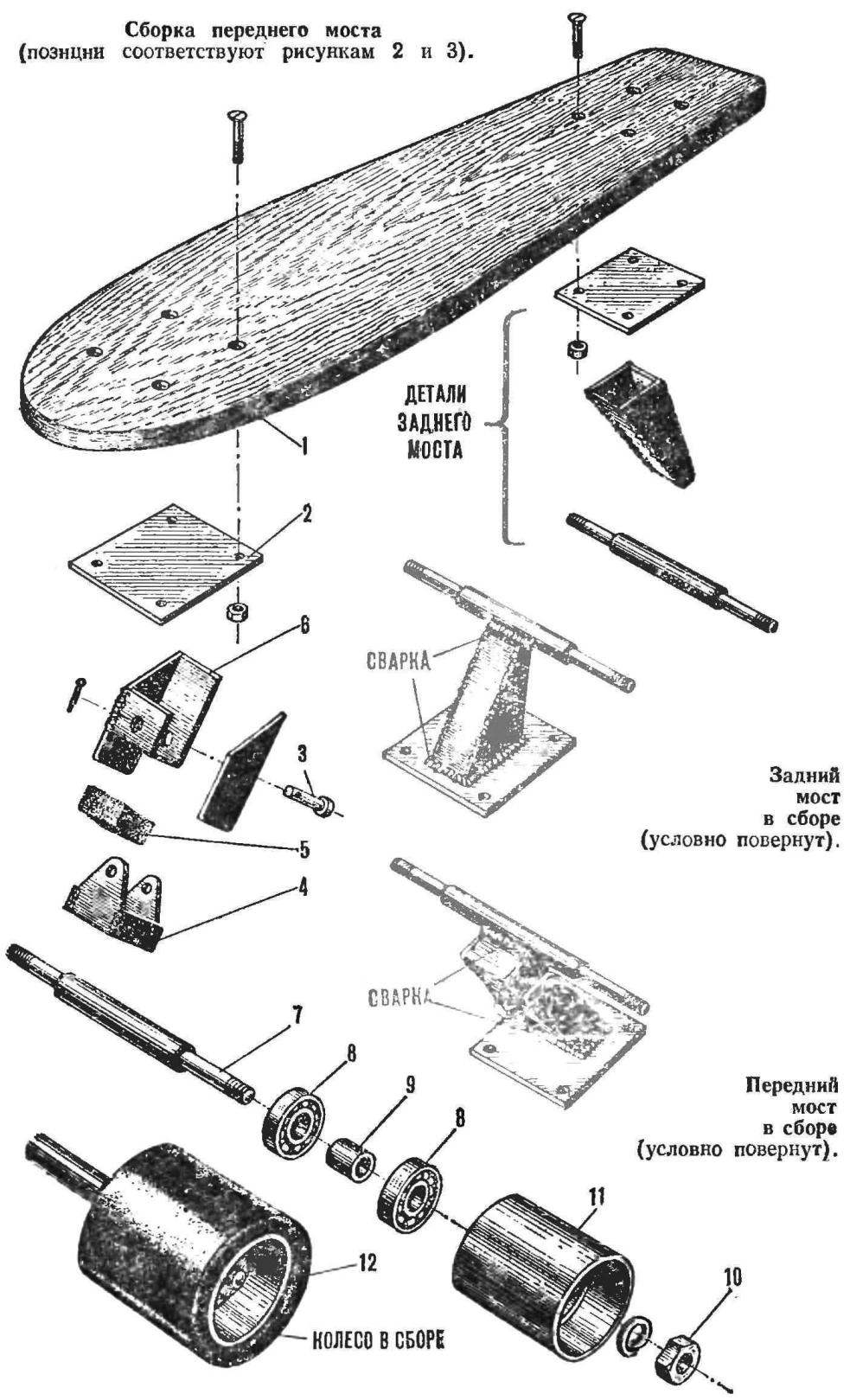

Fig. 2. Front axle surfer:

1 — Board, 2 — basic heel, 3 — axis rotation front axle with a cotter pin, 4 — hinge, 5 — rubber gasket, 6 — bracket, 7 — front axle, 8 — bearing, 9 — sleeve, 10 — nut with spring washer, 11 — wheel hub, 12 — tire.

Material for axles — steel grades 43 or 30KHGSA, subjected to heat treatment — hardening.

Rear axle surfer rigidly connected to the Board. Mounting bracket axis burp from a steel strip of thickness 2.5—3 mm and is welded to the axle and support the heel. Rear axle is fixed on the Board with four bolts M6. The front axle is more complicated. Its design allows the wheels to rotate about an inclined axis. Thanks to this athlete can manage the asphalt surfer, shifting the center of gravity of the body on the appropriate Board. The main parts of the bridge — supporting Pete through which the rotating mechanism is fixed on the Board; a bracket bent from a steel strip of thickness 2.5 mm and welded to the base; a hinge connected to the front wheel axis by welding, and the bracket with your finger. The angle between the axis of the hinge and the plane of the Board is 35°. Between the hinge bracket and put the rubber cushion elastic member that returns the axis of the front wheels in a horizontal position.

A little about methods of learning to drive and about the gear of an athlete. Necessary items of clothing, hockey helmet, elbow pads, knee pads and gloves. On your feet it is best to wear sneakers. This ammunition will save you from many troubles, which usually occur in the early stages of learning.

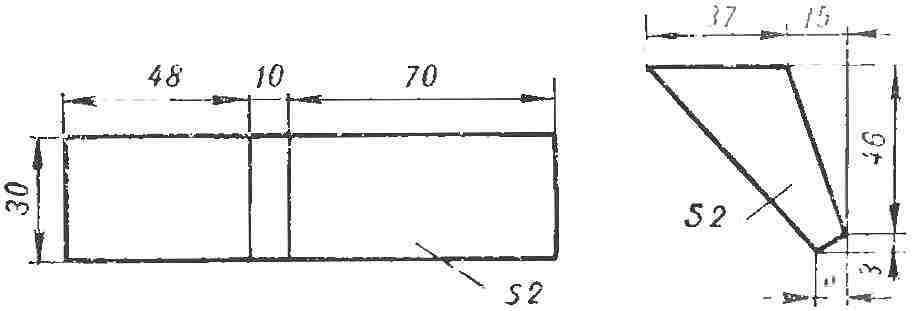

Fig. 3. Rear axle details.

Fig. 4. Asphalt surfer Assembly diagram (2-I part — 2).

To learn the art of driving such an unusual vehicle is better on asphalt tracks with inclination. The most important thing is to capture the ratio of movement of its center of gravity and corresponding changes of the rotation angle of the front axle.

Stand on the Board it is best sideways to the direction of its motion; the feet must be positioned approximately over the axles.

First trains on straight and after complicate the track: enter the snake, learn to do twists and turns. Brakes asphalt surfer no. To stop it, you must transfer the center of gravity to the rear edge of the Board, the front wheels will rise and the edge will press against the asphalt.

It is interesting to make several of these sports equipment and get the best results: the rate of passage of the notched tracks, the quality of performing complex turns and curves on the vehicle range with one slide.