Man I’m not so wealthy to afford to have multiple vehicles for different purposes (even homemade). So the car that was going to build, was conceived as a versatile vehicle not only for transportation of passengers or goods, but also as assistant in different economic Affairs.

Man I’m not so wealthy to afford to have multiple vehicles for different purposes (even homemade). So the car that was going to build, was conceived as a versatile vehicle not only for transportation of passengers or goods, but also as assistant in different economic Affairs.

The place to say that this car is the third one I’ve built yourself. First made in very young years. It was more of a motorcar type buggy with a 2-cylinder engine from a motorcycle “IZH-Jupiter” and a hydraulically driven rear wheels. Instead of the body there was only a frame structure, which was replaced and the frame, and arc security.

The second car has turned more serious—type “jeep”. Built by motor assemblies (rear axle—from “Volga” GAZ-24, front—UAZ-451; 2-cylinder engine from the tractor “Vladimir”). The first car was not so perfect, but I am, as they say, practiced.

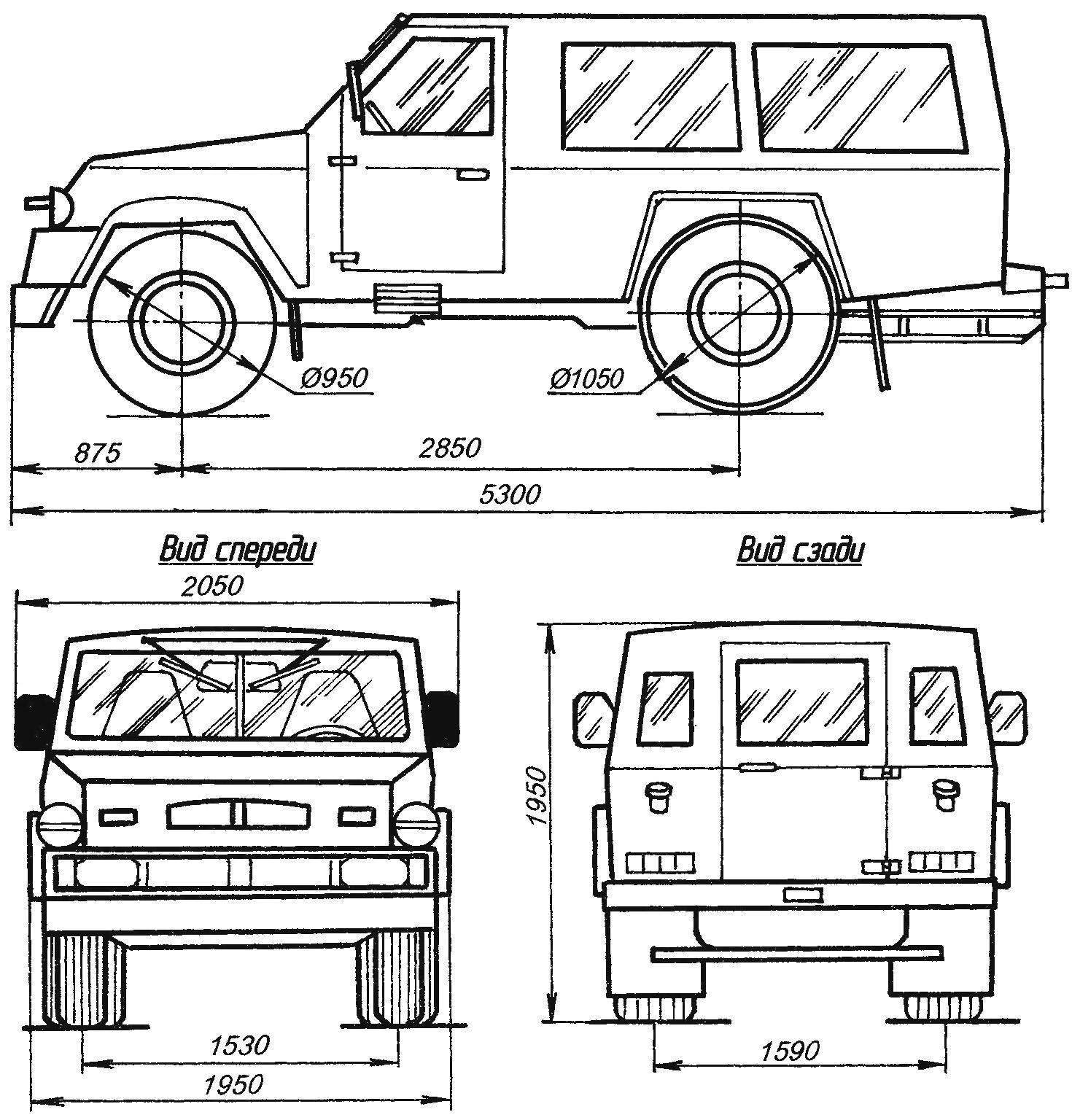

From the description of the third car, it would be necessary to note which production car was the basis of its design. But this question is difficult to answer: only the body and frame completely made, and the units and components of the powertrain, chassis—everything from different machines.

The frame is welded from steel channel No. 10. In design it is extremely simple, with a rectangular and not even spatial. Two longitudinal members connected by five cross members: front, back, and three intermediate. The elements of the frame is welded of numerous brackets, racks, cradles, required for Assembly of the power unit, and the nodes and of transmission mechanisms and chassis. Most often the configuration and installation of these support elements was determined on-site. Since the car body is wider than the frame, then its resistance to outside spars welded several symmetrically arranged cantilevers, made of a channel No. 5.

The hood of the car are integrally formed with the wings and facing radiators. When you raised the hood open access to the powertrain

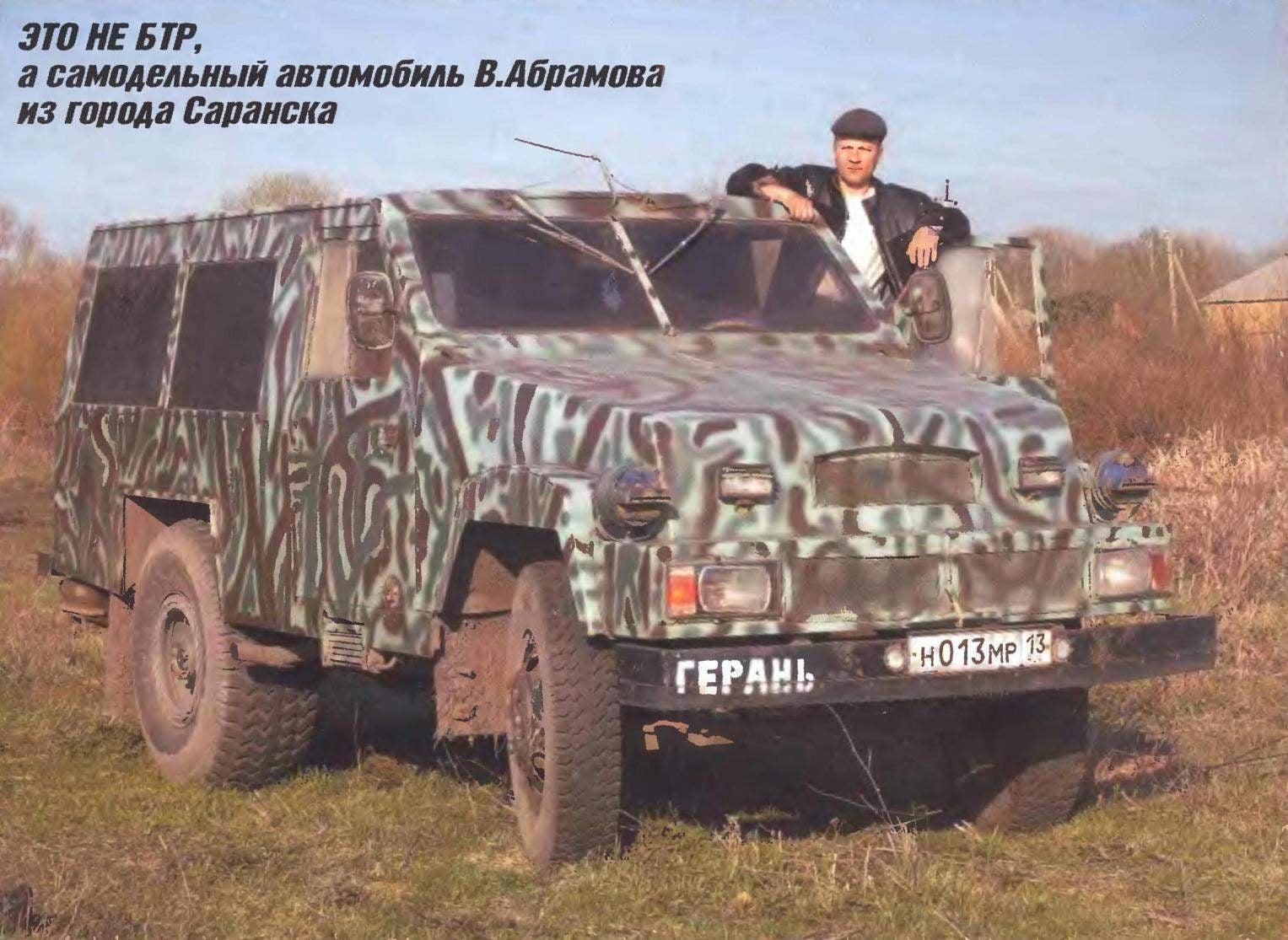

Utility vehicle “Geranium”

The spacious passenger compartment two benches, ia which can hold up to ten passengers. If necessary, they are folded out as a sofa bed

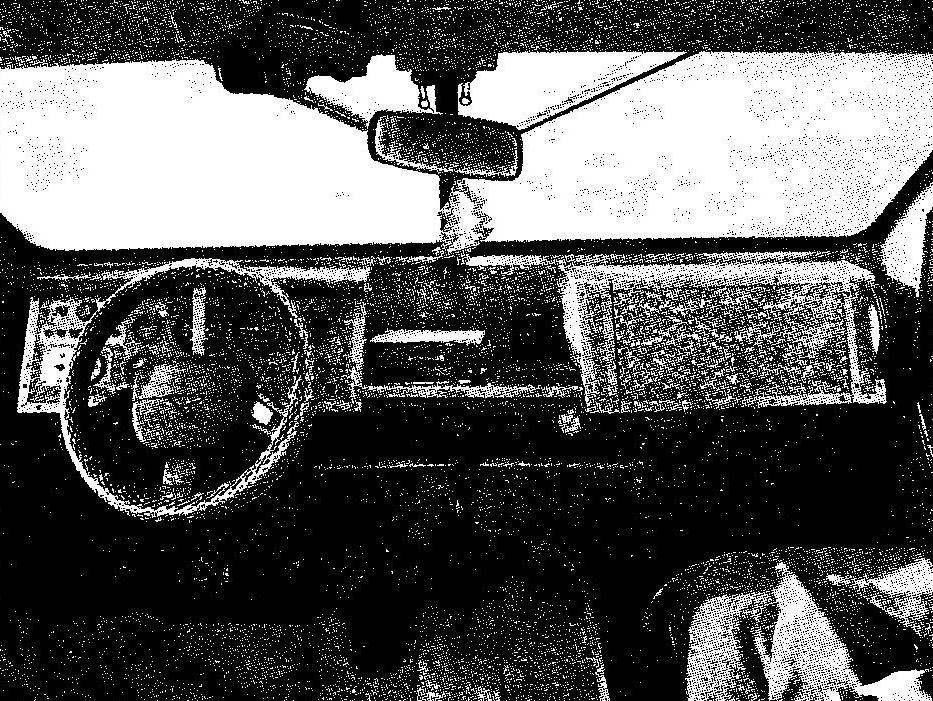

Driver and front passenger

The car body—frame construction from steel plumbing pipes with outer diameter of 32 mm. of Course, such a pretty fat pipe weighted the car, but I managed without excessive auxiliary components such as struts, braces, scarves, etc.—and in the end accelerated the work. The body shell is welded to the frame.

Exterior body panels were made of galvanized steel of 0.8 mm sheet metal, and the wings and wheelhouse are made of plates of stainless steel of the same thickness. Qualitatively to weld thin sheets, it was necessary to have special equipment and highly qualified. Neither one nor the other I have had, but because the panels were attached to the tubes of the frame by the screws M4 with a pitch of about 100 mm. When the metal sheets have docked on the pipes with a 30 mm overlap (forward overlap on the back, and the upper on the lower). Then the head bolts on the outside of the panels to stitch, and they became similar to rivets with flat heads.

Doors, like the side and rear, have a frame made of square pipe 25×25 mm. Sheathed on the outside they are the same galvanized sheet as the body. The Windows on the side doors—not falling, but because they made sliding Windows. The window in the back and rear doors—deaf. Front windshield cut himself out of the triplex.

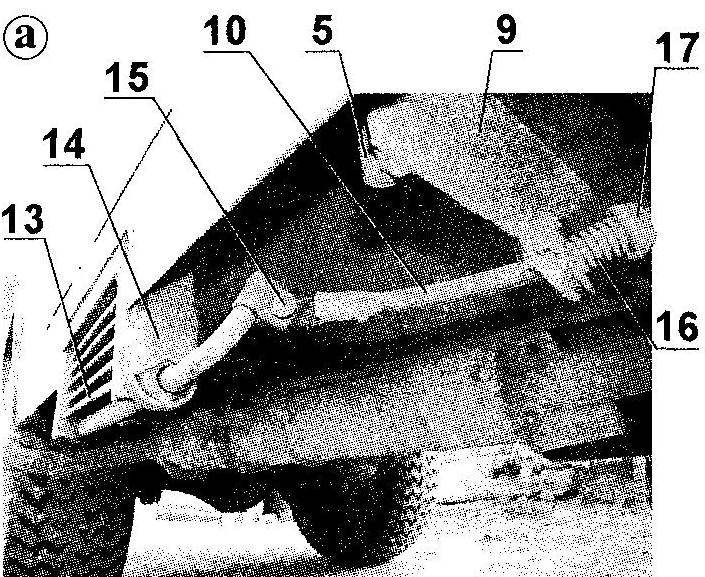

The hood of the car is made with a frame made of pipes with a diameter of 32 mm, as one with wings and cladding of the radiators (they, incidentally, are two: for cooling engine coolant and oil). Together, they made quite a massive structure. So the lift produced by a hydraulic mechanism to swap from a manual lever mounted in the cab. Two of the hydraulic cylinder of the mechanism used from hatches, gear of the aircraft an-24. When you raised the hood open access to powertrain on all sides to the very bottom, and the hood serves as a “canopy” when repairing or servicing a motor in bad weather.

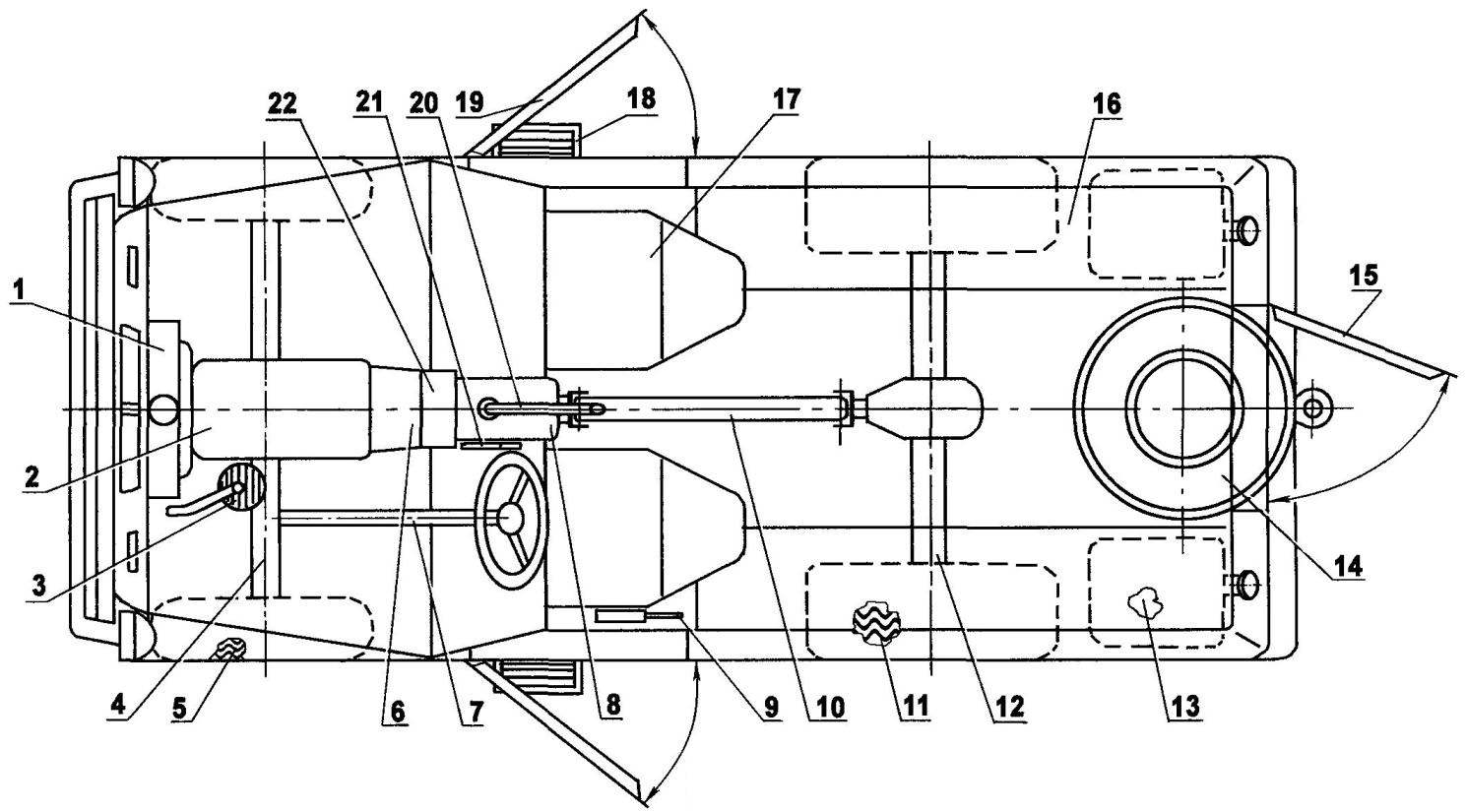

The layout of the main units and assemblies of a car:

1 — the engine cooling system (radiator and fan from car GAS-53); 2—engine D-240, N = 80 HP, (MTZ-80 “Belarus”); 3—starting engine P-10UD (MTZ-80); 4—front axle (GAZ-53); 5 — front wheel (GAZ-53); 6—clutch basket (MTZ-80); 7—steering (GAZ-53); 8 — gear shift (from car ZIL-164); 9—the lever of the hydraulic pumping mechanism for lifting the hood; 10—propeller shaft (GAZ-53); 11—rear wheel (truck truck tractor T-150, 2 pieces); 12—rear axle (ZIL-164); 13—fuel tank capacity 75 l, the steel sheet of 81.5, 2); 14—spare wheel (GAZ-53); 15—back door; 16—side seat (spread, 2); 17—the front seat (of the bus LAZ-6976,2 piece); 18—step (fold-up, steel, circle 10); 19—the side door (2 PCs); 20—a gear lever (on ZIL-164); 21 —the lever of a manual brake (GAZ-53); 22—the transitional cap (front part of the transmission from the ZIL-130)

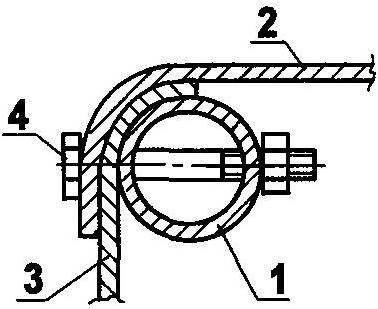

The connection of the outer (facing) body panels to the frame:

1—element frame; 2—upstream (or standing in front) panel; 3—downstream (or behind free standing) panel; 4—bolt M4

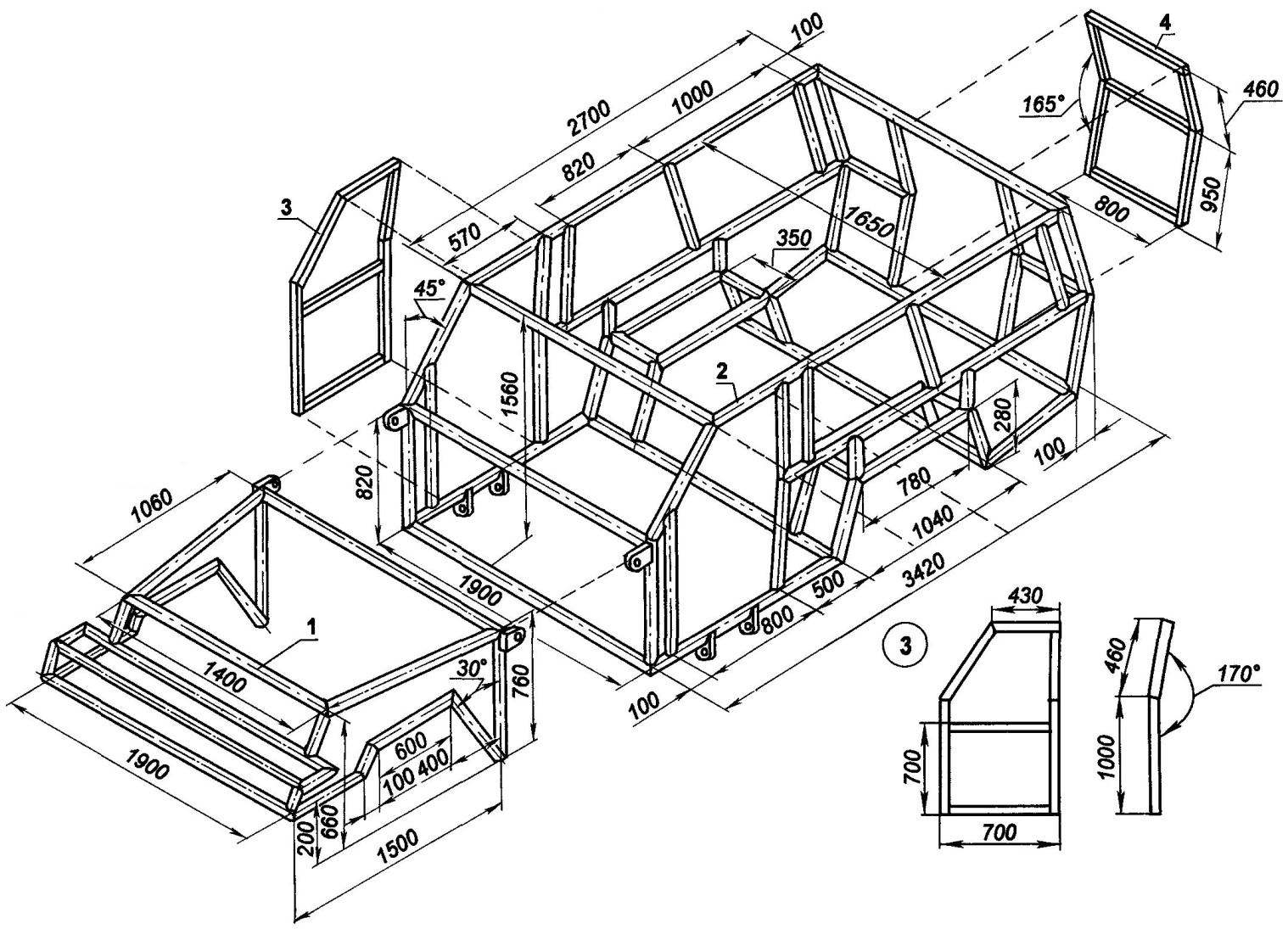

The frame of the car body:

1 —skeleton of the hood (pipe Ø32); 2—frame cabin (pipe Ø32); 3—side frame, door (square tube 25×25); 4—rear door frame (square tube 25×25)

A similar mechanism lowers-raises the tool tray spare wheel stored under the frame at the rear of the machine.

Mechanisms and steps for the side doors. The drive is carried out when the door is opened: the mechanism throws the bandwagon, and when closing—removes it. Swivel thrust (Fig.5, POS. 10) with the levers stands and steps (POS.9 and 12) to ensure efficiency have increased the gaps. In fact, here it would be better to install ball fingers, but it would complicate the mechanism.

Inside the body shell trimmed with 10 mm plywood, which is covered with linoleum on a fabric basis. The ceiling is papered with the usual “perforated” film—the one with all machines. Passenger compartment floor wood, tongue-and-groove boards “trecator”. It is also covered with linoleum. Board attached to the elements of the frame with the M8 bolts, the heads of which are recessed.

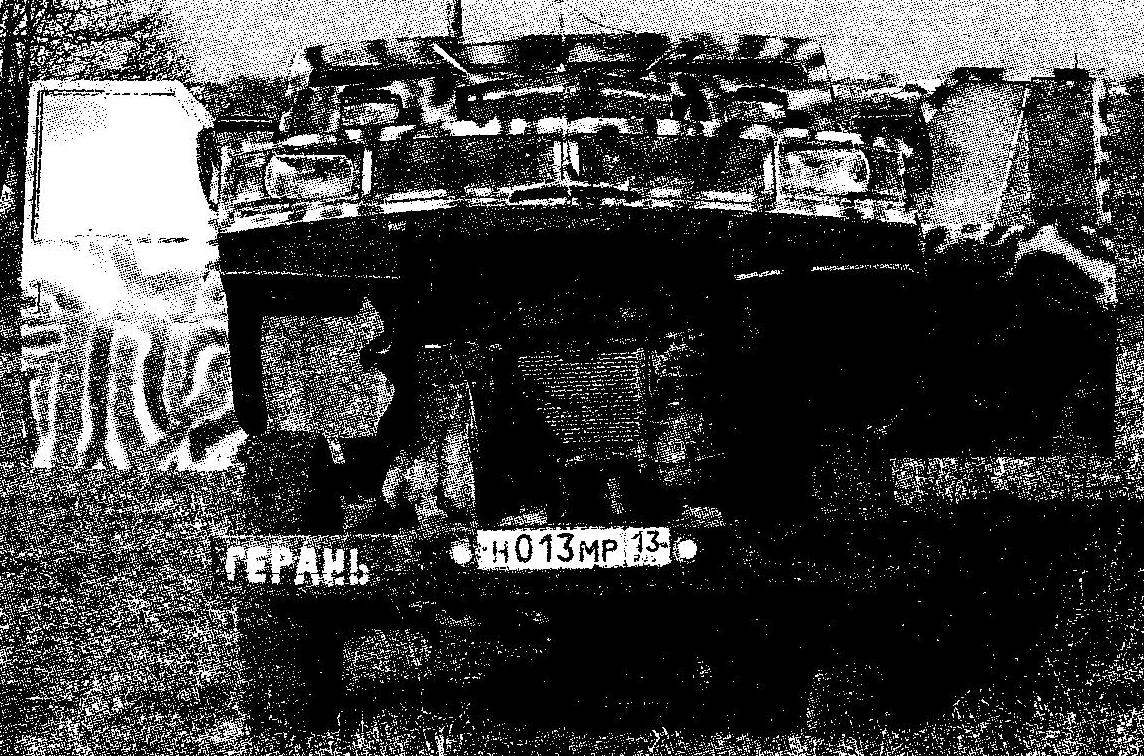

As the power unit of the machine used reliable frugal diesel engine liquid cooling Д240 from the tractor “Belarus”. Engine power 80 HP is not so great for a fairly heavy car (her weight ended up about 2.5 t), but the motor is torquey and rather greedy.

Grip is also applied from the tractor “Belarus”. The remaining transmission units from different machines. So, a five-speed box changes gear adapted from an old truck ZIL-164, driveshaft—ZIL-131, a leading rear axle Assembly from the car GAZ—53. Rear-wheel—truck tractor T-150; they are bigger in diameter and larger may well have replaced the regular saddle from the GAZ-53.

The mechanism of lifting/lowering stage (the right stage in the raised position when the door is closed—outside view; b — right-step in lowered position when the door is open — the view from the cockpit):

1—door; 2 — door leash; 3—rod; 4 — leash racks; 5–swivel stand (pipe Ø32); 6—bracket mounts to the wall of the body; 7—the wall of the body; 8—floor, 9—lever rack; 10—thrust stage (weldment); 11 —emphasis stage; 12—the lever stage; 13—stop; 14—bracket step to the frame (2); 15—hinge (5 PCs); 16—spring (normally stretched); 17 — pin

The car—tractor “heart”: the diesel engine D-240 from MTZ-80 “Belarus”

Front axle with guide wheels used is also from GAZ-53. Although the front and rear wheels are different, the spare tire is only one, the same as the front, and use it only as a “pre-rollers” to get to the service or home.

Brake system (with vacuum booster) and steering used car GAS-53.

The machine is equipped with two communicating fuel tanks, 75 gallons each. Capacity homemade, welded, made of steel sheet 1.5 mm thick. tanks Located under the floor in the rear of the machine, and their neck displayed on the back side, on opposite sides of the door. Fuel consumption is 10,5 (on the highway) to 20 (rough terrain) liters per 100 km and Speed of up to 98 km/h.

The resemblance of the car with APC inspired by memories of service in the army. Hence came the name of the machine — “Geranium” — the name of the former training center of the 104th airborne division, stationed in Azerbaijan, which once served. This similarity is determined and the color of the car—I painted it in three tone camouflage.

The layout of the cabin is also well matched to that of the APC: in the car, only two seats (tourist bus) — driver and front passenger. In the passenger compartment on the sides are benches which can accommodate up to 10 passengers. These seats fold out into a sofa bed (the owner). And then in a compartment formed of four berths.

Was building a machine for a year and a half (and take into account the time to collect parts and assemblies). Participated with the car at the regional review homemade techniques and was awarded the diploma of the 1st degree. Took part in the rally, dedicated to the 60th anniversary of GAI, which is a good half way pulled in tow a van on the base truck ZIL-131.

V. ABRAMOV, Saransk, Mordovia