Before you engage in the construction of microvesicle, I’ve been drawing various versions of its layout, trying on paper for all possible errors and miscalculations, which can only occur in the process. Looking ahead, it should be noted that designing on paper is one thing, fabrication is another. Many of the “roughness” out in the operation of the machine.

Initially, the majority of the items I thought to do it myself, because I dreamed about microvesicle not resemble any of the published pages of technical journals. But when he so lovingly painted mud flaps, fuel tank, saddle embodied in metal, leatherette, and foam, compared to paper, they have lost all its appeal. Reluctantly had to use commercially available parts. But as it turned out, it was good for my car – it has become quite a “trademark” look.

As for the performance of the bike and its reliability, I’m quite satisfied with them because time has passed on it about 3000 km without any breakdowns. The only drawback (but it’s not my fault!) – weak samokatnaya tires. For the front wheel wherever you went, and for the rear… Have to wear on the rim from two pieces, but it is not very helpful.

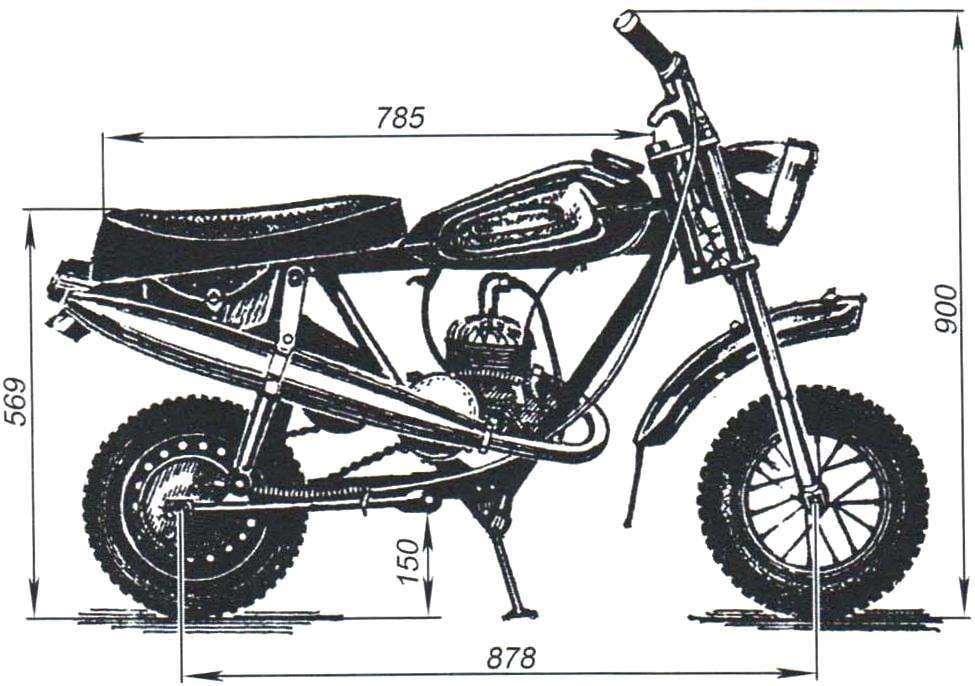

The maximum speed of microvesicle up to 50 km/h, it is well “holds” the road and is quite stable. Dimensions allow you to freely place it in the trunk of a “Moskvich”, and the weight is so small that it can be entered on the fifth floor (no Elevator) and “perched” in any available corner of the apartment.

General view of microvesicle

Frame

Sprocket driven

Now about the design of the machine. The configuration of the frame determined the use of engine D-6. Pipe for it with a diameter of 28 mm and a diameter of 14 mm was borrowed from old bike frames. The rear pendular suspension is welded from pipes with a diameter of 21 mm, Front fork – moped “Riga”. Only had to shorten: cut the feathers and the stem 130 mm, and the feathers on the bottom welded bracket. Front wheel from scooter — no alterations, it fit speedometer reducer. On the handlebars of a motorcycle “Java” are located in the Gaza strip, clutch lever, standard lever drum brake rear wheel, switches, lights and audio signal.

Headlight, gas tank, seat, alarm, rear shocks and muffler — standard, from the moped “Verhovina”. Mud flaps from the same moped — I took one back and cut it in half. The pipe connecting the engine with the muffler, home – made, bent at the place. Stand of a motorcycle is welded of 8mm steel rod and pivotally attached to the frame.

Swingarm rear suspension

Stand

Clip

Rear wheel

One of the most complex parts — rear wheel. It had to be carved from duralumin, because it bears the main burden. Hub and rim are made at the same time, inside the first are two bearings. The driven sprocket Z=28) is welded to the steel flange. The brake drum is on the right.

Tire on rear wheel, double glued two samokatnaya glue “88”.

V. BEREZHNOI, Kharkov, Ukraine

Recommend to read CAR PLOWING Motorists that have a cottage or the HOMESTEAD, in the spring together take up the shovel on par with car-free part of humanity. Meanwhile, they could avoid such wastage of own physical... TOWED MACHINE Starting a towing device (Fig. 1) easy to produce in any model circle. In the absence of a lathe it can be made flat, which, however, some will increase size, but will not affect...  Before you engage in the construction of microvesicle, I’ve been drawing various versions of its layout, trying on paper for all possible errors and miscalculations, which can only occur in the process. Looking ahead, it should be noted that designing on paper is one thing, fabrication is another. Many of the “roughness” out in the operation of the machine.

Before you engage in the construction of microvesicle, I’ve been drawing various versions of its layout, trying on paper for all possible errors and miscalculations, which can only occur in the process. Looking ahead, it should be noted that designing on paper is one thing, fabrication is another. Many of the “roughness” out in the operation of the machine.