DISAPPEARED AS A PROFESSION. It was in the summer months of 1903. Was the construction of the Amur railway. Before the start of the Russo-Japanese war was still six months, but in the air, as they say, smell of gunpowder. People from poverty and landlessness arrived to the far East from the depths of Russia, worked from early morning until late at night: they cut the forest, uprooted stumps, dug and carried in a wheelbarrow the earth, filling the canvas. However, building progressed slowly. Even the strongest and experienced digger can not for the eight-hour working day to remove and shovel shovel more 4-8 cubic meters of soil. The earth is dense and heavy, working with it for centuries was considered one of the most difficult.

DISAPPEARED AS A PROFESSION. It was in the summer months of 1903. Was the construction of the Amur railway. Before the start of the Russo-Japanese war was still six months, but in the air, as they say, smell of gunpowder. People from poverty and landlessness arrived to the far East from the depths of Russia, worked from early morning until late at night: they cut the forest, uprooted stumps, dug and carried in a wheelbarrow the earth, filling the canvas. However, building progressed slowly. Even the strongest and experienced digger can not for the eight-hour working day to remove and shovel shovel more 4-8 cubic meters of soil. The earth is dense and heavy, working with it for centuries was considered one of the most difficult.

And once the builders saw three horses, harnessed to a strange crew: the cart is not a cart, a barrel not a barrel, not a bucket dipper. Rather, it is a bucket, but what size! A little less than the cart! He was moving on two wheels, and the front was based on cross rail, connecting the shafts. But the horses stopped, working lever raised front wall. Horses pull their socks up, tensed. Bucket rest on the ground and began slamming into her teeth on the front edge, slowly filled with. And when the bucket was full, the wall is put in place, and the horse pulled a heavy load to construct the mound. There is a bucket knocked over; it spilled as much land as could bring in a few grabara. So called people hurrying from one-wheeled wheelbarrows — Grabarka, filled with earth. This episode marked the emergence in Russia of the first scraper.

Now, by the way, the word “Grabar” and “large” completely forgotten, which once again demonstrates a radical change in working conditions. And in the first five years none of the big building without a lot of such workers is not treated. But on the construction of the Turkestan-Siberian railway — Turksib — used a lot of horse-drawn scrapers, and no they were not surprised. Soon the rapid development of earth moving equipment completely replaced the profession grabara.

MACHINE-UNIVERSAL

Any construction begins with excavation and ends. For the Foundation of any building — whether residential, industrial — we need the pit. Communications — power & telephone cables, water, sewer, gas pipe — trench.

Rails of Railways are placed on the concrete and sleepers, and those, in turn, on the earthen mound. To build the airfield, you need to plan a huge plot of land — to demolish the hill and to fill the hole.

And what about these Grand buildings, like a giant reservoir and dam? Here we have to remove and move millions of cubic meters of soil.

Excavators on construction sites perform a huge amount of earthwork. But to transport the ground they can’t. It should do the truck. Is it possible to combine the functions of both machines in one? This question was asked at the time, the designers, and to light a bulldozer, a car which she digs and moves earth itself. However, far. And if you need away? Obviously, in the chain between a bulldozer, on the one hand, and an excavator with a dump truck on the other — should appear intermediate: scraper — machine that digs, and takes the ground a sufficient distance.

It is this criterion — the range of departure of the earth and determines the choice for the construction of a car.

If you need the excavated soil to drive to a distance not exceeding a hundred meters, more economical to use a bulldozer.

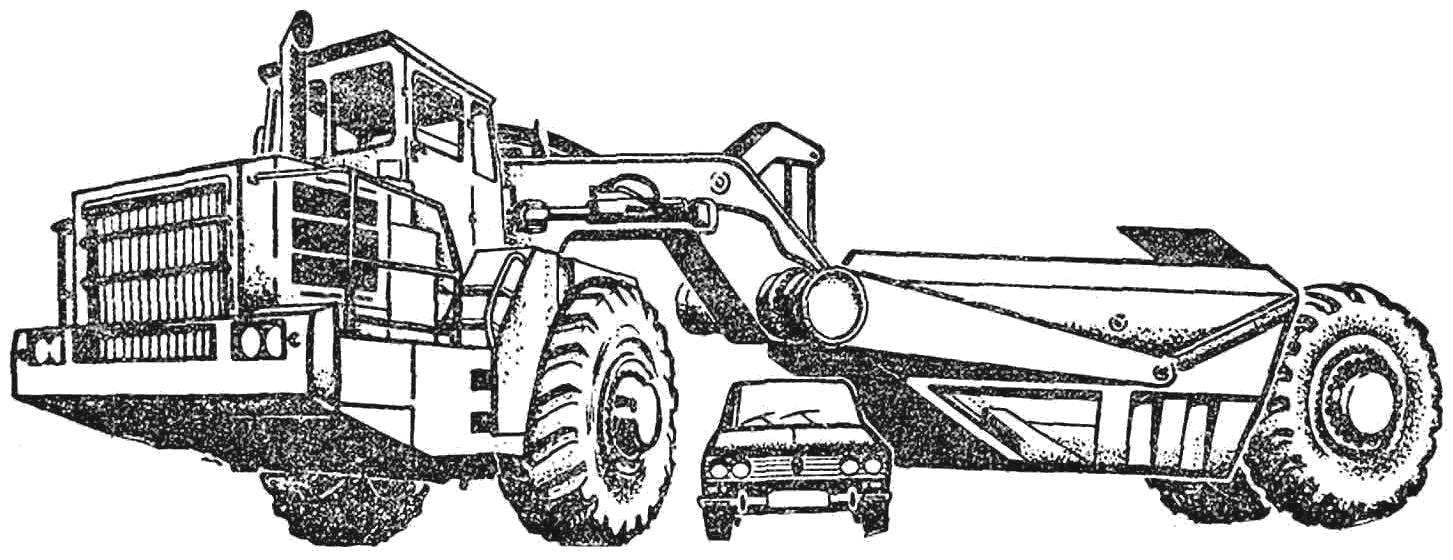

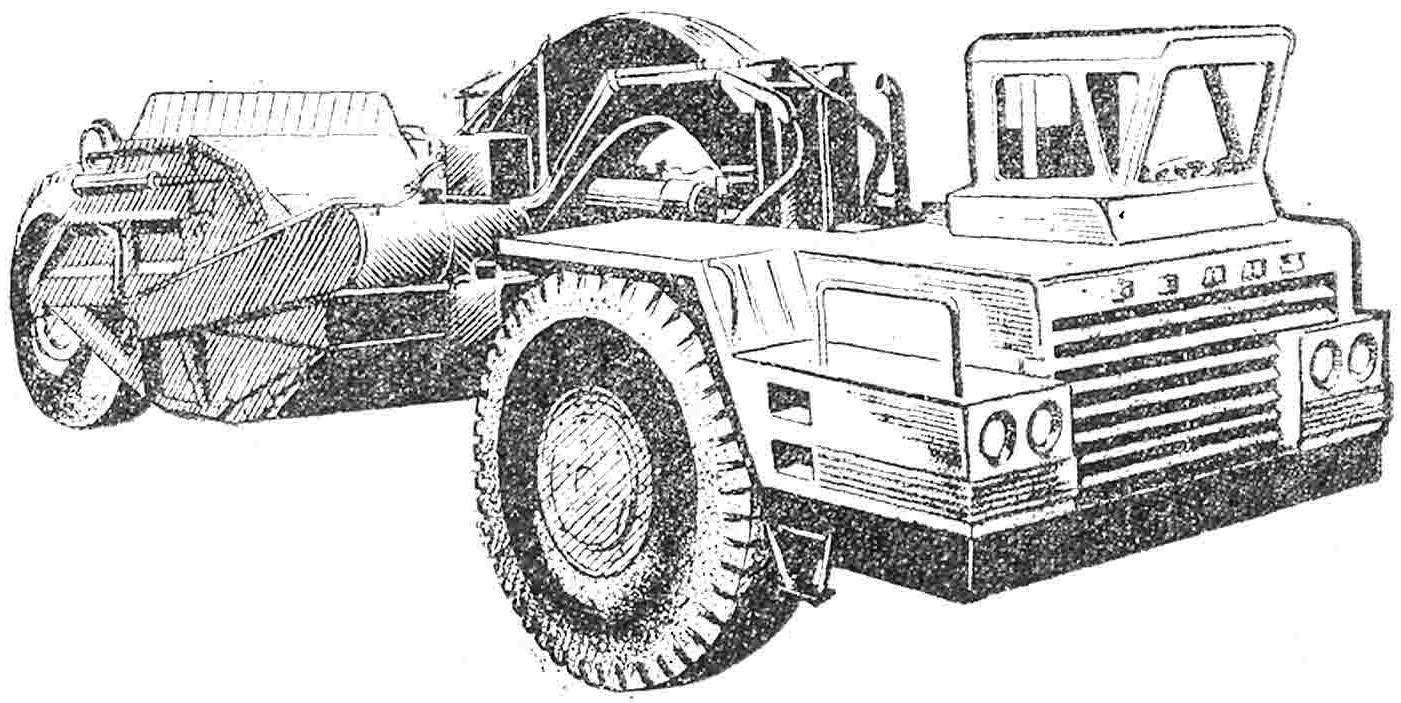

Fig. 1. Self-propelled scraper D-567 with a single axle tractor MoAZ-546.

Over 100 and up to 800-1500 meters — this distance requires the use of scrapers hitched to a tractor,— that is, not self-propelled.

But if you need to transport cargo over a distance of 3000 m, it is best to use a self-propelled scraper. And the faster it is, the greater the capacity of the bucket, the better.

Well, on long haul scraper uneconomical. Needed a truck.

Structural diagrams of scrapers a lot. First of all, there are scrapers trailed, and there are self-propelled. First do not have an independent engine, and stalling the tractor. Such machines are used where the volume of earthworks is relatively small. But self-propelled scrapers and more and more powerful: after all, each of these machines has its own engine.

There are differences in the methods of discharge of earth from the bucket. The bucket can tip forward, can — ago. It happens that moves him forward the back wall, pushing the ground.

Scraper bowl equipped with knives thrust into the ground from the force developed by the tractor And if the ground is too hard and the effort is not enough? Then behind there is another tractor, not pulling, and pushing. Get something like a great plane or train with two locomotives.

STEEL COLUMN

Speaking of towed scrapers, it should be noted that these structures are not completely independent. We therefore consider only self-propelled scrapers. The range of machines of this kind opens the scraper D-357П. The machine consists of a single axle tractor MoAZ-529 equipped with engine capacity of 180 HP and bucket capacity of 8 m3 (the lowest for domestic self-propelled scrapers).

The bucket and the tractor are connected by a swivel hitch that allows you to turn right and left 90°. Such exceptional agility built into the design in order to be able to turn around in the narrow spaces of construction sites.

The design is widely used hydraulics to lower and raise the bucket, turn the machine. All this, of course, facilitates the work of schreyerite. Helps to alleviate of his work and also that this single cab is closed from all sides, which scraper is provided with a spring suspension. And to improve the performance of the ground shovel in the bucket dozer device provided on the tractor T-100M.

D-567 — scraper, a little more powerful than the previous D-357П, and should eventually be replaced. D-567 (Fig. 1) has a bucket capacity of 10 m3. The engine power of the tractor of MoAZ-546 — 240 HP Soil from bucket, as in the previous design, pushes the back wall.

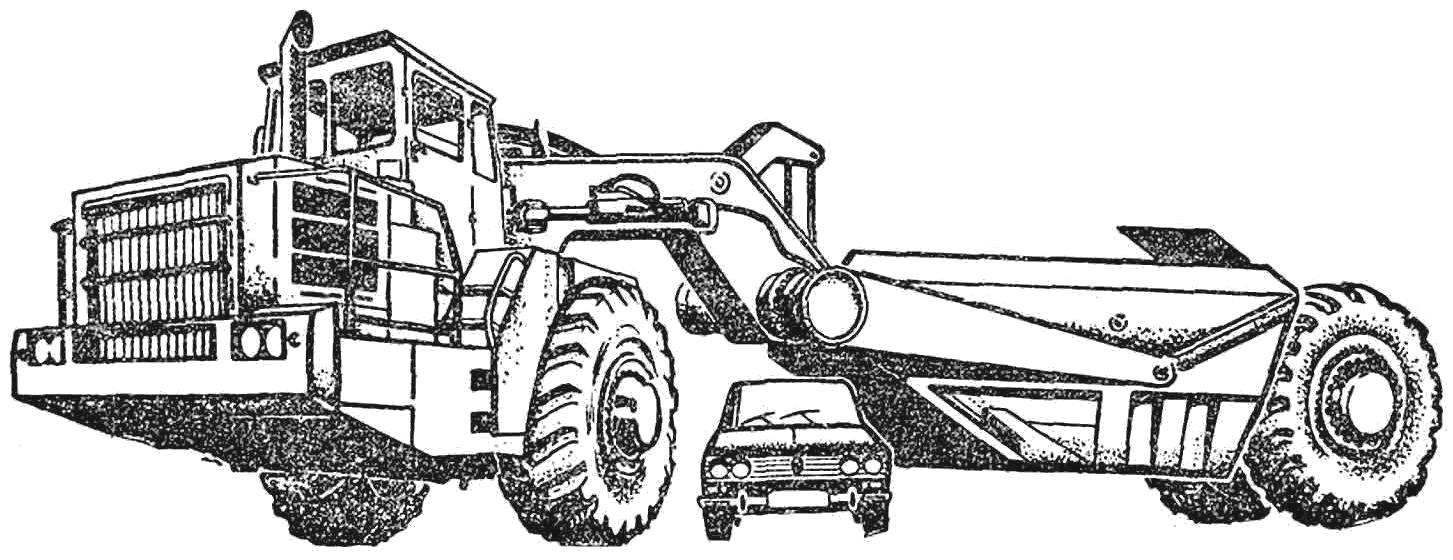

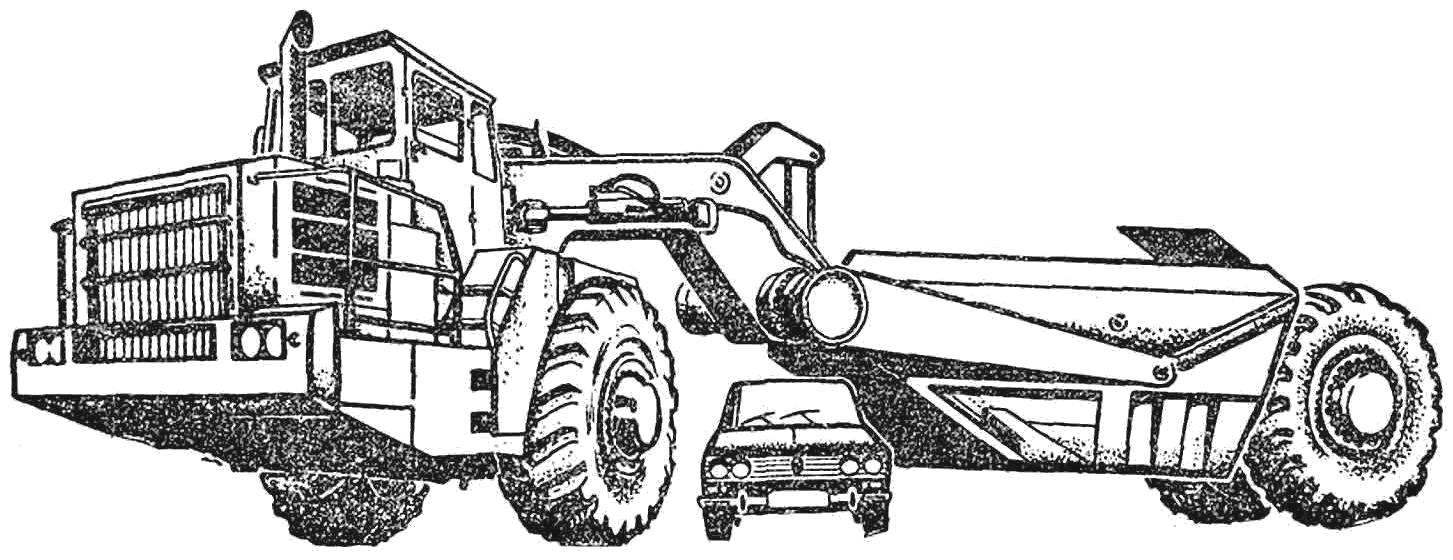

Fig. 2. Scraper D-392.

But the scraper D-392 (Fig. 2) is very different from the previous two. First, the tractor is the machine is not in the Mogilev and the Belarusian automobile plant — BelAZ powerful-531 with an engine of 360 HP second, suspension of a driving axle — pneumatic, that is the most modern, providing the smoothest experience. This means that the scraper can travel at high speed, thus to operate more efficiently. And here, too, helps to fill the bucket powerful dozer on a tracked tractor T-180, T-250, and is also widely applied hydraulics. With the help of telescopic hydraulic cylinders extends the rear wall; control of the working bodies of the scraper — hydraulic,

THE MOST POWERFUL

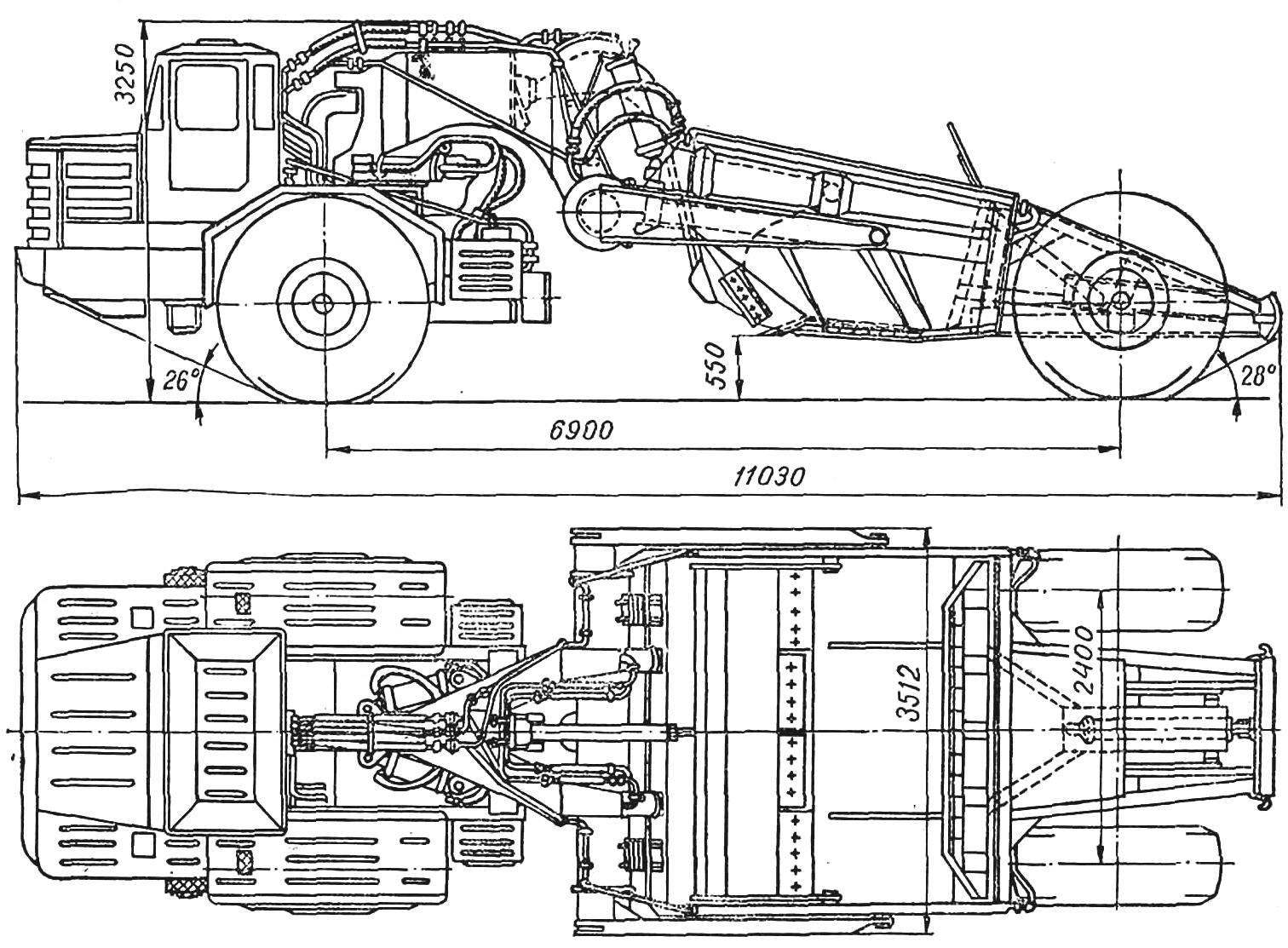

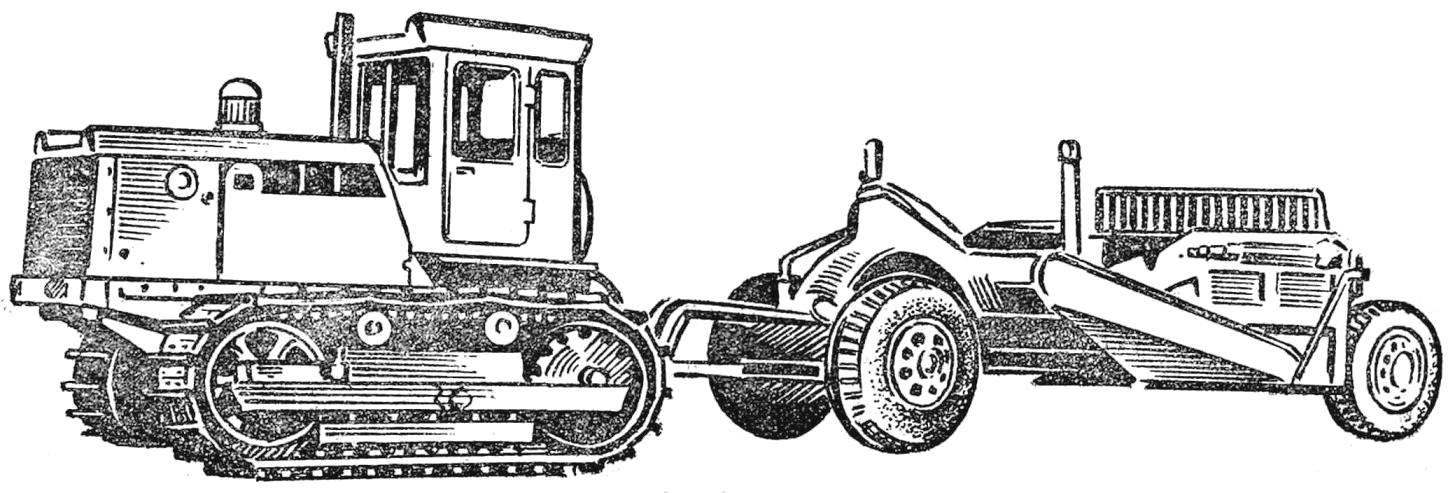

The most powerful domestic scraper is DZ-67 (Fig. 3). The bucket capacity of this huge machine — 25 m3 of earth. Under such a large bucket can safely pass a passenger car. In one day DZ-67 can select up to 850 m3 of earth, to take her to a distance from 500 to 5000 m and to pour it there layer up to 650 mm. Above the project worked with scientists and engineers of the all-Union scientific-research Institute of construction and road machinery (Vniistroydormash), order of Lenin Chelyabinsk factory of road cars of a name of Kolodenko, Minsk SLE of reclamation and other organizations.

DZ-67 differs in design from other scrapers. And the main feature of this machine is that it is equipped with in-wheel motors. That is, there is carried out the same construction principle as in the powerful trucks Belarusian automobile plant. The diesel engine drives a generator of electric current, the current goes to the motors fixed on the wheels of the rear axle, the shafts of the motors rotate, and with them — and wheels. This is done in the trucks because the purely mechanical transmission of power from engine to wheels, transmission, driveshaft, rear axle — would require a too large weight and size of all these units in such a huge machine. Electric transmission more compact, it allows you to work continuously. And this is important, because in all conditions the machine can work in a favorable mode.

Fig. 3. Self-propelled scraper-giant DZ-67 with in-wheel motors.

As it is implemented in DZ-67? Twelve-cylinder four-stroke Y-type diesel M-301 with a capacity of 850 HP with gazturboservis actuates a generator, and that supplies current to the 4 leading motor-wheels. It is interesting to note some design features of the entire system. The engine is equipped with not one, as usual, but three air purifiers: after all, where digging and land transportation, there is dust. And the generator and motors are driven by automatic control systems.

When any of the wheels slips, the generator power is distributed among all the motor-wheels evenly. Thanks to this scraper develops a maximum tractive effort in all conditions. Manual transmission provides is not always the case.

In the scheme of transmission of many protective devices. Electromagnetic relay protects the generator from short circuit. Thermal relay — motor motor-wheel against overload. Special relay triggered by damage to the insulation and thus prevents the possibility of emergency cases.

Motor-wheel consists of a wheel, a traction motor, reducer and brake. The motor is located directly inside the wheel, and most interestingly, his body serves as the axis of the whole Assembly. That is, there also is a combination of the functions, thus achieving a compact Assembly and minimum weight. But the gearbox is three — stage, with the first planetary stage is that, on the contrary, taken out to the outside, the dimensions of the wheel. And this achieves the best cooling.

Brake motor-wheels, drum and disc. Also not so long ago appeared a constructive kind. Since the plane of the clamp of the disc more than the pads, and the brake force is significant. The disc brake is activated by the pressure of the compressed air that goes from the compressor to the pneumatic system. But this is a known method. What does Novo — ventilation system, the outlet of the wheels dust. The novelty is developed in the research Institute of plumbing. Fan-paleological per minute drives about 40 m3 of dust.

Of course, it is necessary to tell and about some other unique design features of the machine.

The engine and turbocharger are cooled by water that drives the pump is mounted on the upper crankcase.

The machine is equipped with a complex hydraulic system. Hydraulically scraper is rotated; a hydraulic system raises, lowers the bucket, and expanded it into the ground and moves the back wall, pushing the ground, raises and lowers the flap of the bucket. And here is another characteristic innovation of this design: hydraulic steering and working bodies in other machines separate, are here United in one. This allows the use of both systems total units: tank, pumps, filters, piping, and makes the system more compact.

Range of stepless speed regulation and traction — 1:15. Speed while digging without the help of a pusher — 2-4 km/h on a dirt road with a full bucket scraper can reach 25 km/h.

Tire scraper huge: diameter — 2.5 m, width — 950 mm.

Maximum operating hydraulic pressure — 140 kg/cm2. This is a very large value.

The scraper has a high permeability and can down and up the slopes, reaching up to 12°.

Double cab equipped with heat and sound insulation. And the person that is in it, you need to talk too much.

DRIVING OPERATOR

Who controls such a huge and heavy duty machine? Driver? Scrapartist? No, operator. We are accustomed to, that this word means a man in a white coat dotted among the devices remotes. But the operator now work profession, the scope of which is increasing, Operators control the operation of steelmaking and rolling plants, chemical plants, workshops, refineries and many others. Why a person working on such a complex and perfect machine, the design of which found the application of electrical engineering, electronics, hydraulics, mechanics and other, not to call the operator? His work does not require great physical effort. Before him a shield with the scales of electric appliances, the testimony which he is guided, and management is also built into electrical systems. Rather, the working bodies are controlled by a separate electro-hydraulic units. And thus, the car combines electric traction transmission and electro-hydraulic control system of the working bodies. It, first, creates favorable conditions to the entire workflow of the scraper could be fully automated, and secondly, it puts the work of the person managing the machine to a higher level.

It is clear that such a powerful and sophisticated machines that represent the crowning achievement of engineering and scientific thought in the field, should be performed taking into account the latest trends in the development of technology. The current technique is characterized by this situation, when a large amount of work must be combined with high precision. But still, if you think about it and imagine the real picture of the scraper, it will appear that the kind of new products to use here is impossible, and not necessary. Because excavation is not only the heaviest but also the most “black” — dirty, dusty, do not require special accuracy. Why semivodny and earth-moving machines of the latest super complex, expensive systems?

The fact of the matter is that the scraper is sometimes necessary to perform such work, which metaphorically can be called “planing” of the earth. Plan — that is, to level the surface for construction of roads, embankments, airfield, to prepare the fields for planting crops, fill with water, so she was standing straight and not “dripping — you need very carefully.

Fig. 4. Automated scraper D-498А.

For such work the order of Lenin Chelyabinsk road machinery plant name, Koloshenko has produced and tested a prototype of the scraper D-498А (Fig. 4) on the basis of tractor T-130 with the system “Stayopen-1” for automatic stabilization provisions of the ladle during operation. System “Stayopen-1”, developed by Vniistroidormash scraper with hydraulic control, allows you to automatically maintain a given angle of the longitudinal profile of the planned surface. Thus the performance of the scraper increases.

Scraper D-498А runs behind the tractor. And of course, the overall appearance is not noticeable angle sensor because it is mounted on a bracket near the axis of the rear wheels. This is a freely suspended pendulum connected to a movable contact of a potentiometer included in a bridge circuit. The value of the electrical sensor signal proportional to its angular deviation from the preset position. The sensor signals through amplifiers go to the control unit, and then the command is supplied to the electromagnets reverse hydrosolate. This unit is mounted on the bumper in front of the tractor and operated by the command unit of the hydraulic movement of the bucket. All this gives, of course, the most General, approximate idea of the work of this scheme. But tests showed that the machine with a bucket capacity of 7 m3 leveled land with an average deviation of roughness from the profile line not exceeding 4 cm.

Pick up a shovel. With the maximum available to you carefully try to flatten the ground. And you will see what it’s like 4 cm when excavation works.

R. YAROV